Patents

Literature

47results about How to "Simplified molding steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

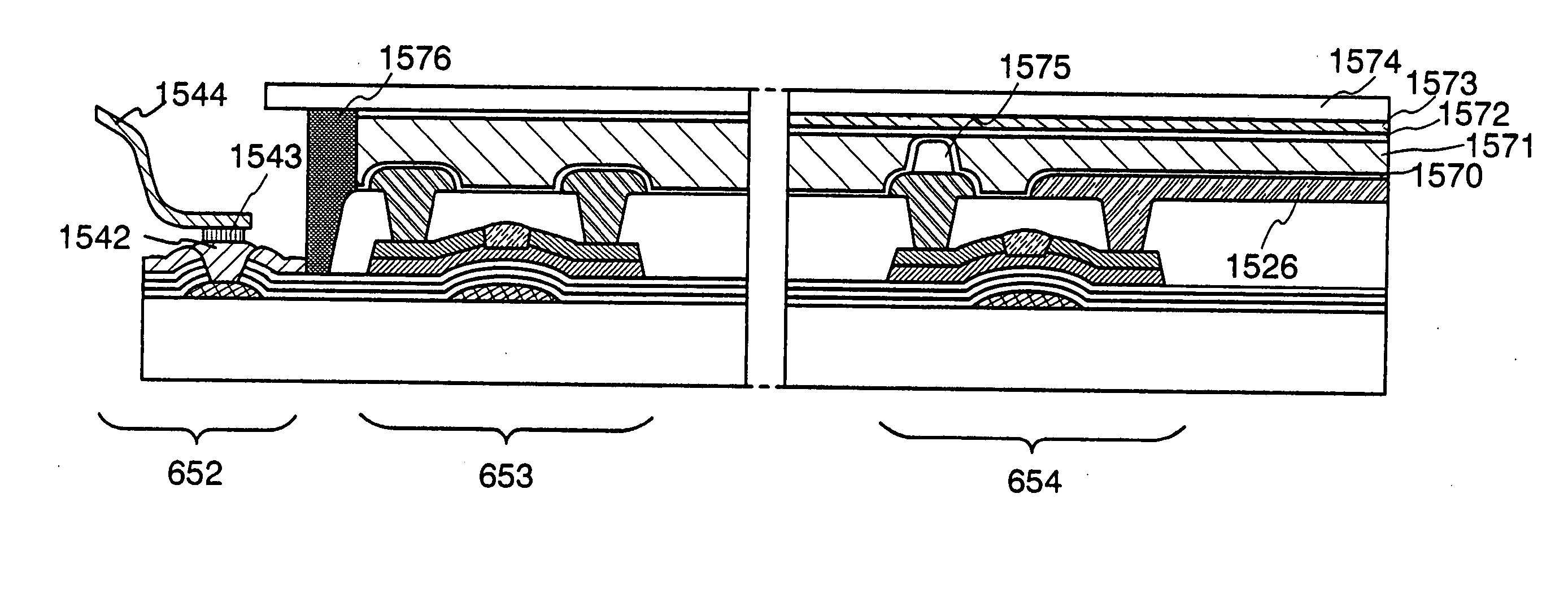

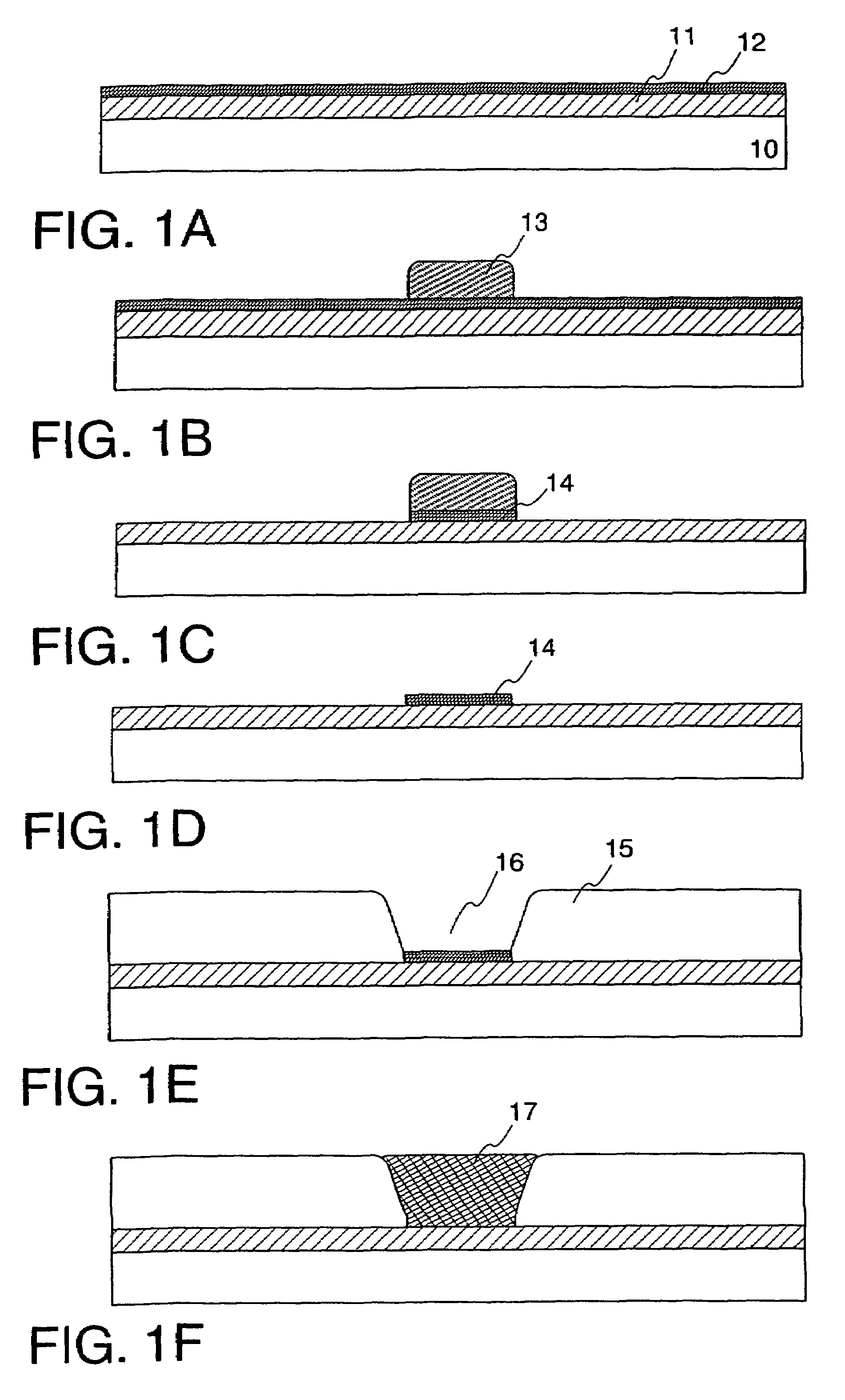

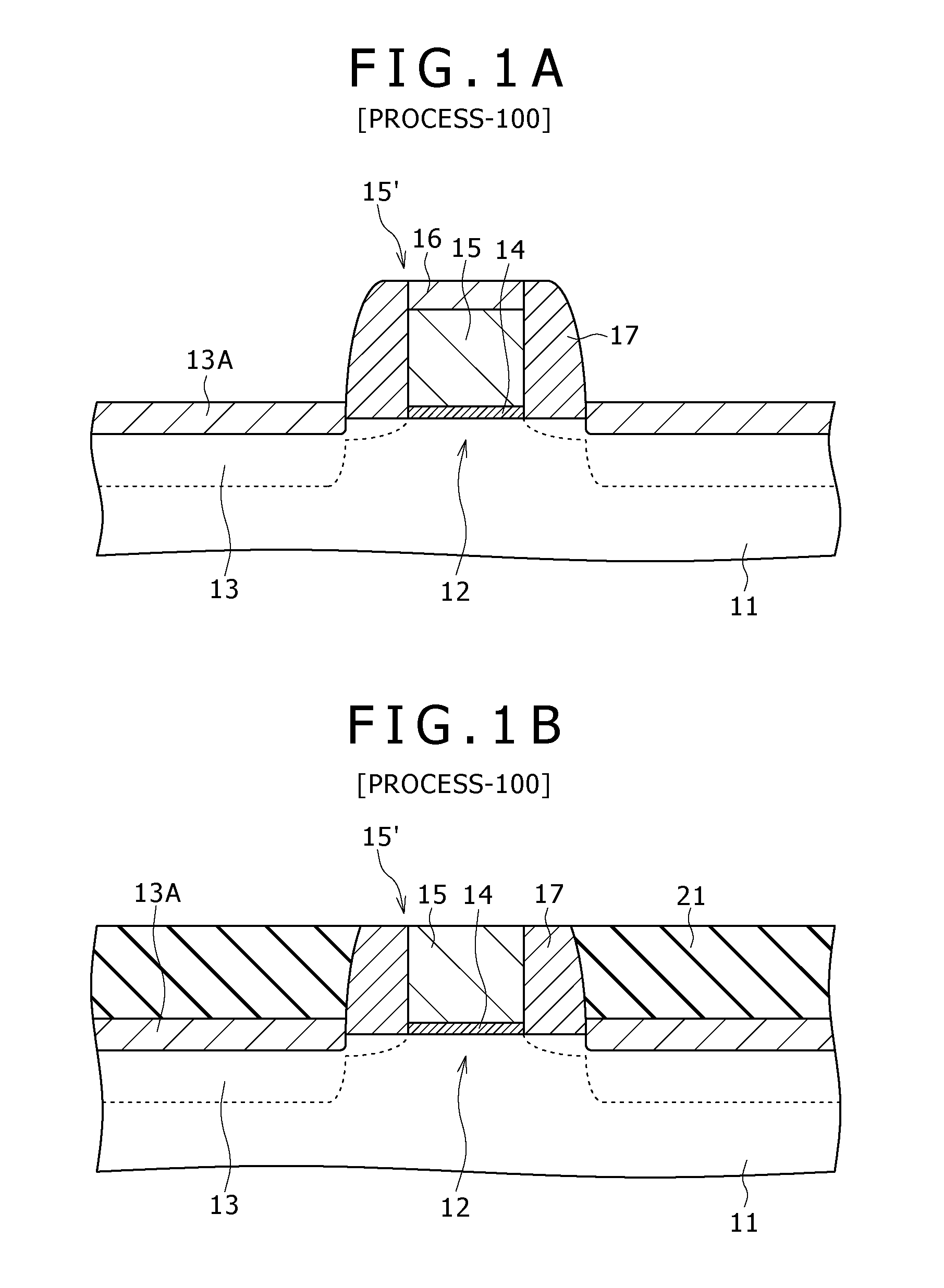

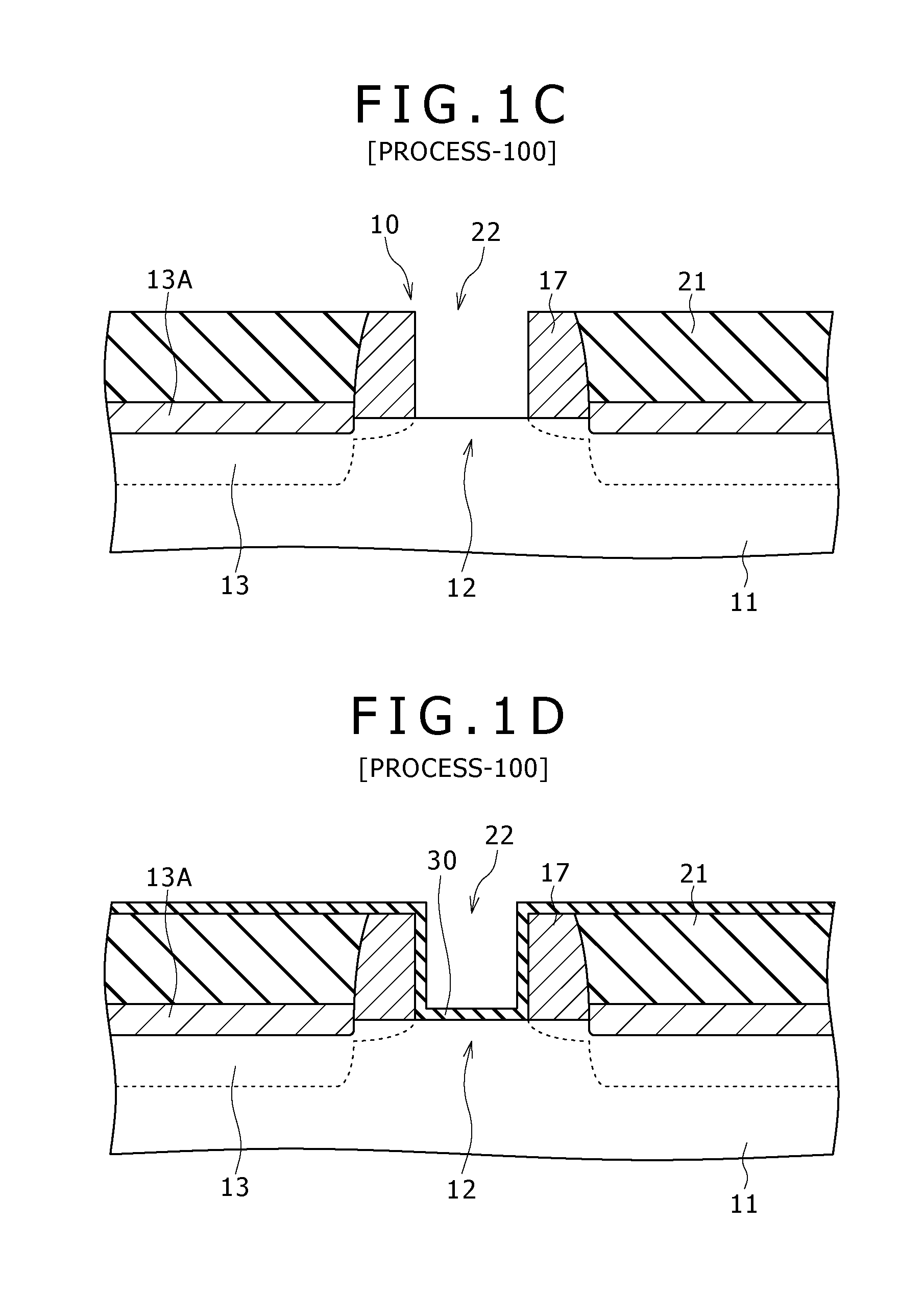

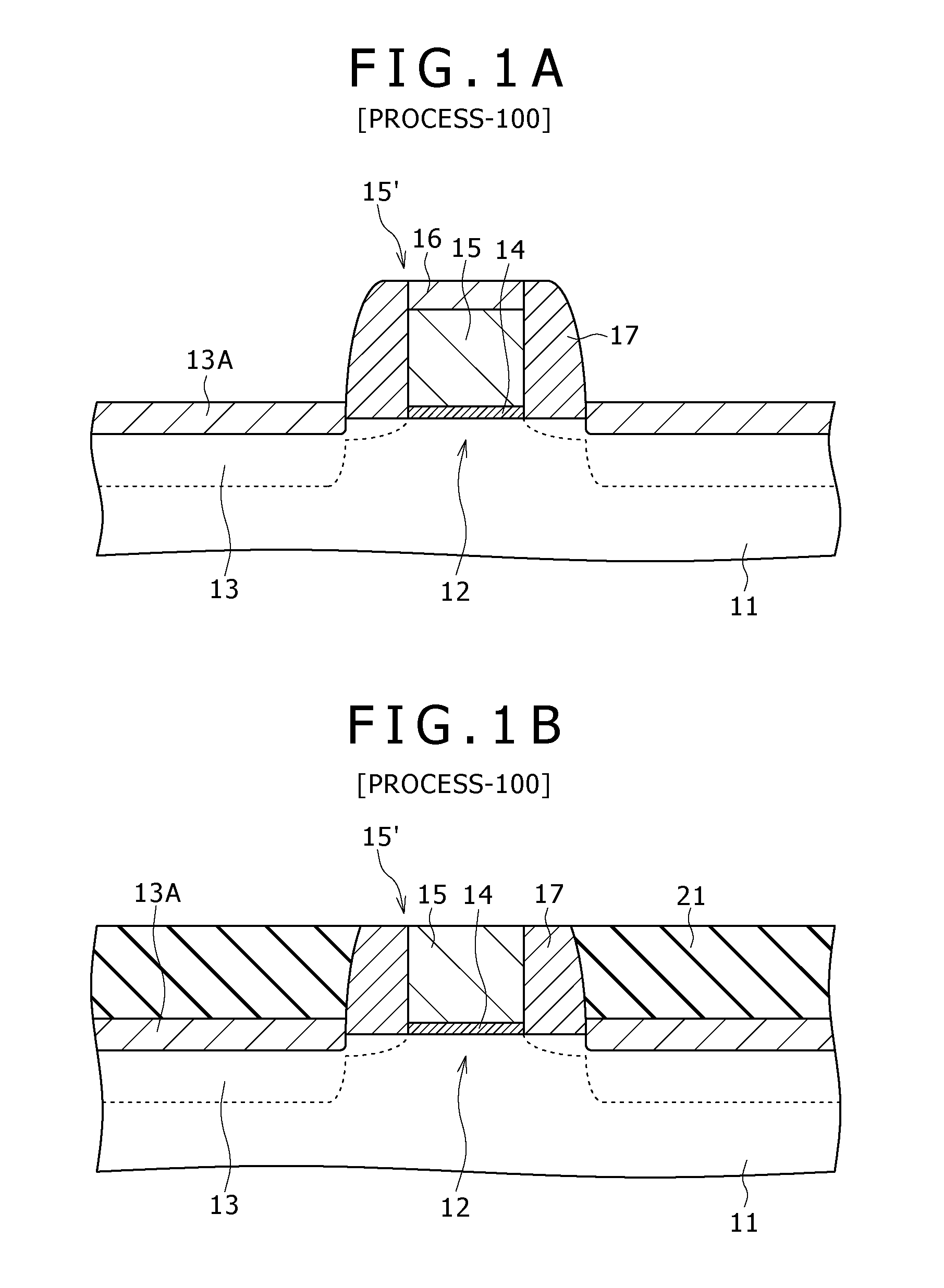

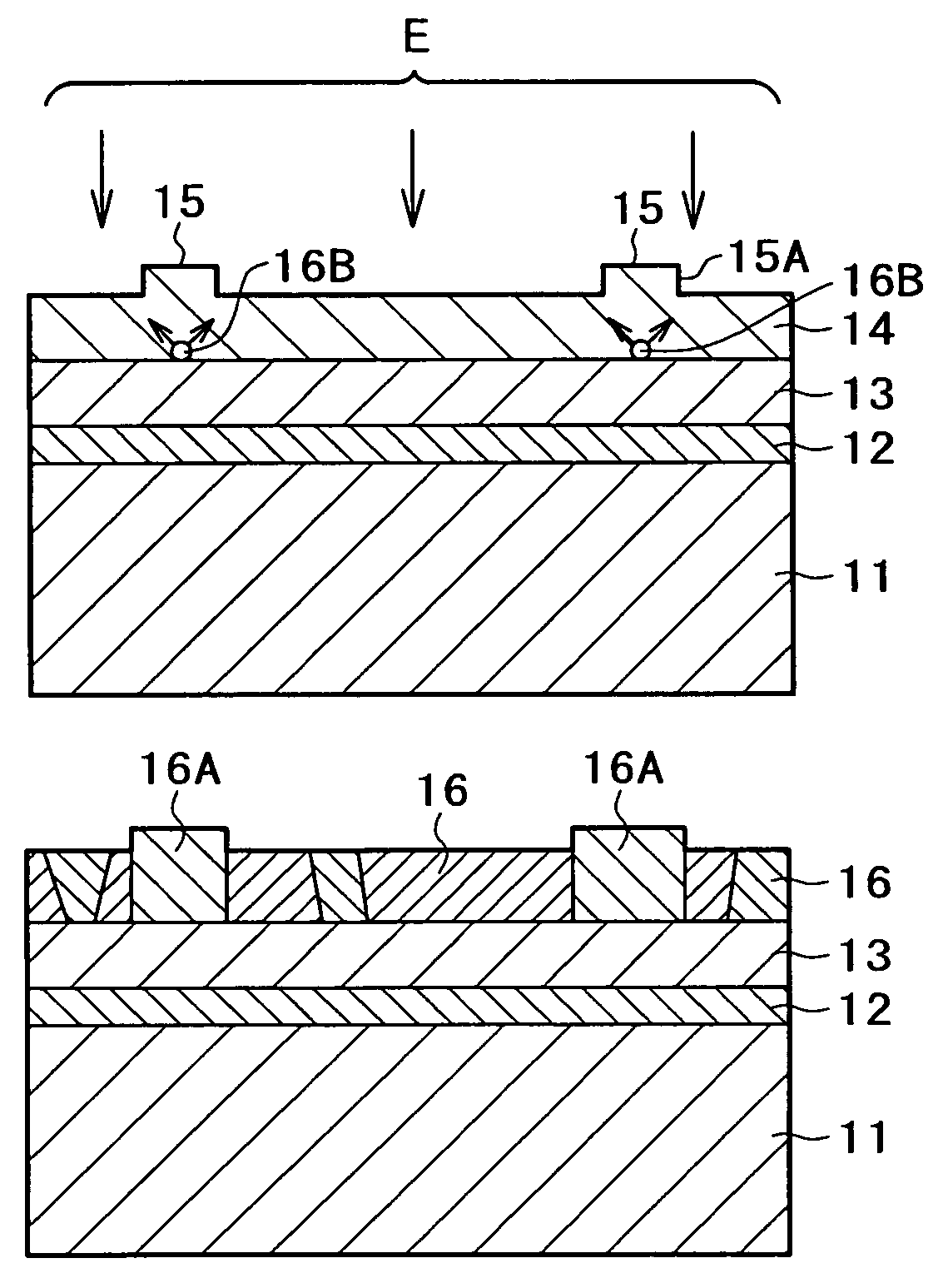

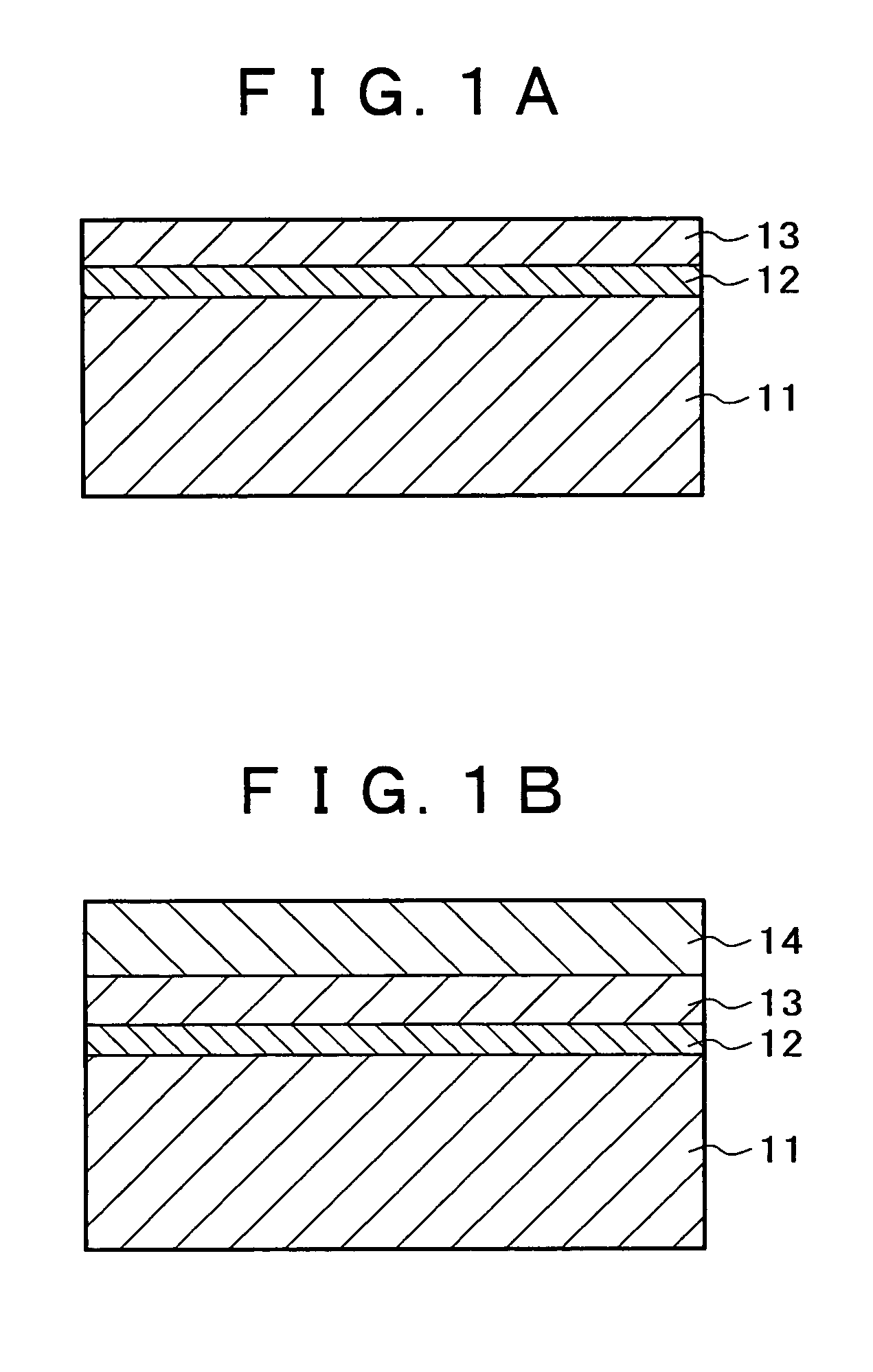

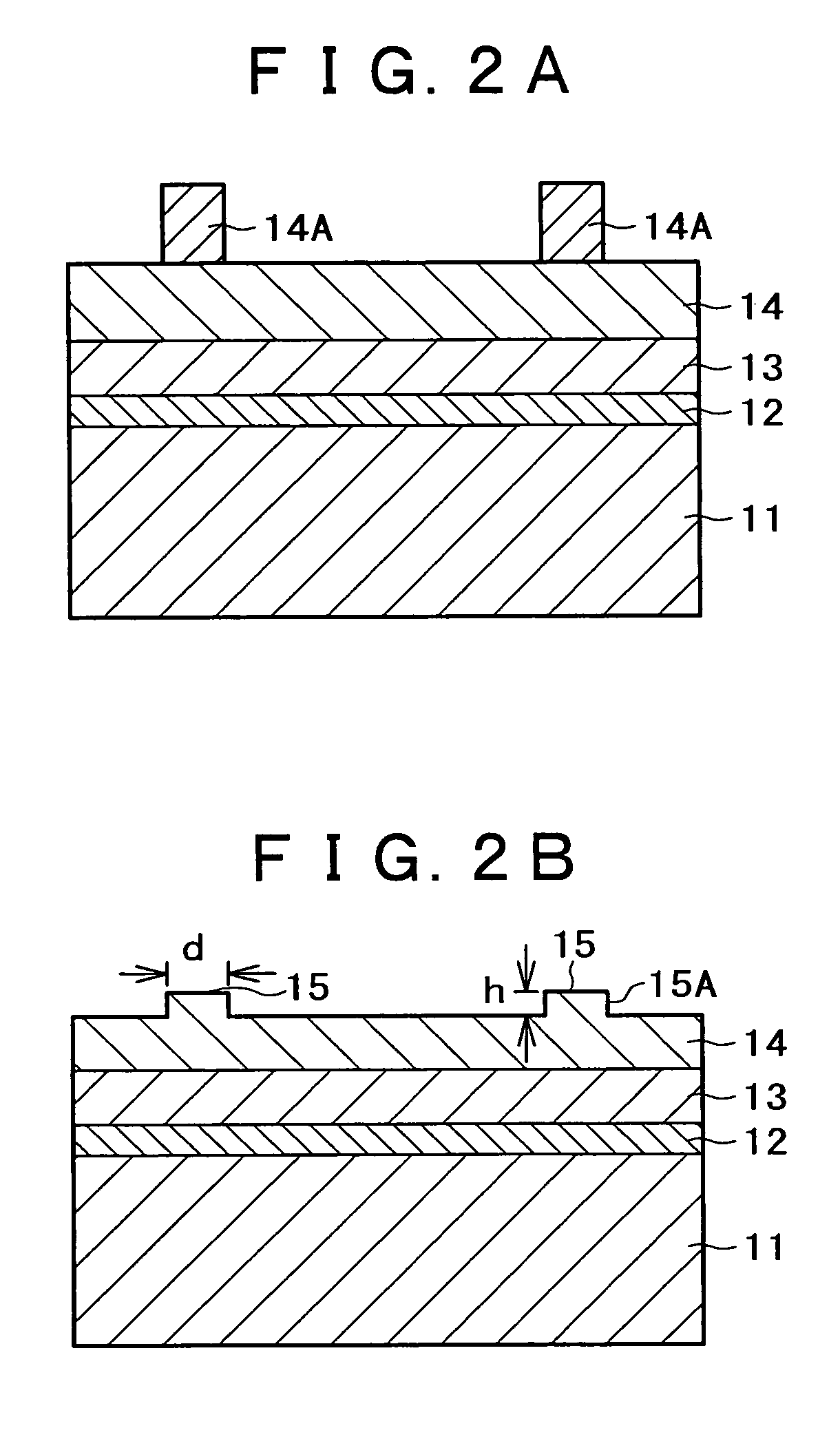

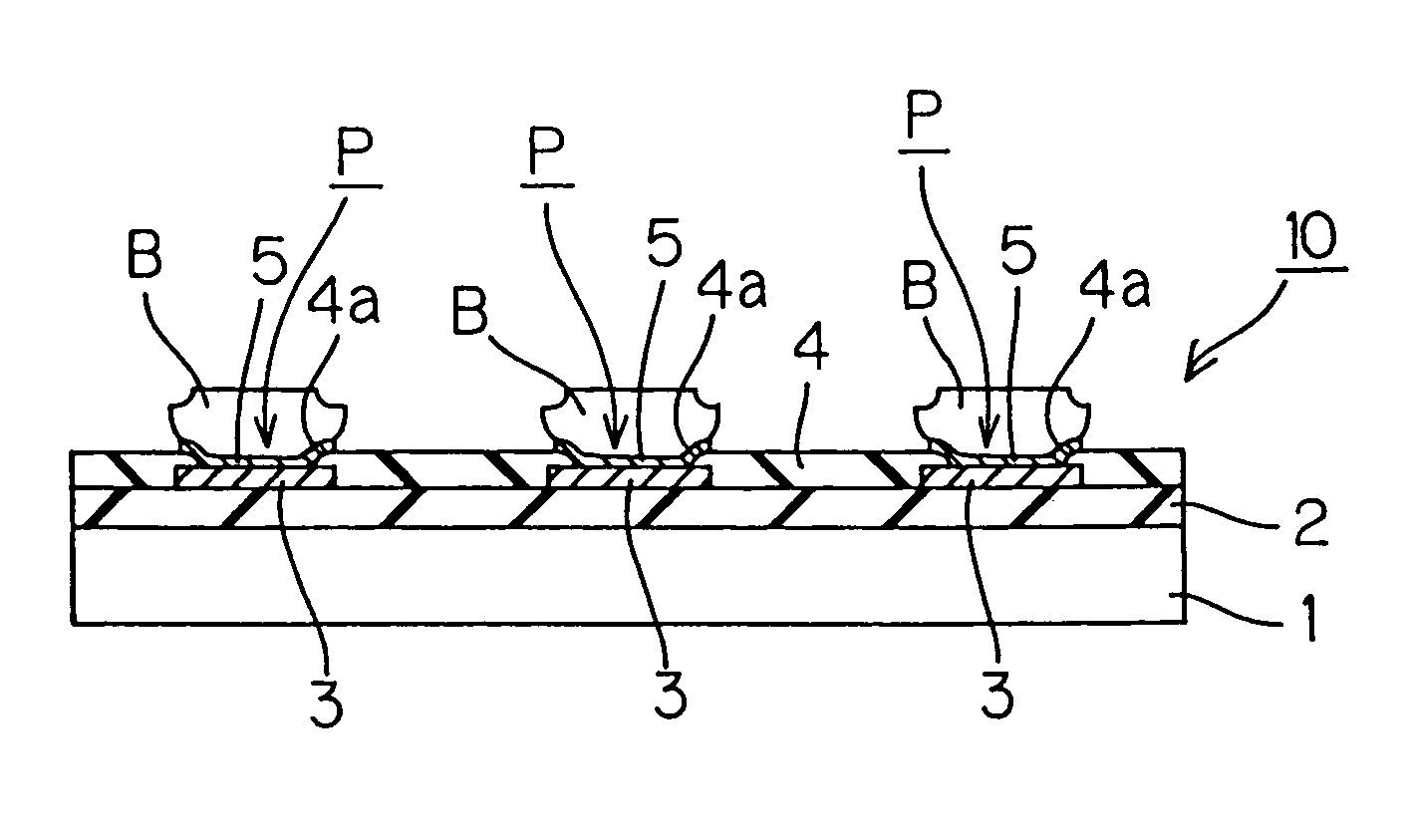

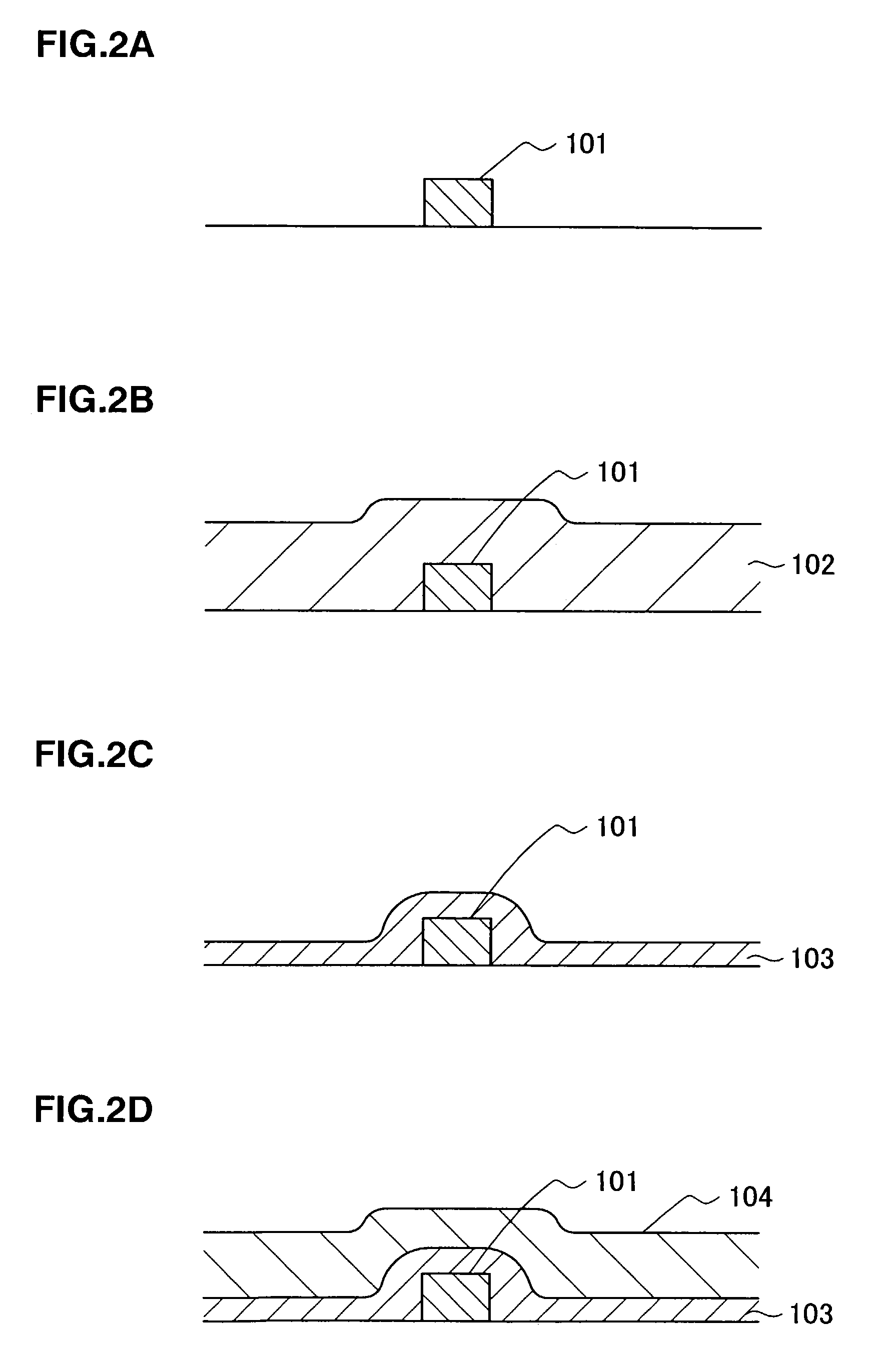

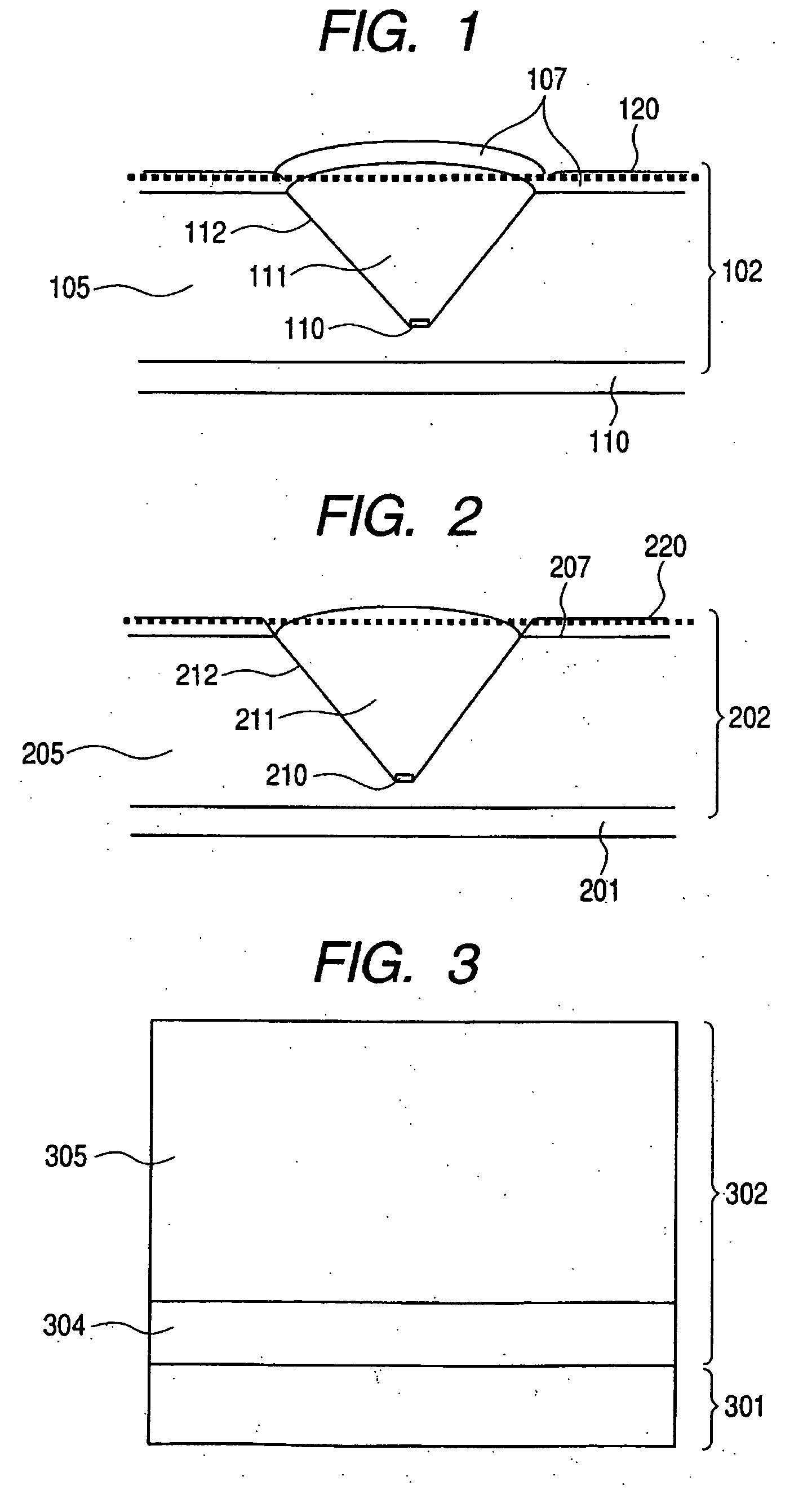

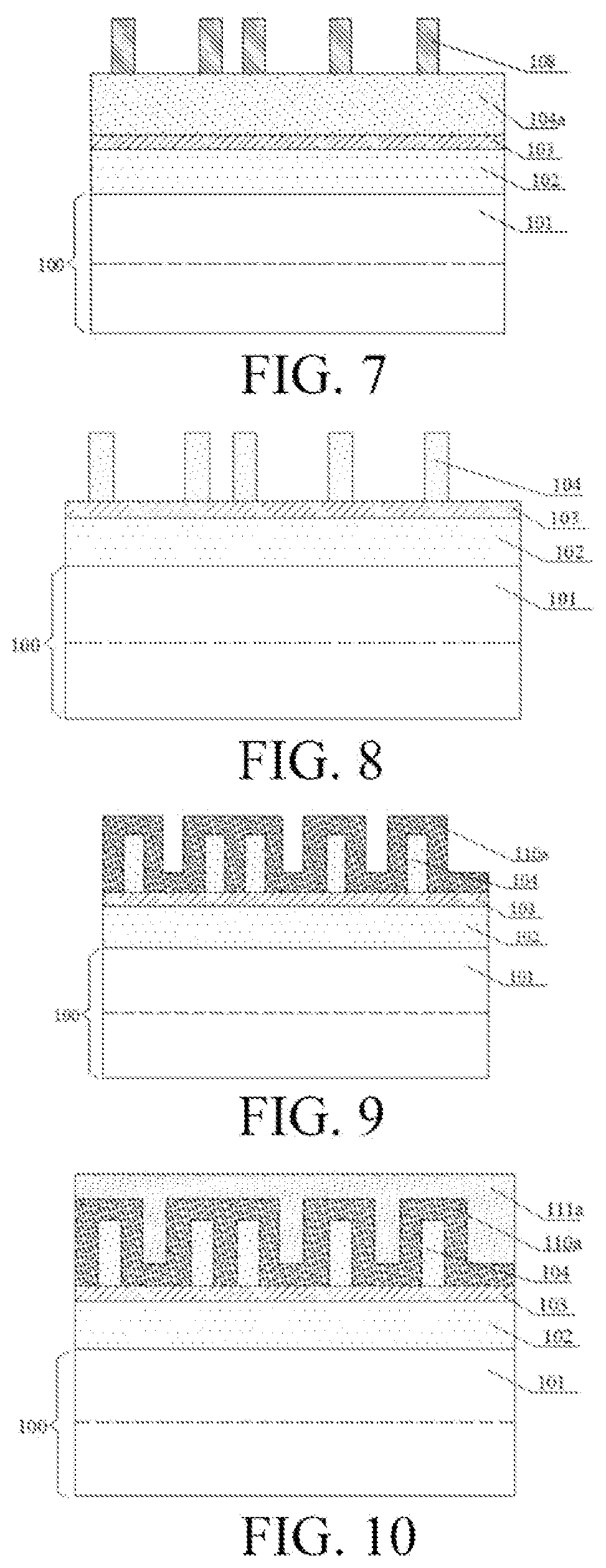

Forming method of contact hole, and manufacturing method of semicondutor device, liquid crystal display device and EL display device

When forming a contact hole by a conventional manufacturing step of a semiconductor device, a resist is required to be formed on almost entire surface of a substrate so as to be applied on a film other than an area in which a contact hole is to be formed, leading to drastically reduced throughput. According to a forming method of a contact hole and a manufacturing method of a semiconductor device, an EL display device and a liquid crystal display device of the invention, an island shape organic film is selectively formed over a semiconductor layer, a conductive layer or an insulating layer, and an insulating film is formed around the island shape organic film to form a contact hole. Therefore, a conventional patterning using a resist is not required, and high throughput and low cost can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

