Flue forming device and flue forming method using same

A molding device and molding method technology, applied to ceramic molding cores, ceramic molding machines, ceramic molding mandrels, etc., can solve the problems of low mechanized production efficiency, large investment in manpower and material resources, and difficulty in extracting internal molds, and achieve simplified Forming steps, improved production efficiency, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

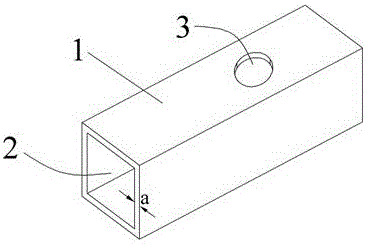

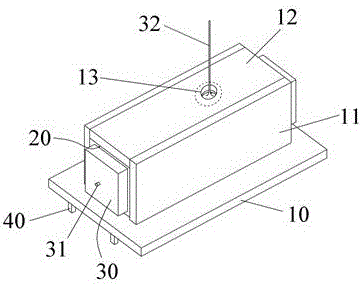

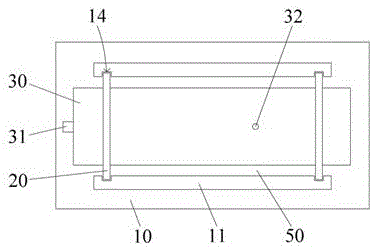

[0036] Such as figure 2 , 3 As shown, the flue forming device includes an outer mold and an inner mold. The outer mold includes a base plate 10, and the base plate 10 is provided with two side plates 11 parallel to each other. The side plates 11 are detachably fixed on the base plate 10, and the side plates 11 Two detachable baffles 20 are provided at both ends. The baffles 20 are hollow frames. The baffles 20 are provided with a cover plate 12 parallel to the bottom plate 10. The cover plate 12 is provided with a grout that penetrates the surface of the plate. Port 13, the dotted line in the grouting port 13 area is the position of the flue hole 3 after the flue is formed, the inner mold is an inflatable cylinder 30, and the cylinder 30 is in the shape of the inner wall of the flue after inflation, the bottom plate 10, the baffle plate 20, The cover plate 12 and the column body 30 together form a flue cavity 50, which is the cavity formed by the flue. By using the column 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com