Large-scale tilting casting machine

A casting machine, a large-scale technology, applied to casting equipment, manufacturing tools, equipment for feeding molten metal into molds, etc., can solve problems such as complicated workflow and inconvenient operation, and achieve strong safety, improved efficiency, and simplified molding The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

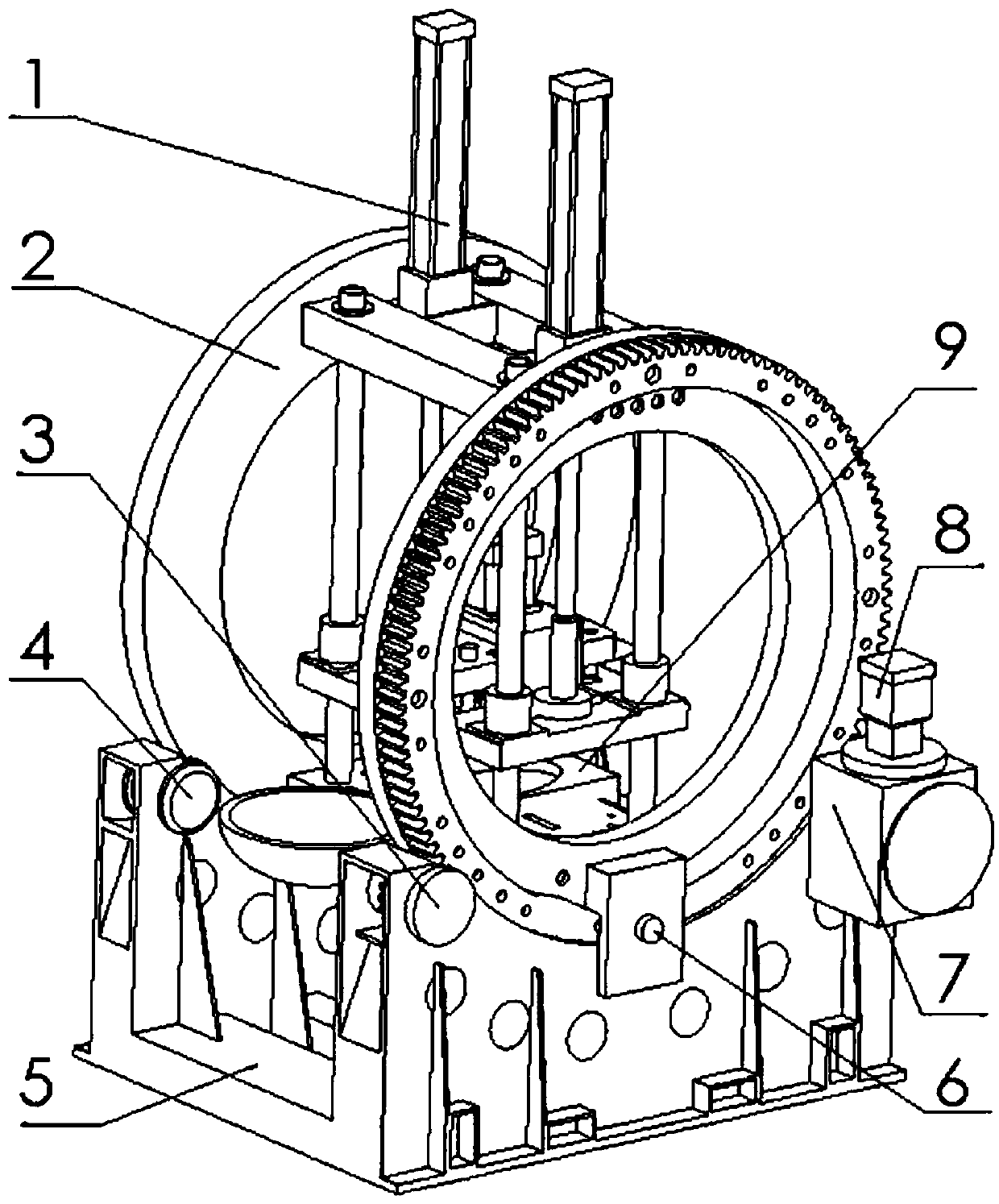

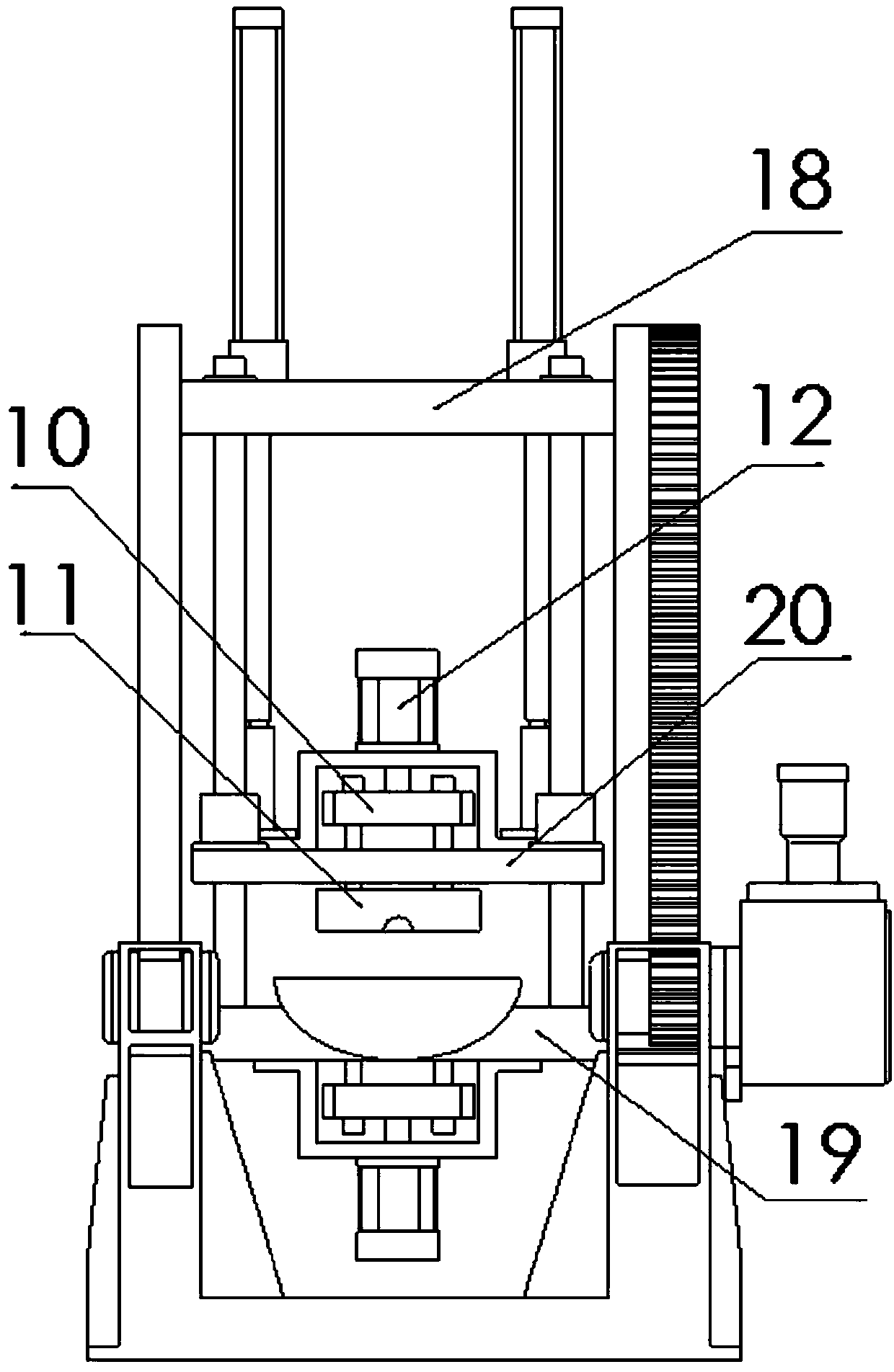