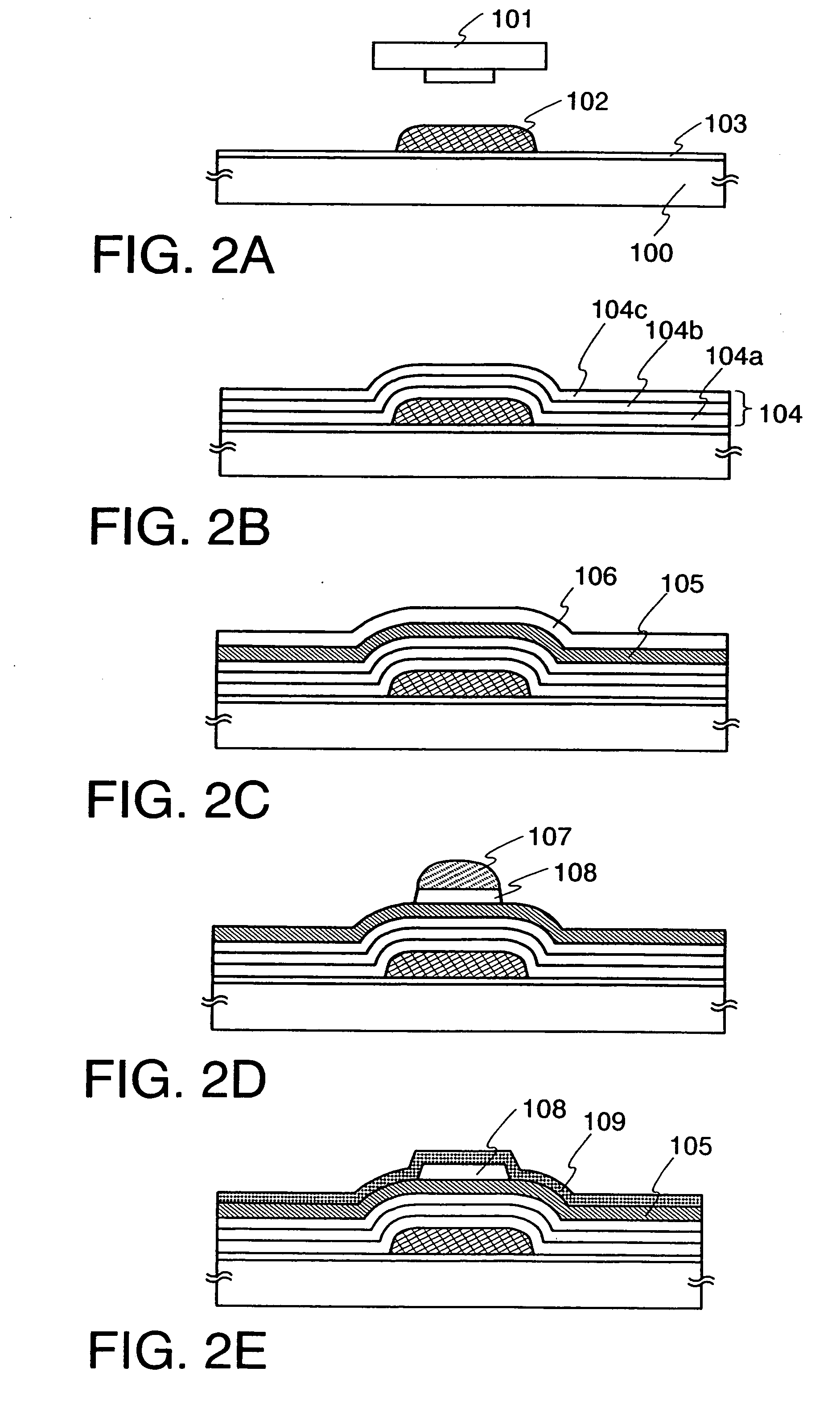

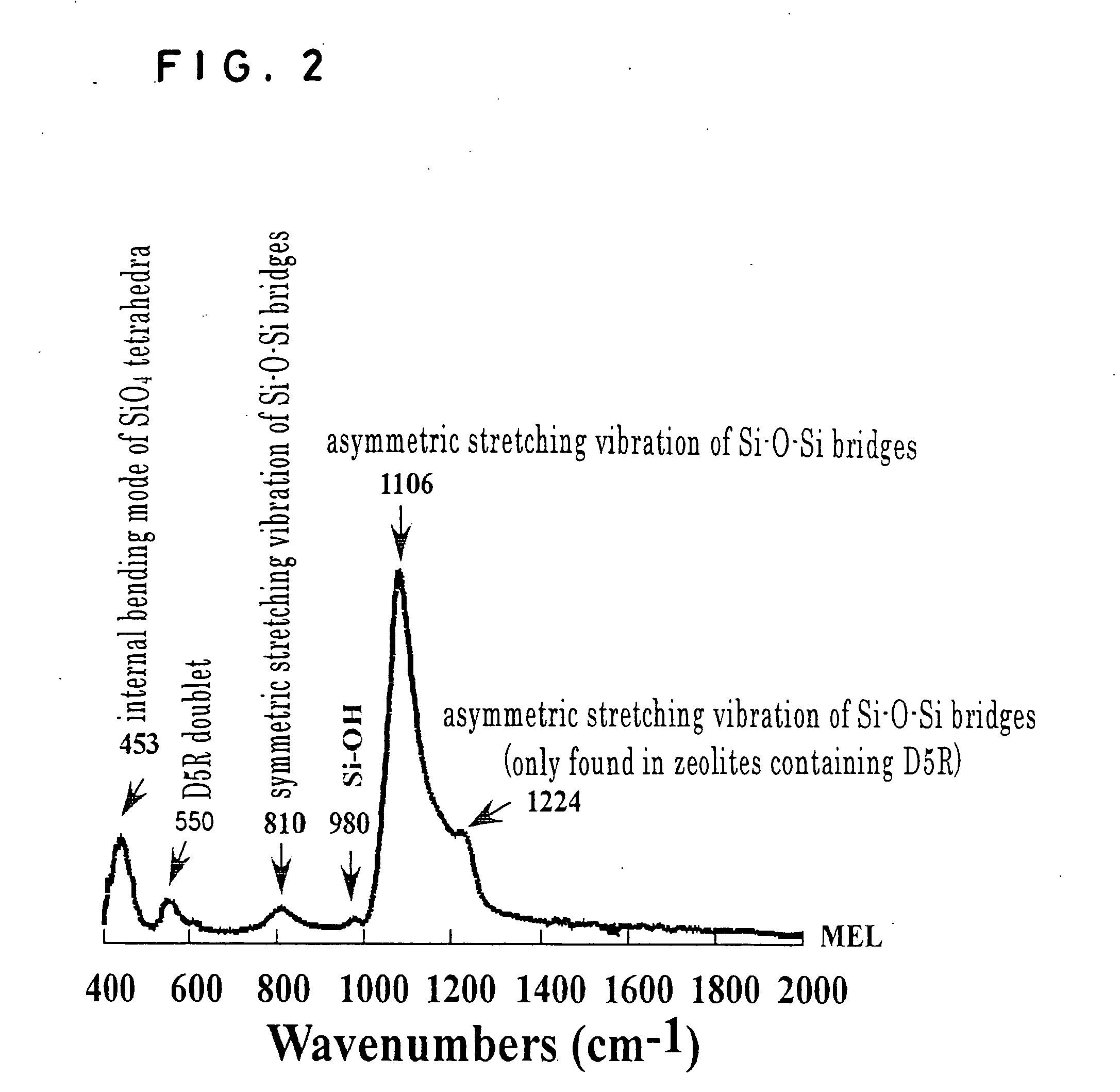

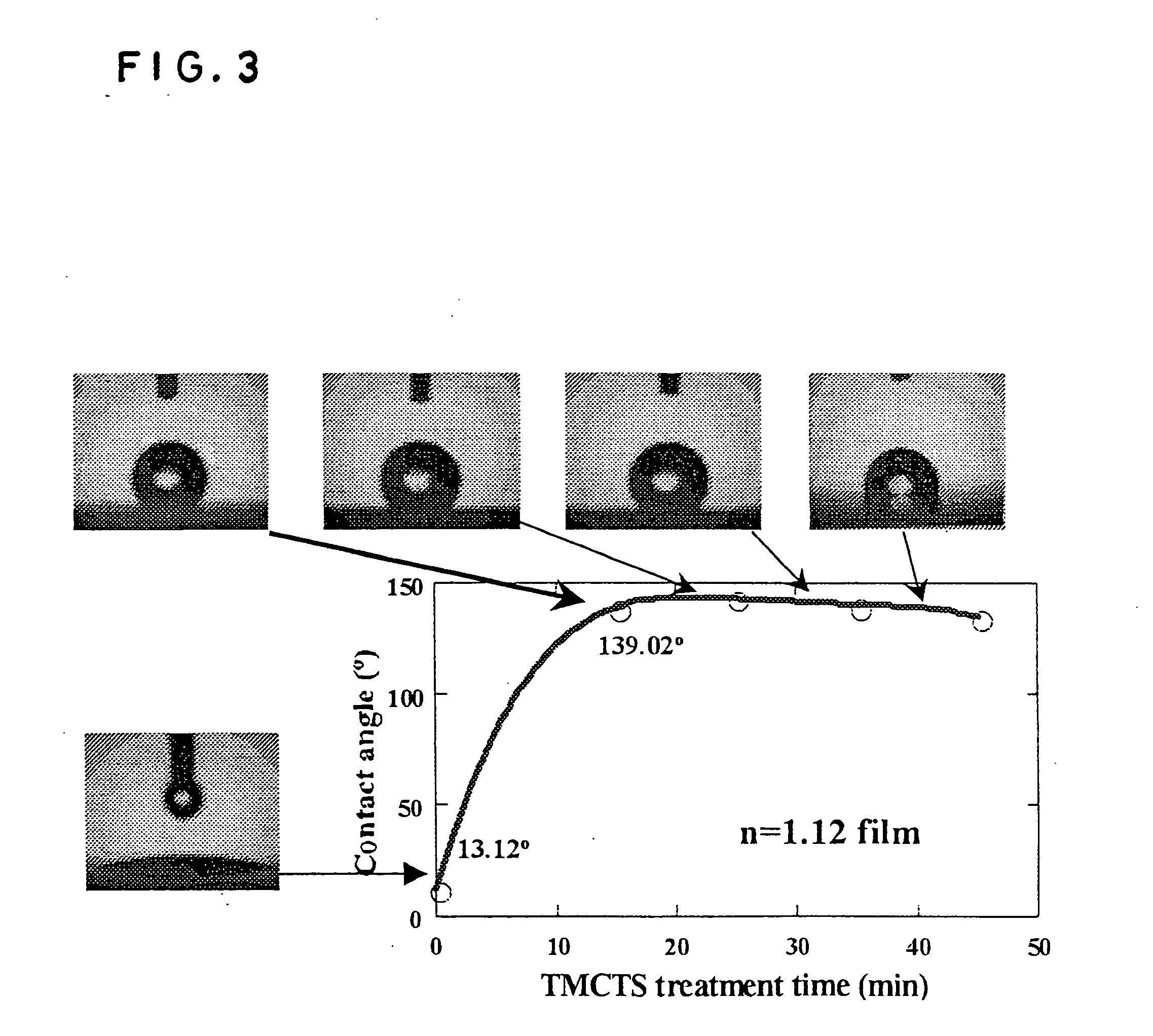

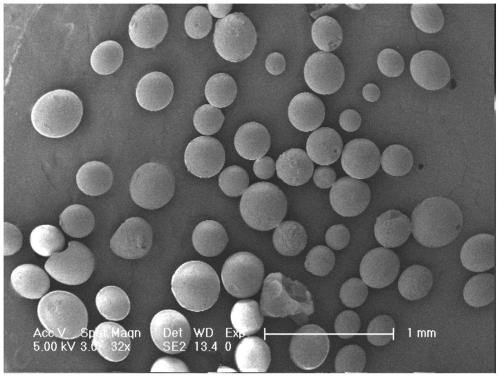

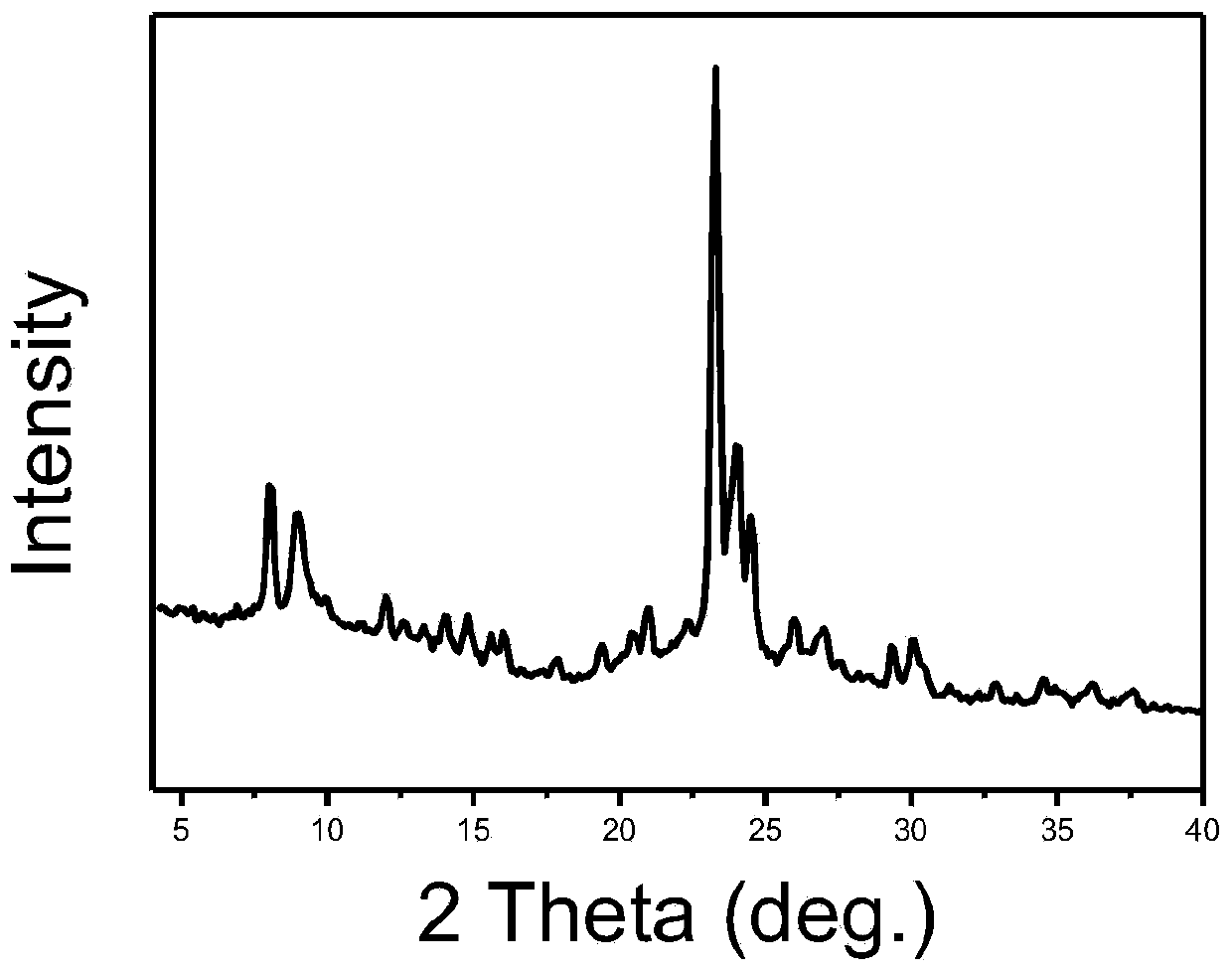

Zeolite nano-crystal suspension, zeolite nano-crystal production method, zeolite nano-crystal suspension production method, and zeolite thin film

InactiveUS20060063662A1High strengthHigh mechanical strengthAluminium compoundsMolecular sieve catalystsOrganic solventAlcohol

A zeolite suspension contains MEL-type zeolite nanocrystals as a principal component. A method for the production of MEL-type zeolite nanocrystals includes the steps of aging a synthesized solution comprising TEOS, TBAOH, water and alcohol and subjecting the aged solution to hydrothermal crystallization treatment at a predetermined temperature. A method for the production of a zeolite suspension includes the steps of aging a synthesized solution comprising TEOS, TBAOH, water and alcohol, subjecting the aged solution to hydrothermal crystallization treatment to produce MEL-type zeolite nanocrystals and mixing a composition having a surfactant dissolved in at least one organic solvent or a mixed solvent of alcohol-based organic solvents, amide-based organic solvents and ketone-based organic solvents with a zeolite nano-crystal suspension containing the MEL-type zeolite nanocrystals to produce a zeolite suspension.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

