Friction coupling for turnout switch machine

A switch machine and coupling technology, applied in the field of transportation, can solve the problems of large friction belt wear, high maintenance manpower, high production cost, etc., and achieve the effect of reducing friction, reducing investment and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

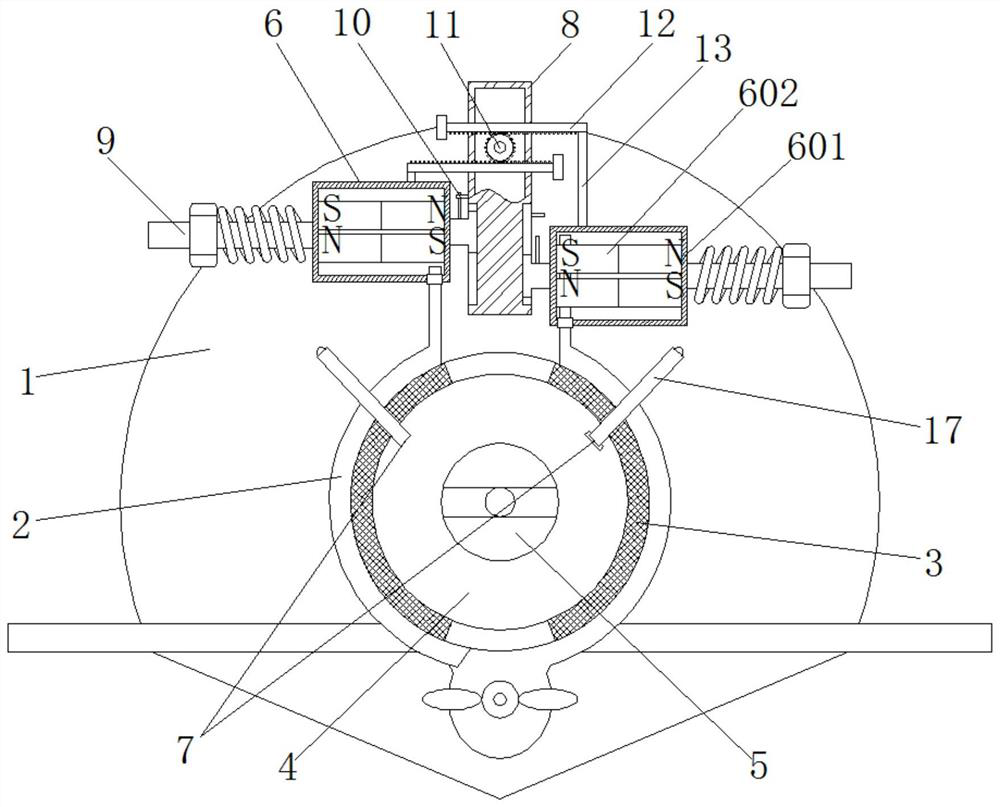

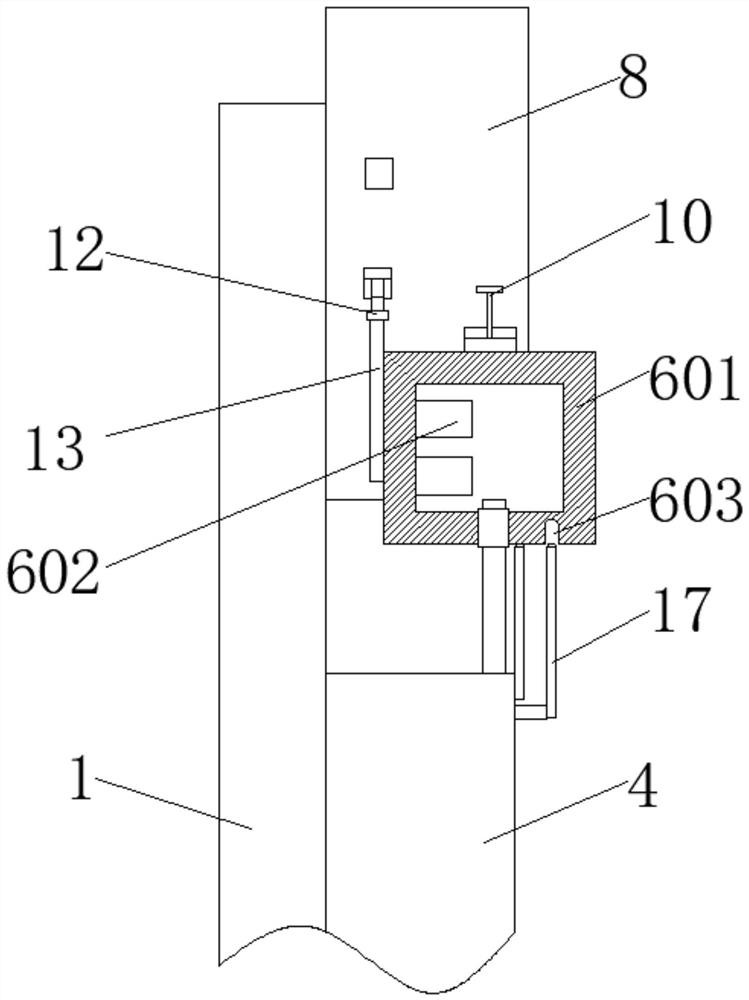

[0028] See attached Figure 1-2, the force applying structure 6 includes a housing 601 and a magnet group 602, the magnet group 602 is fixedly installed in the inner cavity of the housing 601, the magnet group 602 is two permanent magnet blocks with opposite polarities on the same side, and the two permanent magnet blocks are arranged up and down , the polarities of the opposite ends of the magnet groups 602 in the two force-applying structures 6 are respectively opposite, that is, when the heights of the two sets of magnet groups 602 are the same, the two symmetrical permanent magnet blocks of the same height attract each other, that is, the magnet groups 602 generally behave as attraction, when When the two groups of magnet groups 602 are located at the upper and lower limit positions respectively, the permanent magnet blocks at the high position of the magnet group 602 at the upper limit position and the permanent magnet blocks at the high position of the magnet group 602 at...

