Cylinder shaping mechanism

A molding mechanism and cylinder technology, applied in molding tools, applications, household appliances, etc., can solve the problems of low production efficiency, many process steps, complicated process, etc., and achieve the effects of fast molding, improved production efficiency, and simplified molding steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

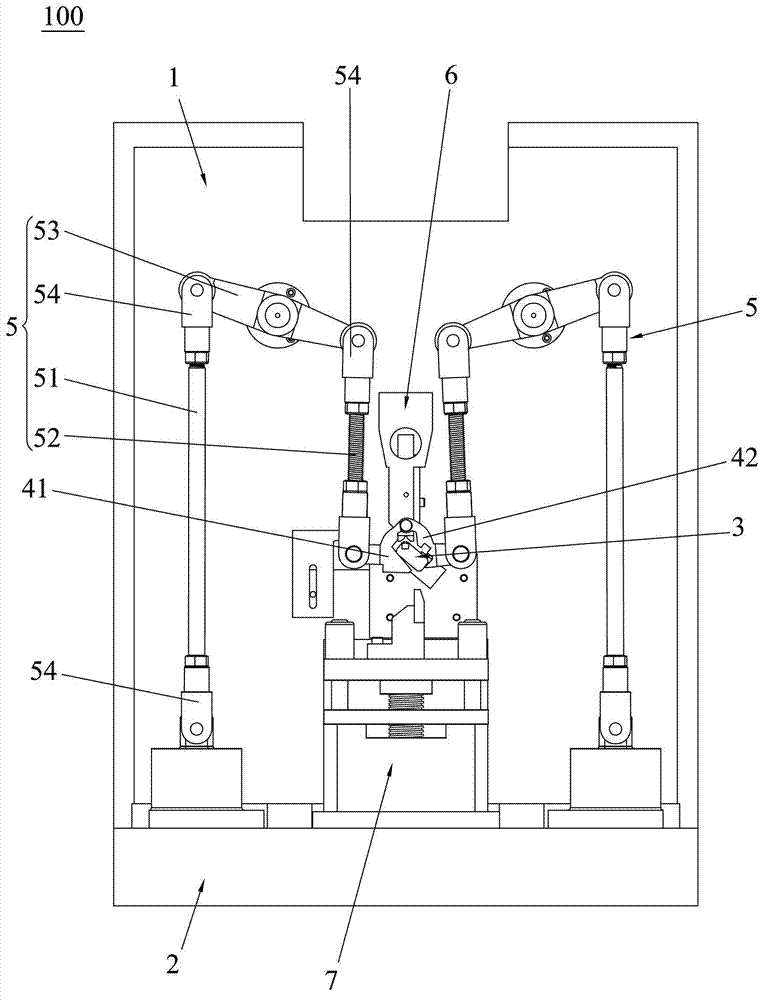

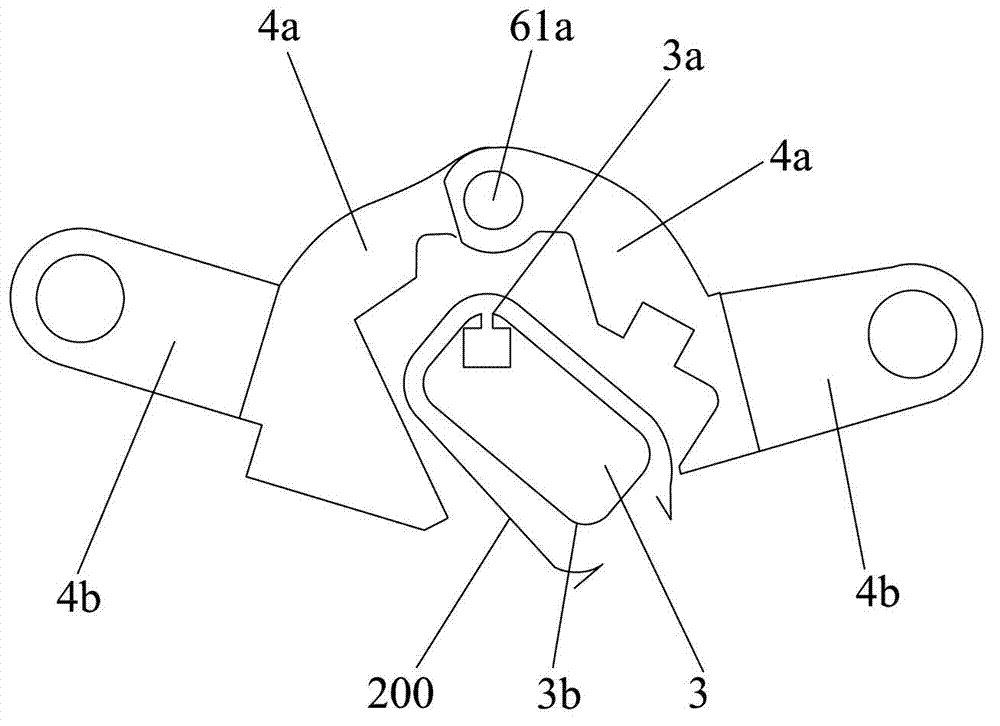

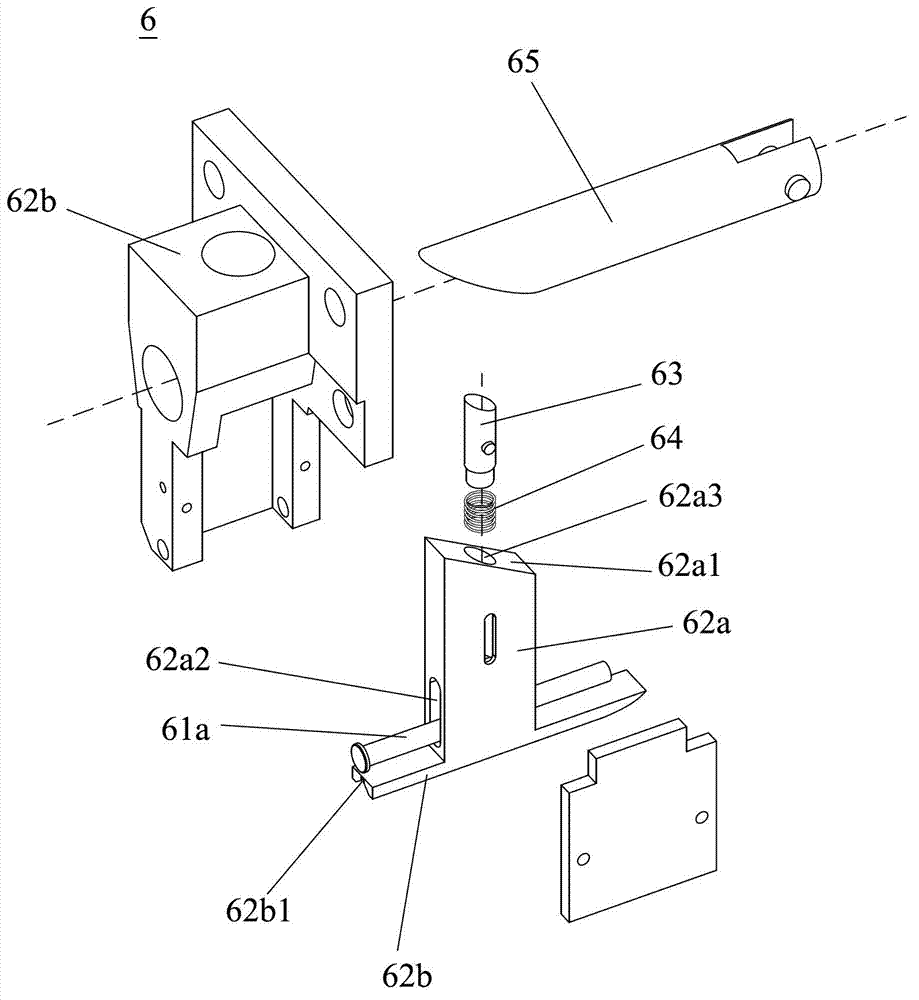

[0020] Such as figure 1 As shown, the cylinder forming mechanism 100 of the present invention is used to extrude the metal plate 200 to form the cylinder, and the cylinder forming mechanism 100 includes a frame 1, a driving mechanism 2, a punch 3, a pair of dies, namely Left and right dies 41, 42, a pair of push mechanisms 5, an upper die assembly 6 and a lower die assembly 7; the punch 3 is fixed on the frame 1 and is connected to the cross section of the cylinder The same, specifically, the punch 3 is a strip type, one end of which is vertically fixed on the plane of the frame 1, the cross section of the punch 3 is a rectangular structure and the four corners are arc-shaped transitions, and The punch 3 is arranged obliquely so that the two arc surfaces 3a, 3b on the same diagonal line are the uppermost end and the lowermost end of the punch 3 respectively.

[0021] combine figure 1 see figure 2 The pushing mechanism 5 is symmetrically located on both sides of the punch 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com