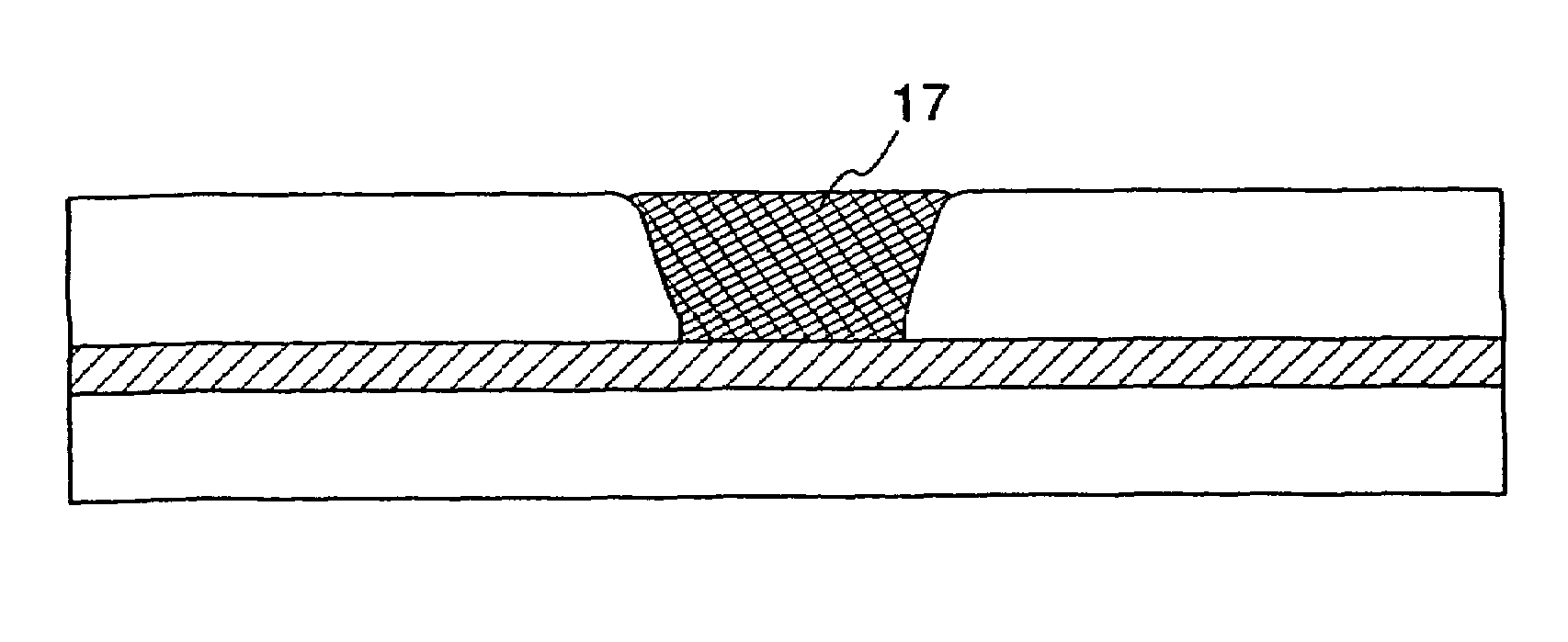

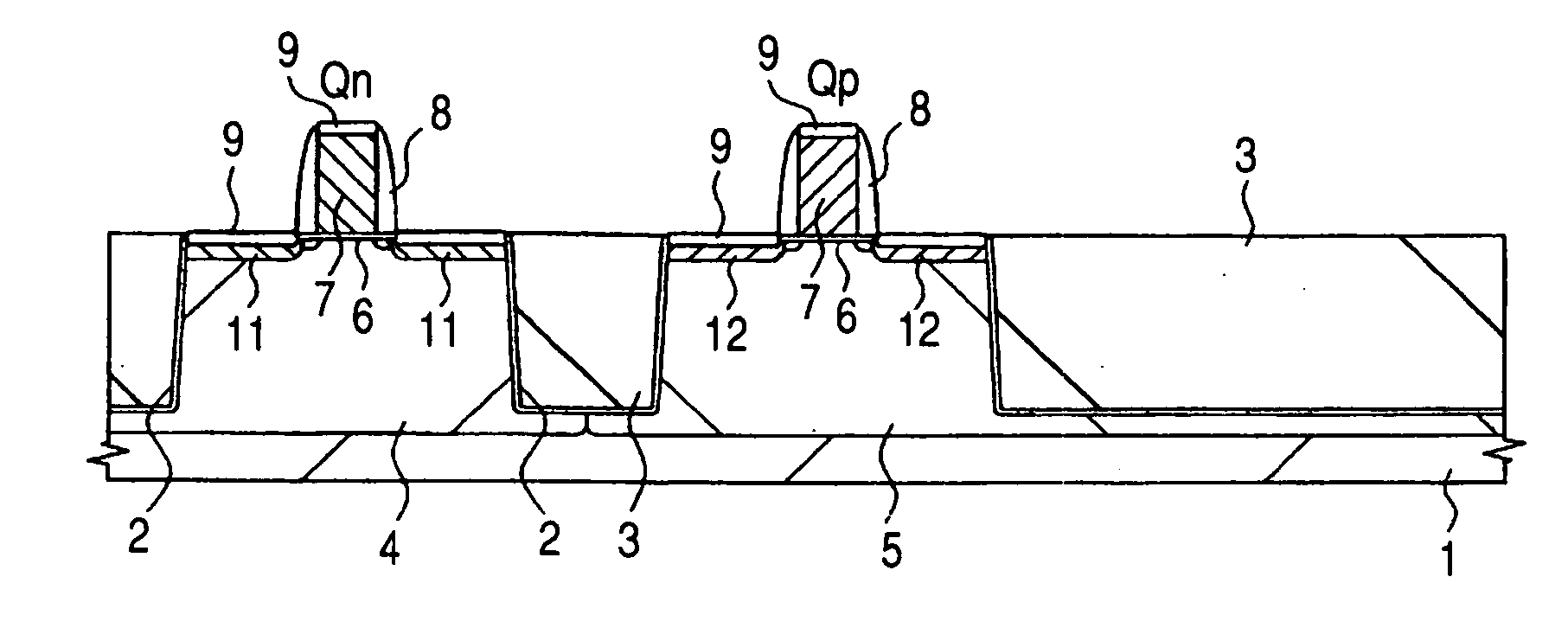

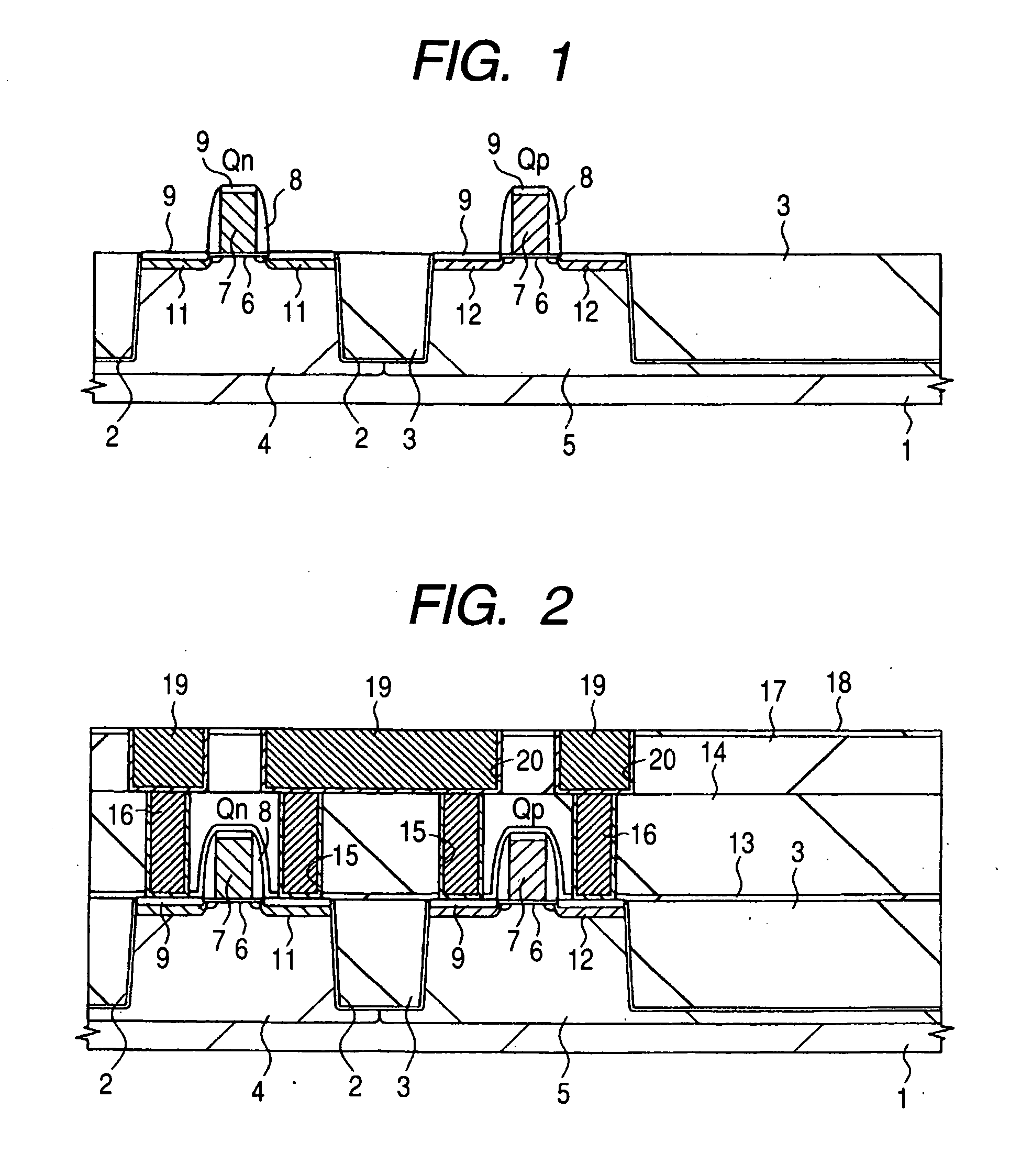

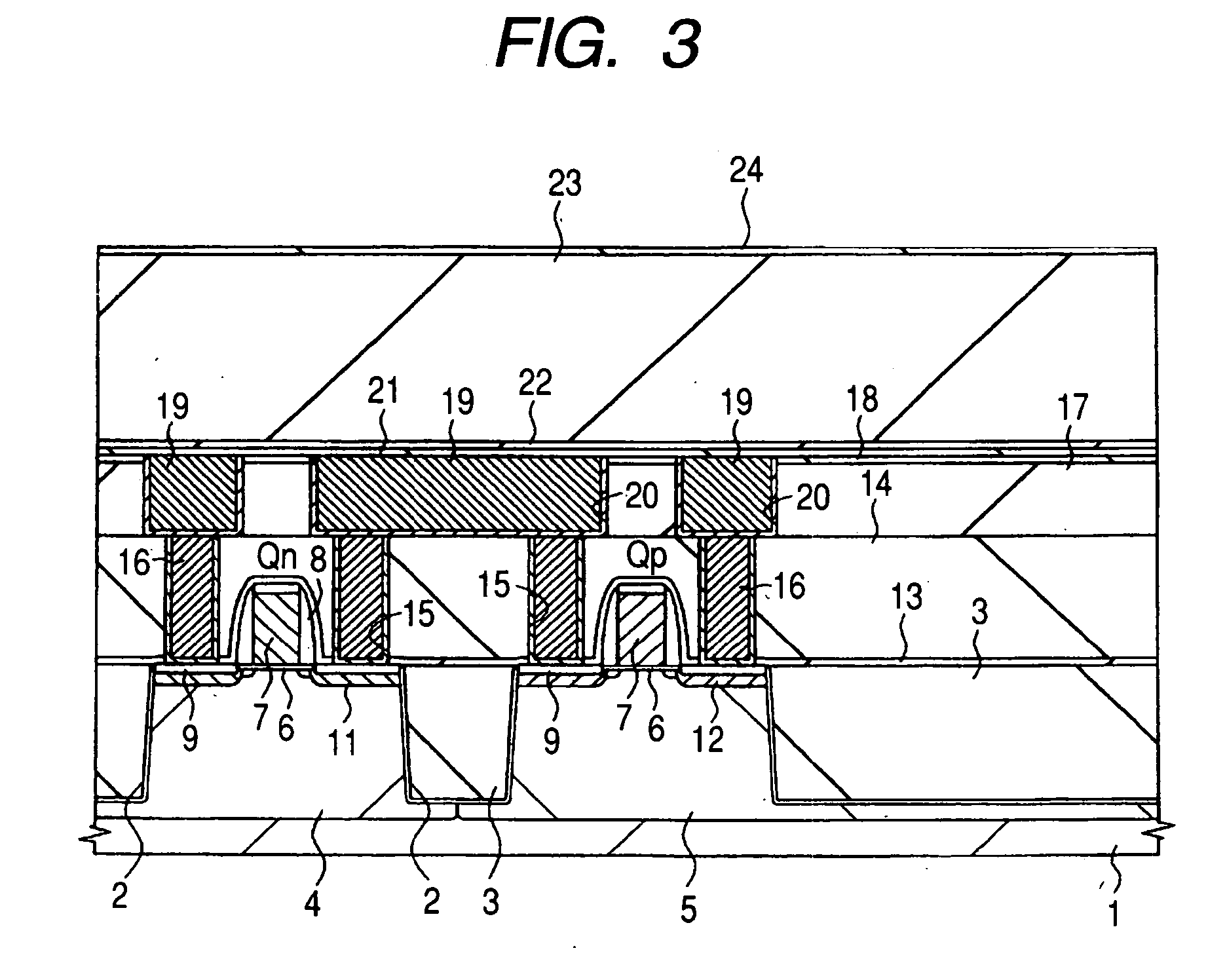

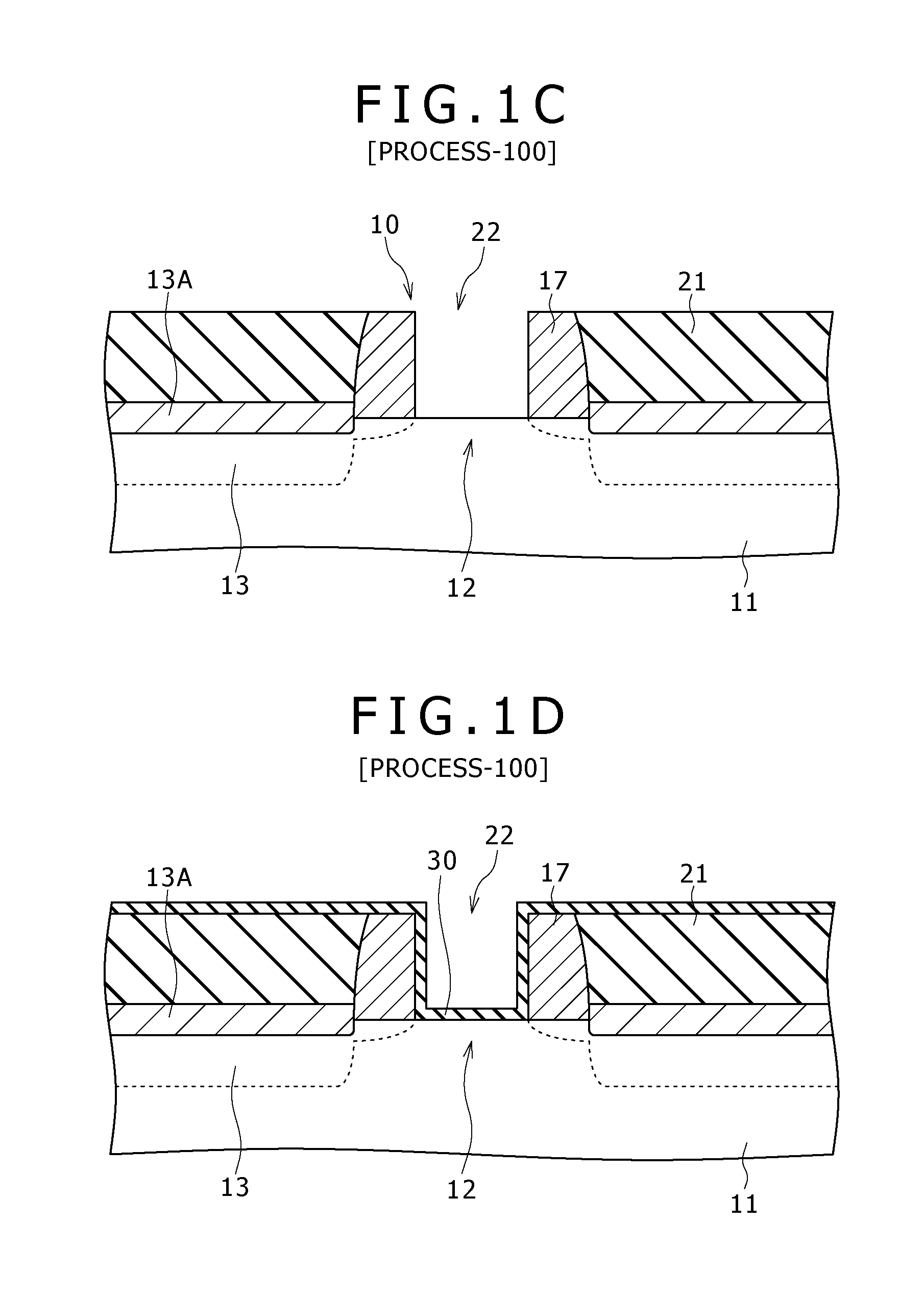

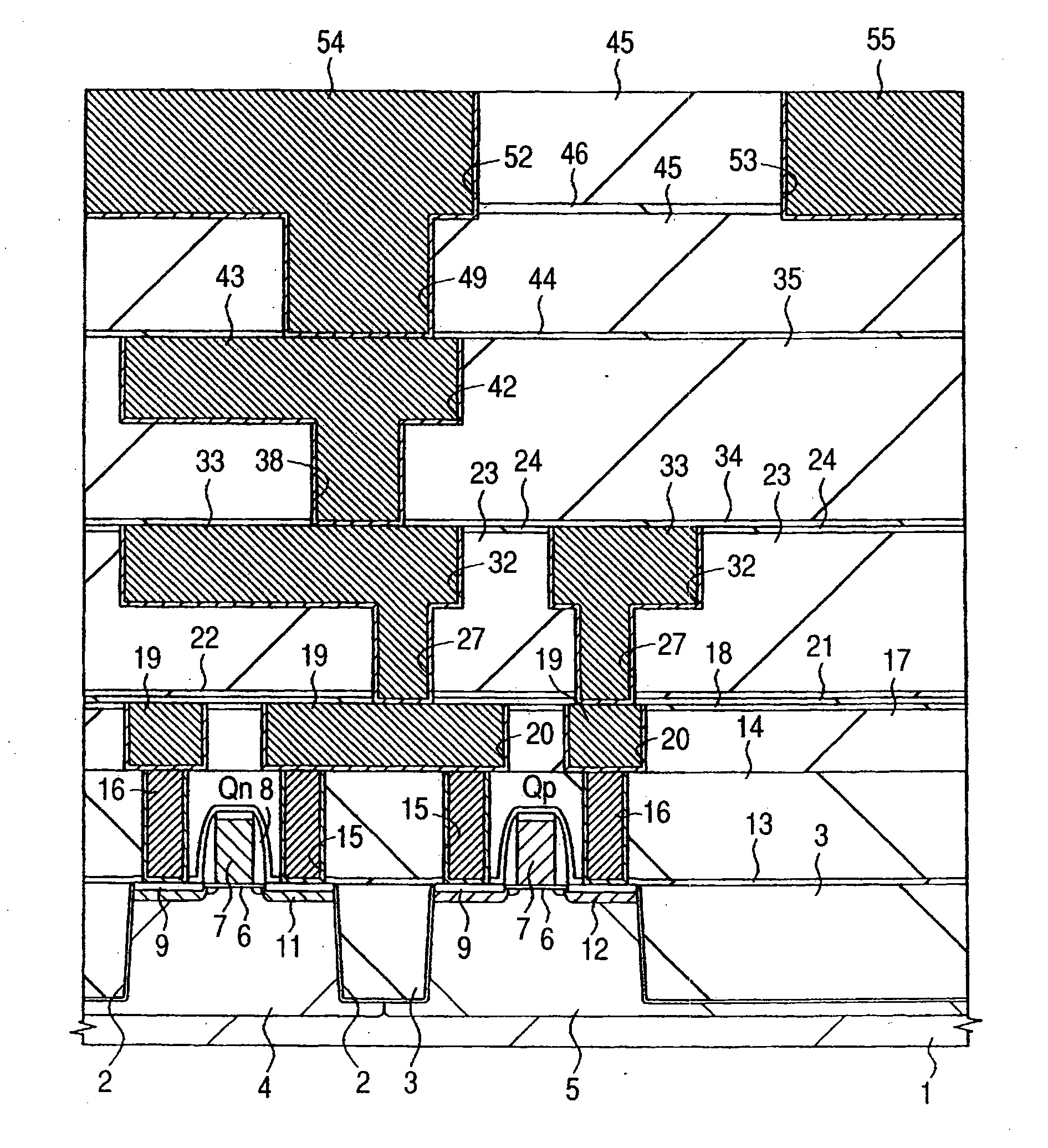

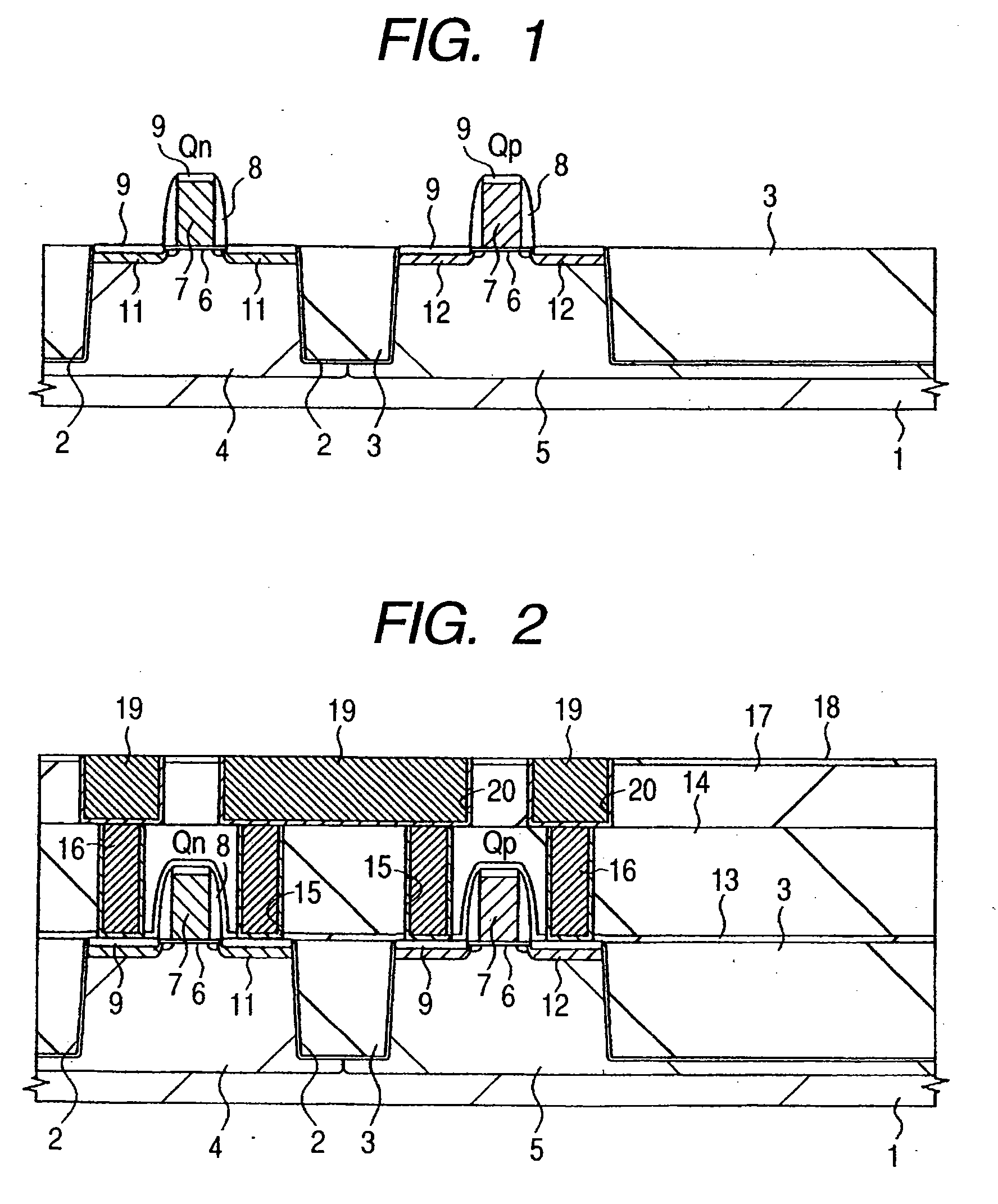

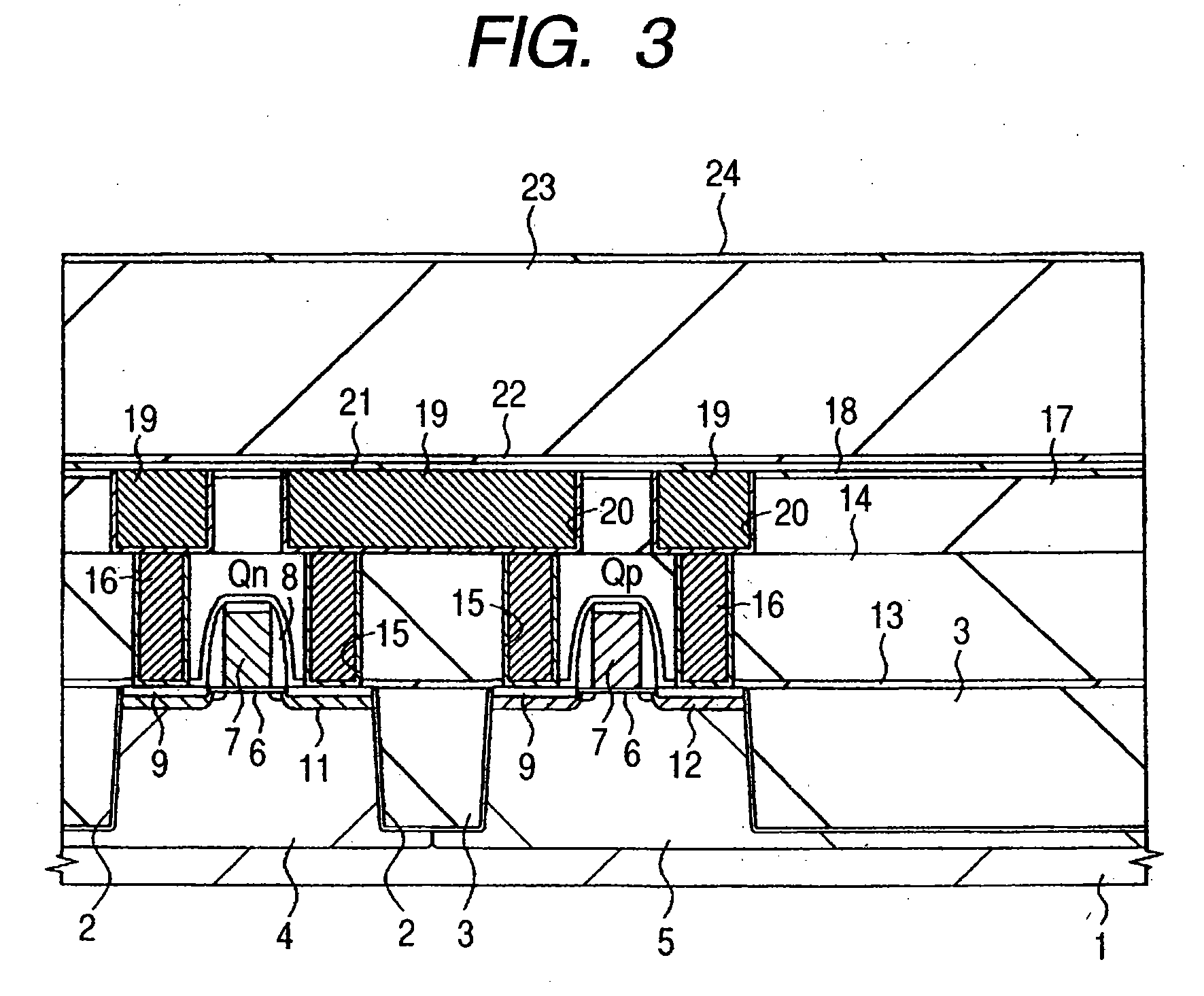

Forming method of contact hole, and manufacturing method of semiconductor device, liquid crystal display device and EL display device

When forming a contact hole by a conventional manufacturing step of a semiconductor device, a resist is required to be formed on almost entire surface of a substrate so as to be applied on a film other than an area in which a contact hole is to be formed, leading to drastically reduced throughput. According to a forming method of a contact hole and a manufacturing method of a semiconductor device, an EL display device and a liquid crystal display device of the invention, an island shape organic film is selectively formed over a semiconductor layer, a conductive layer or an insulating layer, and an insulating film is formed around the island shape organic film to form a contact hole. Therefore, a conventional patterning using a resist is not required, and high throughput and low cost can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

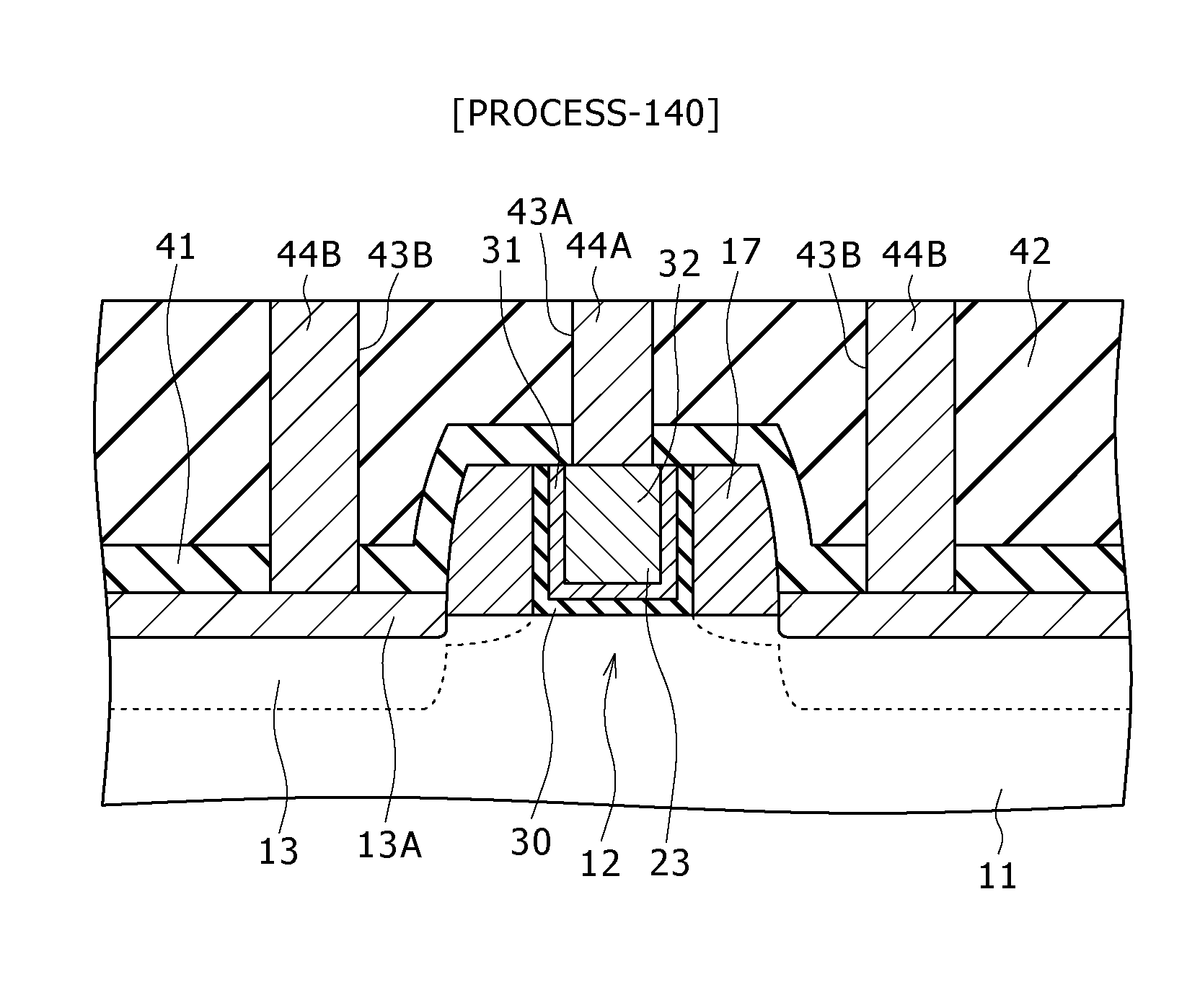

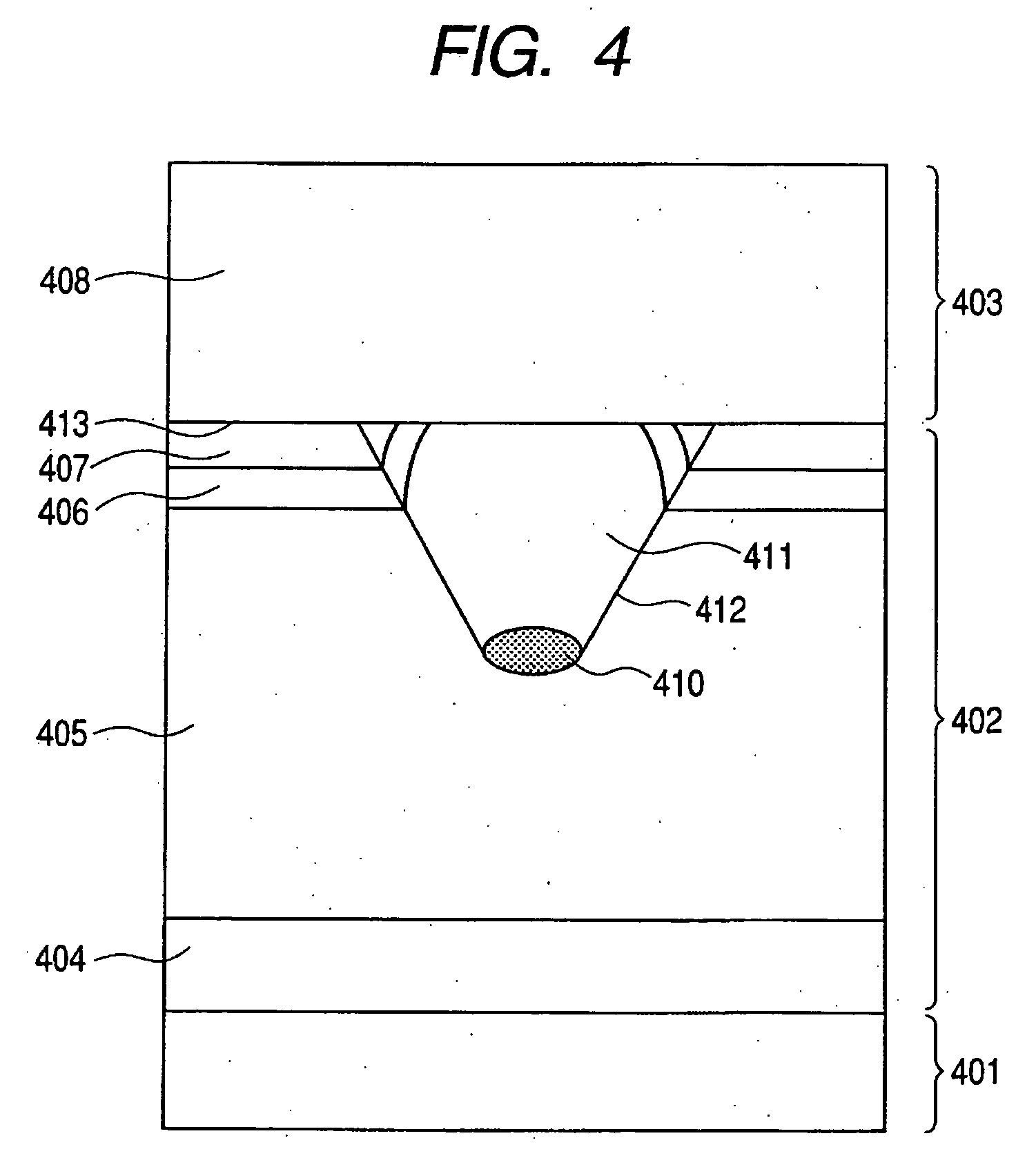

Method for manufacturing insulated gate field effect transistor

ActiveUS20080197426A1Reduce contact resistanceReduce gate capacitanceTransistorSolid-state devicesEngineeringConductive materials

Disclosed herein is a method for manufacturing an insulated gate field effect transistor, the method including the steps of: (a) preparing a base that includes source / drain regions, a channel forming region, a gate insulating film formed on the channel forming region, an insulating layer covering the source / drain regions, and a gate electrode formation opening provided in a partial portion of the insulating layer above the channel forming region; (b) forming a gate electrode by burying a conductive material layer in the gate electrode formation opening; (c) removing the insulating layer; and (d) depositing a first interlayer insulating layer and a second interlayer insulating layer sequentially across an entire surface, wherein in the step (d), the first interlayer insulating layer is deposited in a deposition atmosphere containing no oxygen atom.

Owner:SONY CORP

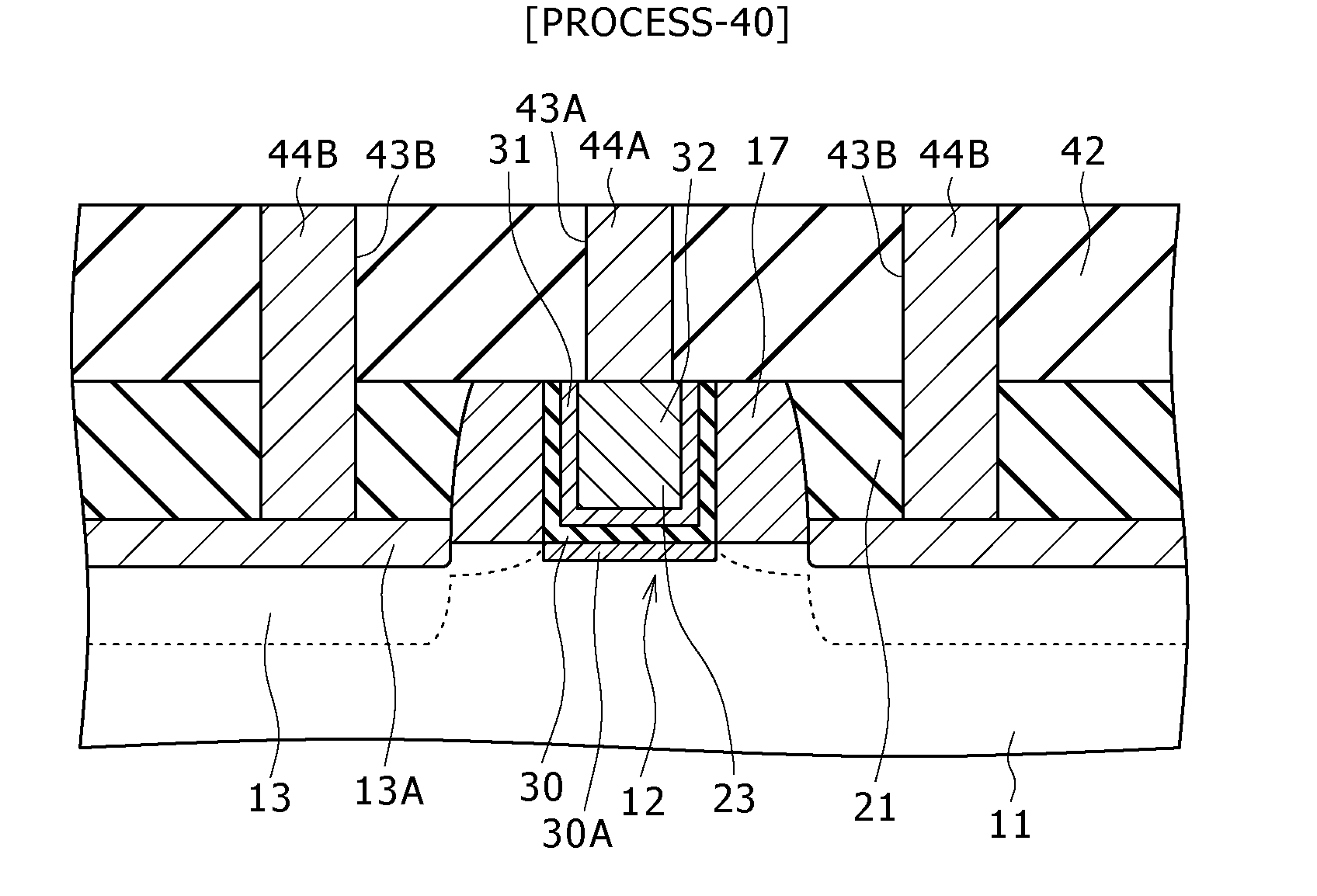

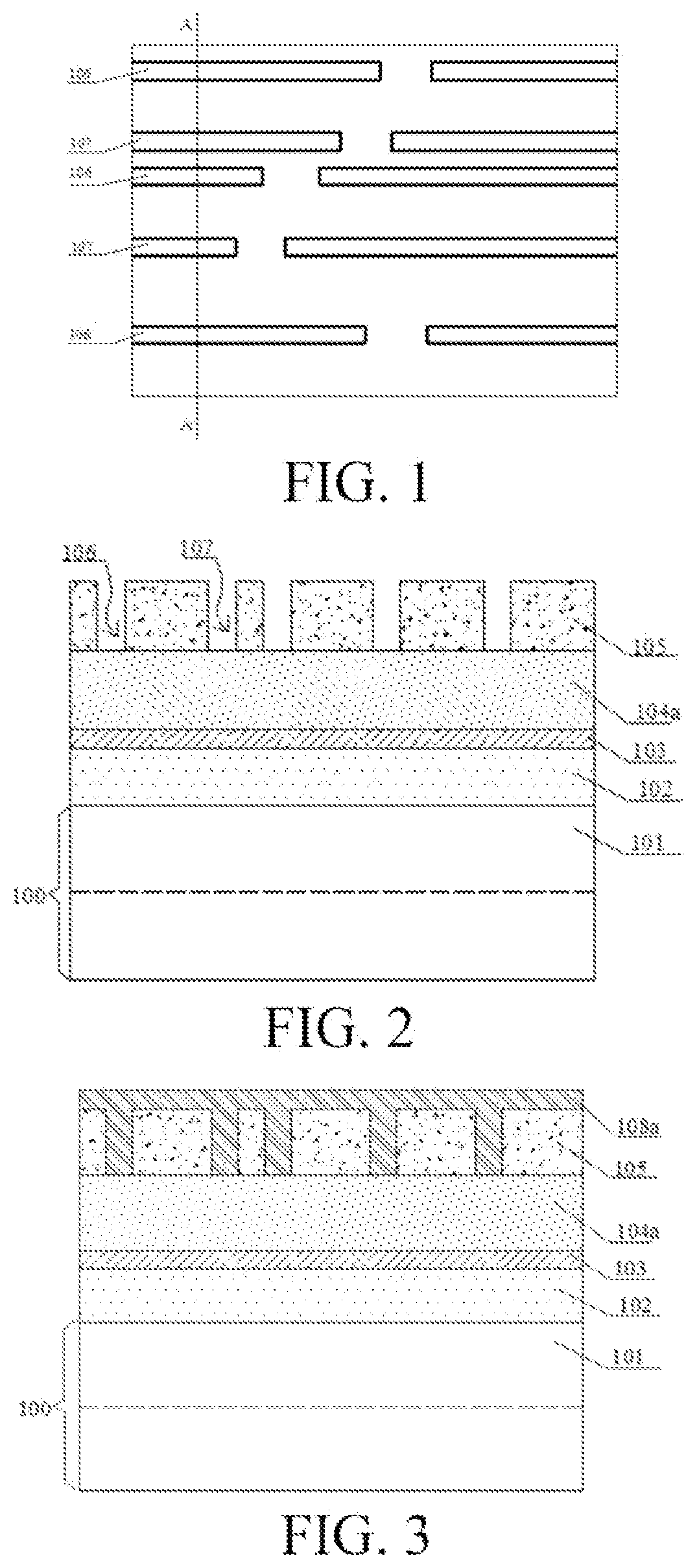

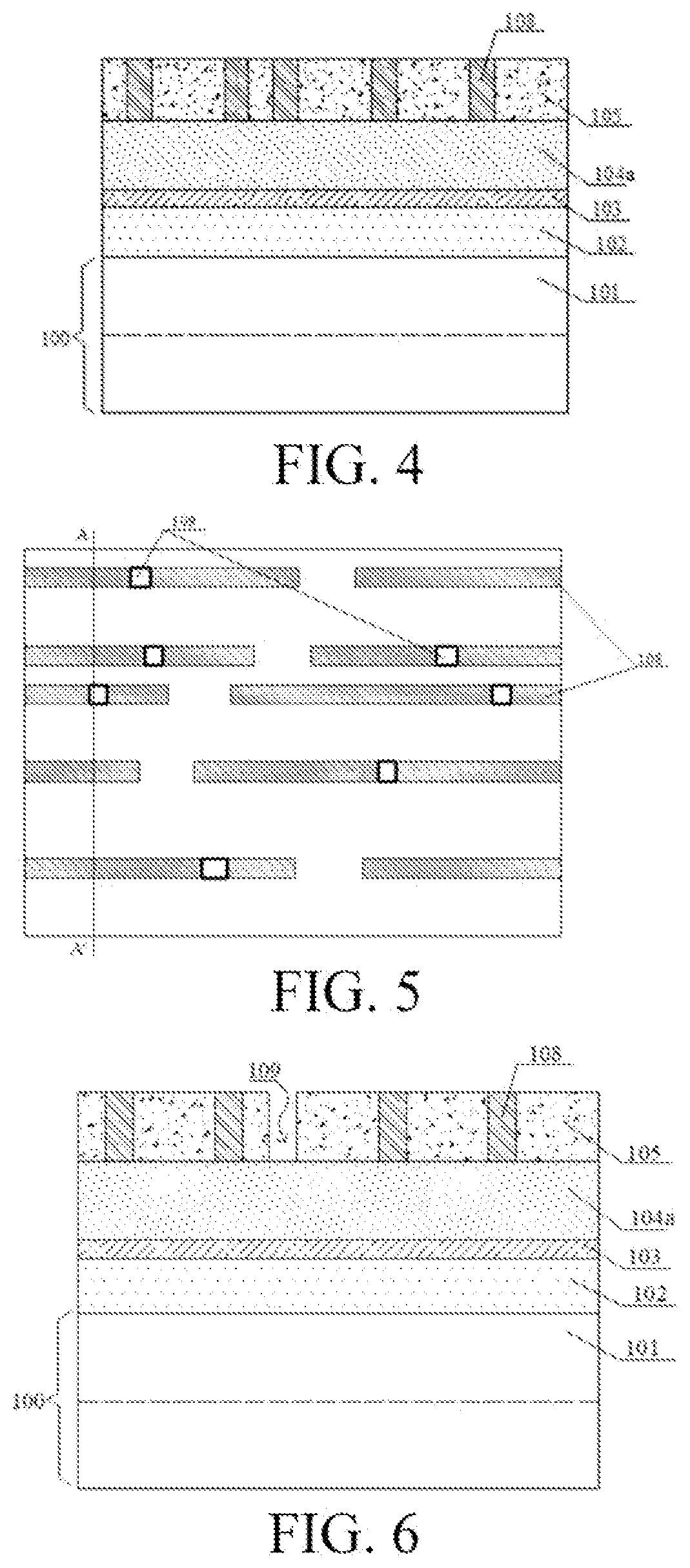

Semiconductor device and a method of manufacturing the same

ActiveUS20070020829A1High yieldSimplified molding stepsSemiconductor/solid-state device detailsSolid-state devicesResistDevice material

For simplifying the dual-damascene formation steps of a multilevel Cu interconnect, a formation step of an antireflective film below a photoresist film is omitted. Described specifically, an interlayer insulating film is dry etched with a photoresist film formed thereover as a mask, and interconnect trenches are formed by terminating etching at the surface of a stopper film formed in the interlayer insulating film. The stopper film is made of an SiCN film having a low optical reflectance, thereby causing it to serve as an antireflective film when the photoresist film is exposed.

