stator of electric machine

A stator and machine technology, applied in the field of placing various windings in the center, can solve the problems of accessibility and difficulty in embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

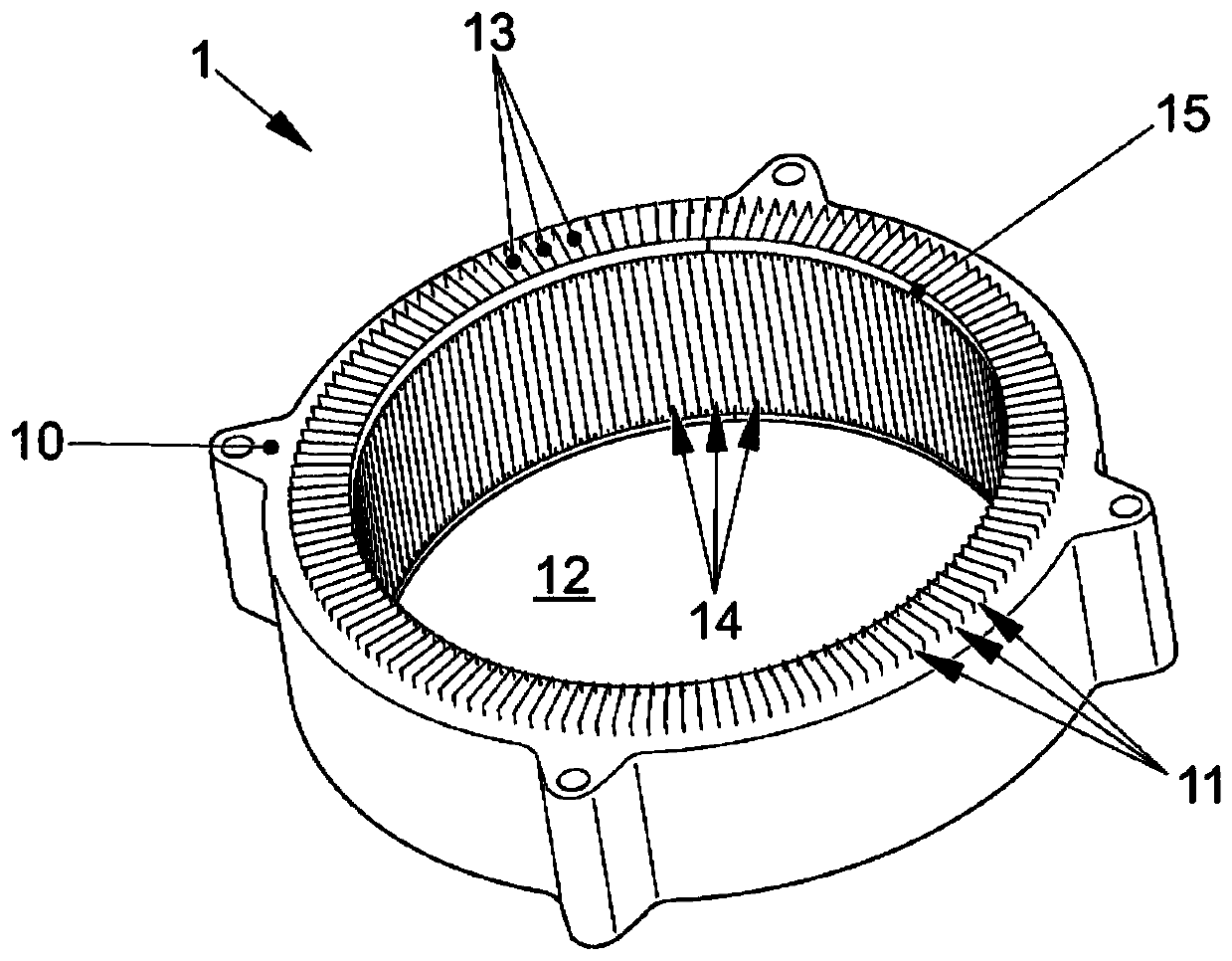

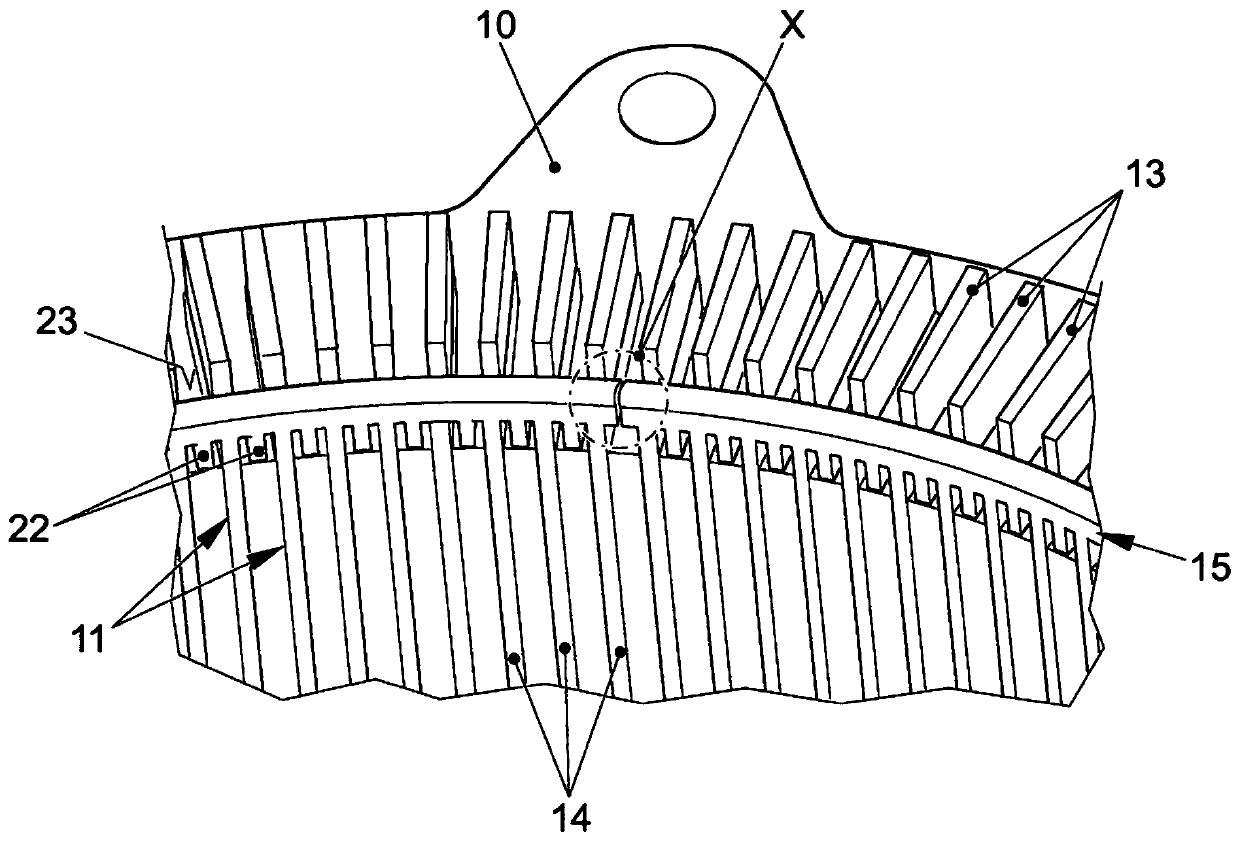

[0025] figure 1 A stator 1 for an electric machine is shown in perspective and has an annular stator body 10 as a main component, wherein the ring describes the basic structure of the stator body 10 . A ring inner side 12 is formed within the annular stator body 10 , and from the ring inner side 12 an annular groove 11 extends radially outward into the stator body 10 and into which a winding 13 engages. To form an electric machine, a rotor is arranged in the inner ring 12 and performs a rotation in the inner ring 12 when the winding 13 is energized in a correspondingly controlled manner. Ring inner side 12 substantially forms a cylindrical jacket shape and has an axial direction which describes the width direction of stator body 10 , and winding slots 11 protrude radially into stator body 10 from the inside to the outside.