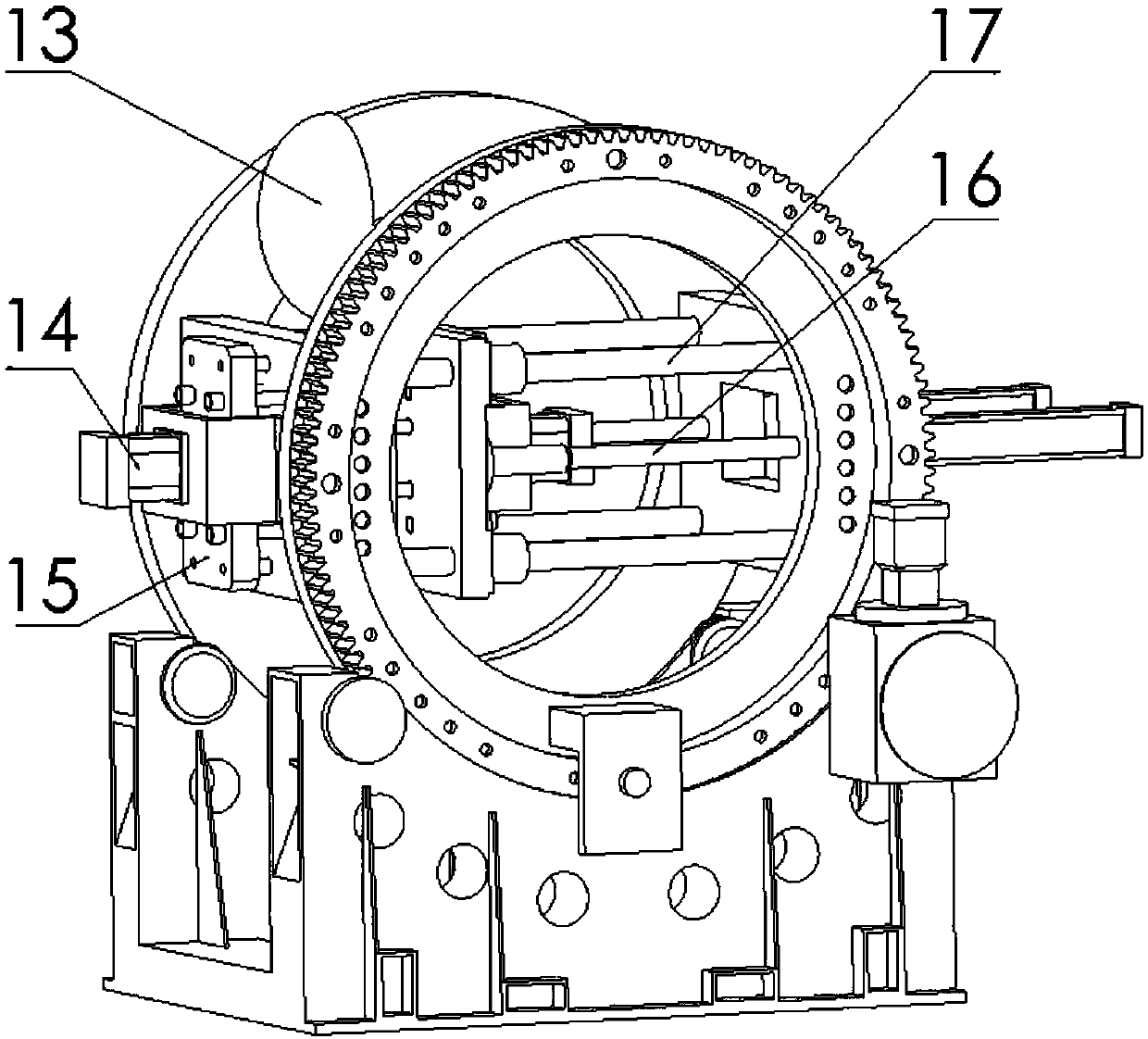

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] refer to Figure 1 to Figure 3 As shown, the large-scale tilting casting machine of this embodiment includes a base 5, and a driving device, a transmission device, a tilting device and a mold positioning device arranged on the base 5, the driving device is connected to the transmission device, and the transmission device and the tilting device are fixed The connection drives it to tilt. The tilting device includes a fixedly connected liquid metal container 13. The mold positioning device is connected to the tilting device. The mold positioning device makes the upper and lower molds precisely positioned and coaxial with the outlet of the liquid metal container 13 (coaxial: The outlet of the liquid metal container 13 is always aimed at the mould, and the whole tilting process liquid metal all flows into the mould).

[0024] The base 5 is set as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com