Method and apparatus for manufacturing lens on LED apparatus

A technology of LED device and manufacturing method, which is applied to components of lighting devices, lighting devices, semiconductor devices of light-emitting elements, etc., can solve problems such as differences in refractive index and reduced light-gathering efficiency, and achieve cost reduction and light-gathering efficiency. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

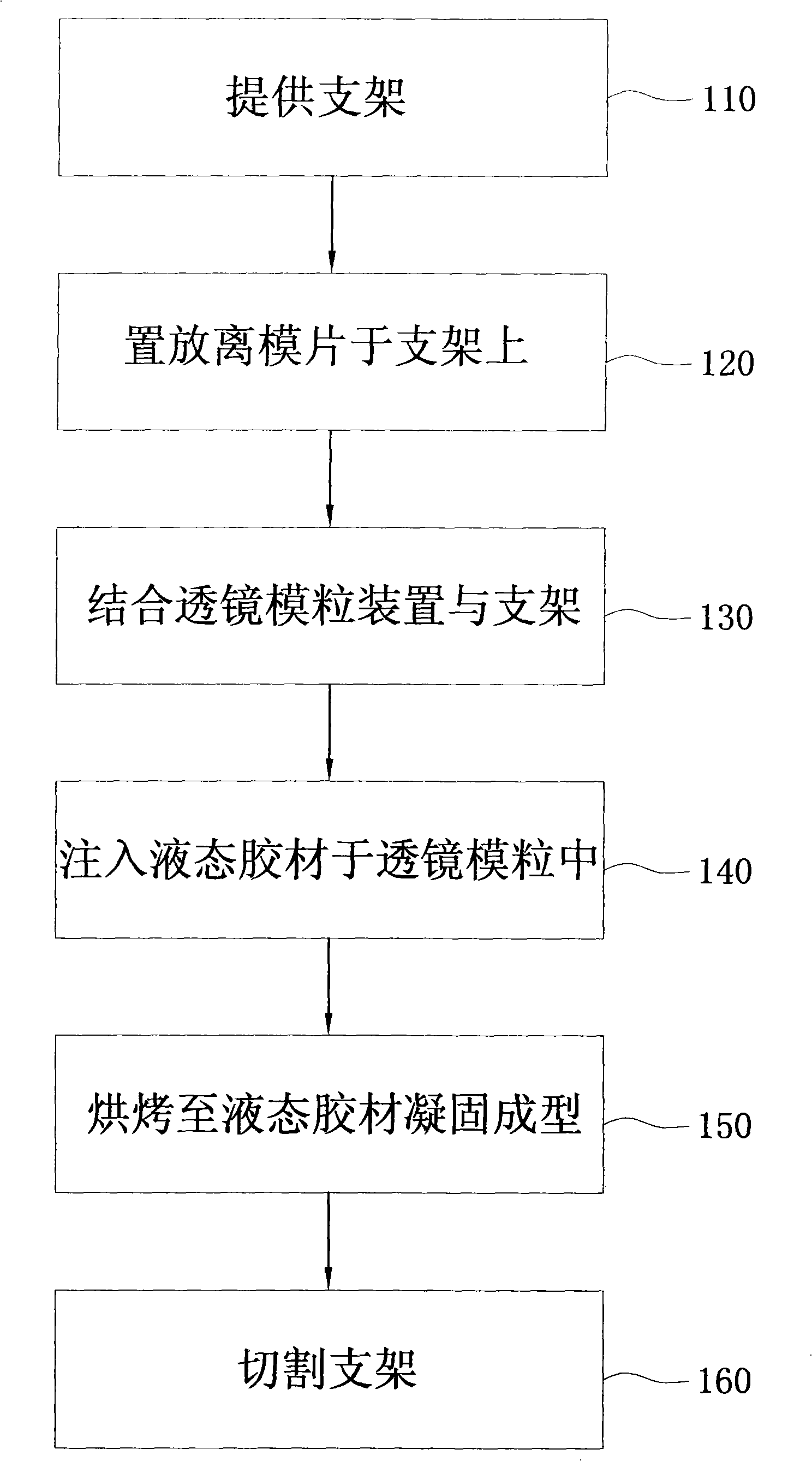

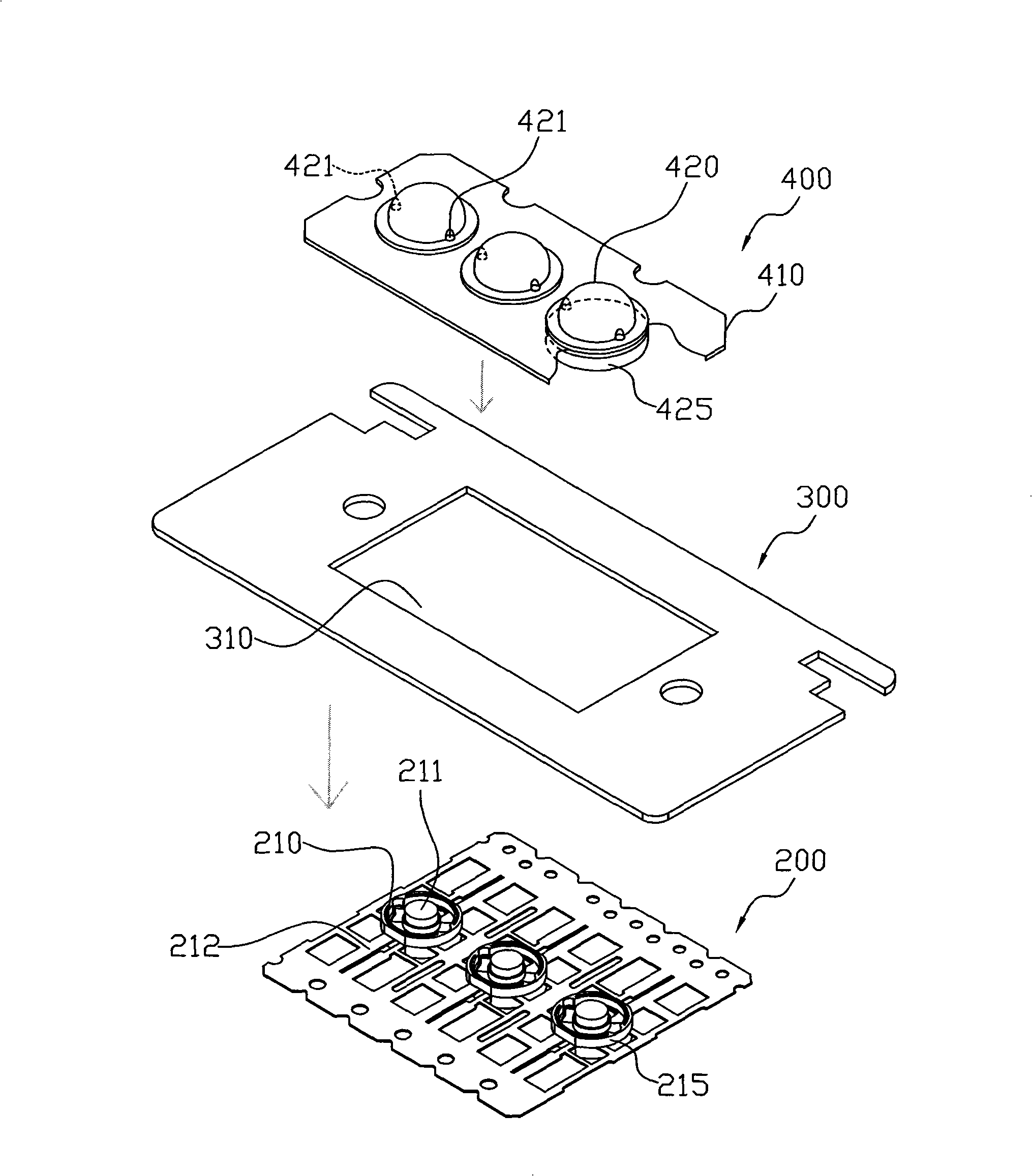

