Spliced aluminum alloy screen window

An aluminum alloy, splicing technology, which is applied in the field of window screens, can solve problems such as separation and deformation, failure to prevent rain, and looseness, and achieve the effects of flexible assembly, sliding, labor-saving, and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

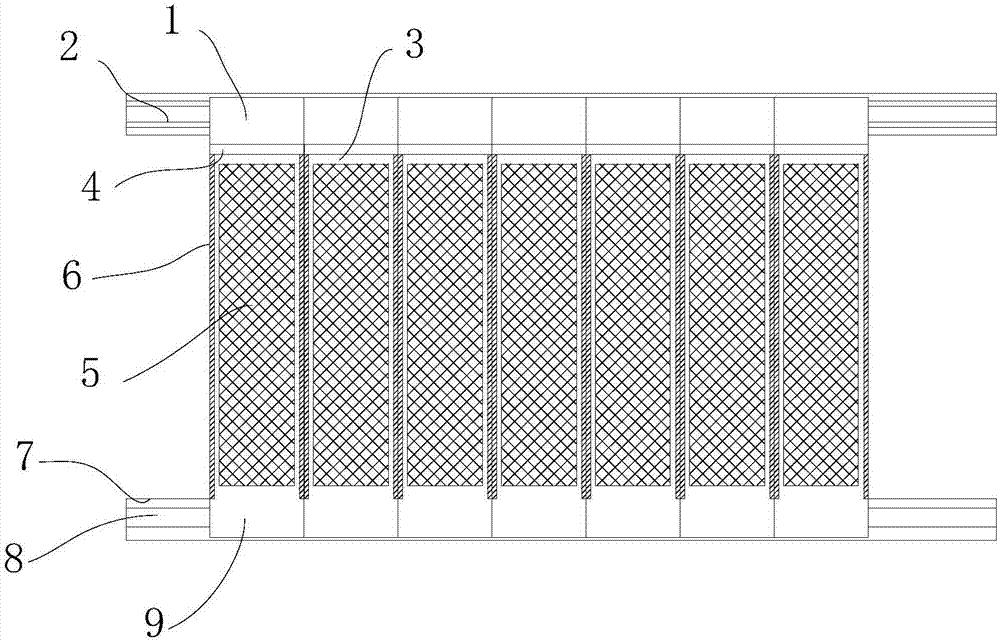

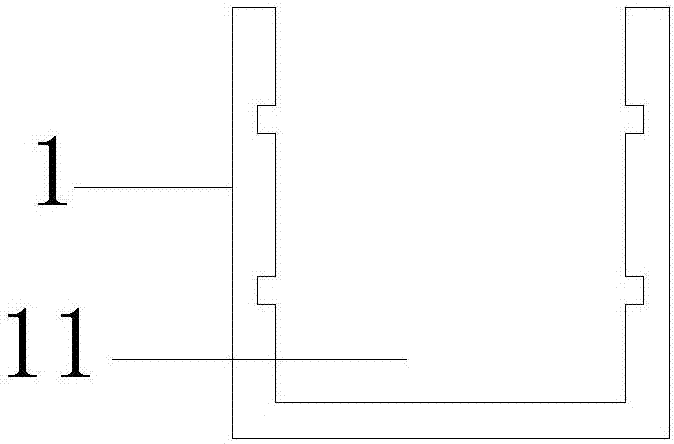

[0014] Such as figure 1 As shown in this book, the spliced aluminum alloy screen window includes a screen window assembled by more than one spliced board, each spliced board is sealed by magnetic force, and the upper and lower ends of more than one spliced board are respectively installed on the first frame 2 And on the second frame 7, a sliding sleeve 1 is provided on the top of the splicing plate, and the sliding sleeve 1 is provided with a sliding cavity 11 facing the first frame 2, and the sliding cavity of the sliding sleeve 1 is installed on the bottom surface of the first frame 2 Move up and move left and right along the first frame 2, the sliding sleeve 1 and the splicing plate are rotationally connected by the hinge structure 4, and the bottom of the splicing plate is magnetically attracted to one side end surface of the second frame 7.

[0015] In this embodiment, the splicing panels all include an outer frame body 3 and a gauze 5 arranged in the middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com