Embodiment 2

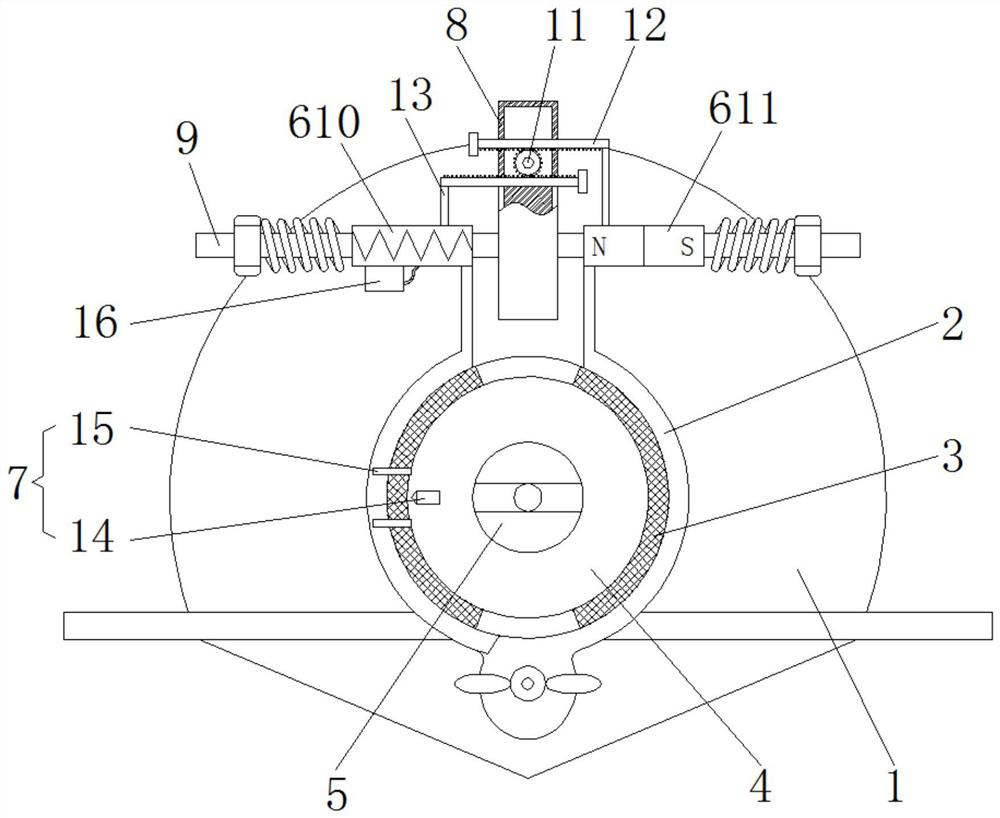

[0030] See attached image 3 As shown, the force applying structure 6 is set as an electromagnet 610 and a permanent magnet 611 respectively and is connected with the vertical bar of the friction brake plate 2. The rack 12 is connected, where the length of the support rod 13 can be fixed, the electromagnet 610 and the permanent magnet 611 are respectively slidably connected to the connecting rod 9, the connecting rod 9 is fixedly connected to the outer wall of the connecting box 8, and the permanent magnet 611 is electrically connected There is a current controller 16, and the current controller 16 feeds positive and negative currents into the electromagnet 610, so that the magnetic poles at the opposite ends of the electromagnet 610 and the permanent magnet 611 are opposite or the same, so as to achieve the purpose of attracting or repelling the permanent magnet 611 and the electromagnet 610; Trigger assembly 7 is set as magnetic head 14 and magnetic grid 15, when installing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com