Owner:RENESAS ELECTRONICS CORP

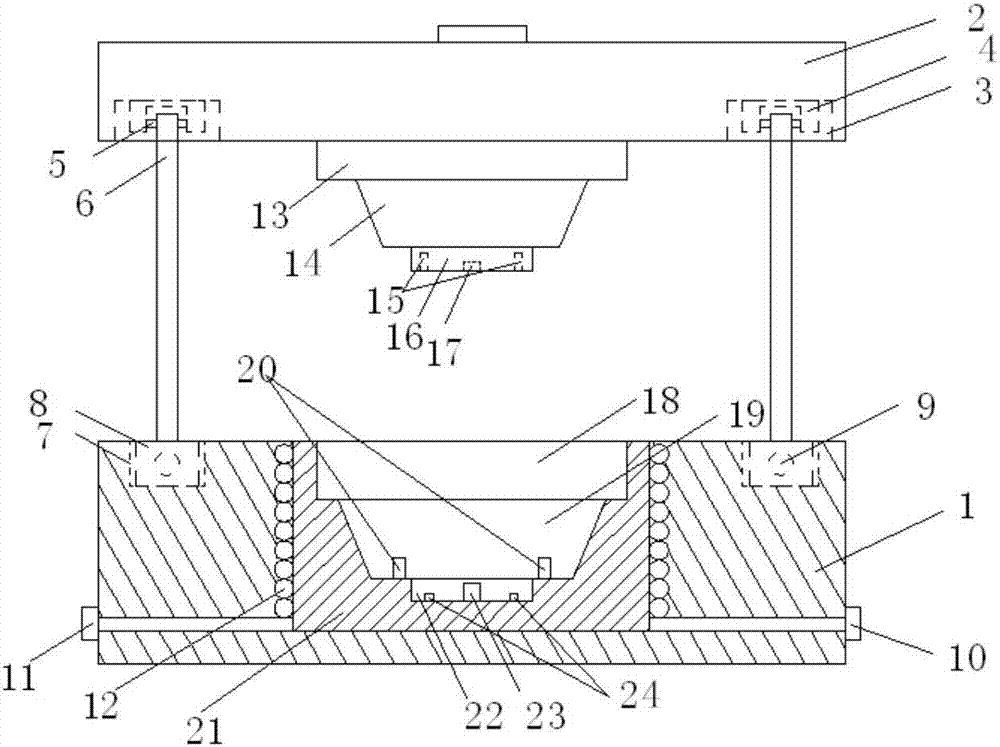

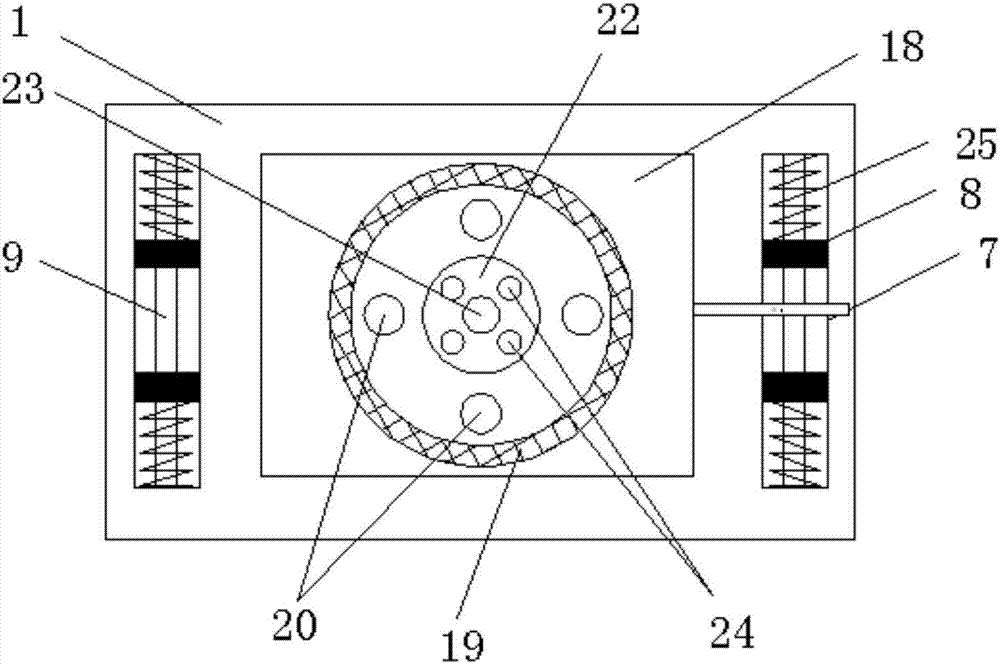

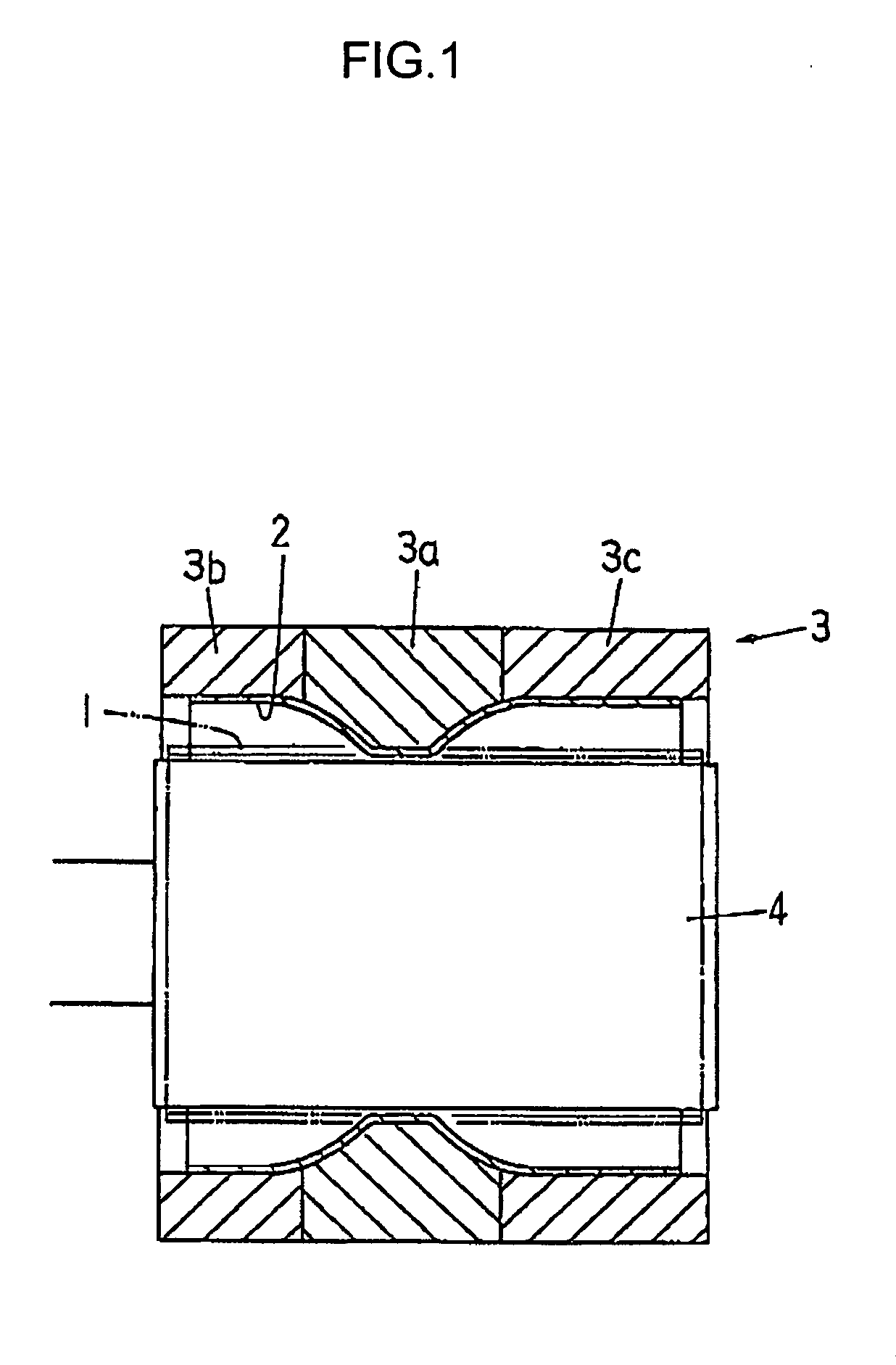

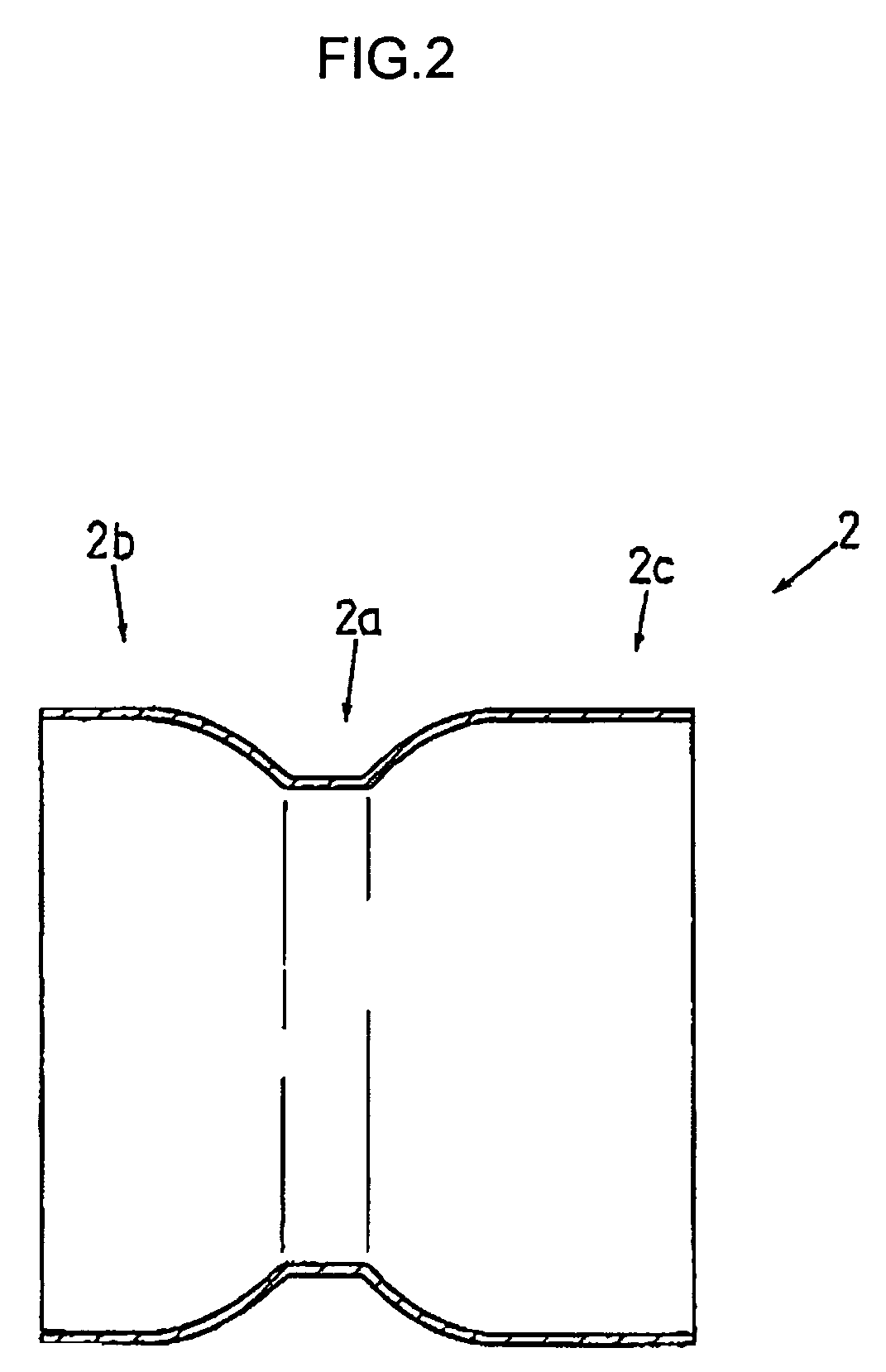

High-precision forming mold and method for thickly-laid composite material boxes

The invention relates to a composite material forming technology and specifically relates to a high-precision forming mold and method for thickly-laid composite material boxes. The high-precision forming mold for thickly-laid composite material boxes is designed in the present invention and comprises a box bottom female die (1), a box body sidewall pressure transfer block (2), a knockout plate (3), a box sidewall female die (4), a male die (5) and a bottom plate (6). On the basis of the high-precision forming mold for thickly-laid composite material boxes, box prepreg layers of a composite material are laid one by one on the male die (5); every two to three prepreg layers are vacuumized and pre-compacted, and a plurality of times of vacuumizing and pre-compacting are carried out until the prepregs are completely fitted with the die; subsequently, more than three times of pre-pressing by using a press are carried out, followed by a process of opening the mold to supplement materials and shaping, and hot press molding. The accuracy of inner and outer molded surfaces of a composite material box formed by using the mold and the method of the present invention can be above + / -mm, and therefore, the composite material box can be glued in an aerospace part as a force-bearing part and may meet later assembly requirements.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

Method for manufacturing insulated gate field effect transistor

ActiveUS8486789B2Function increaseSimplified molding stepsTransistorSolid-state devicesEngineeringConductive materials

Disclosed herein is a method for manufacturing an insulated gate field effect transistor, the method including the steps of: (a) preparing a base that includes source / drain regions, a channel forming region, a gate insulating film formed on the channel forming region, an insulating layer covering the source / drain regions, and a gate electrode formation opening provided in a partial portion of the insulating layer above the channel forming region; (b) forming a gate electrode by burying a conductive material layer in the gate electrode formation opening; (c) removing the insulating layer; and (d) depositing a first interlayer insulating layer and a second interlayer insulating layer sequentially across an entire surface, wherein in the step (d), the first interlayer insulating layer is deposited in a deposition atmosphere containing no oxygen atom.

Owner:SONY CORP

Solid-state image pickup device and a method of manufacturing the same

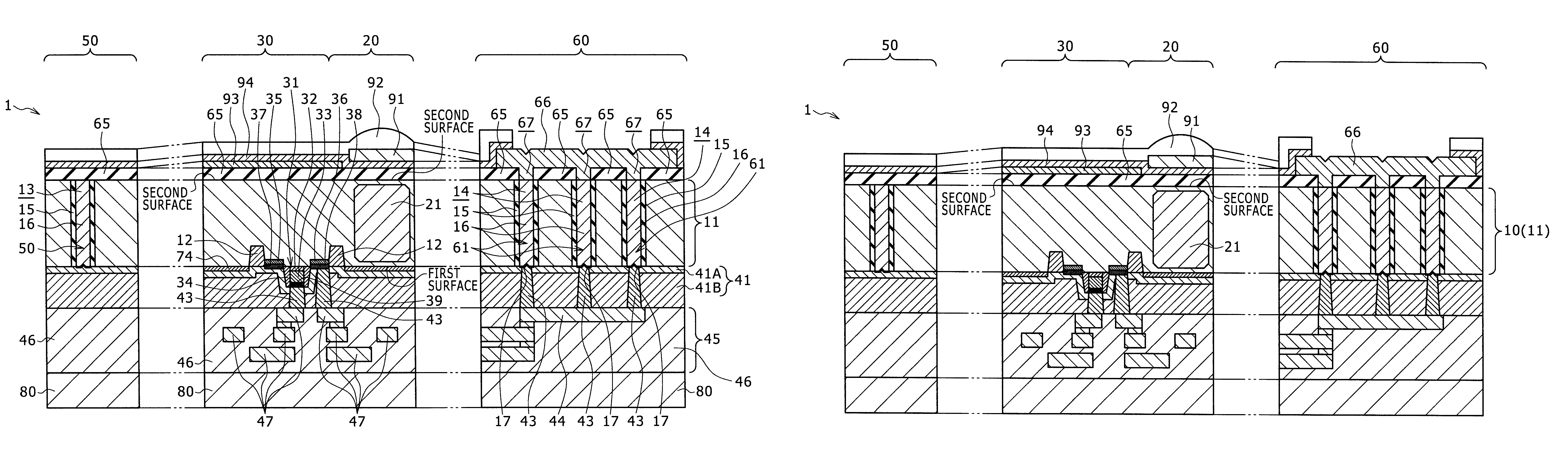

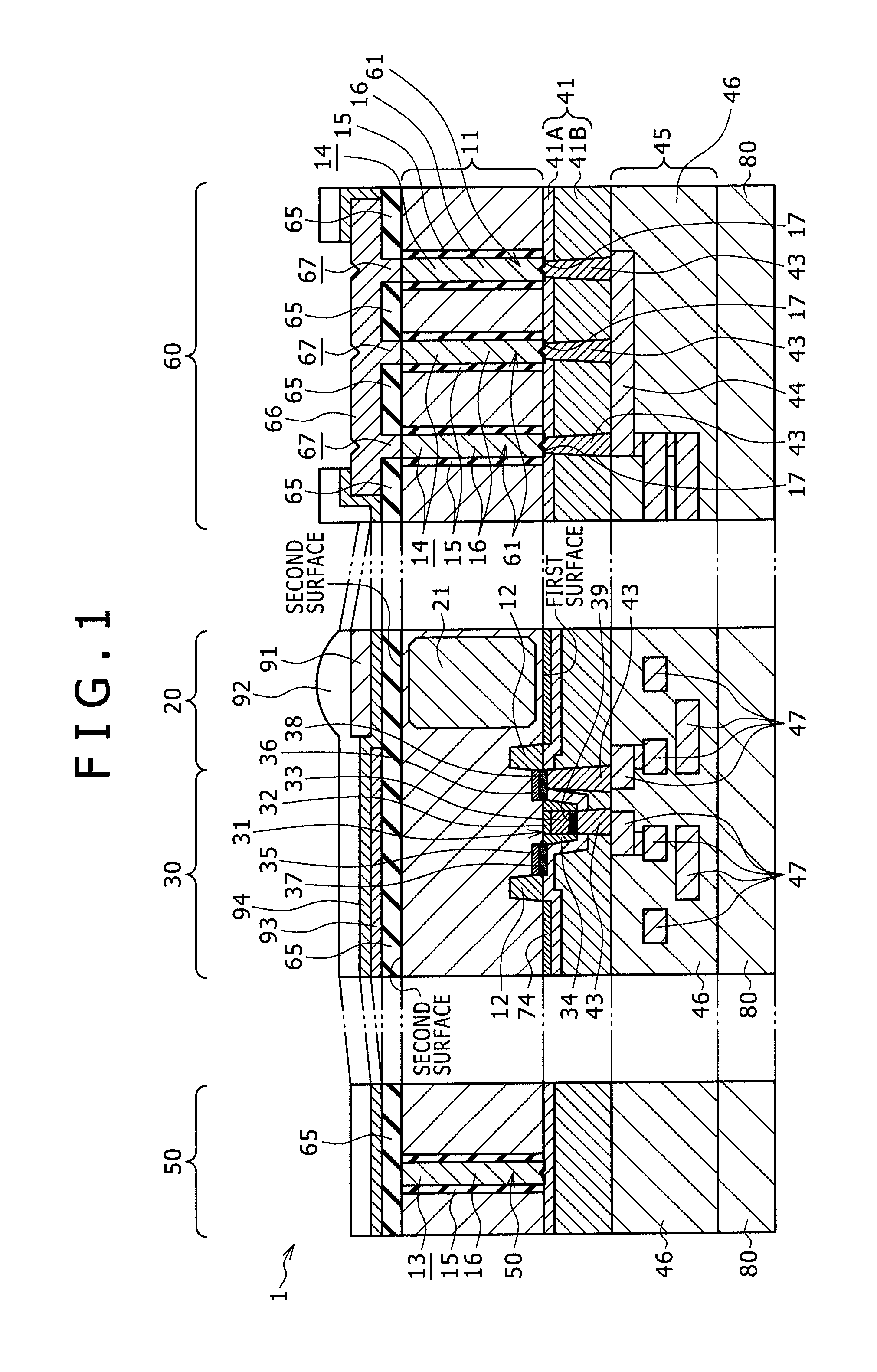

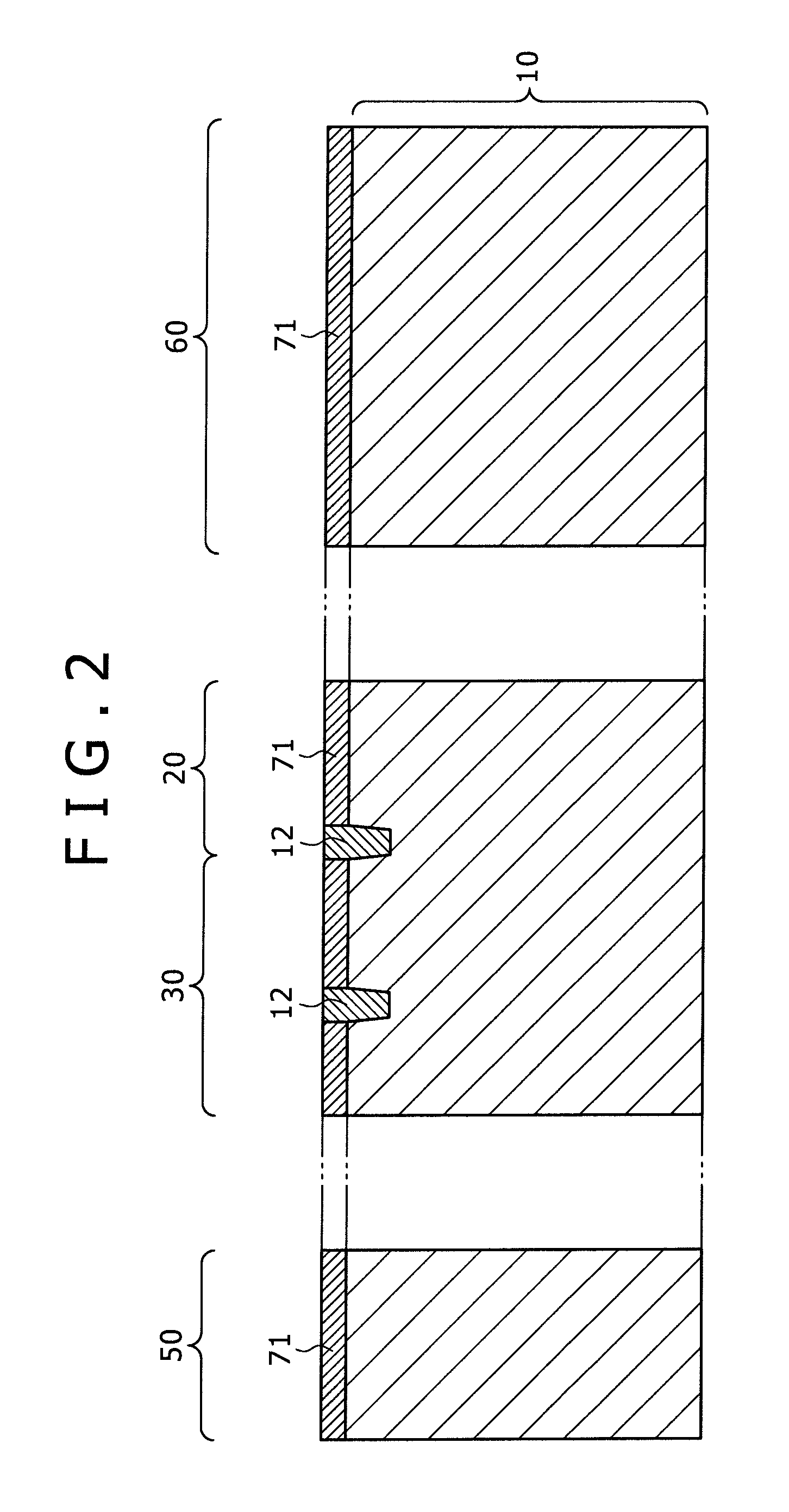

InactiveUS8247306B2Reduce areaSimple manufacturing processSemiconductor/solid-state device detailsSolid-state devicesPhotoelectric conversionConductive materials

A solid-state image pickup device includes: a silicon layer; a pixel portion formed in the silicon layer for processing and outputting signal charges obtained by carrying out photoelectric conversion for incident lights; an alignment mark formed in a periphery of the pixel portion and in the silicon layer; and a contact portion through which a first electrode within a wiring layer formed on a first surface of the silicon layer, and a second electrode formed on a second surface opposite to the first surface of the silicon layer through an insulating film are connected, wherein the alignment mark and the contact portion are formed from conductive layers made of the same conductive material and formed within respective holes each extending completely through the silicon layer through respective insulating layers made of the same material.

