Uninterrupted staple yarn knitting machine

A technology of weaving machine and short filament, applied in the direction of loom, textile, textile and paper making, etc., can solve the problems of continuous weaving pattern and inability to form complete etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

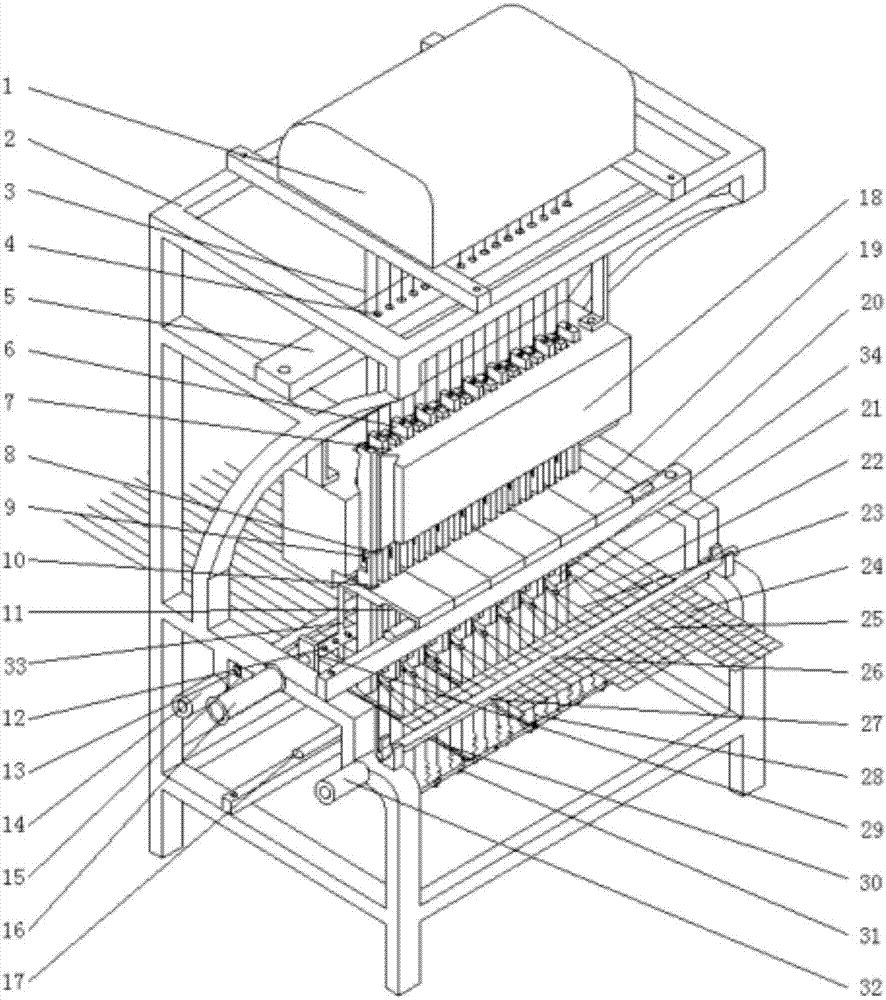

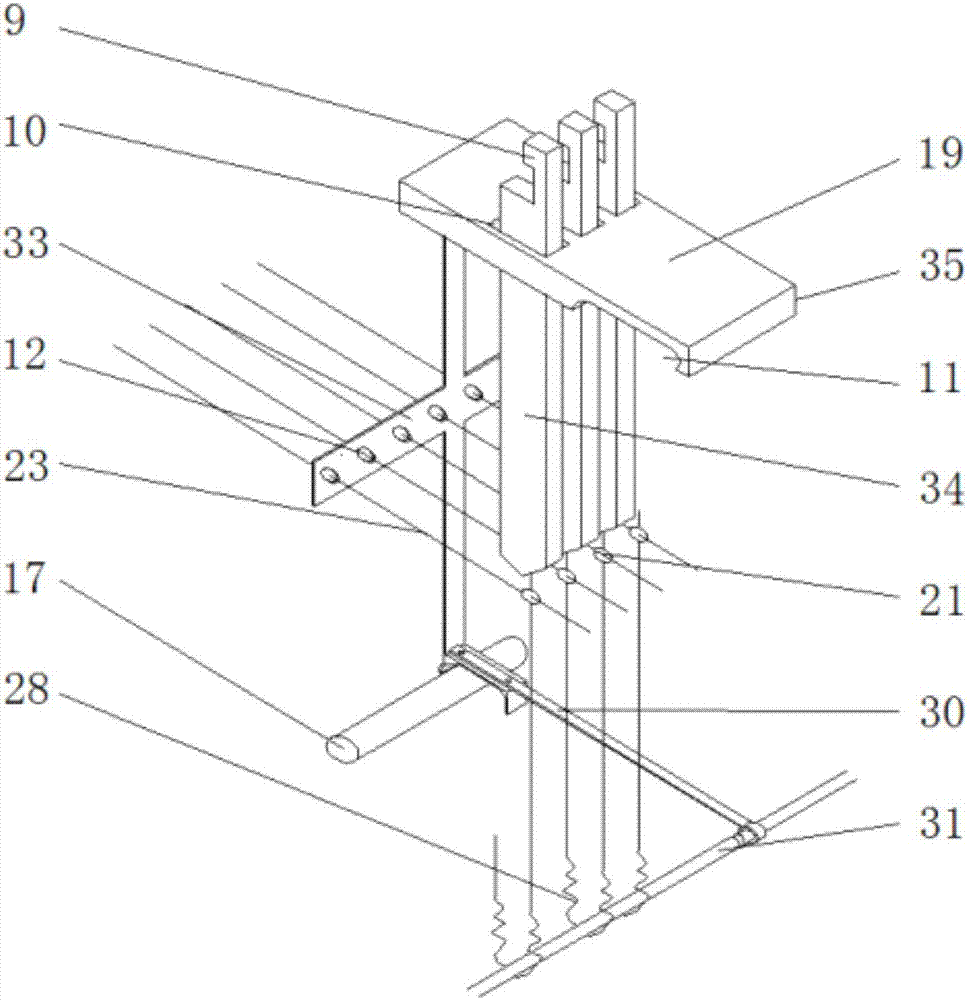

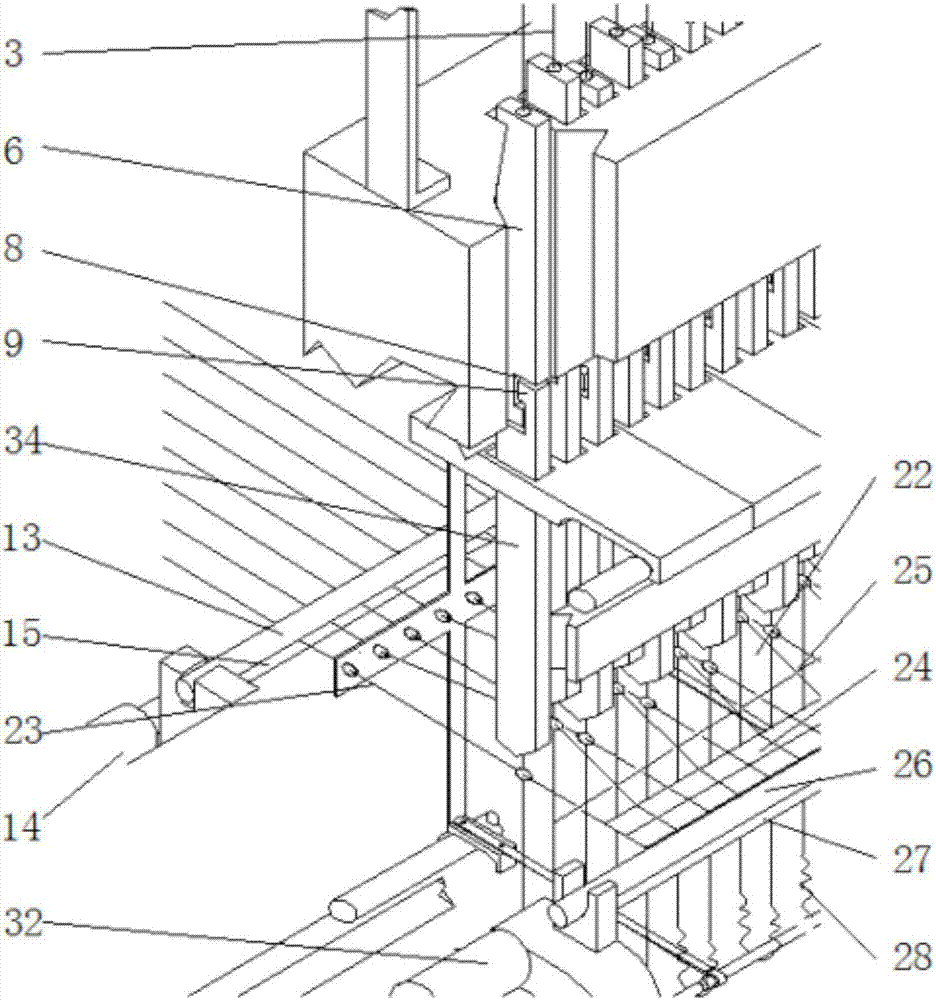

[0018] Example: such as figure 1 As shown, the short yarn infinite knitting machine of the present invention includes a frame, a jacquard machine, a target board, a main control board, a warp controller, a shift mechanism, a removal and addition mechanism, a coiling mechanism, and a warp let-off mechanism. The above-mentioned jacquard machine 1 Installed on the top of the rectangular frame 2, the eye board 5 is fixedly installed on the frame 2 below the jacquard machine 1, and the main control board 18 is located below the eye board 5, and is respectively fixed on the slide bar on the frame 2 below. 17 and slide bar 20 are supported. The displacement mechanism and the removal and addition mechanism are right in front of the warp controller 19. The coiling mechanism and the let-off mechanism are installed horizontally at the front and back of the warp control 19 respectively, and are controlled by the motor 14 and the motor 32 respectively. The upper end of the wire 3 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com