Flow priority control loop

A priority control and loop technology, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, servo motor components, etc., can solve the problem that it is difficult to ensure the accuracy of component movements, and cannot ensure the stability of flow priority valve control, etc. problems, to reduce the frequency of use, save energy, and extend the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

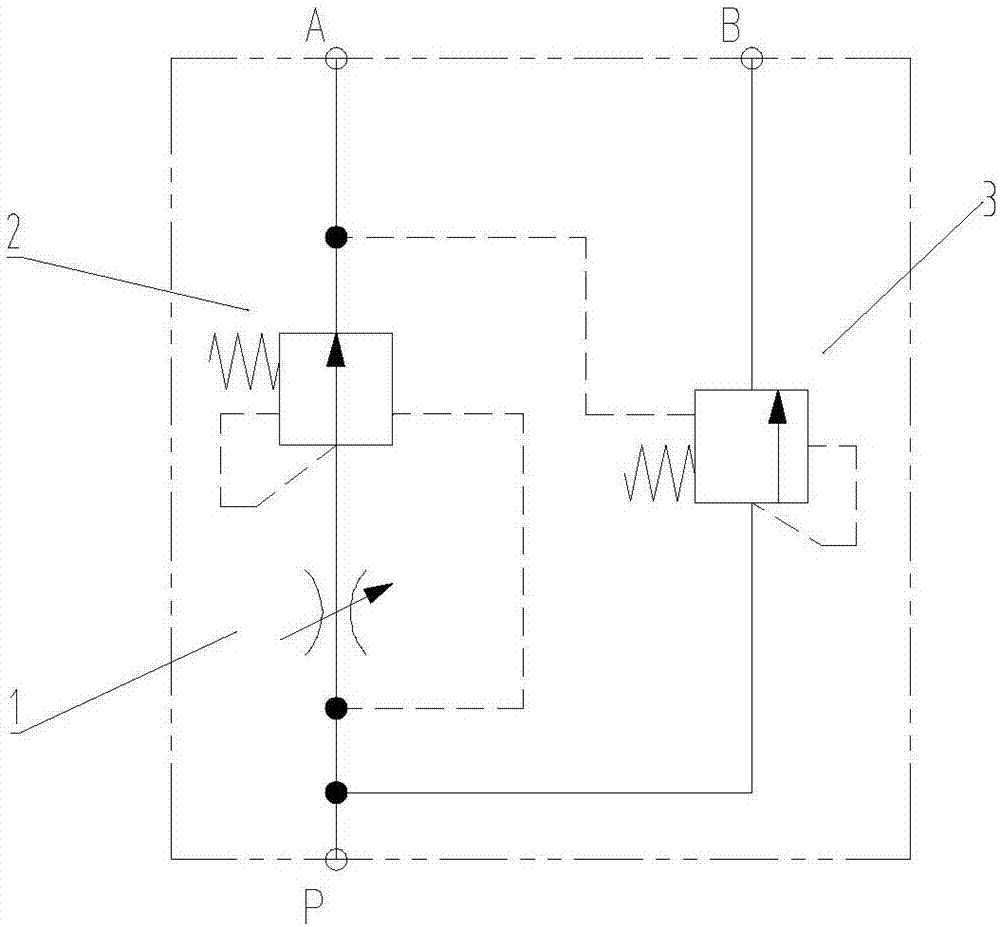

[0022] like figure 1 The first embodiment shown is a flow priority control circuit, which has an oil inlet P, a first working port A and a second working port B, and the oil between the oil inlet P and the first working port A The adjustable flow valve 1 and the pressure compensation valve 2 are arranged in series in series on the road, and the two control oil ports of the spring chamber and the non-spring chamber of the pressure compensation valve 2 are respectively connected with the oil inlet and the oil outlet of the adjustable flow valve 1, and the A pressure control valve 3 is set on the oil circuit between the oil port P and the second working port B. The opening of the pressure control valve 3 is related to the oil pressure of the first working port A and the oil inlet P, and the oil inlet P The oil pressure makes the valve port opening of the pressure control valve 3 tend to increase, and the oil pressure of the first working port A makes the valve port opening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com