Owner:SONY SEMICON SOLUTIONS CORP

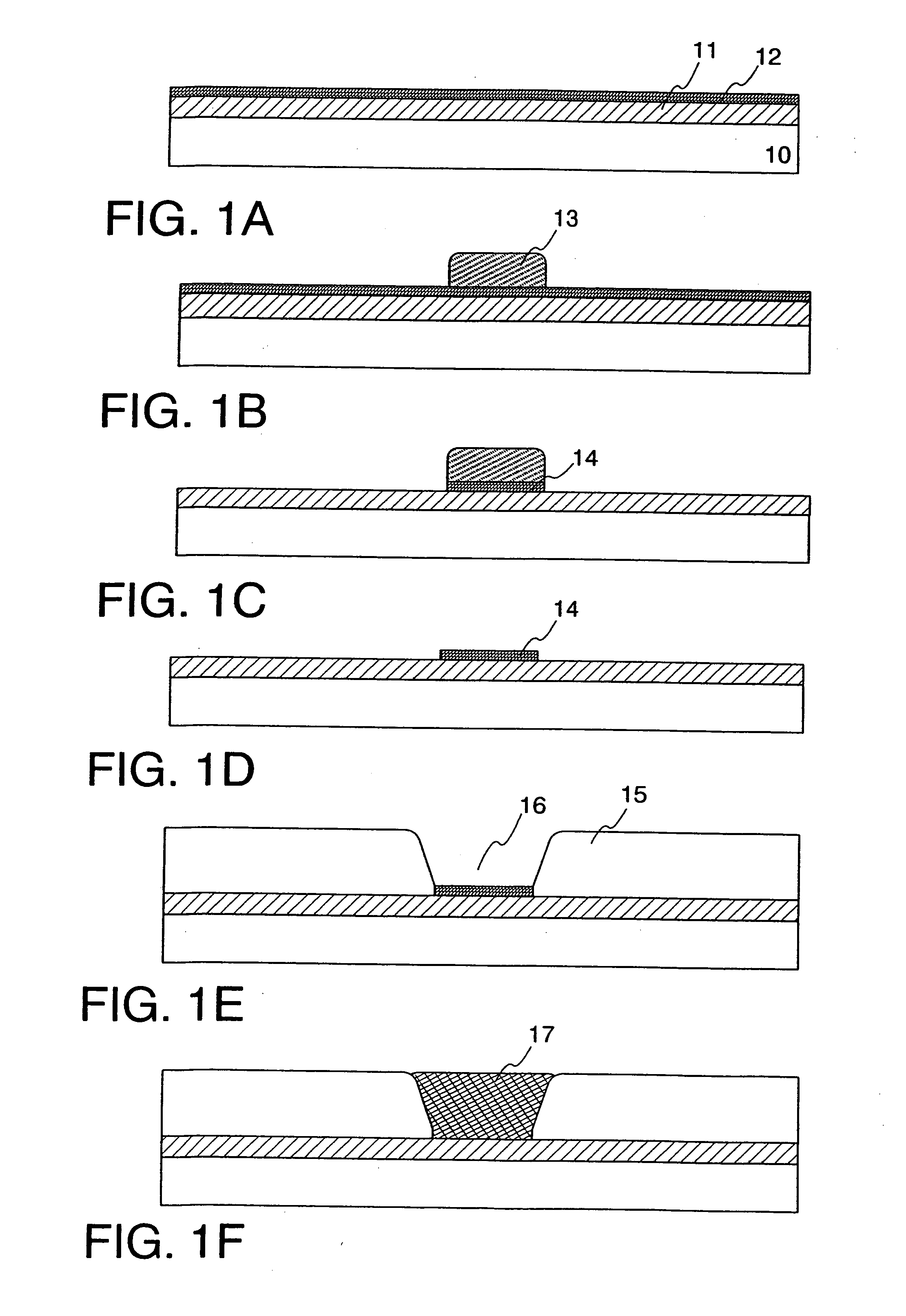

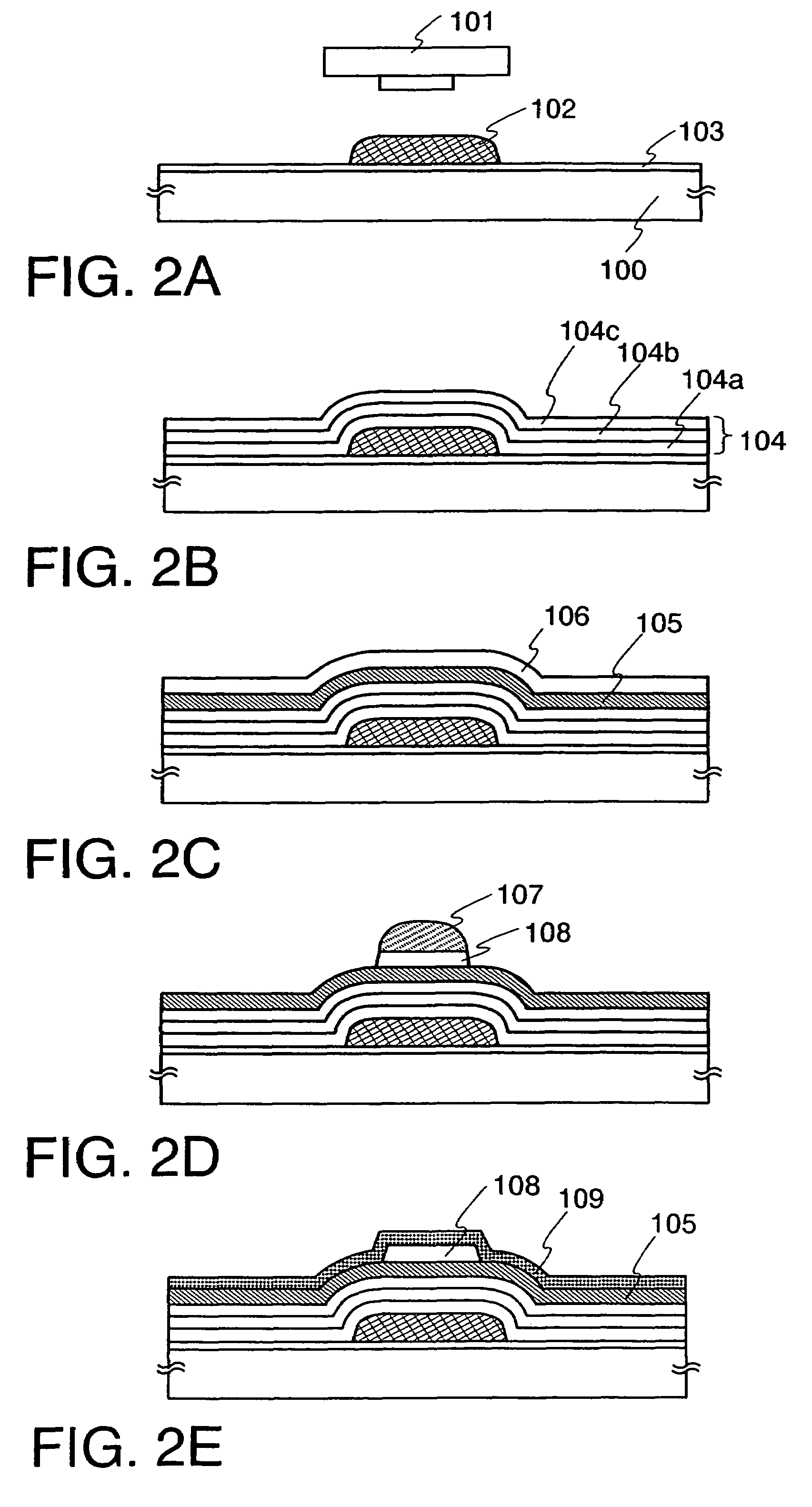

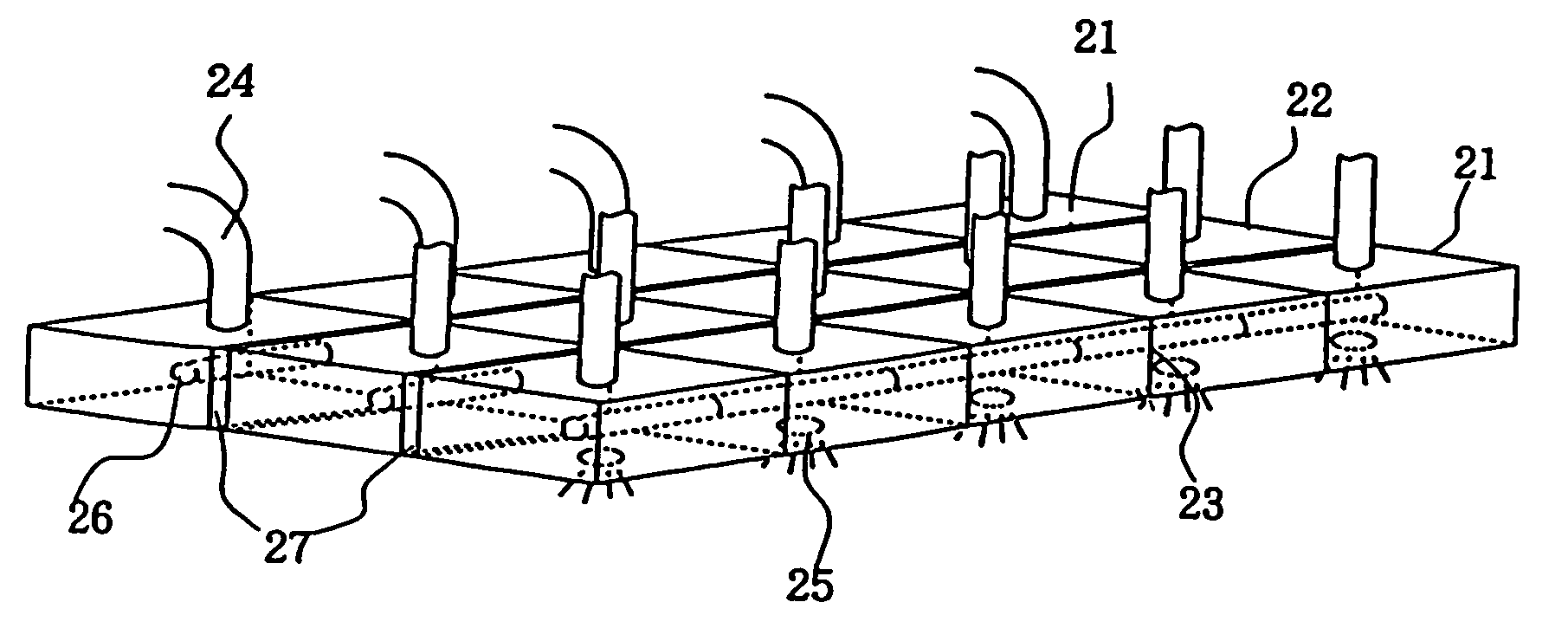

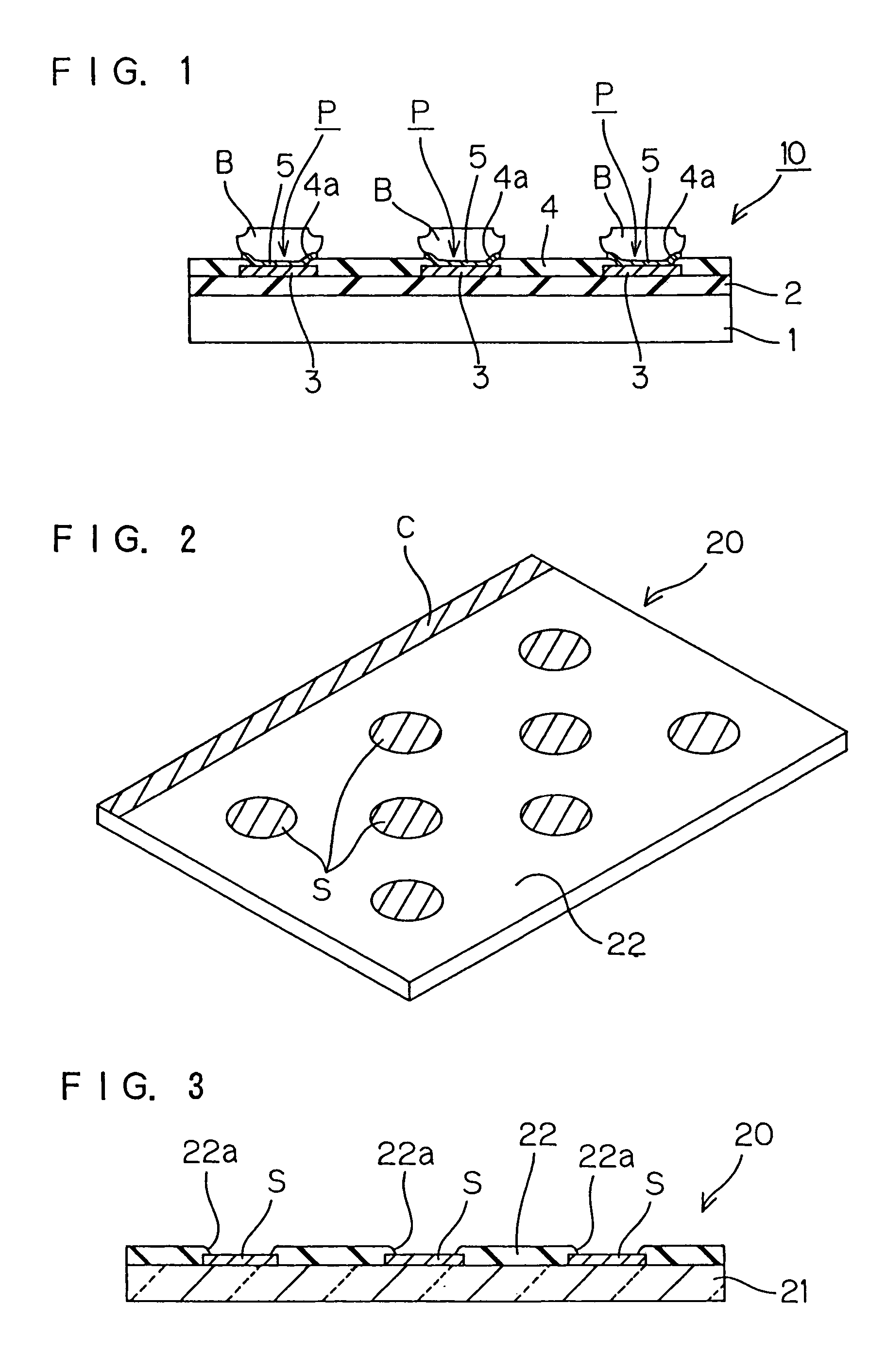

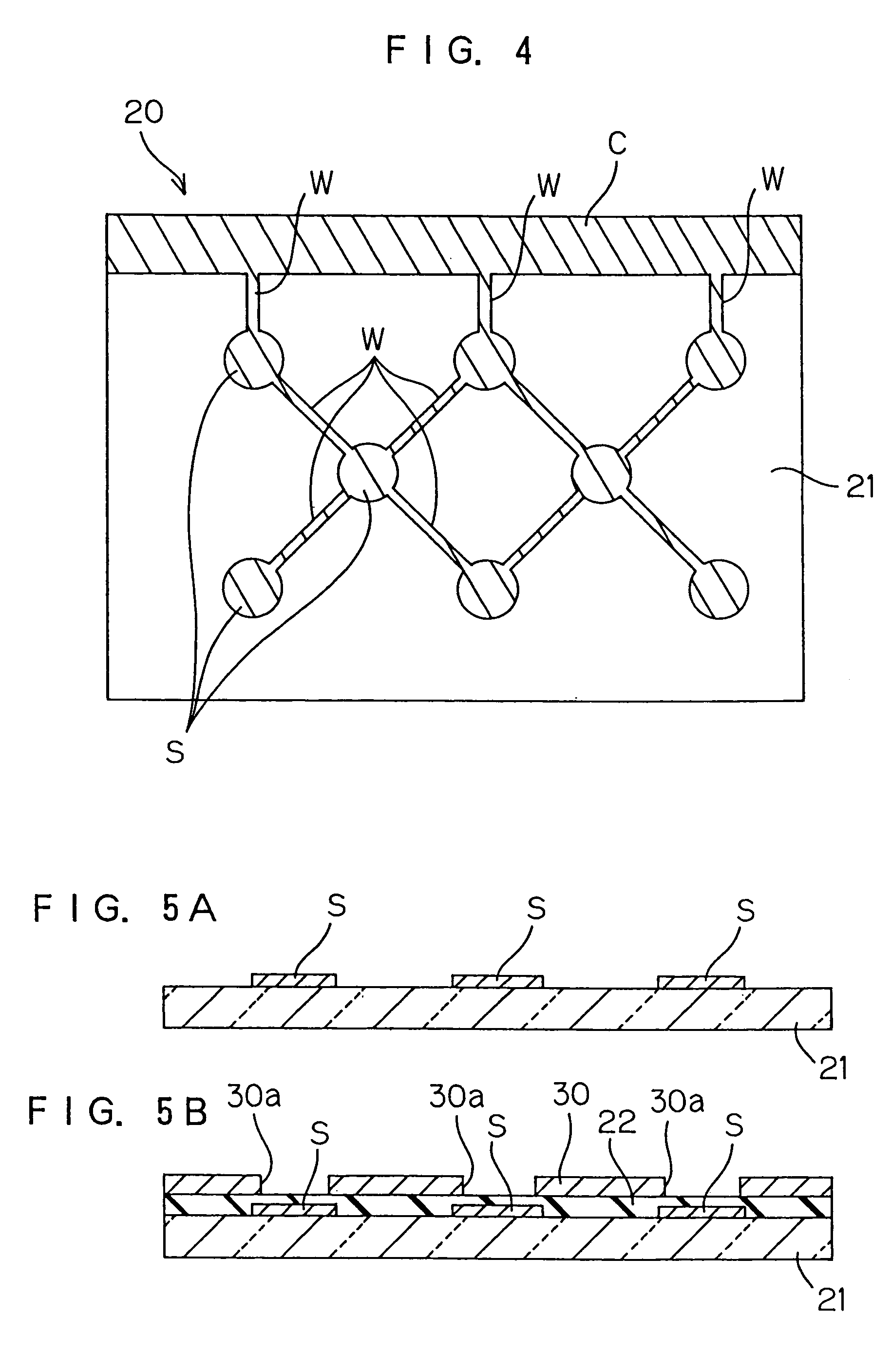

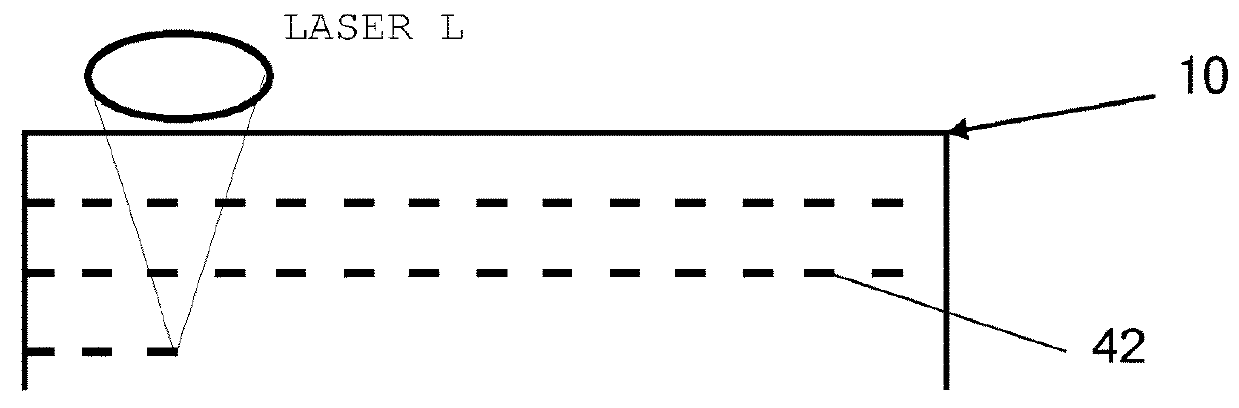

Method for manufacturing an oriented crystalline semiconductor using a pulsed laser

InactiveUS6972246B2Improve flatnessSimple stepsTransistorPolycrystalline material growthPlane orientationCrystalline semiconductor

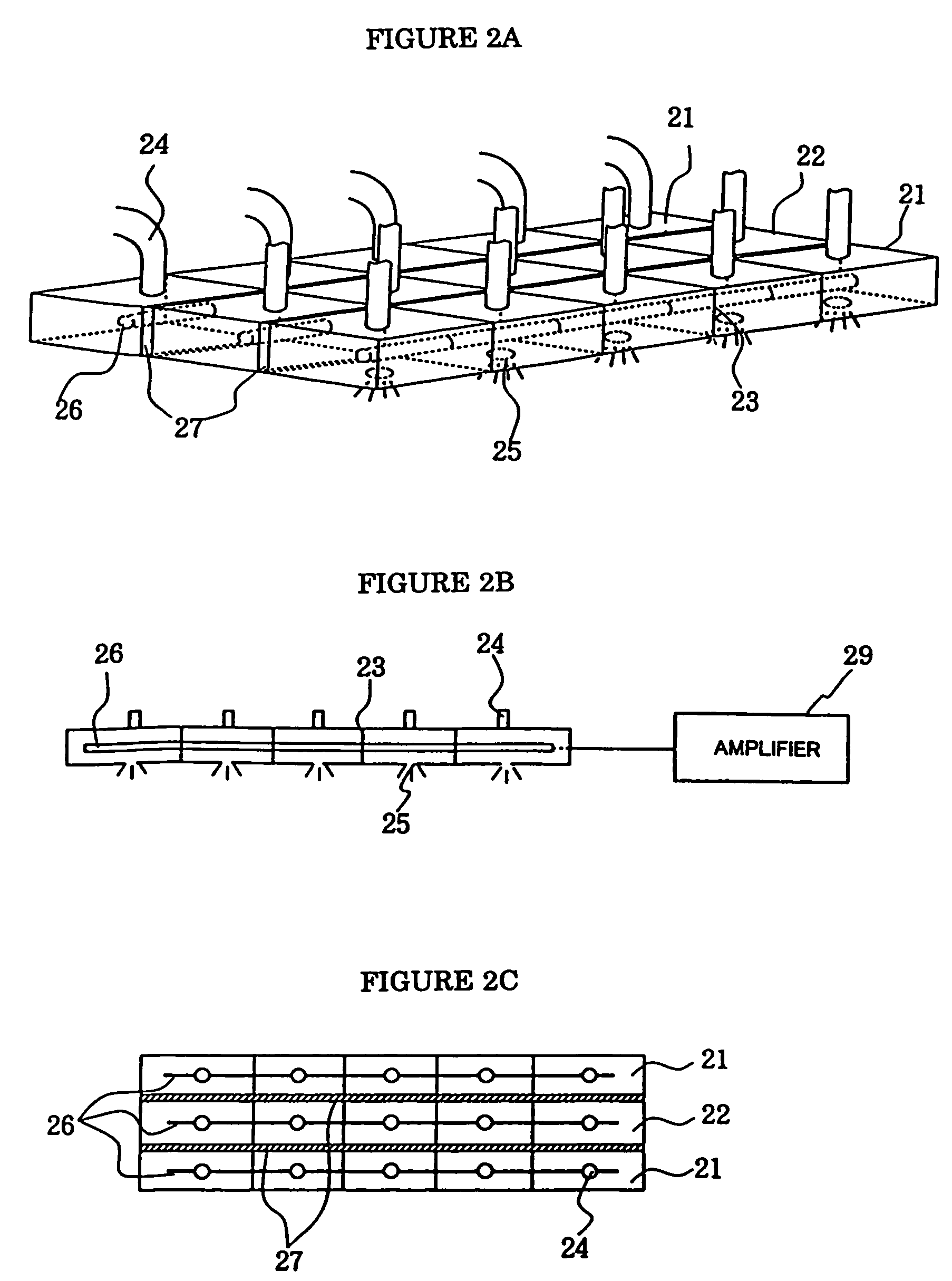

A manufacturing method for a crystalline semiconductor material including a plurality of semiconductor crystal grains is provided. The manufacturing method includes forming an amorphous or polycrystalline semiconductor layer on a substrate having a flat surface; forming a plurality of projections each having a side wall surface substantially perpendicular to the flat surface of the substrate, a height set in the range of about 1 nm to less than or equal to about ¼ of the thickness of the semiconductor layer, and a lateral dimension set in the range of about 3 μm to about 18 μm in a direction parallel to the flat surface of the substrate; and heating the semiconductor layer a number of times by using a pulsed laser thereby forming the crystalline semiconductor material including the crystal grains each having a specific plane orientation with respect to a direction perpendicular to the flat surface of the substrate so that the crystal grains respectively correspond to the projections. Accordingly, the position, size, and plane orientation of a crystal can be controlled by a simple step, and a crystalline semiconductor material excellent in planarity as a film can be formed.

Owner:SONY CORP

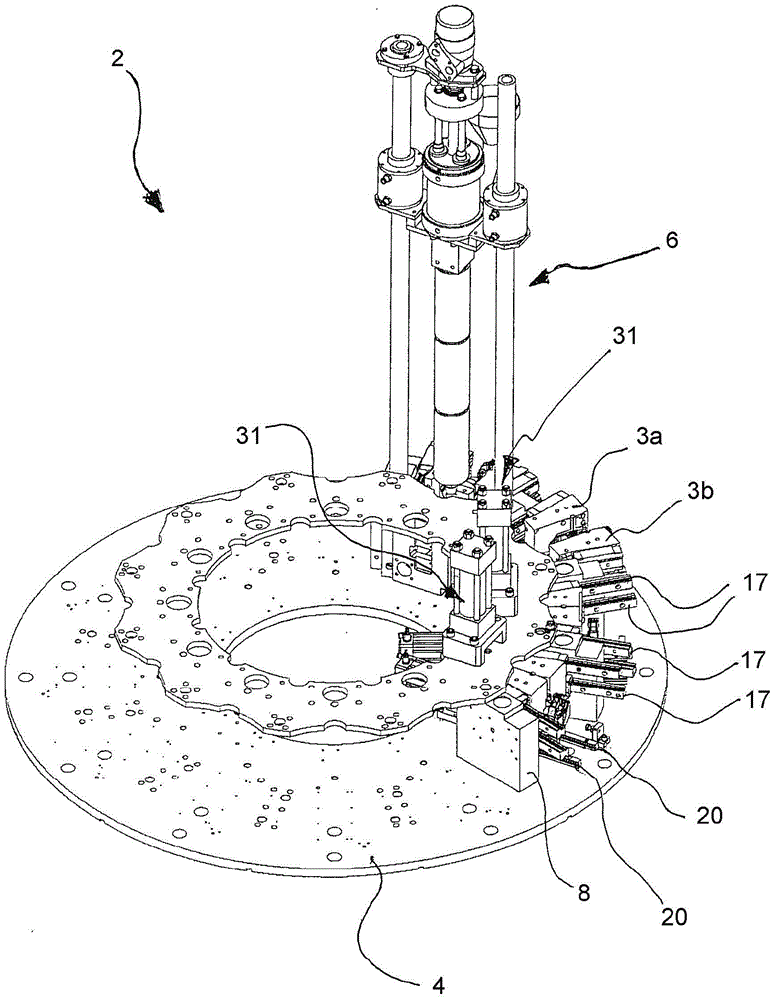

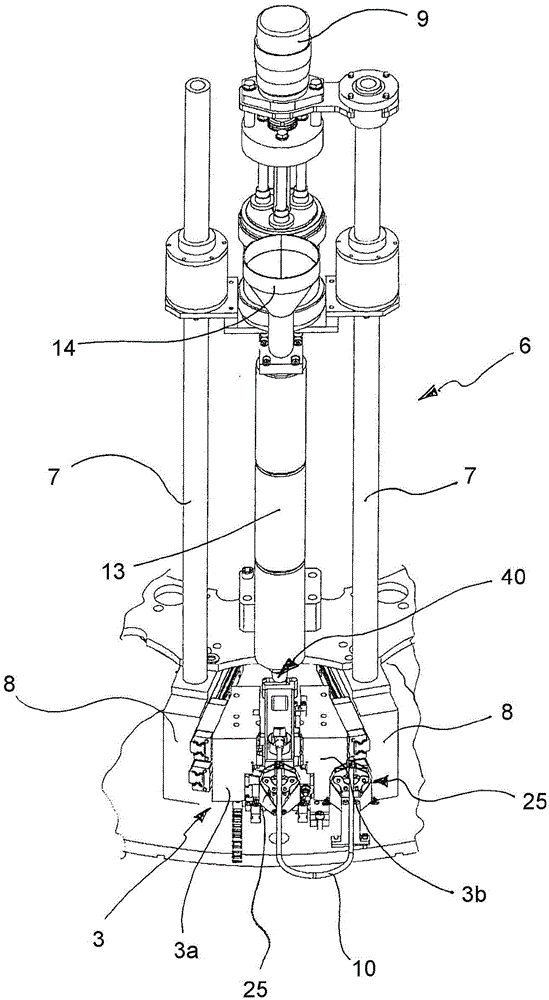

Injection molding machine

InactiveCN105538590ASimplified molding stepsAchieve high adaptabilityLine/current collector detailsEngineeringInjection molding machine

The invention relates to an injection molding machine. The injection molding machine comprises multiple molds (3) and injection molders (6) for all the molds; and the molds and the corresponding injection molders are mounted on a platform (4), and rotate with the platform.

Owner:CURTI COSTR MECCANICHE

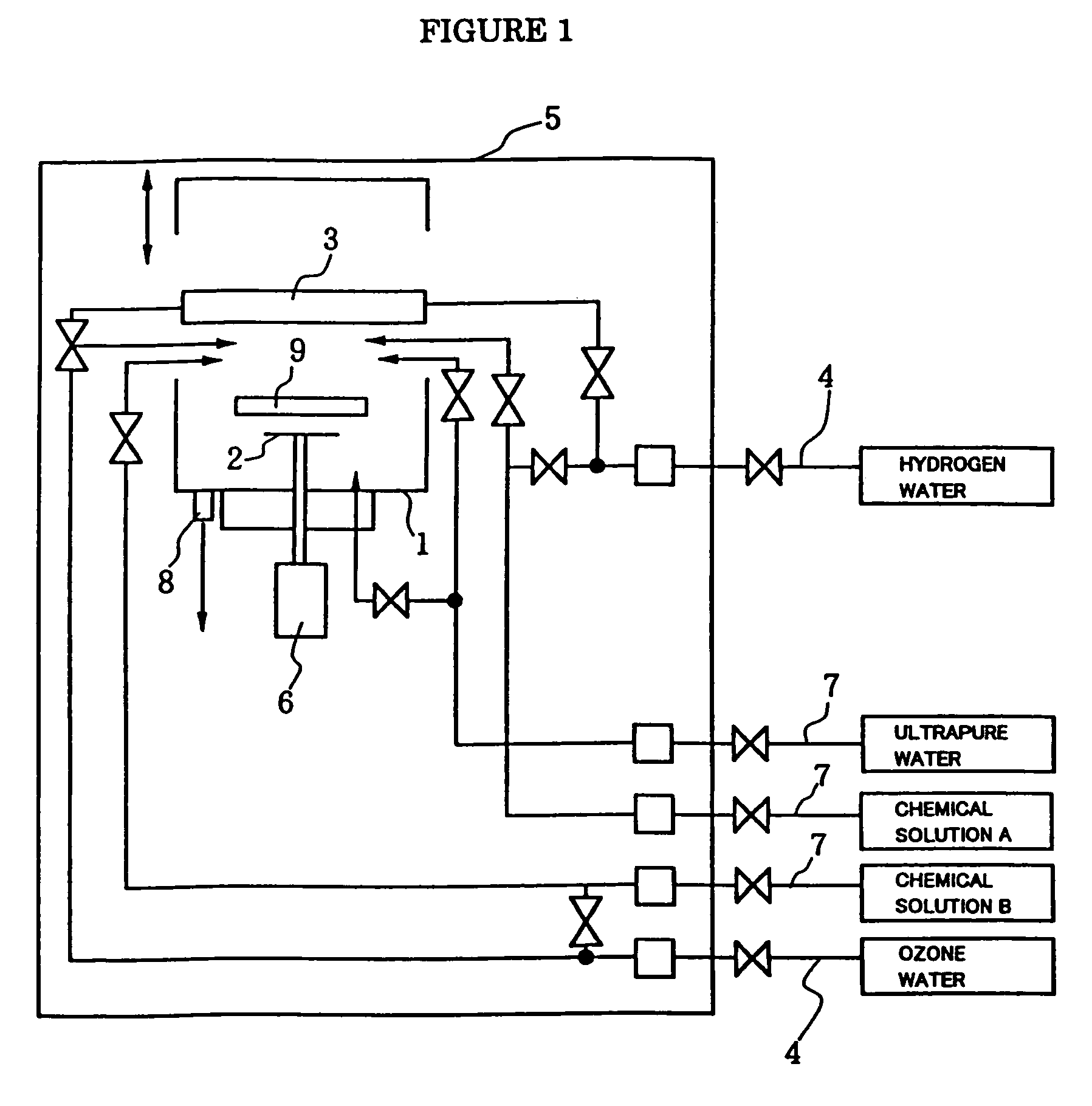

Substrate treatment process and apparatus

InactiveUS6983756B2Similar effectLoad largeLighting and heating apparatusElectrostatic cleaningEngineeringNozzle

A substrate treatment apparatus comprises a treatment vessel, a substrate holder for rotating the substrate in a horizontal plane in the treatment vessel, a nozzle unit arranged in an upper part of the treatment vessel such that a liquid is downwardly fed, a feed line for feeding the liquid to the nozzle unit, and a chamber enclosing therein the apparatus in its entirety. The nozzle unit is constructed in a form of a bar such that as viewed in plan, the liquid ejected from the nozzle unit reaches the substrate with an area range having a length not smaller than a diameter of the substrate and a width smaller than the diameter of the substrate.

Owner:M FSI

Production process for semiconductor device

InactiveUS7009294B2Low costSimplified molding stepsSemiconductor/solid-state device detailsSolid-state devicesMetal electrodesSemiconductor

A production process for a semiconductor device having a metal electrode on a semiconductor substrate thereof. A metal electrode portion is formed on a surface of another substrate for electrode transfer. Then, the metal electrode portion is transferred from the electrode transfer substrate onto the semiconductor substrate by pressing together the electrode transfer substrate and the semiconductor substrate. The electrode transfer substrate has, for example, a seed film provided on the surface thereof, and the formation of the metal electrode portion on the electrode transfer substrate may be achieved by depositing a material for the metal electrode on the seed film by plating. The electrode transfer substrate may have an insulating film which covers a surface of the seed film except a portion thereof on which the metal electrode portion is to be formed.

Owner:ROHM CO LTD

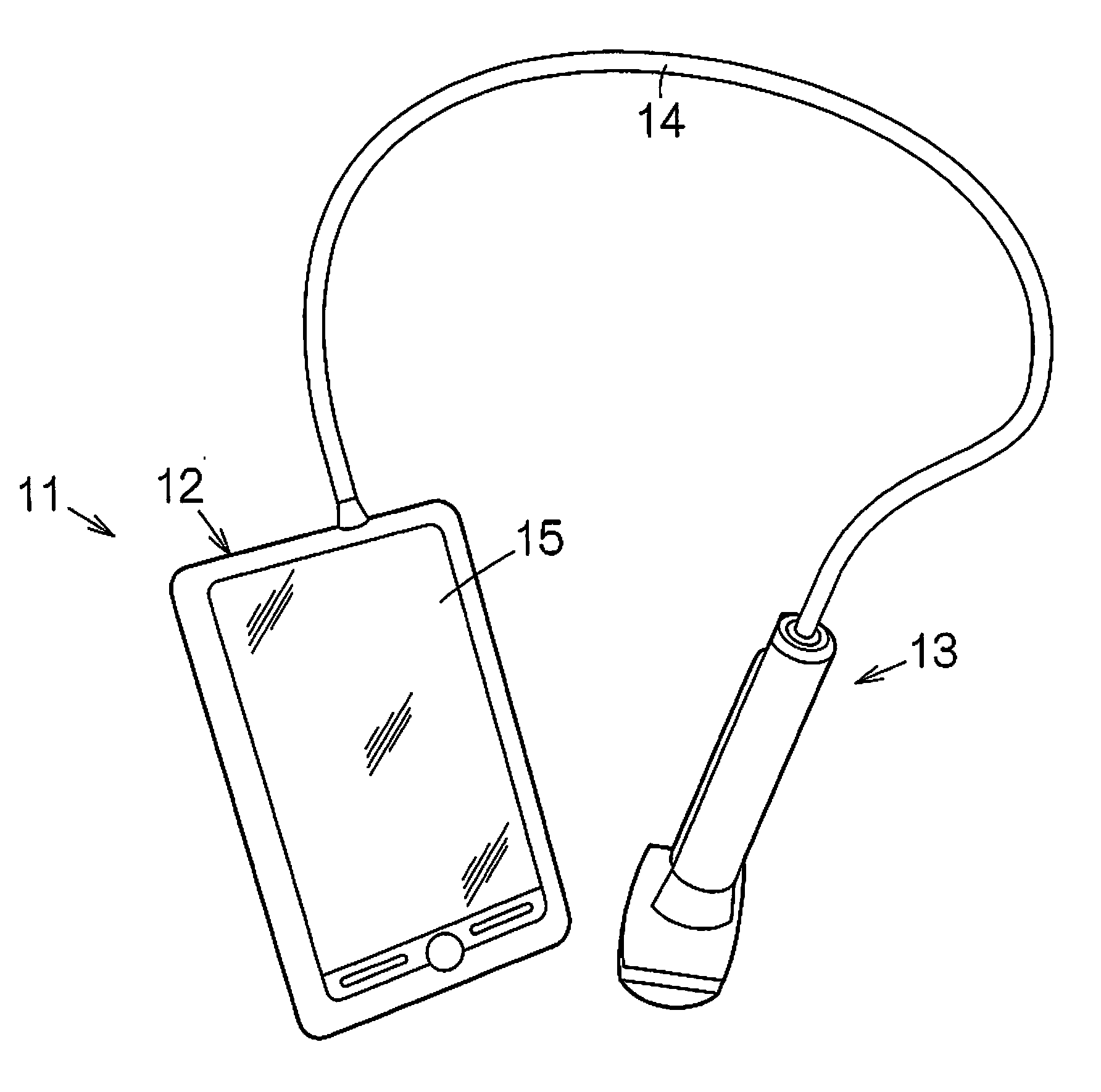

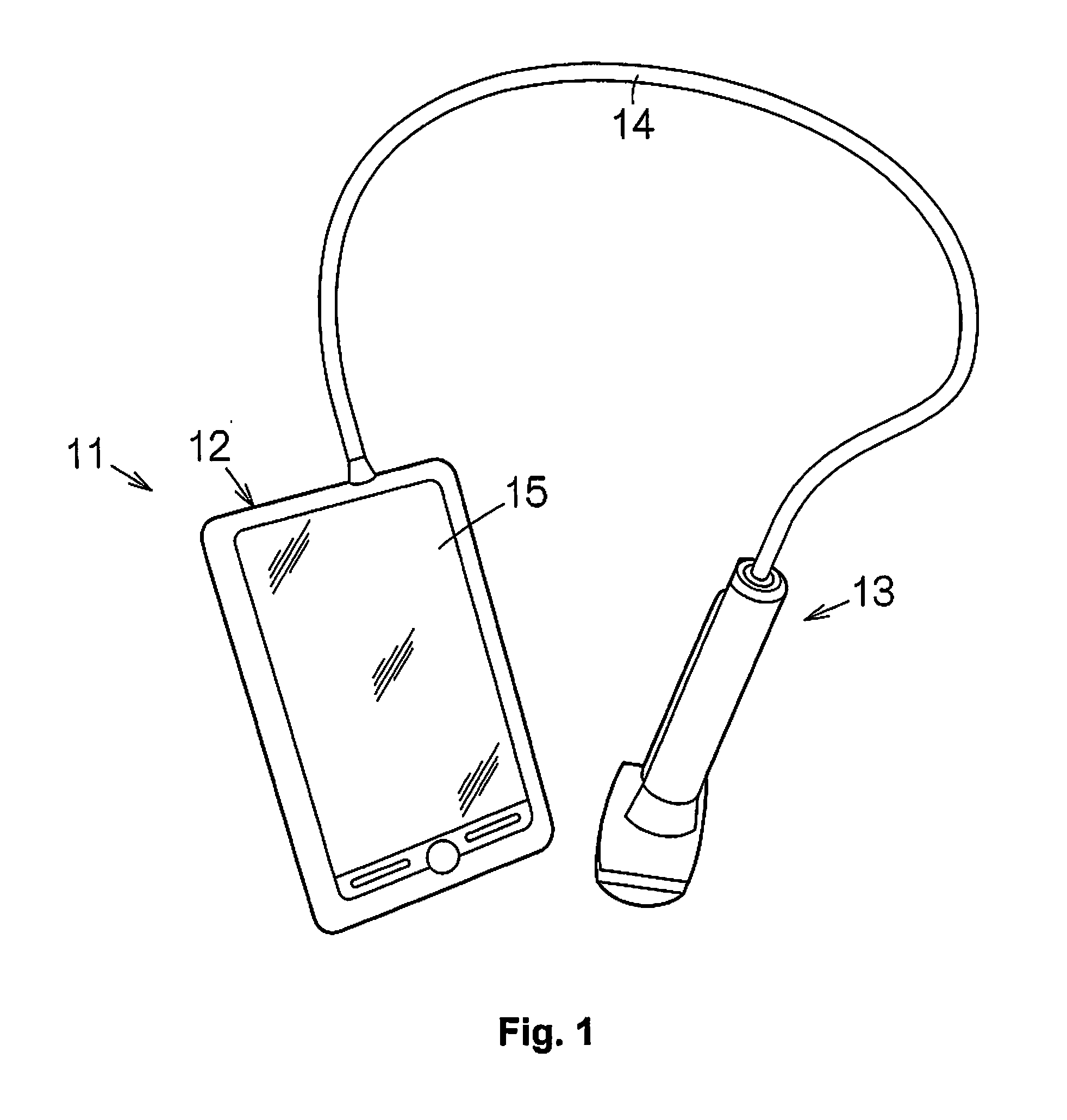

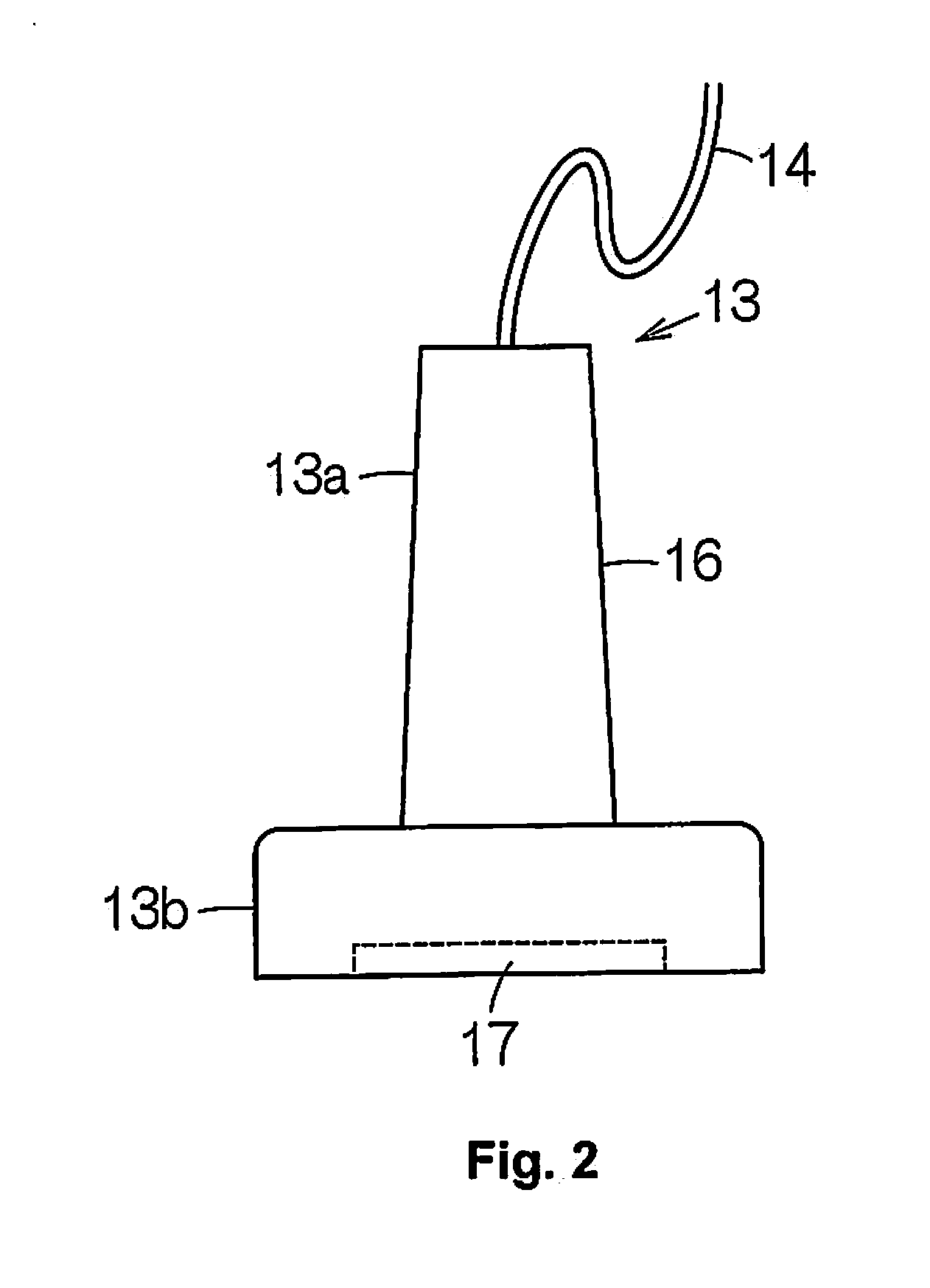

Ultrasonic device, probe, electronic device, and ultrasound imaging apparatus

InactiveUS20150216504A1Avoid deformationSimplified molding stepsMedical devicesMechanical vibrations separationUltrasound imagingSonification

An ultrasonic device includes a substrate, an acoustic matching layer, an acoustic lens, and a structure. The substrate has an element array including a plurality of thin-film ultrasonic transducer elements arranged in an array form. The acoustic matching layer covers the element array. The acoustic lens is arranged on the acoustic matching layer. The structure is arranged between the acoustic lens and the substrate and has a larger compressive strength than a compressive strength of the acoustic matching layer.

