Injection molding machine

An injection molding machine, injection molding technology, applied in the direction of electrical components, circuits, connections, etc., to solve the problem of impossible to process two cable ends together, impossible to automatically perform this test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

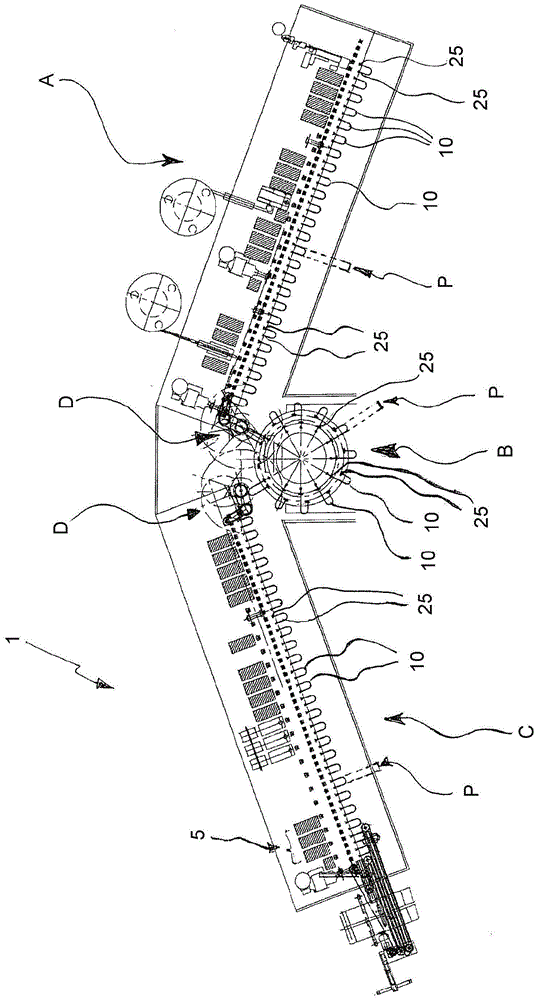

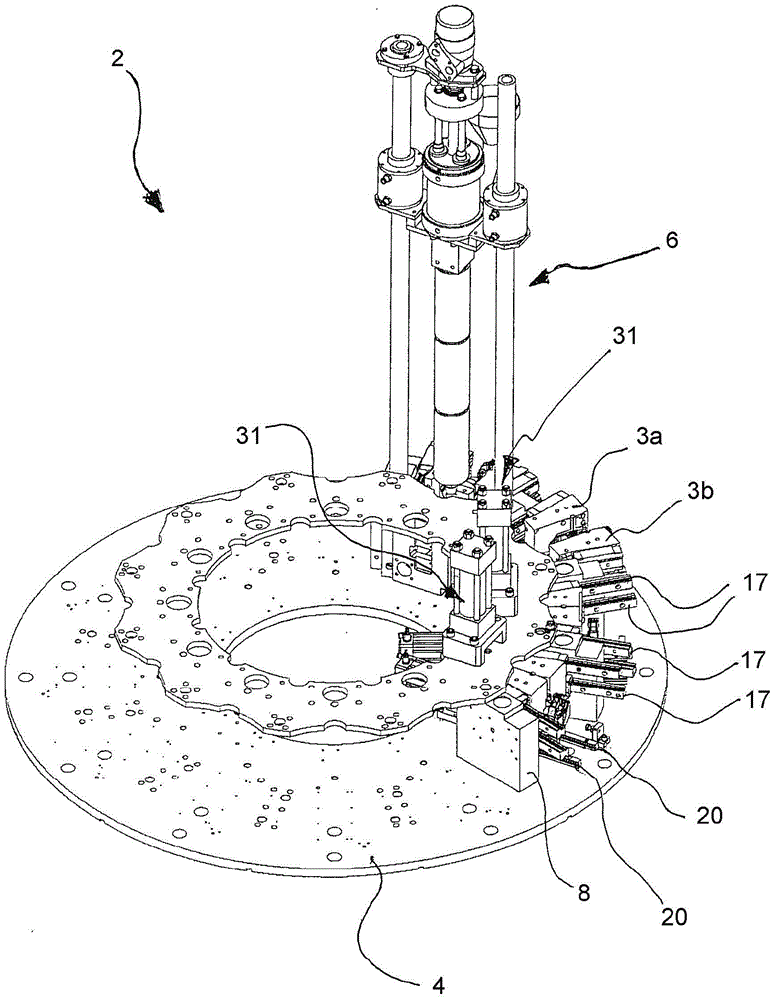

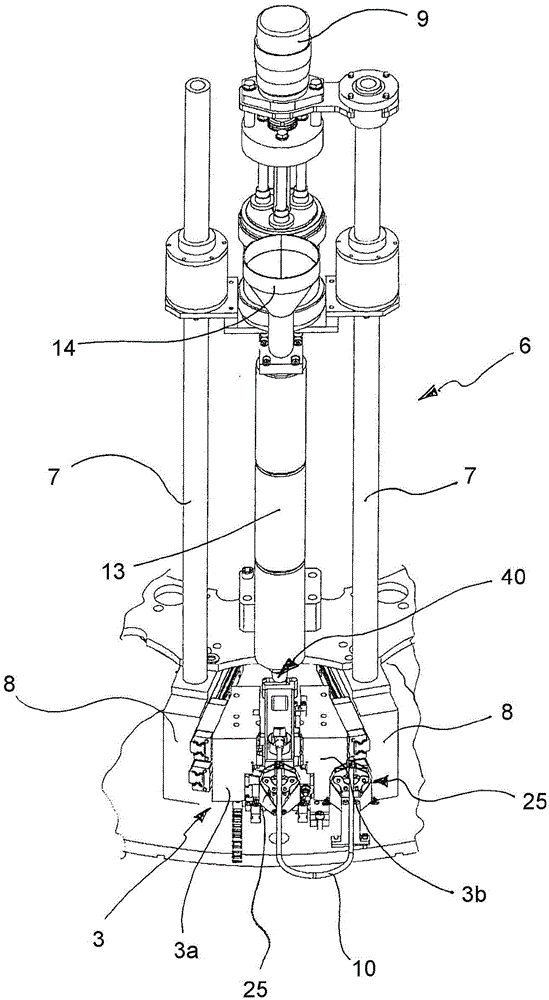

[0038] figure 1 Shown is a partial plan view of an embodiment of a production apparatus 1 for the production (overmolding) of elongated flexible members 10, preferably cables, said apparatus comprising a first section A for preparing at least one end of the cable; molding section B, by means of which section B injects thermoplastic material on at least one end of the cable; and section C, wherein the unprocessed end in section A is further processed processing. The apparatus 1 of the invention is characterized in that it also comprises means for testing the cable 10 before outputting the cable 10 from the apparatus, holding means for holding both ends of the cable in all processing stations, and holding means for removing said ends from a section. A moving device that holds the device for moving the device to the next section.

[0039] As mentioned above, the apparatus of the present invention is used for overmolding connecting cable ends, live or otherwise, in particular, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com