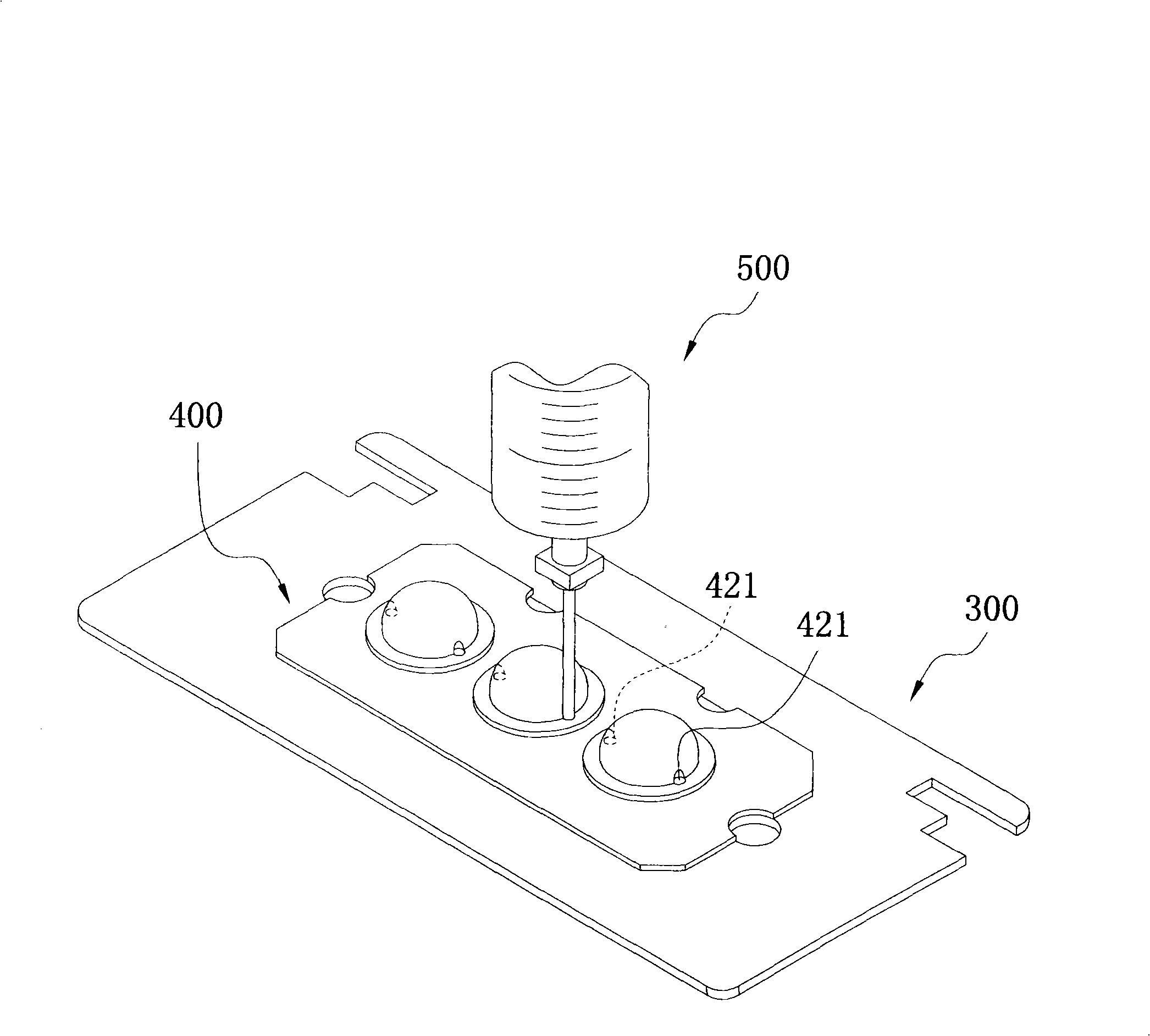

[0033] Please refer to figure 1 as well as figure 2 . figure 1 It is a flowchart of the lens manufacturing method of the present invention; figure 2 A three-dimensional exploded view showing the assembly structure in the lens manufacturing method of the present invention.

[0034] The lens manufacturing method of the present invention includes providing a bracket, placing a mold piece on the bracket, combining the lens module device with the bracket, injecting liquid glue, and baking and solidifying.

[0035] The bracket 200 includes a plurality of LED modules 210 , and each LED module 210 includes a die bonding area 211 and a lead frame 212 . The die-bonding area 211 is for the LED die to be fixed therein, and wires are connected from the LED die to the lead frame 212 through a wire bonding process (Wire Bonding) to drive the LED die to emit light. Each LED module 210 further includes a first combining portion 215 . The release sheet 300 includes a hollow area 310 corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com