Owner:SEIKO EPSON CORP

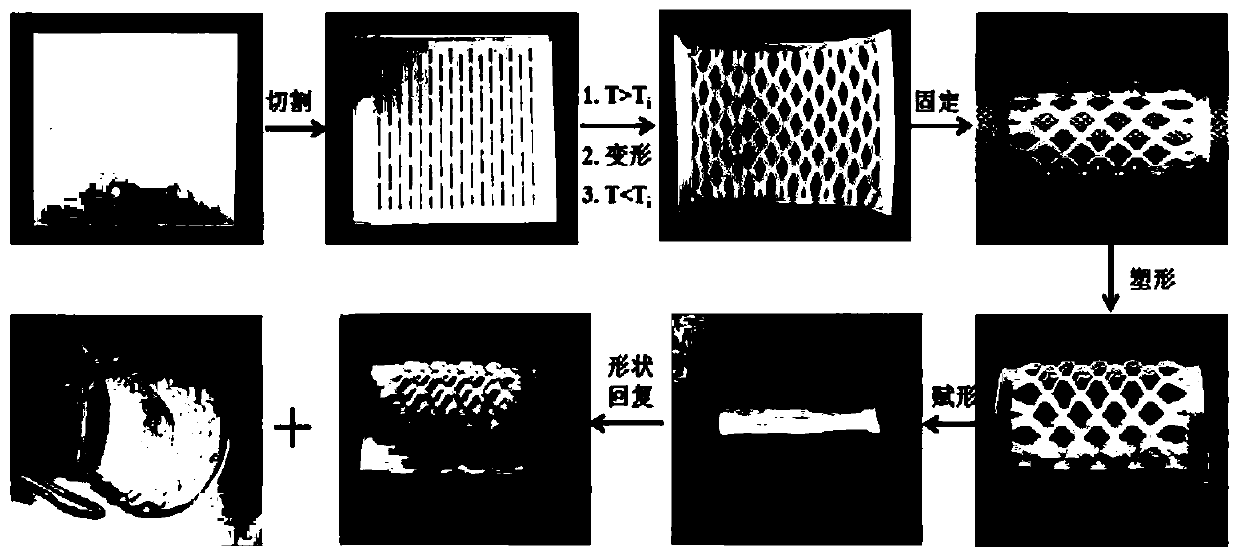

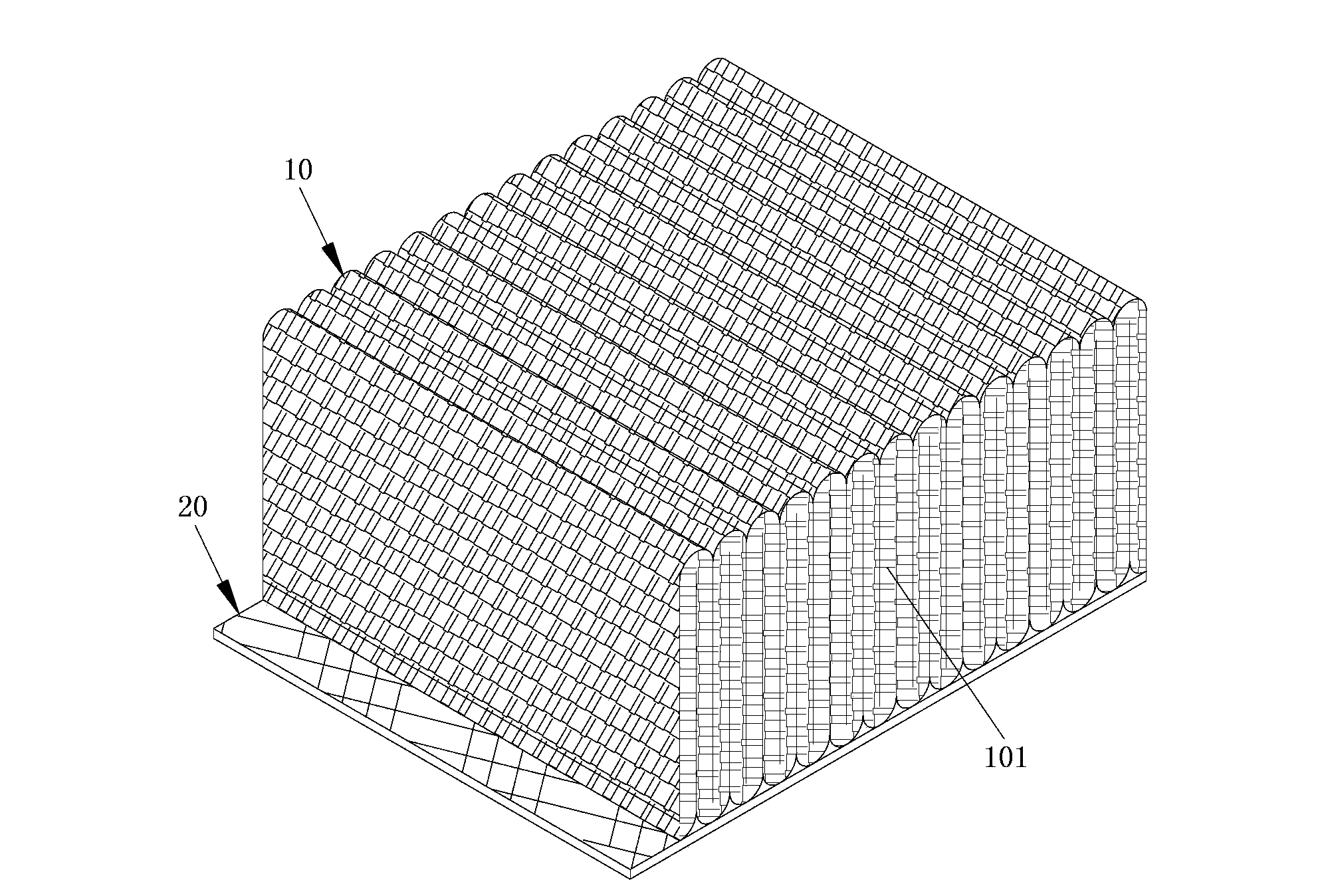

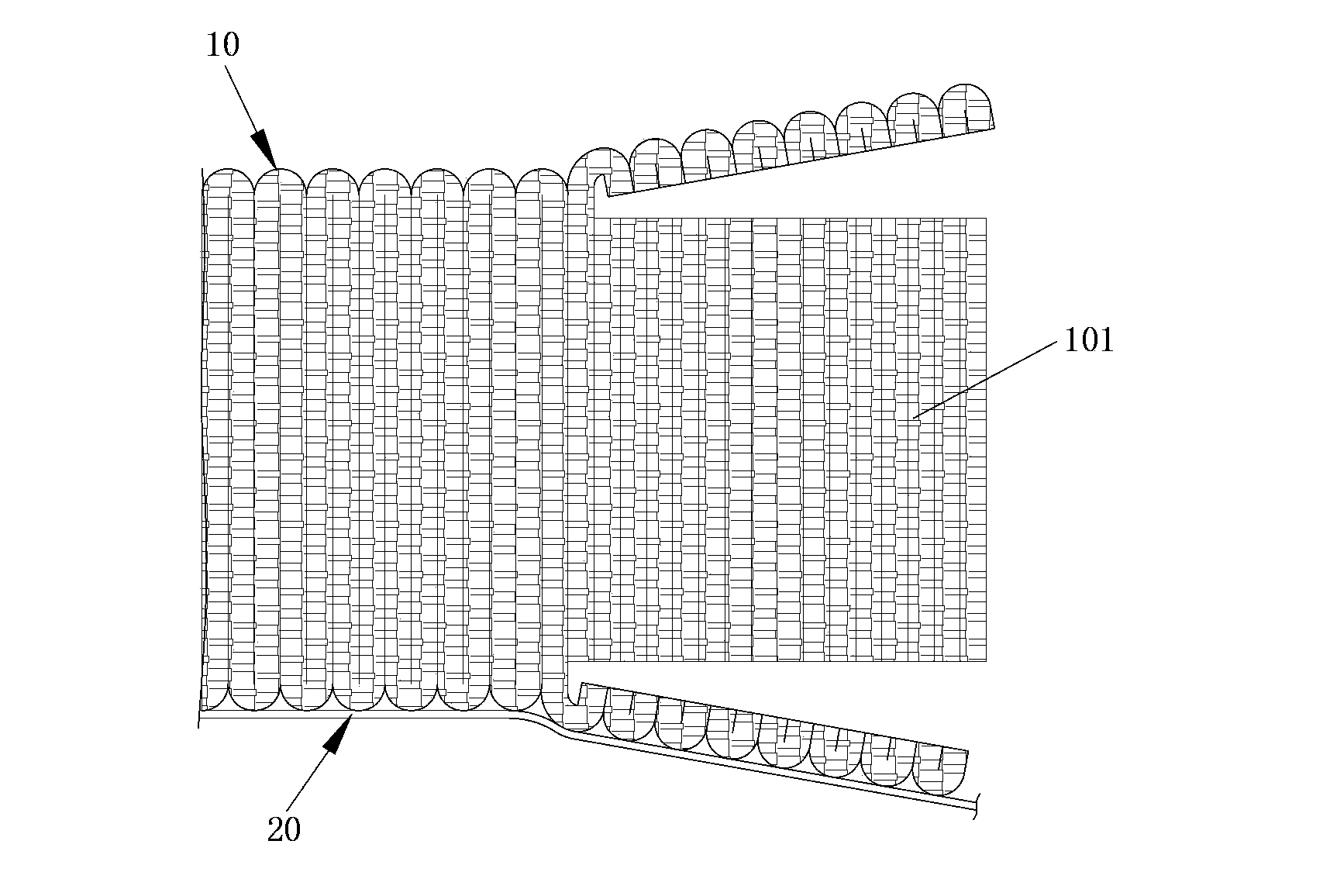

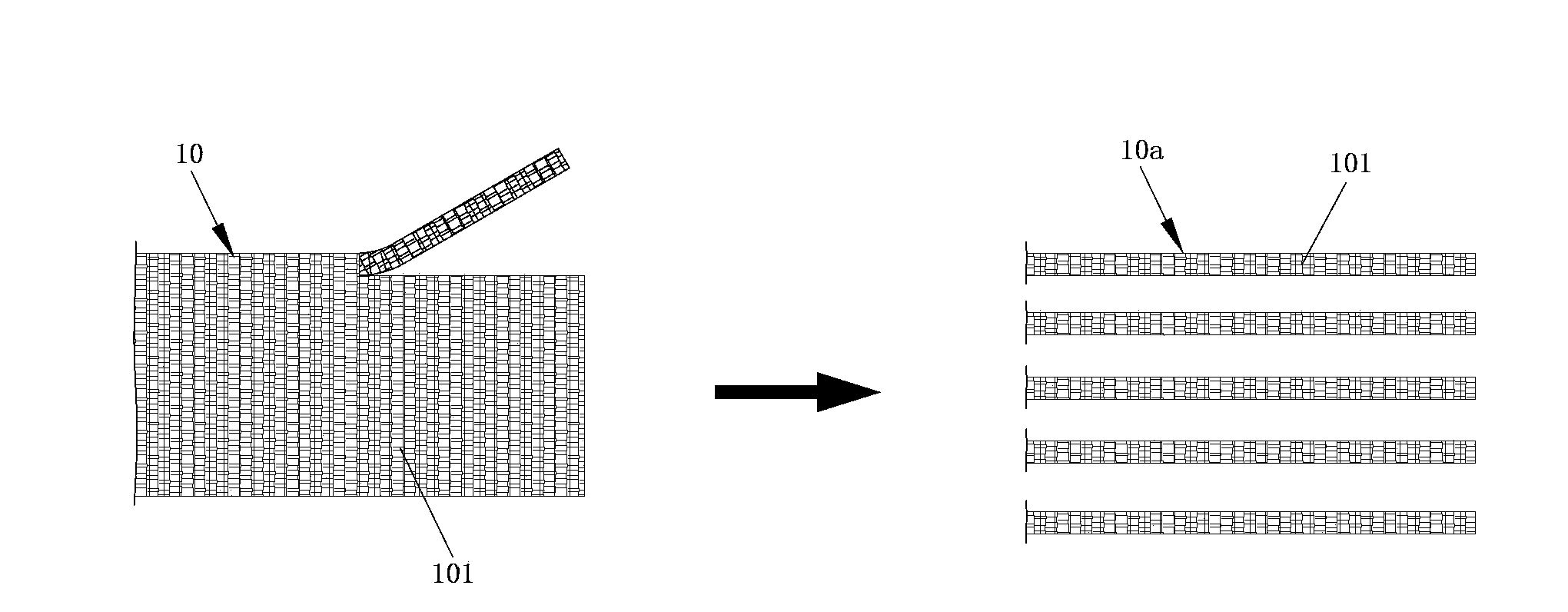

4D deformed reticulated hollowed degradable vascular stent with concave-convex structures on inner and outer surfaces, preparation method and application method thereof

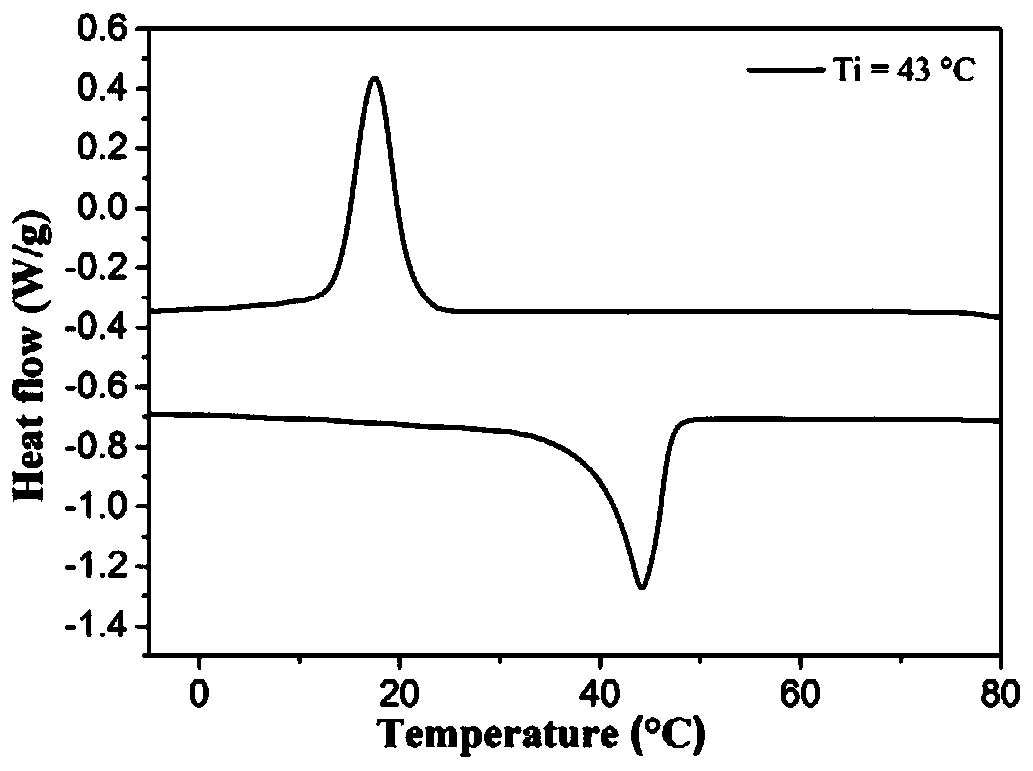

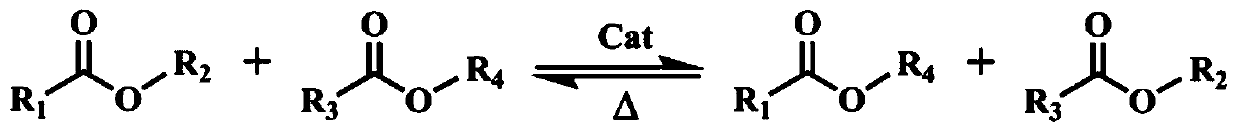

PendingCN111590914AReduce sizeExcellent adhesionStentsDomestic articlesPolymer scienceThermosetting polymer

The invention discloses a 4D deformed reticulated hollowed degradable vascular stent with concave-convex structures on the inner and outer surfaces, a preparation method and a use method thereof. A thermoplastic polymer containing a dynamic covalent bond, a thermosetting polymer containing a functional group capable of further crosslinking or a thermosetting polymer is used as a raw material, theraw material is cut or clipped to form a desired hollowed structure, the material is heated to more than or equal to the transition temperature and then stretched to obtain a reticulated hollowed pattern with concave-convex structures on the inner and outer surfaces, the raw material is rolled into a tubular shape and fixed, then bond exchange of the dynamic covalent bond is activated or the functional group is initiated for crosslinking, molding is finished, and a shape-permanent vascular stent product is obtained. The brand-new method for producing in-vivo stents provided by the invention has the characteristics of simple operation, high molding speed, simple process steps, no need of professional equipment and the like, and the integrated design of once molding of the complex stent shape, rapid manufacturing and 4D self-deformation function is realized.

Owner:LINYI UNIVERSITY

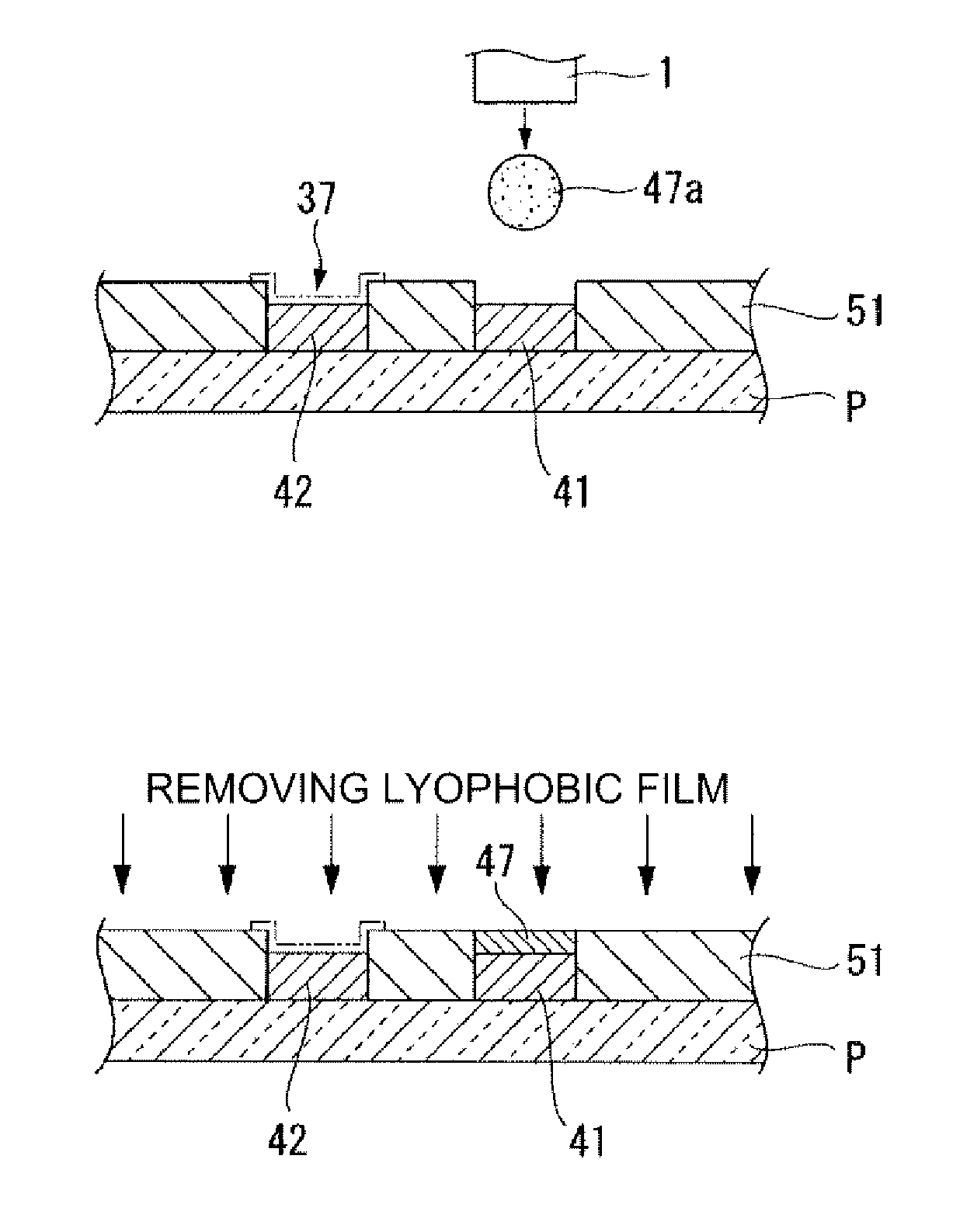

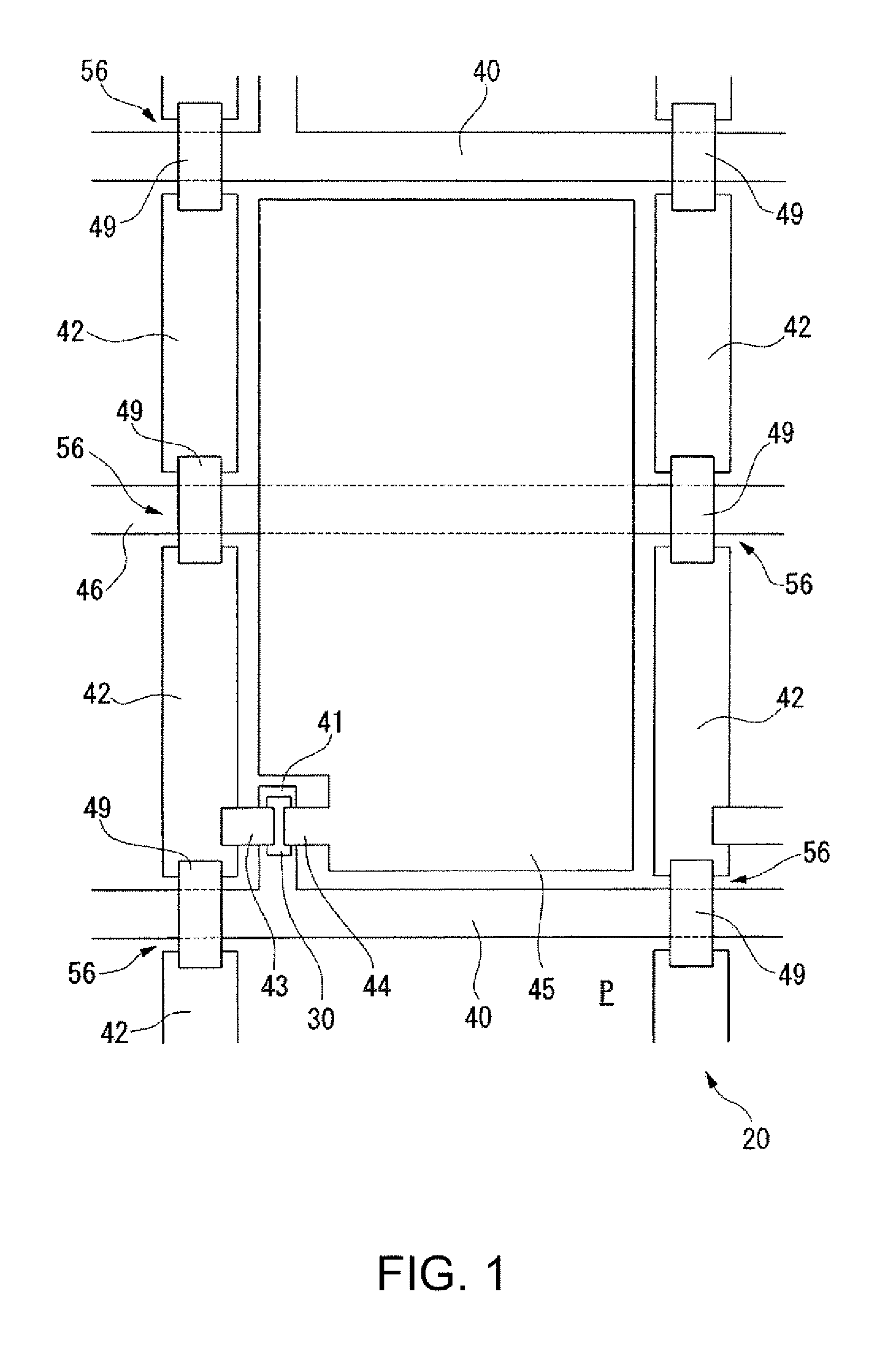

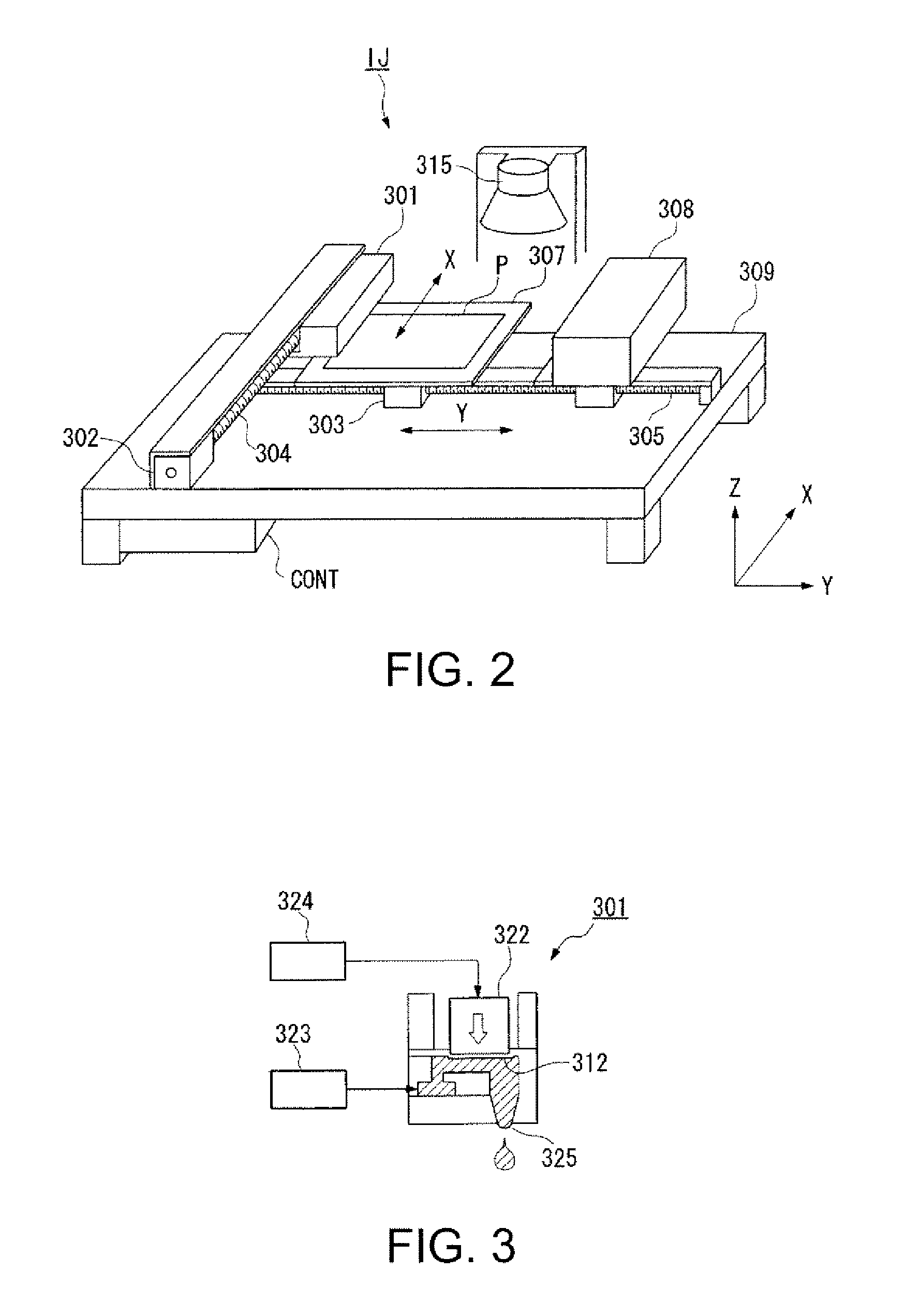

Method of forming film pattern, active matrix substrate, electro-optic device, and electronic apparatus

InactiveUS7371698B2Improve productivitySimplified molding stepsTransistorElectroluminescent light sourcesActive matrixElectron

A method of forming a film pattern includes the steps of forming a bank for partitioning a pattern forming area including a first pattern forming area and a second pattern forming area having an intersection with the first pattern forming area and divided in the intersection into sub-areas, disposing a functional liquid to the first pattern forming area to form a first film pattern, and disposing a functional liquid to the sub-areas to form second film patterns, executing a lyophobic process on the entire surface of a substrate including the first film pattern, the second film patterns, and the bank, weakening the lyophobicity on the substrate while selectively maintaining the lyophobicity on predetermined positions of the respective second film patterns formed in a divided condition after executing the lyophobic process, stacking a cap layer on the first film pattern and the second film patterns after weakening the lyophobicity, removing the lyophobicity in the predetermined positions of the respective second film patterns formed in the divided condition after stacking the cap layer, and forming a conductive film between the predetermined position of one of the second film patterns and the predetermined position of another of the second film patterns to electrically connect the second film patterns formed in the divided condition.