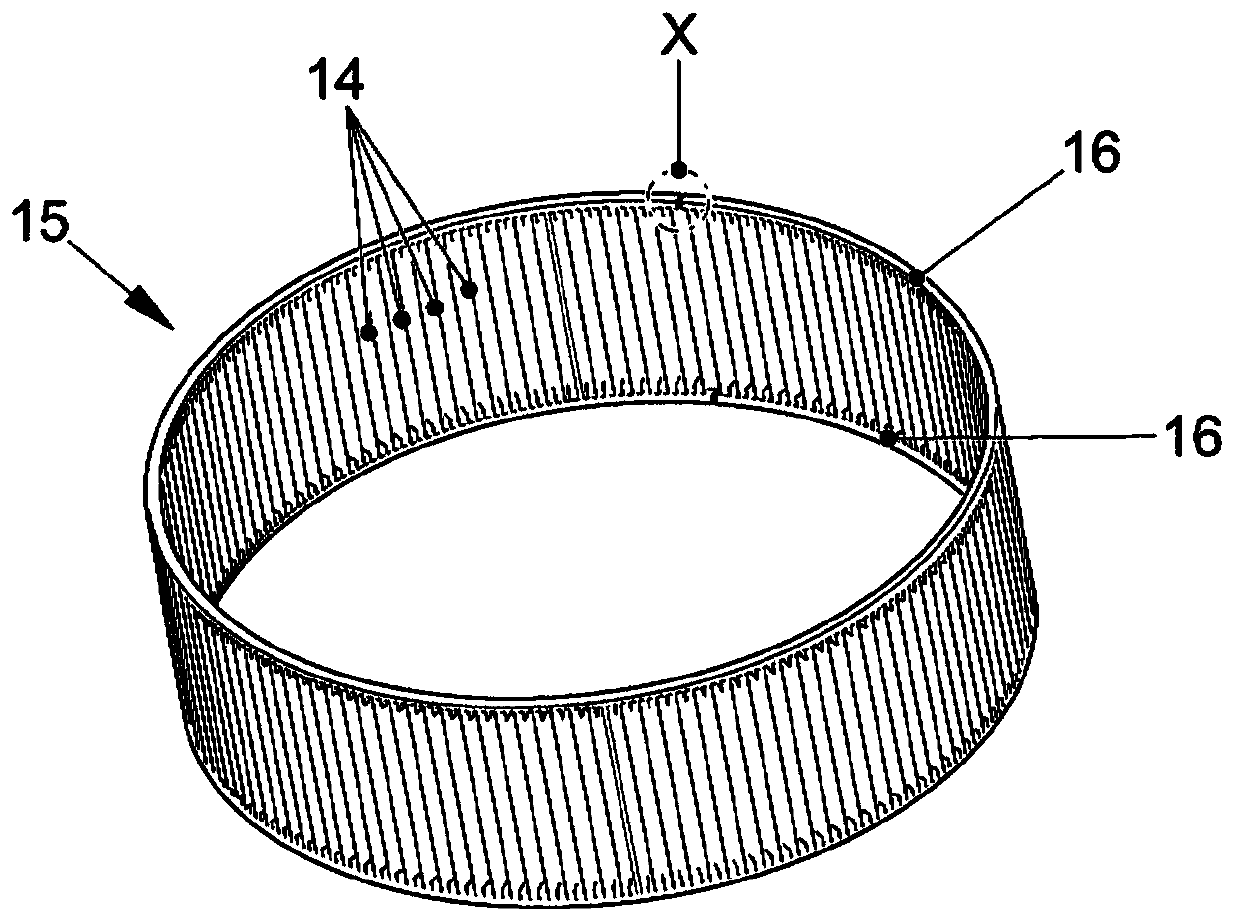

[0026] The insertion of a sliding cover cage 15 into the stator body 10 is shown from the ring inner side 12 , and the sliding cover cage 15 has a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com