Self-locking control device for hoisting equipment

A control device and lifting equipment technology, applied in the direction of safety devices, transportation and packaging, load suspension components, etc., can solve problems such as easy slipping, hidden safety hazards, poor reliability, etc., and achieve improved safety in use, ingenious structure, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

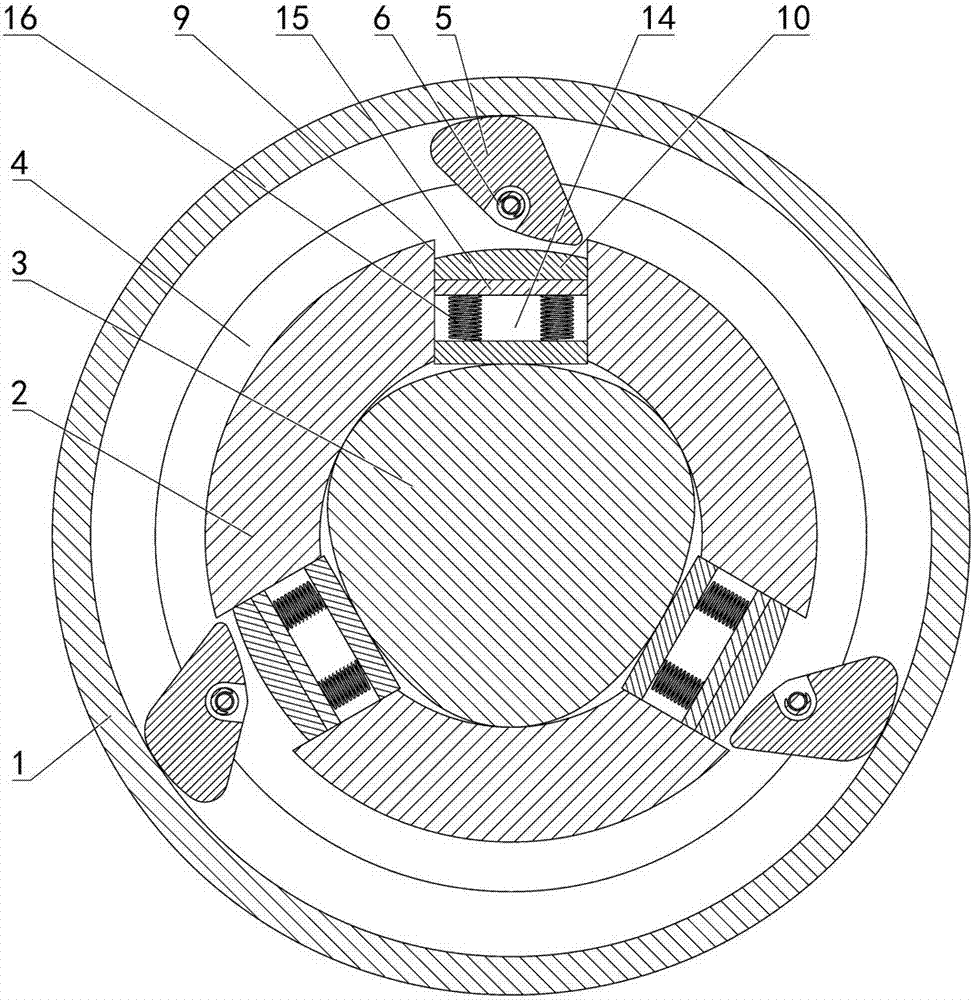

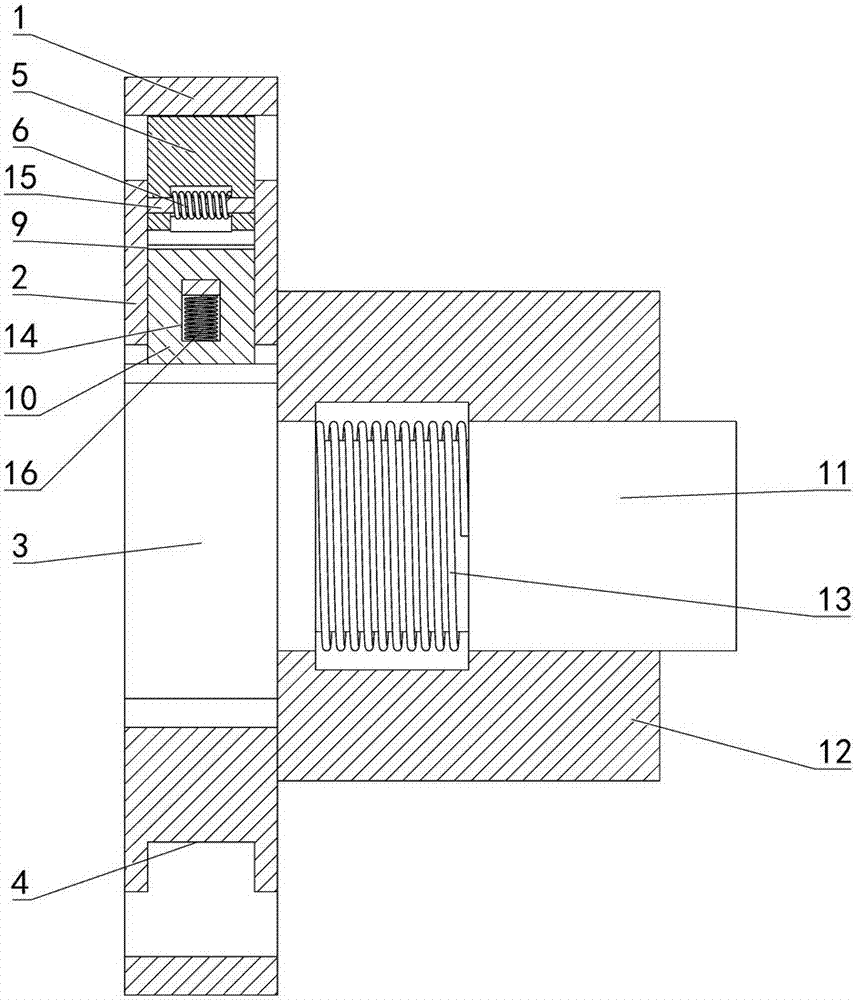

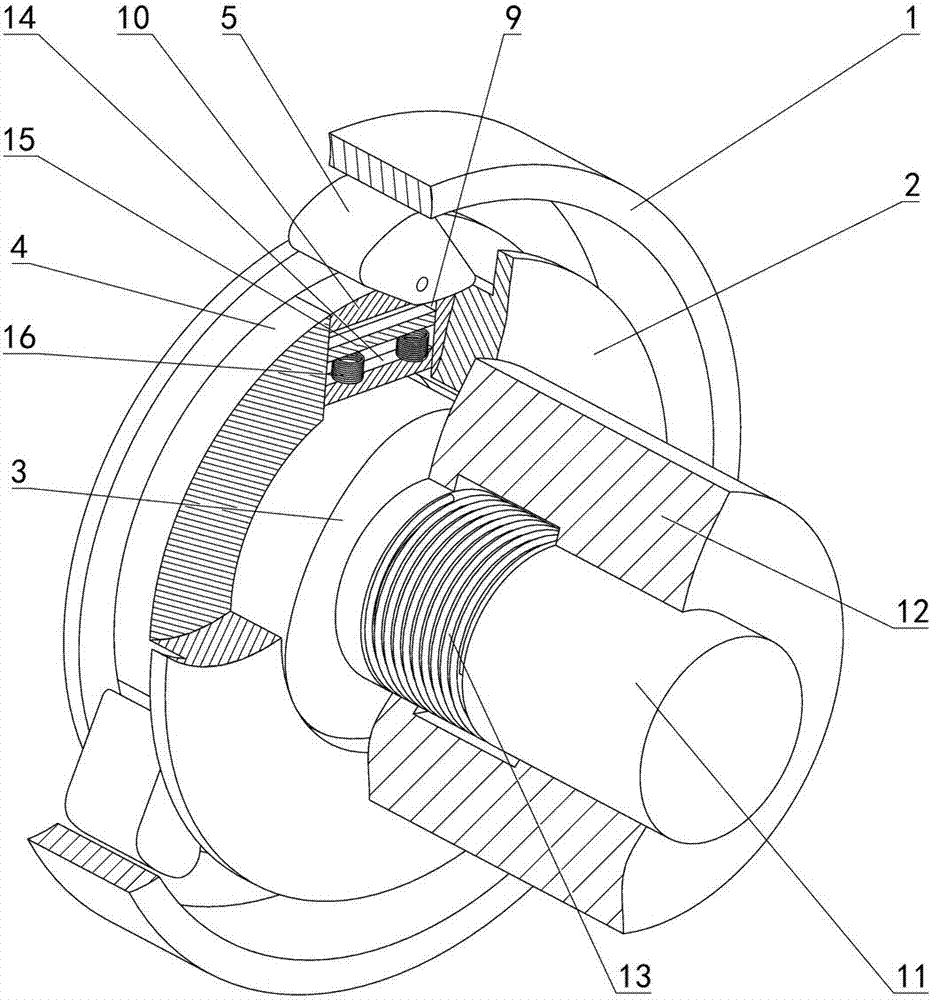

[0012] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Depend on Figure 1 to Figure 3 Given, the present invention includes a fixed outer ring 1, an inner ring 2 placed inside the fixed outer ring 1 and a disc cam 3 placed inside the inner ring 2, and a circumferential groove 4 is provided on the outer edge surface of the inner ring 2, A plurality of wedges 5 evenly distributed on the circumference are hinged on the inner ring 2 through the end face of the circumferential groove 4. The hinged part of the wedges 5 is equipped with a torsion spring 6. One end of the torsion spring 6 is connected to the inner ring 2, and the other end is connected to the inner ring 2. The wedges 5 are connected to form a structure in which the wedges 5 are rotated on the inner ring 2 through the torsion spring 6 so that one end of the wedges 5 is pressed into contact with the fixed oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com