Owner:SEIKO EPSON CORP

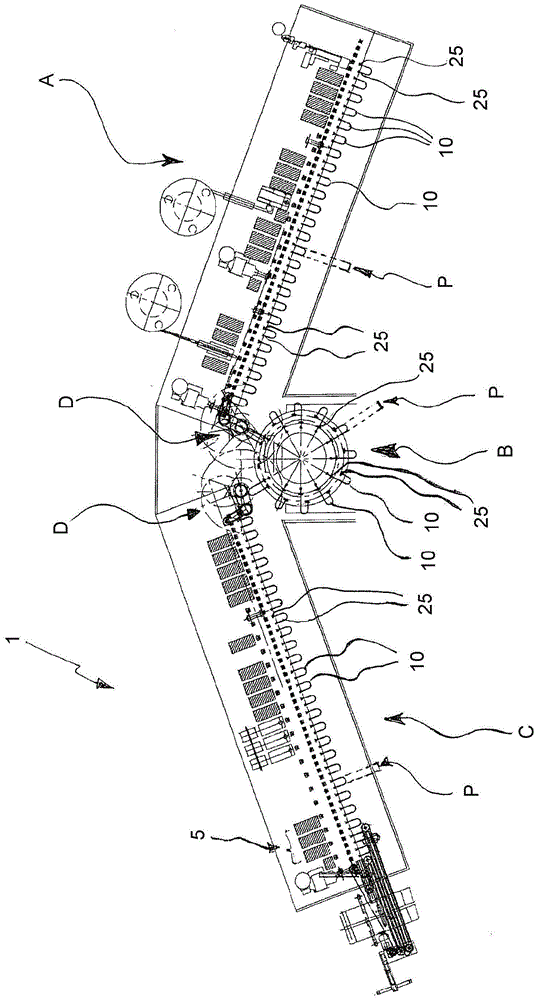

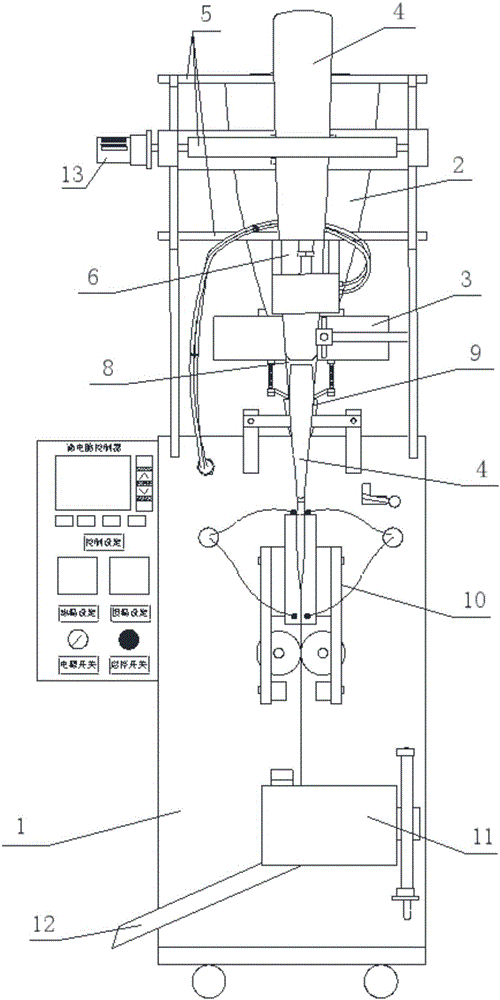

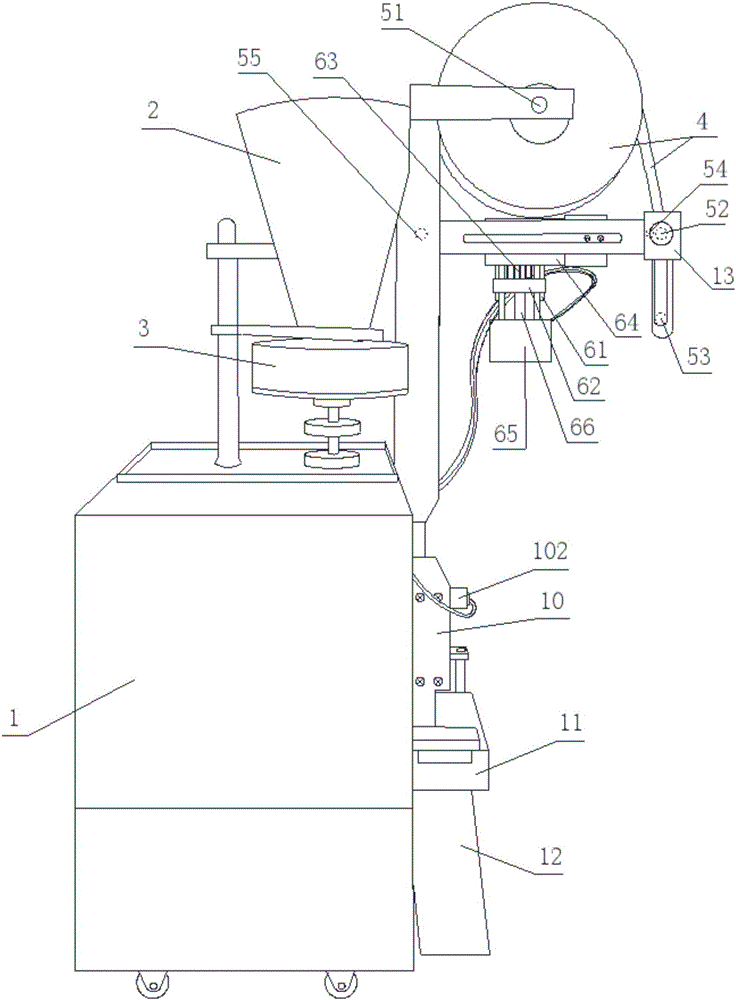

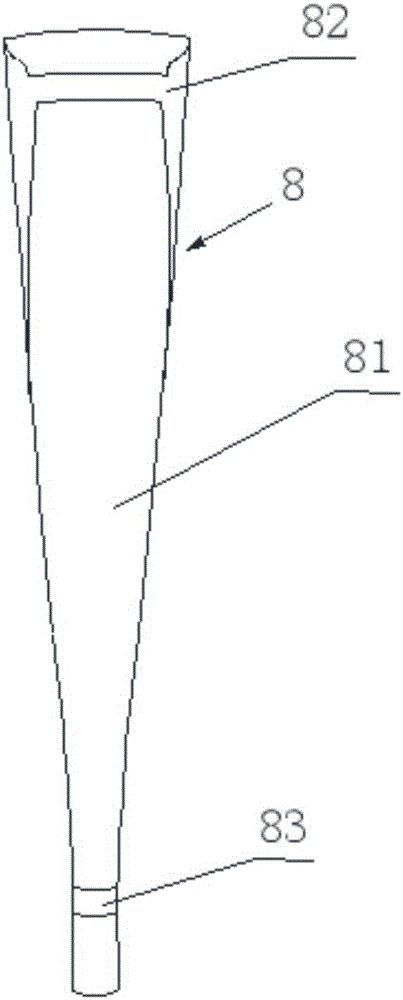

Automatic living-body subpackage-bag-type trichogramma releasing device and preparation method thereof

The invention discloses an automatic living-body subpackage-bag-type trichogramma releasing device and a preparation method thereof. The automatic living-body subpackage-bag-type trichogramma releasing device comprises a machine body. The machine body comprises a bracket mechanism and a cabinet mechanism. One side of the bracket mechanism is provided with a plurality of transmission shafts. The transmission shafts are wound by packaging paper. The packaging paper is locked in a forming machine through a hole puncher by the transmission shafts. The hole puncher is communicated with an external air pump. The other side of the bracket mechanism is provided with a discharging device, and the discharging device is communicated with a disc screening machine. The disc screening machine is communicated with a funnel device, and a joining port of the funnel device is extended to the side face of the forming machine and a packaging bag of which the bottom is sealed. The forming machine is stretched into a heat sealing machine. The lower end of the heat sealing machine is provided with an automatic cutting machine. The automatic cutting machine is connected with a chute. The heat sealing machine, the transmission shafts, the hole puncher and the disc screening machine are controlled by a circuit and program control device. According to the provided automatic living-body subpackage-bag-type trichogramma releasing device and the preparation method thereof, the operation is convenient, and the industrial large-scale efficient production is easy.

Owner:HUNAN ACAD OF FORESTRY +2

Semiconductor device and a method of manufacturing the same

ActiveUS20080211108A1High yieldSimplified molding stepsSemiconductor/solid-state device detailsSolid-state devicesResistPhotoresist

For simplifying the dual-damascene formation steps of a multilevel Cu interconnect, a formation step of an antireflective film below a photoresist film is omitted. Described specifically, an interlayer insulating film is dry etched with a photoresist film formed thereover as a mask, and interconnect trenches are formed by terminating etching at the surface of a stopper film formed in the interlayer insulating film. The stopper film is made of an SiCN film having a low optical reflectance, thereby causing it to serve as an antireflective film when the photoresist film is exposed.

Owner:RENESAS ELECTRONICS CORP

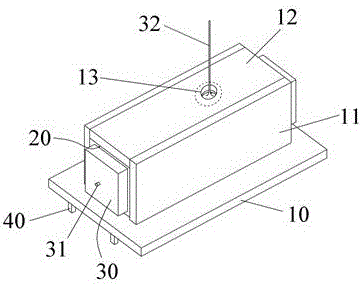

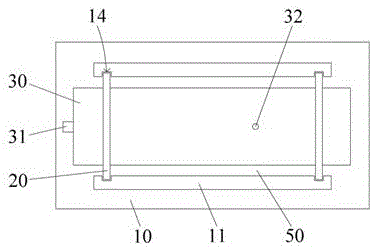

Flue forming device and flue forming method using same

The invention relates to a flue forming device and a flue forming method using the same, and belongs to the field of building devices. The flue forming device comprises an outer formwork and an inner formwork. The outer formwork comprises a bottom plate; two parallel side plates are arranged on the bottom plate; the side plates are detachably fixed to the bottom plate; two detachable baffles are arranged at the two ends of each side plate; the baffles are hollow frame bodies; cover plates parallel to the bottom plate are arranged on the baffles; and grouting openings penetrating through plate surfaces are formed in the cover plates. The inner formwork is an inflatable column body; after inflation, the column body is in a flue inner wall shape; and the bottom plate, the baffles, the cover plates and the column body together define a flue cavity. The inflatable column body is designed to serve as the inner formwork, and the inner formwork can be taken down from the inner wall of a flue conveniently after forming of the flue. The invention further provides the flue forming method using the flue forming device. The flue forming method comprises the steps of outer formwork splicing, inner formwork inflation, bottom layer slurry injection, fully filling of slurry, and inner formwork and outer formwork dismounting.

Owner:合肥超威光电科技有限公司

Manufacturing method for semiconductor device having a T-type gate electrode

InactiveUS6979634B2Difficult to etchAvoid impuritiesSemiconductor/solid-state device manufacturingSemiconductor devicesTitaniumCobalt silicide

This invention provides a semiconductor device manufacturing method including forming a T type gate electrode having a wide region in an upper portion, the method including steps of: forming rectangular gate polysilicon; forming a nitride film covering the polysilicon; forming an oxide film thick on the nitride film; etching back the oxide film to expose the nitride film; etching the exposed nitride film, exposing the gate polysilicon, and forming a space; forming undoped polysilicon burying the space; etching back the undoped polysilicon to form a wide portion in the upper portion of the gate polysilicon; and etching the oxide film and the nitride film; siliciding the wide undoped silicon to form titanium suicide (or cobalt silicide). This manufacturing method makes it possible to easily form the T type gate electrode with good yield.

Owner:LAPIS SEMICON CO LTD

Forming die for automobile wrought aluminum steering joints

The invention discloses a forming die for automobile wrought aluminum steering joints. The forming die comprises an upper die base and a lower die base, wherein the lower die base is of a hollow structure; a mounting block is vertically arranged inside the lower die base; the top part of the mounting block and the top part of the lower die base are positioned on the same horizontal plane; a sunken first mounting groove is formed in the top part of the mounting block; a sunken second mounting groove is formed in the bottom inner wall of the first mounting groove; the side wall of the second mounting groove is a sector-shaped cross section; four first fixed rods which are annularly distributed are arranged on the bottom inner wall of the second mounting groove; a third mounting groove is formed in the bottom inner wall of the second mounting groove; and the third mounting groove is positioned among the four first fixed rods. The forming die has a better buffer effect; moreover, the damage to the upper die base or the lower die base caused by instant impact force is avoided, and the service life of the upper die base or the lower die base is prolonged; in addition, the formation steps of the steering joints are simple, and operation of working personnel is facilitated.

Owner:JIANGSU ZHONGSE RABILY IND CO LTD

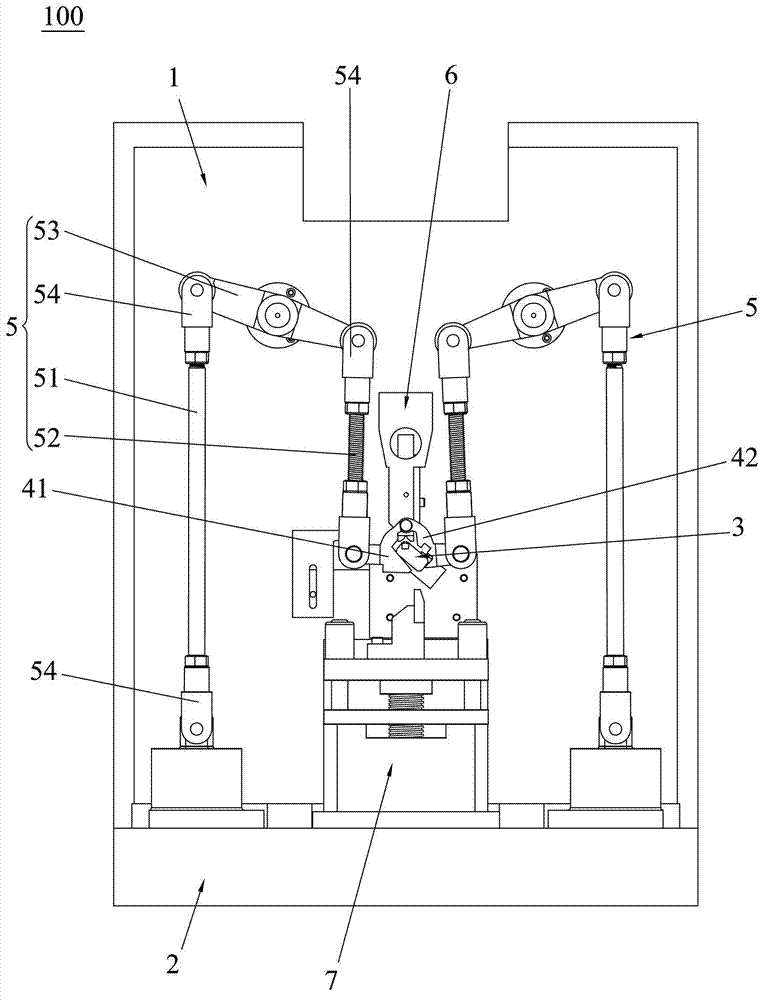

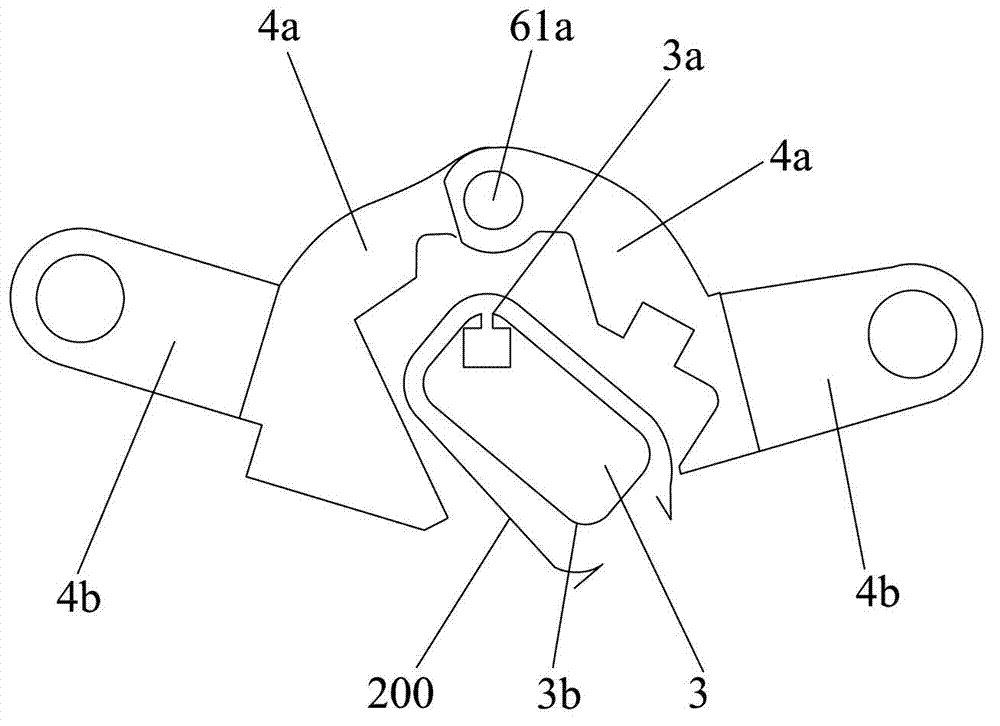

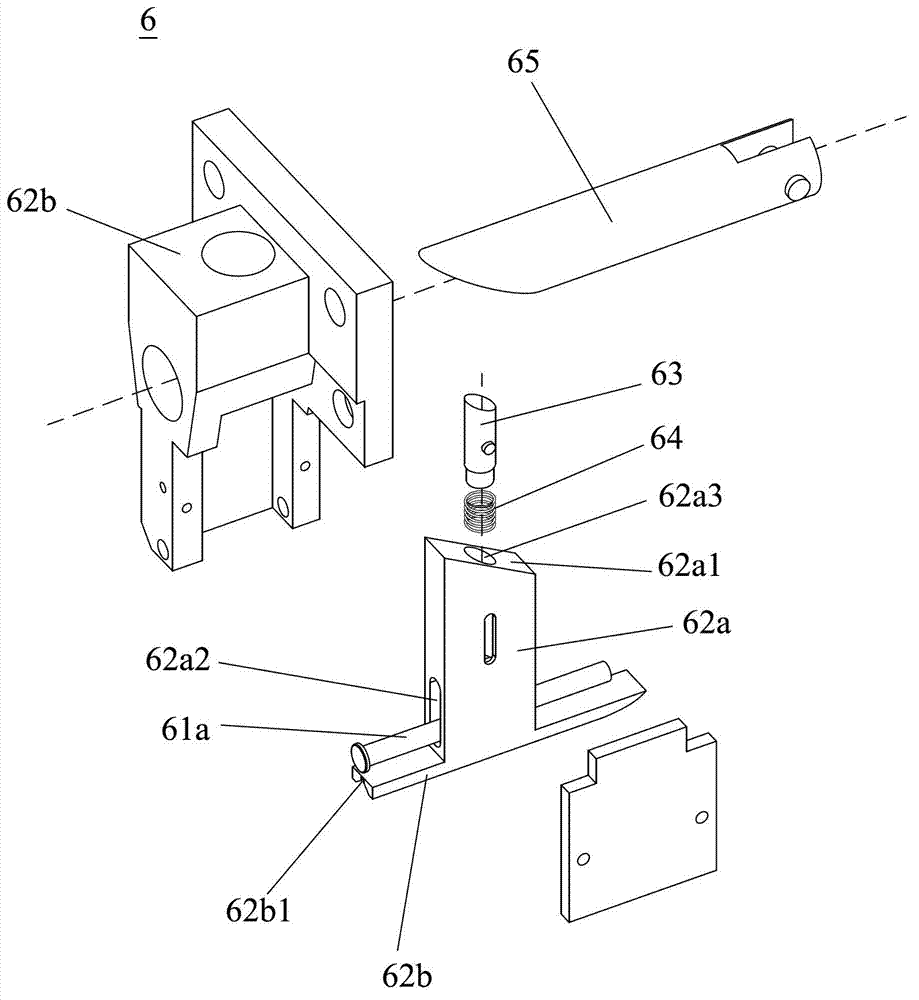

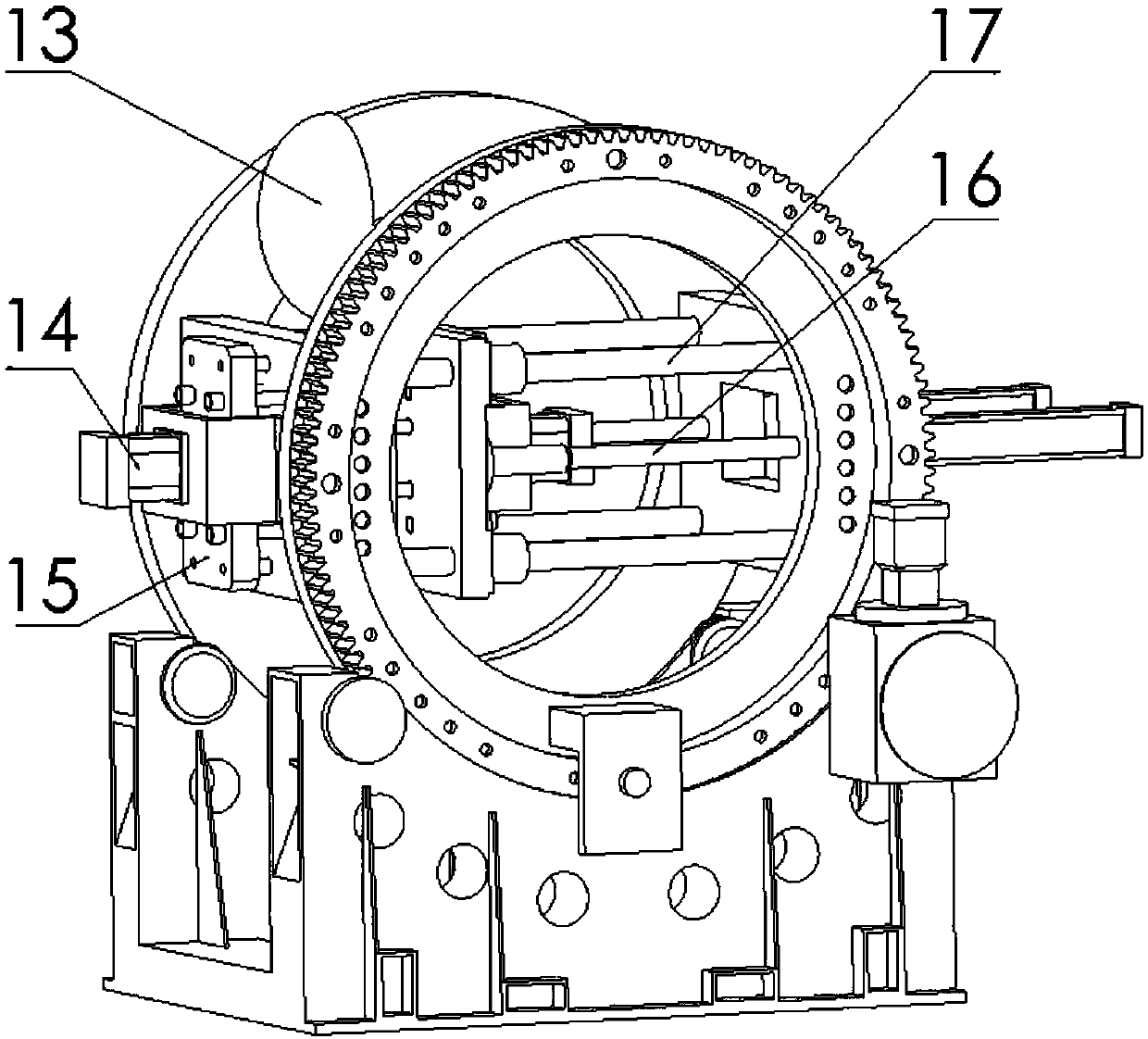

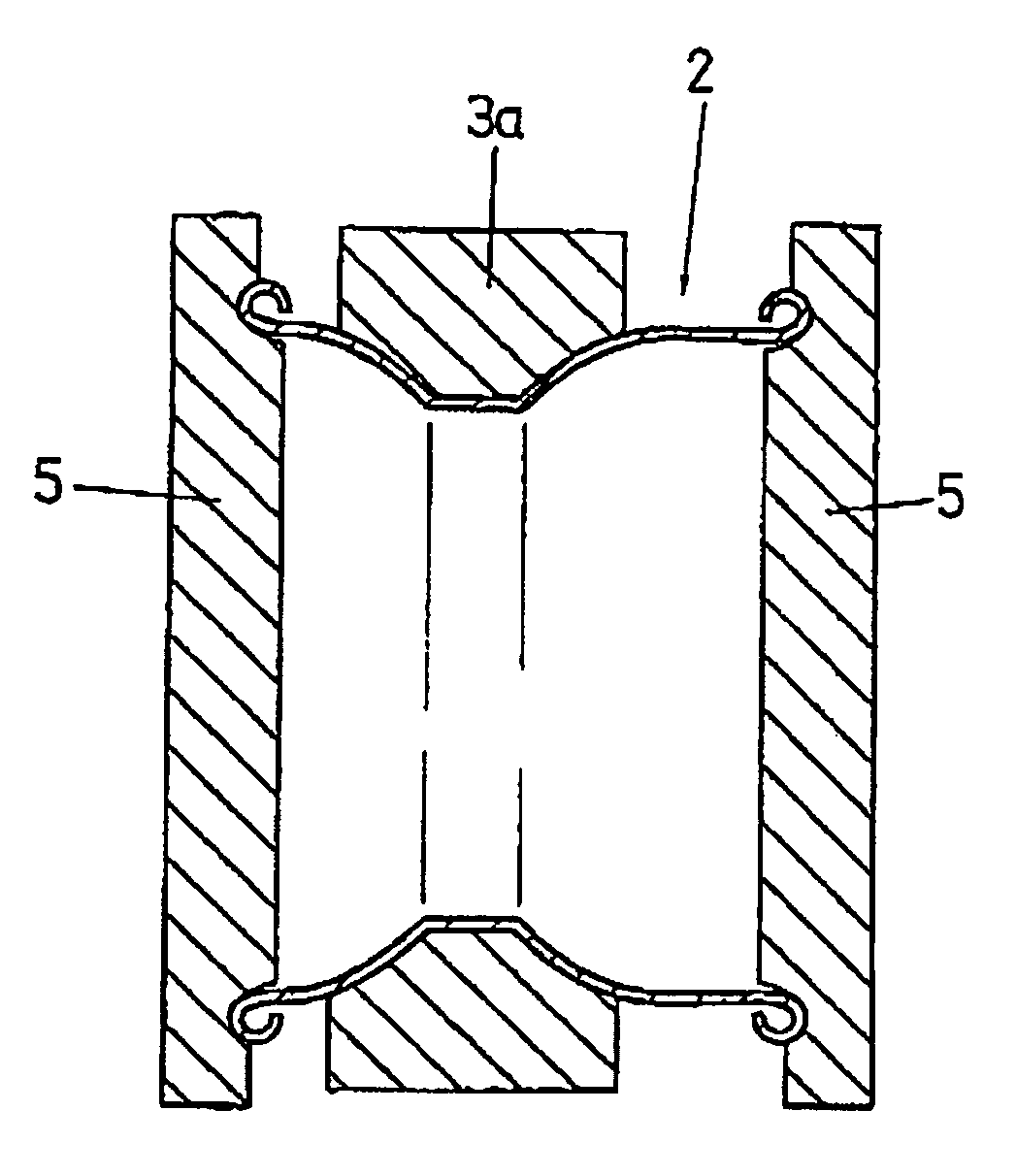

Cylinder shaping mechanism

InactiveCN102814362ASimplified molding stepsFast formingShaping toolsHollow articlesMetal sheetEngineering

The invention discloses a cylinder shaping mechanism, which is applicable to form a cylinder by extruding a metal sheet. The cylinder shaping mechanism comprises a frame, a driving mechanism, a convex die, a pair of concave dies and a pair of pushing mechanisms, wherein the cross section of the convex die is the same as that of the cylinder body, and the convex die is fixed on the frame; the pushing mechanism comprises a first connecting rod, a second connecting rod and a swing arm; one end of the first connecting rod is pivoted with one end of the swing arm, the swing arm is arranged in a horizontal manner and the middle part of the swing arm is pivoted to the frame; the other end of the swing arm is pivoted with one end of the second connecting rod, the concave dies are arranged at both sides of the convex die and provided with pivoting parts and rotating parts; the pivoting parts are pivoted on the frame and the rotating part are pivoted on the other end of the second connecting rod; the pushing mechanism can be driven by the driving mechanism simultaneously, so that the convex die can be coated by two concave dies; and therefore, the cylinder body is formed by extruding the metal sheet. By adopting the cylinder shaping mechanism, the shaping steps can be simplified and the producing efficiency is improved.

Owner:DONGGUAN JINGLI CAN

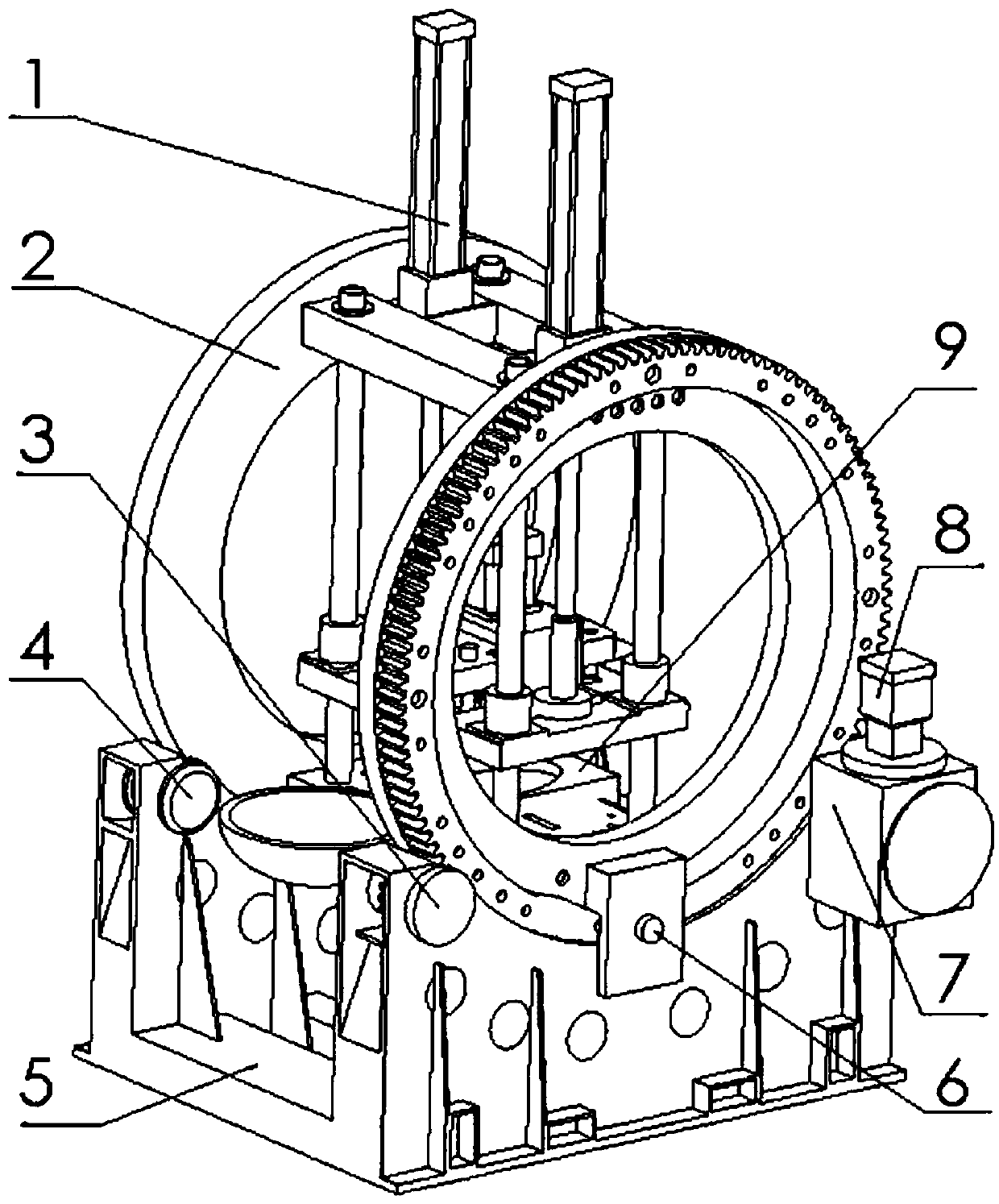

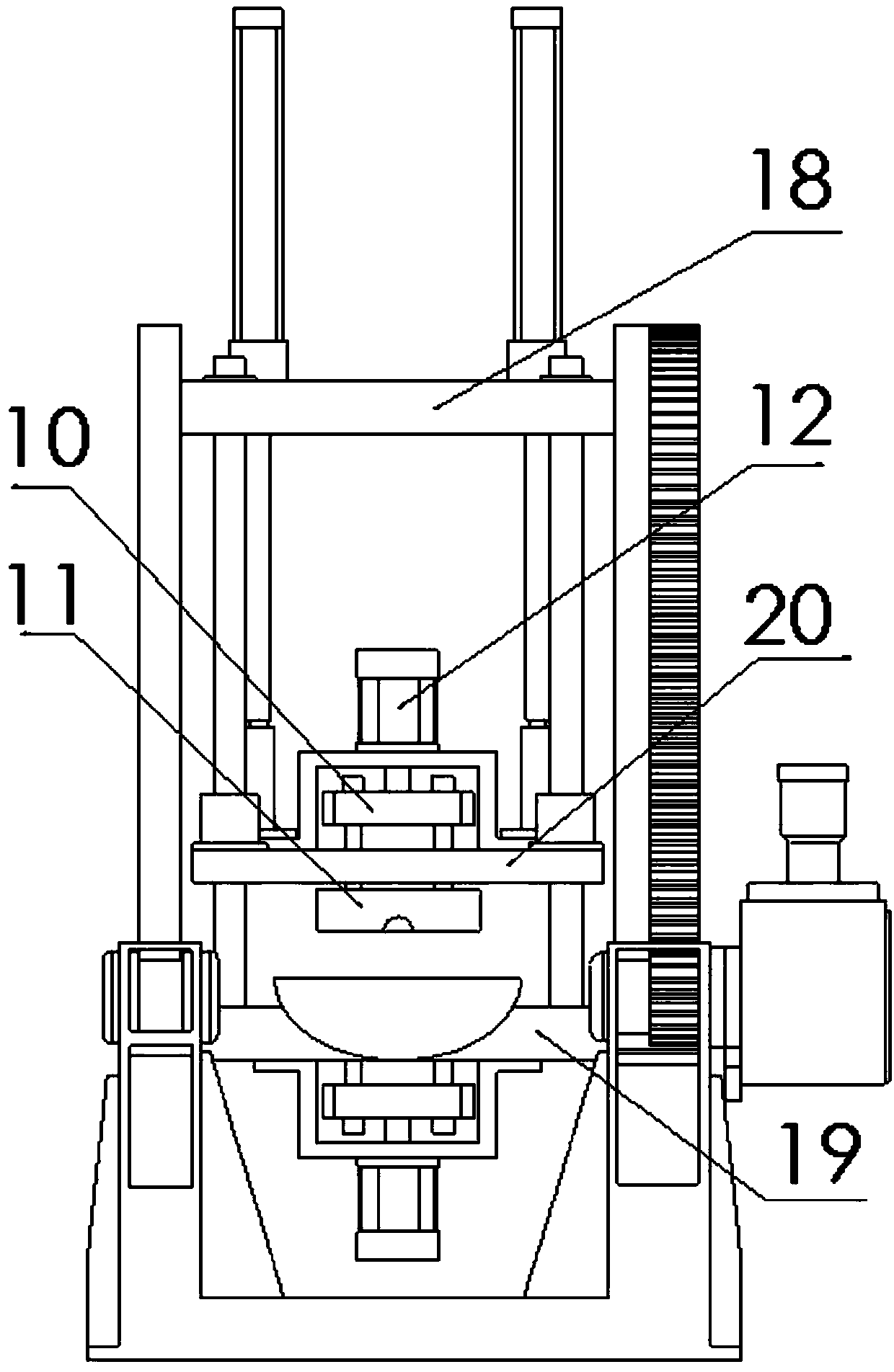

Large-scale tilting casting machine

PendingCN109530666ASimplified molding stepsStrong securityMolten metal conveying equipmentsEngineeringMechanical engineering

The invention belongs to the technical field of mechanical engineering, and relates to a large-scale tilting casting machine. The large tilting casting machine comprises a base, a driving device, a transmission device, a tilting device and a mold positioning device; the driving device is connected with the transmission device, the transmission device is fixedly connected with the tilting device todrive the tilting device to tilt, and the tilting device is arranged on the base; the tilting device comprises a liquid metal container which is fixedly connected, and the mold positioning device isconnected with the tilting device; the mold positioning device makes an upper mold and a lower mold accurately positioned and coaxial with an outlet of the liquid metal container. By rotating a rotating body of the casting machine, metal liquid automatically flows into the molds so that the molds can be fully cooled and formed, the forming step is simplified, the operation is simple, and the safety is achieved.

