Forming die for automobile wrought aluminum steering joints

A technology for forming dies and steering knuckles, which is applied in the field of forming dies for forging aluminum steering knuckles of automobiles, can solve the problems of insignificant buffering effect of forming dies, cumbersome forming steps, inconvenient operation, etc. The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

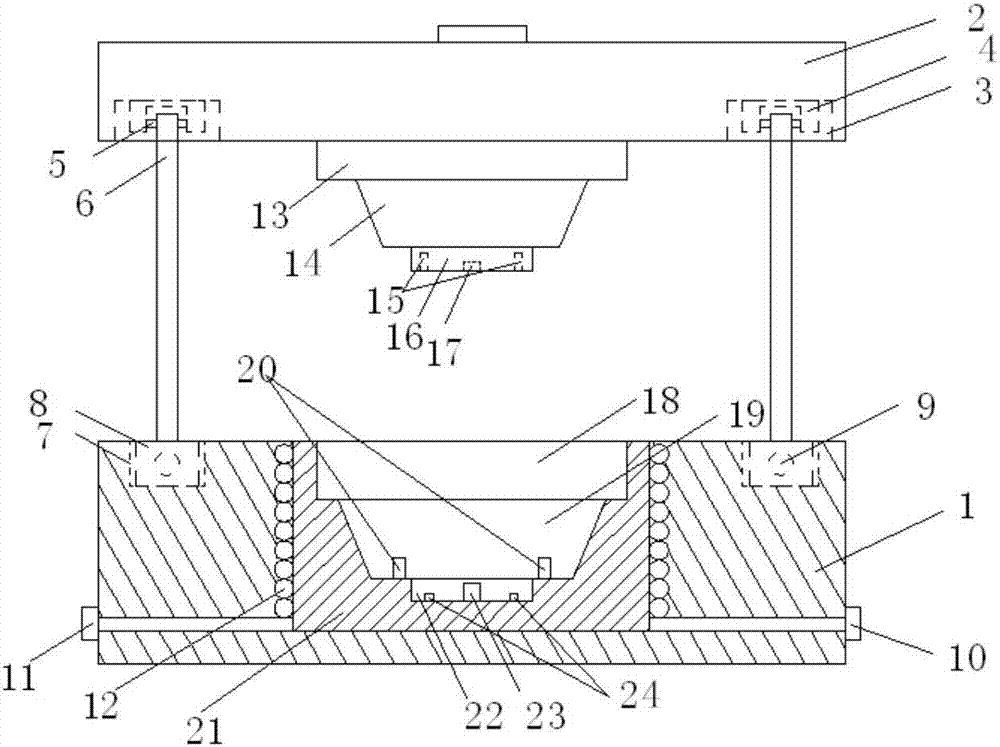

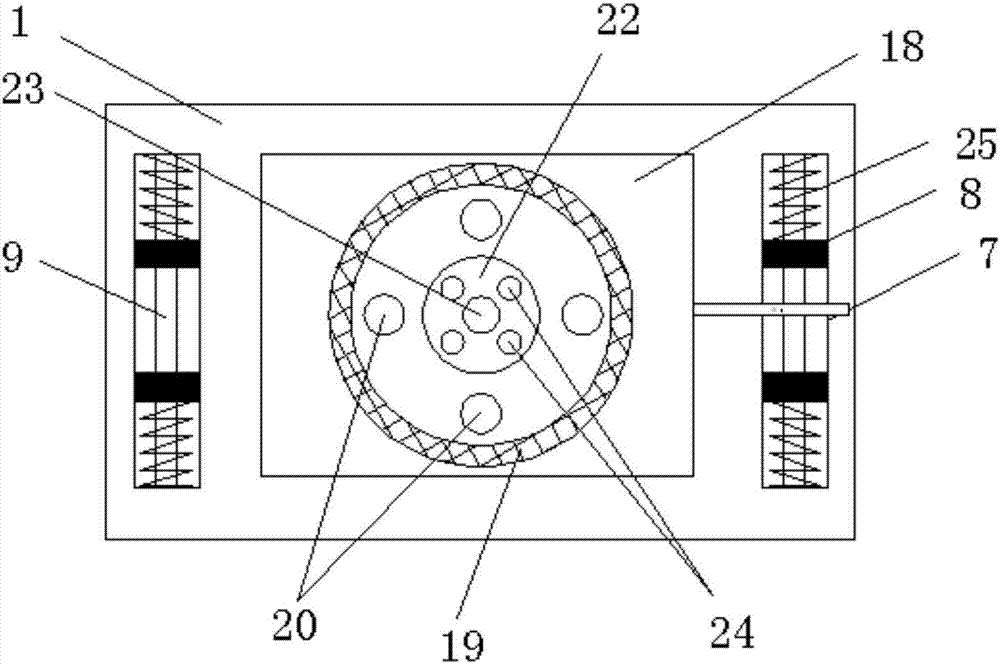

[0019] refer to Figure 1-2 In this embodiment, a molding die for automobile forged aluminum steering knuckle is proposed, which includes an upper mold base 2 and a lower mold base 1, the lower mold base 1 is a hollow structure, and the inside of the lower mold base 1 is vertically provided with a mounting block 21, and the top of the mounting block 21 and the top of the lower mold base 1 are on the same level, the top of the mounting block 21 is provided with a sunken first mounting groove 18, and the bottom inner wall of the first mounting groove 18 is provided with a sunken The second mounting groove 19, the side wall of the second mounting groove 19 is a fan-shaped section, and the bottom inner wall of the second mounting groove 19 is provided with four first fixed rods 20 distributed in a ring, the second mounting groove 19 The inner wall of the bottom is provided with a third installation groove 22, and the third installation groove 22 is located between the four first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com