Rolling method of 22mm thick specification x80 large diameter pipeline steel

A large-diameter, pipeline steel technology, applied in the rolling field of 22mm thick X80 large-diameter pipeline steel, can solve the problem of not mentioning the production process of 22mm thick X80 pipeline steel, etc., achieving significant economic benefits, improved qualification rate, excellent quality The effect of welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

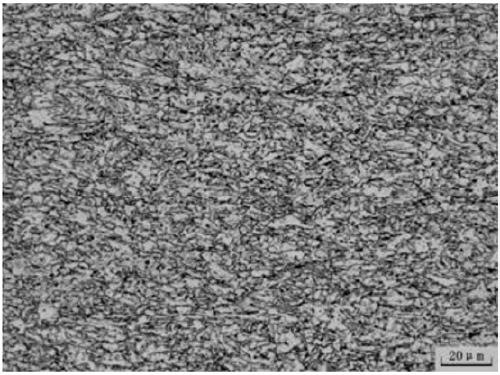

Image

Examples

Embodiment example 3

[0050] The thickness of the rough-rolled intermediate slab is 68mm, the rolling start temperature is 1165°C, the entrance temperature of the final pass is 972°C, and the reduction rate of the final pass is 25.6%.

[0051] The starting temperature of finish rolling is 936°C, the finish rolling temperature is 815°C, the compression ratio of finish rolling is 3.1 times, and the cumulative reduction ratio is 68%.

[0052] After finishing rolling, the plate enters the high-efficiency dense laminar flow cooling system with a cooling rate of 30°C / s and a coiling temperature of 405°C. Finally, the finished board can be obtained.

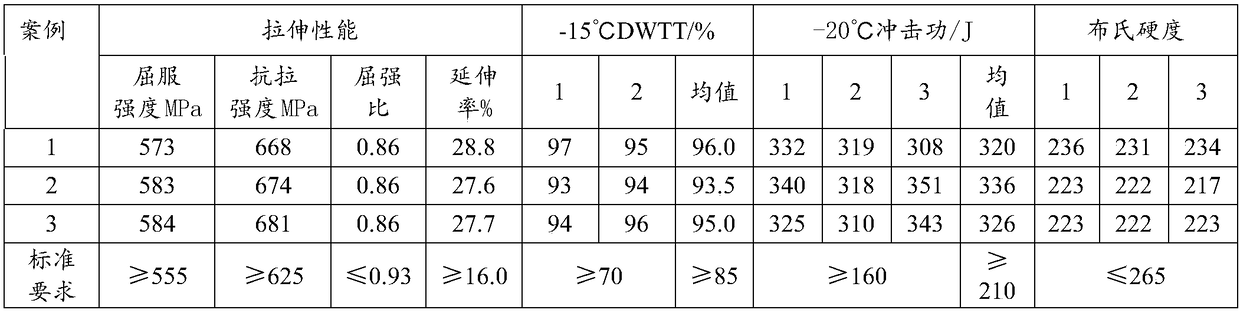

[0053] Table 1 shows the mechanical properties of the coils corresponding to Cases 1 to 3 of the present invention, and Table 2 shows the mechanical properties of steel pipes welded to the coils corresponding to Cases 1 to 3 of the present invention.

[0054] Table 1 Mechanical properties of steel plates

[0055]

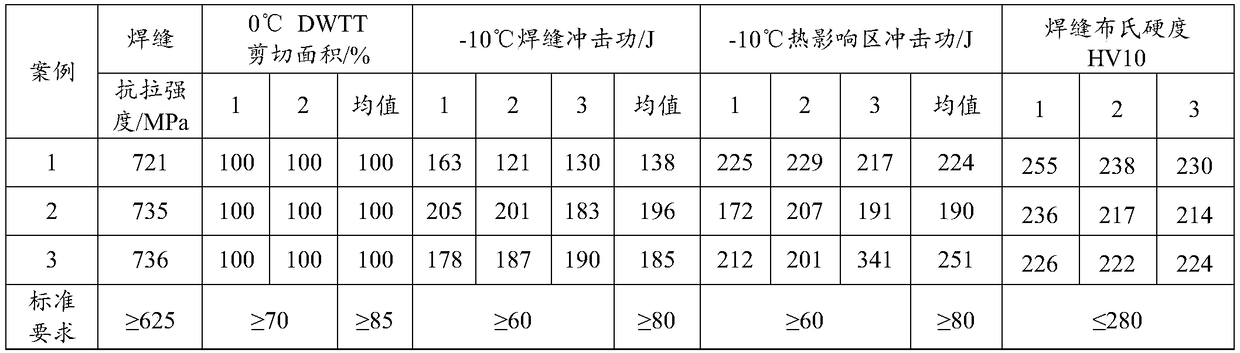

[0056] Table 2 Mechanical properties o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com