Owner:JIANGSU TIANHONG MACHINERY IND

Electrostatic adsorption type upright cellucotton molding method

InactiveCN103382626ASimplified molding stepsShort working hoursNon-woven fabricsElectrostatic adsorptionEngineering

The invention relates to an electrostatic adsorption type upright cellucotton molding method which comprises the following steps: after opening staple fiber, putting the opened staple fiber in an electrostatic space formed between an upper electrostatic plate and a lower electrostatic plate, drawing by using an electrostatic principle to form an upright structure, heating the stapler fiber forming an upright structure through drawing to be bonded into flake-like upright cellucotton, and taking out the flake-like upright cellucotton from the electrostatic space formed between the upper electrostatic plate and the lower electrostatic plate. Therefore, the method has the advantages that the molding step is simple, the production cost is low, and the material waste is not caused.

Owner:郑 宏明

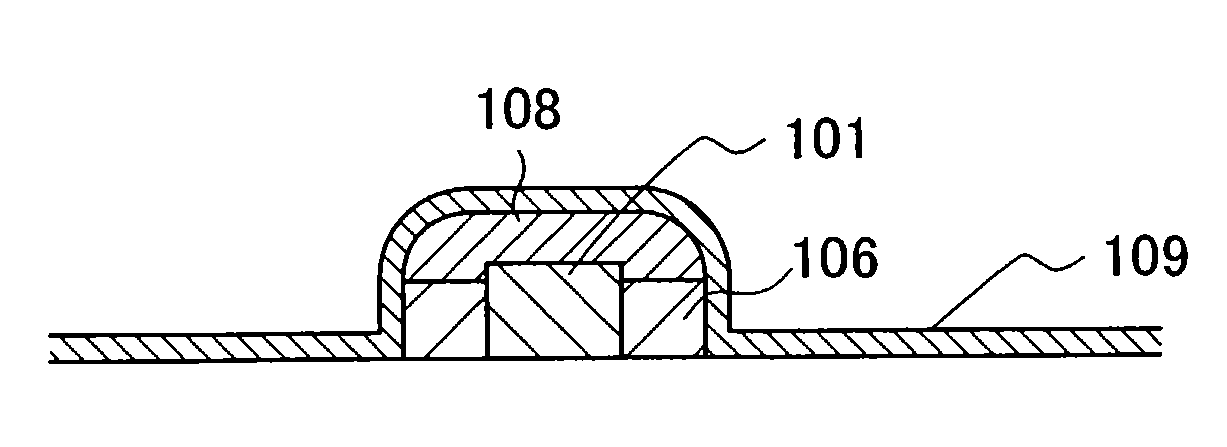

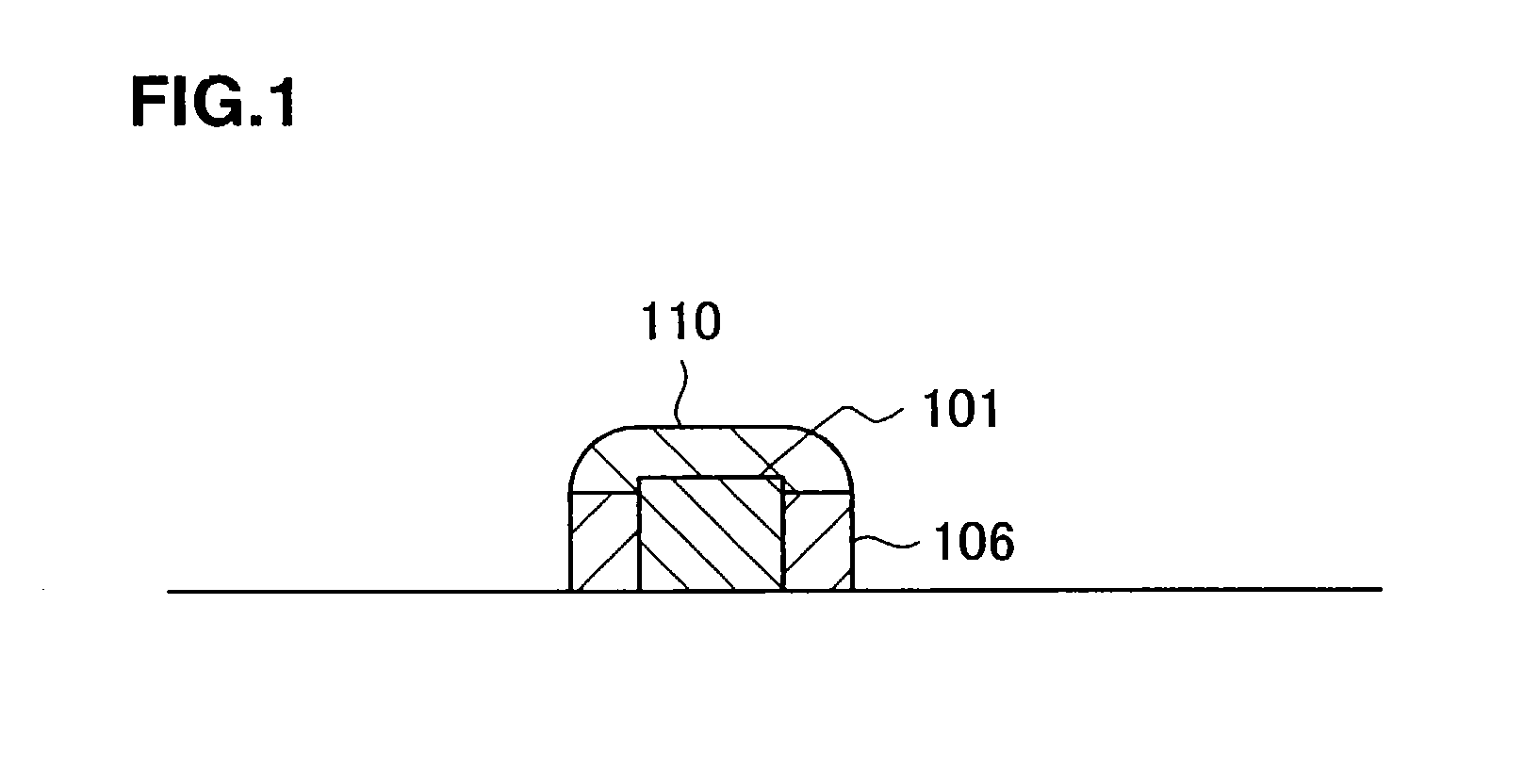

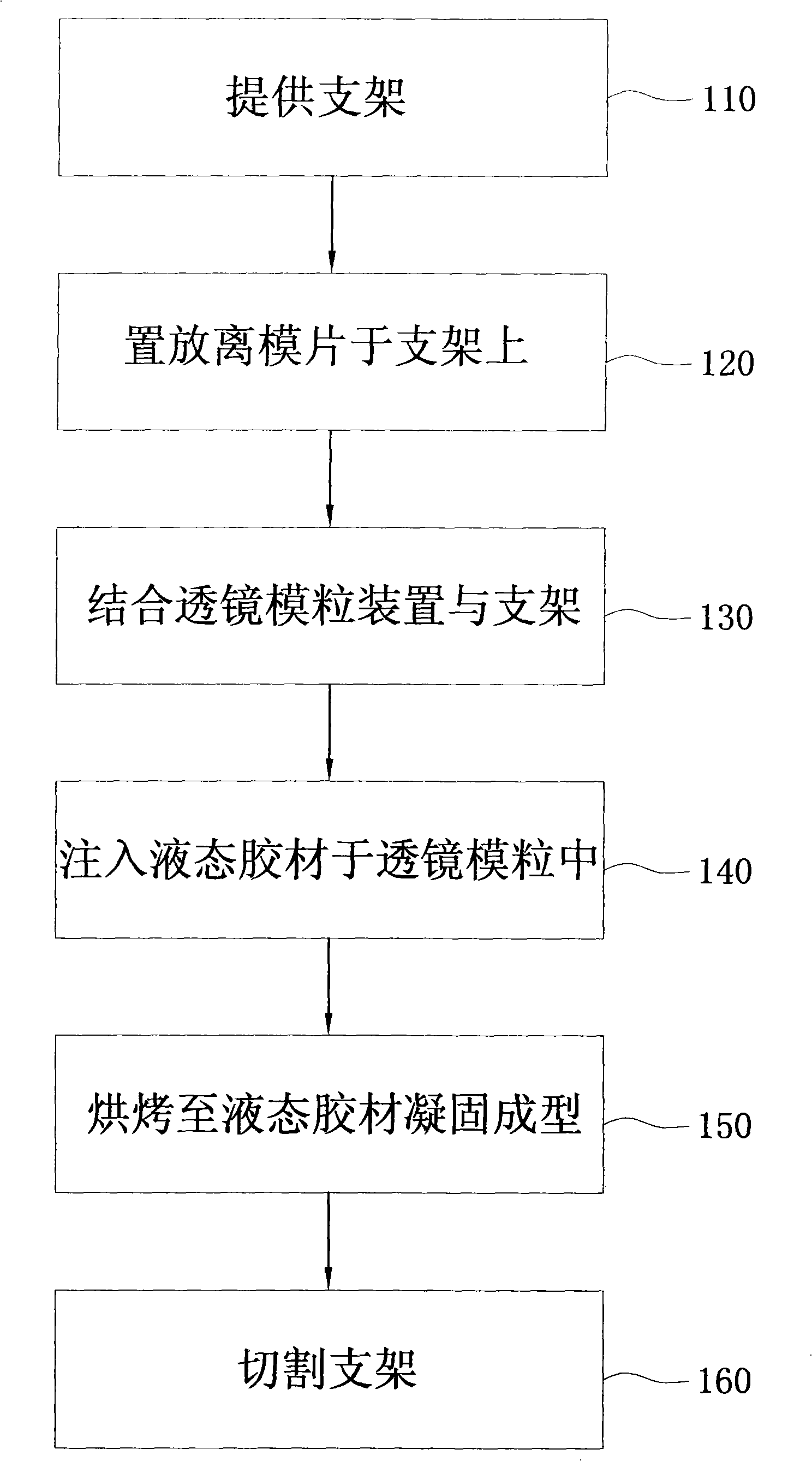

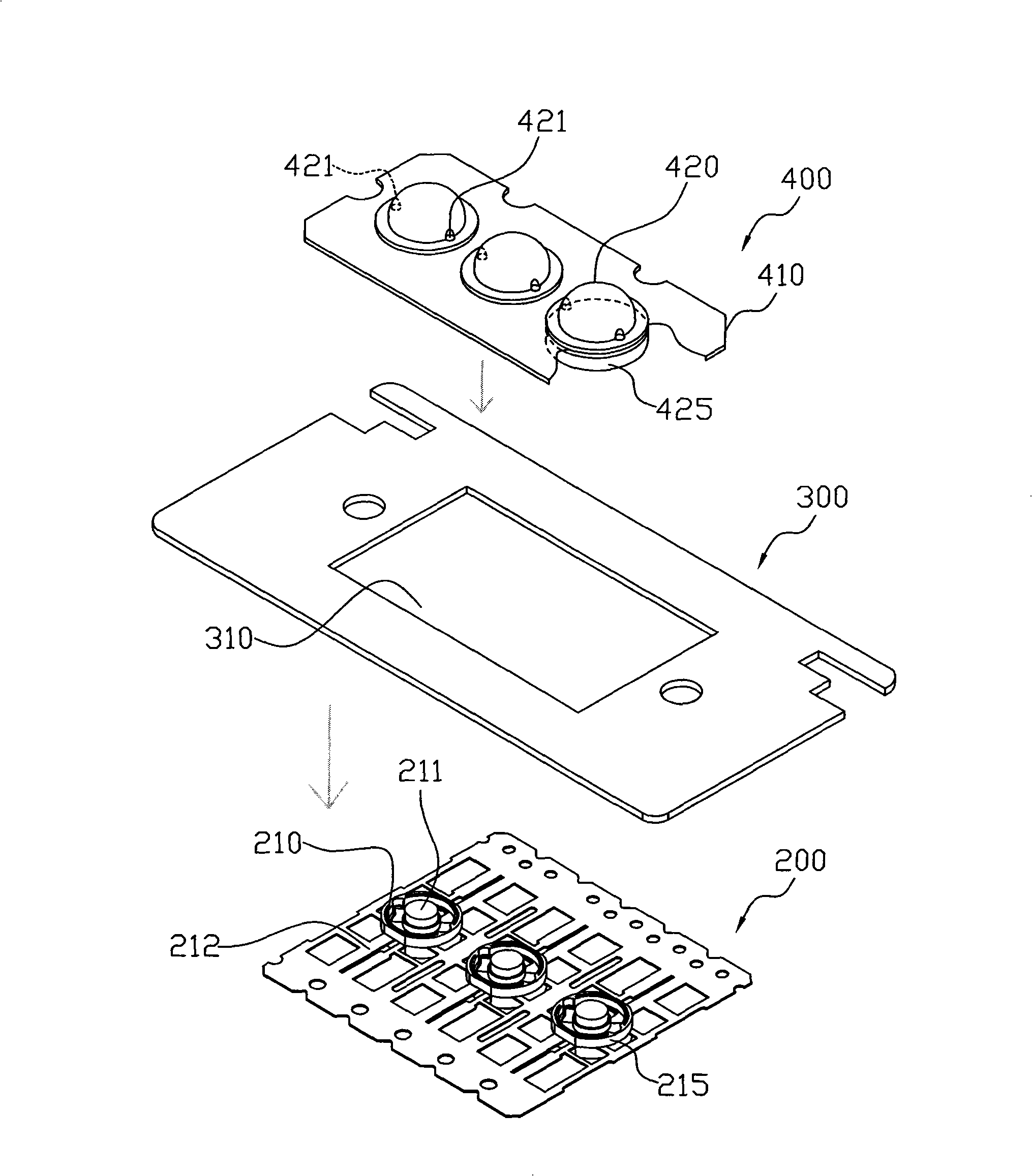

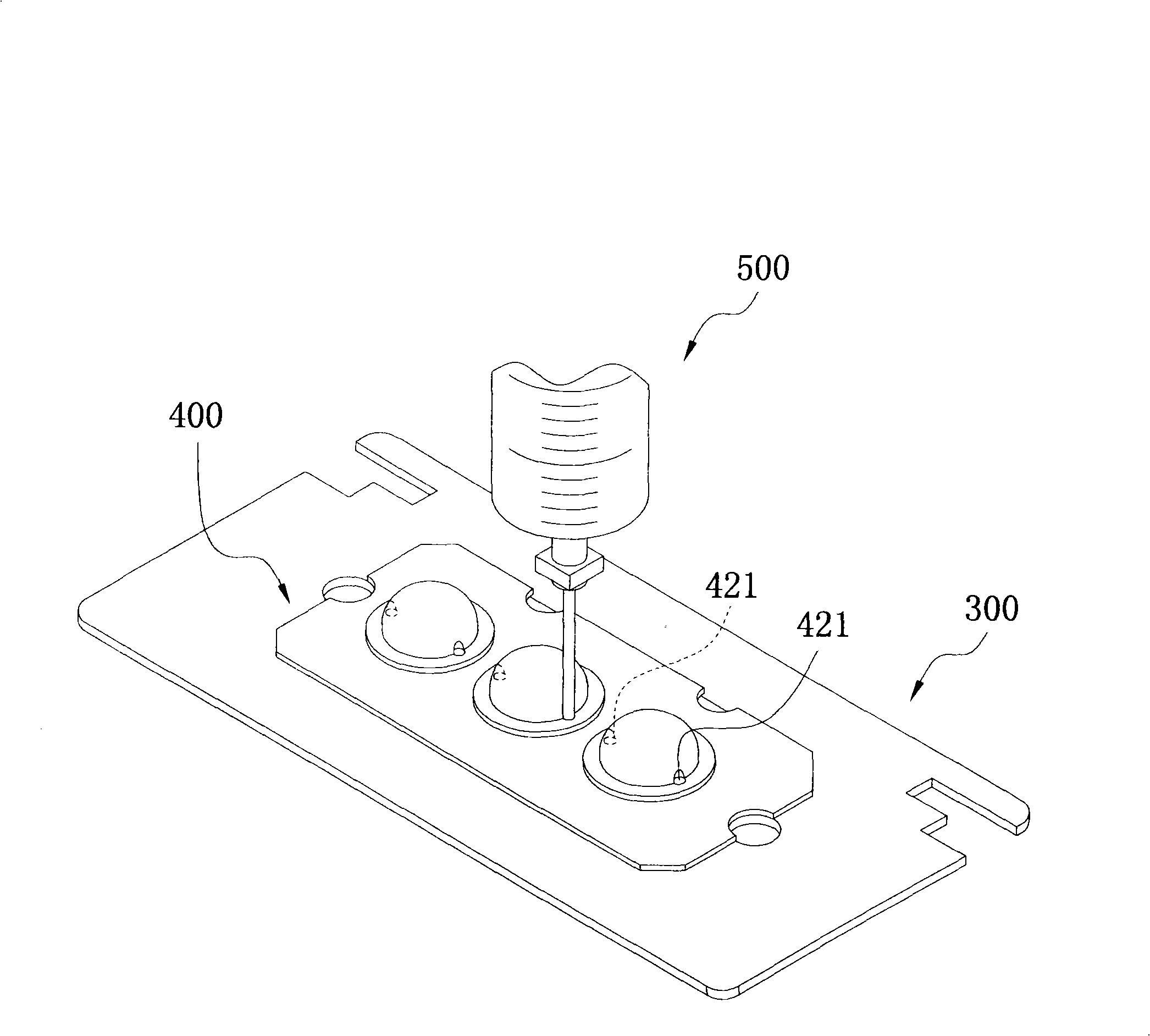

Method and apparatus for manufacturing lens on LED apparatus

InactiveCN101354118ASimplified molding stepsShorten the timePoint-like light sourceLight fasteningsEngineering

The invention discloses a method for manufacturing a lens on an LED device. The manufacturing method includes the following steps: a stand which includes a plurality of LED modules is provided; a module separating sheet which consists of a hollow area is placed on the stand and the hollow area ensures that the LED modules are exposed; a lens module particle device and the stand are combined, wherein, the lens module particle device comprises a plurality of lens module particles each of which even comprises two through holes and corresponds to each LED module on the stand; a liquid gum is injected by making use of one through hole of each lens module particle, followed by drying, solidifying and forming. The invention also provides a module particle device for making the lens on the LED device, which comprises a basic plate and a plurality of lens module particles installed on the basic plate and each lens module particle consists of two through holes used for injecting with the liquid gum. By adopting the invention, the steps of the process for forming the lens can be simplified and the time spent in the whole process can also be shortened; in addition, the cost can also be reduced due to the reusage of the lens module particle device.

Owner:EVERLIGHT ELECTRONICS

Production process of soft cotton high-elasticity paper diaper

InactiveCN112869952APromote absorptionGuaranteed water retentionAbsorbent padsBaby linensPolyesterPolymer science

The invention discloses a production process of a cotton soft high-elasticity paper diaper, and relates to the field of hygienic products. According to the production process of the soft cotton high-elasticity paper diaper, a surface layer, an absorption core layer and a leakage-proof bottom layer are included, the leakage-proof bottom layer is formed by compounding a PE breathable microporous film and melt-blown cloth, a surface layer base material is chitin fiber spunlace cloth, and an absorption core layer base material is any one of polypropylene fiber, polyester or chinlon non-woven fabric. The production process comprises the four steps of finishing liquid preparation, surface layer forming, absorption core preparation and composite forming. According to the production process of the soft cotton high-elasticity paper diaper, the paper diaper is divided into the surface layer, the absorption core layer and the leakage-proof bottom layer, the surface layer and the absorption core layer are similar in step and can be processed at the same time, the leakage-proof bottom layer is formed by compounding two materials, the overall forming step is simplified. The raw materials of the absorbing core layer are processed by a two-stage homogenizing process, so that the absorbing capacity and the water locking capacity of the paper diaper are improved, and popularization and application are facilitated.

Owner:吉安丽姝科技有限公司

Ceramic electronic component and manufacturing method thereof

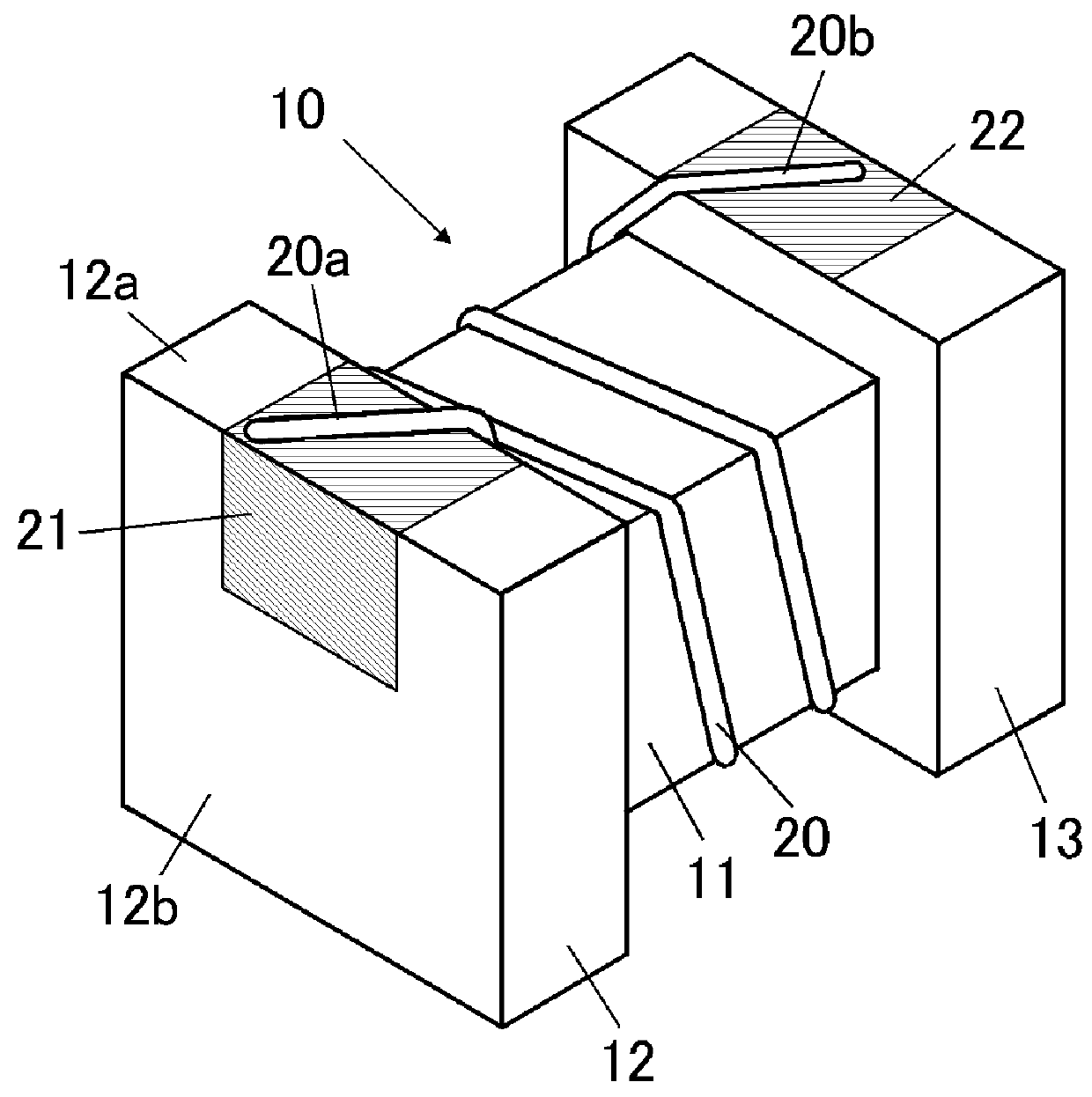

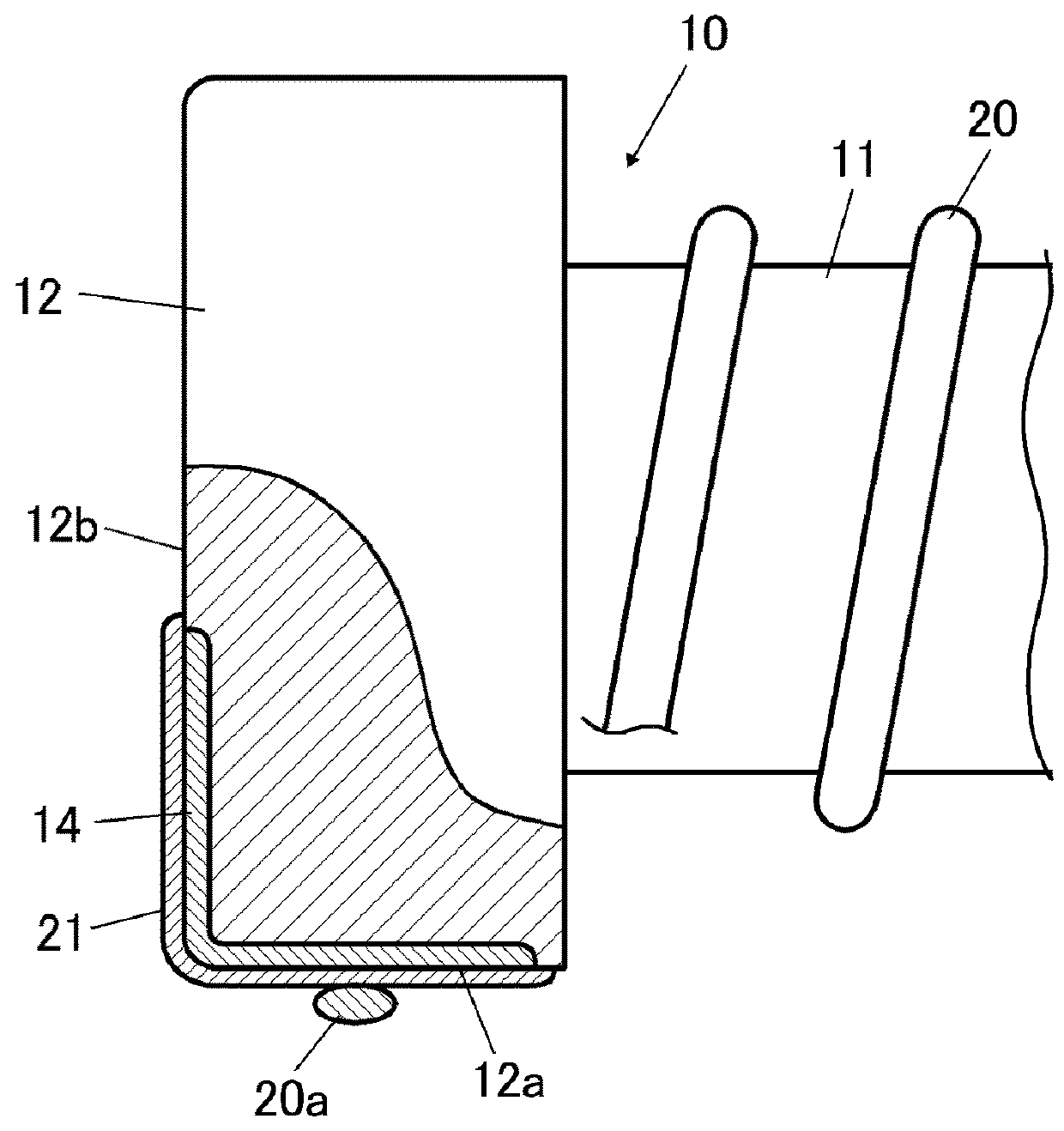

InactiveUS20180166202A1Irradiation position can be changedHigh productivityStacked capacitorsTransformers/inductances coils/windings/connectionsOxideElectroplating

A ceramic electronic component and manufacturing method are capable of easily forming a plating electrode on any portion of a surface of a ceramic body. The ceramic electronic component includes a ceramic body containing a metal oxide, a modified layer formed on a surface layer portion of the ceramic body, on which a portion of the metal oxide is melted and solidified, and an electrode comprising a plated metal formed on the modified layer. In the modified layer, at least one of metal elements constituting the metal oxide is segregated. Plated metal is likely to be deposited due to segregation of the metal elements.

Owner:MURATA MFG CO LTD

Method for molding vehicular wheel rim

ActiveUS7861412B2Easy to curlEffective moldingAutomatic control devicesTooth pluggers/hammersAxial compressionEngineering

Owner:DAIDO KOGYO CO LTD

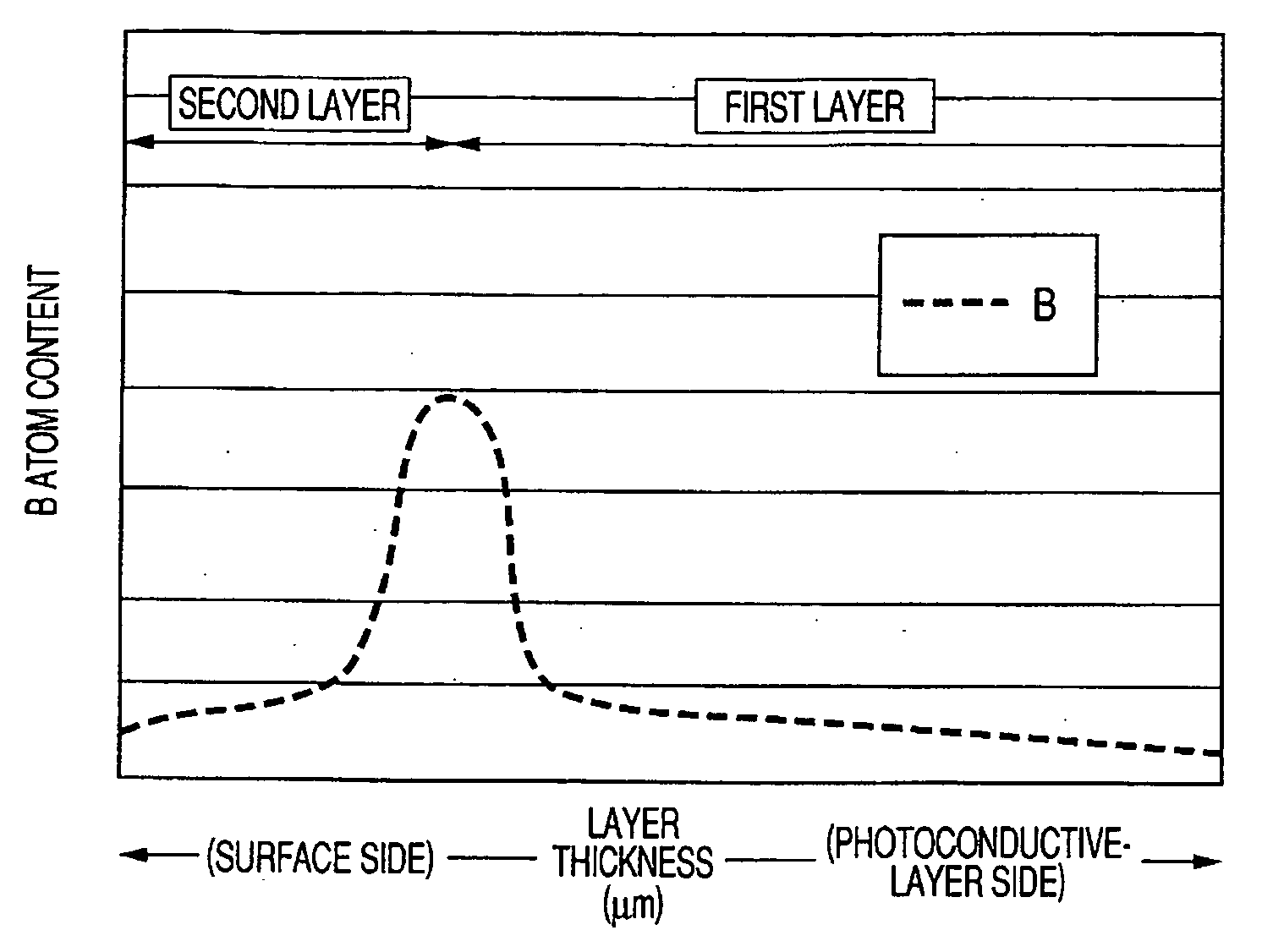

Process for producing negative charging electrophotographic photosensive member, negative charging electrophotographic photosensitive member, and electrophotographic apparatus using same

InactiveUS20060127783A1Improve adhesionReduce image defectsElectrographic process apparatusHydrogenEngineering

The invention provides a process for producing a negative-charging electrophotographic photosensitive member which can improve the adherence between a first layer and a second layer without lowering the effect of lessening image defects and realize a reduction in overall costs, a negative-charging electrophotographic photosensitive member produced by the process, and an electrophotographic apparatus. In the process for producing a negative-charging electrophotographic photosensitive member, a first layer is deposited on a substarte, at least the vertexes of protuberances are removed, the substrate with the first layer deposited theron is placed in a film forming furnace, the first layer surface is plasma-treated with a gas containing at least a Group 13 element in the periodic table and a dilution gas composed of at least one selected from hydrogen, argon and helium, and a layer formed of a non-single-crystal material is deposited as the second layer on the first layer.

Owner:CANON KK

Method for forming semiconductor structure

PendingUS20220102205A1Improve formation qualitySimplified molding stepsSemiconductor/solid-state device manufacturingLithography processSemiconductor structure

A method for forming a semiconductor structure is provided. In one form, a method includes: providing a base; forming a pattern memory layer on the base, where at least a first trench and a second trench are provided on the pattern memory layer, where an extending direction of the first trench is parallel to an extending direction of the second trench, and the first trench and the second trench are formed using different masks; and forming mandrel lines separated on the base at positions of the base that correspond to the first trench and the second trench. By using the method, a problem that a photoresist peels off during etching due to an elongated shape when separated mandrel lines are directly formed can be avoided. Further, a problem of a relatively high requirement on a filling material when the mandrel lines are formed directly by using a plurality of photolithography processes can be avoided, to lower the requirement on the filling material.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A kind of preparation method of self-supporting metal modified ZSM-5 molecular sieve and its application in the synthesis of isoprene

ActiveCN107961812BAvoid cumbersome proceduresLow costMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention provides a method for preparing a self-supporting metal-modified ZSM-5 molecular sieve, comprising the following steps: firstly, immersing silica gel particles in a metal salt solution to obtain a metal-containing precursor; The precursor and the basic template agent used to form the ZSM-5 molecular sieve are mixed and then subjected to crystallization treatment, and then calcined to obtain a self-supporting metal-modified ZSM-5 molecular sieve. In the present invention, the active metal is directly compounded with the silica gel, and then the molecular sieve is synthesized and shaped, so as to realize the one-step preparation of the self-supporting metal-ZSM-5 zeolite molecular sieve catalyst, and avoid the tedious process of the catalyst's post-forming process. The preparation method provided by the invention It is simple, reduces the preparation cost of the catalyst, and has good raw material conversion rate and product yield in the isoprene synthesis reaction, which is beneficial to industrial production and the popularization and application of the metal-ZSM-5 zeolite molecular sieve catalyst.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com