Method for computing ice melting time of power transmission lines in consideration of water films

A transmission line and time calculation technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of different heat conduction, poor practicability and calculation accuracy of the calculation model for melting ice of transmission wires, and no consideration of water film, etc., to achieve Accurate heat analysis, prevention of power grid ice disaster accidents, and improvement of the effect of ice melting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

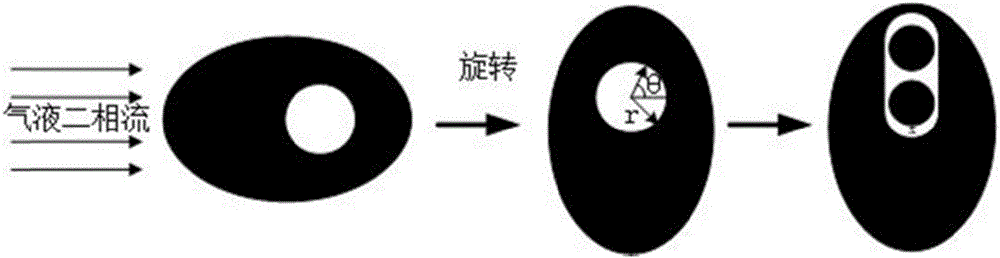

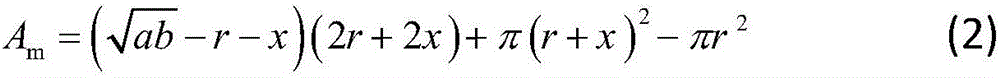

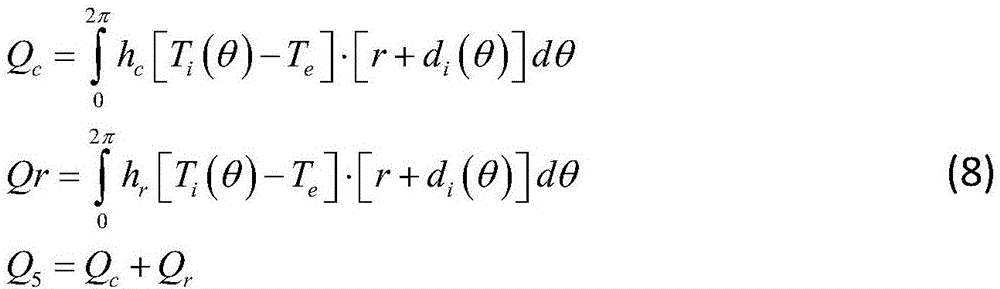

[0036] The invention provides a method for calculating the ice-melting time of a power transmission line considering the water film. Before the melting of ice begins, the wire and the ice layer are considered to be at the same temperature as the environment, and the wire is a good conductor of heat. During the melting process, the wire is regarded as an isothermal body. like figure 1 The icing formation and melting process are shown in four stages: the first stage, elliptical icing, under the influence of the wind, the ice on the windward side of the wire is more iced than the leeward side; the second stage, Melting ice produces a water film. After the ice melting begins, the inner surface of the ice layer that is in direct contact with the wire will be melted first after the temperature of the conductor rises to 0I, and a water film with a thickness of x will be produced; in the third stage, the ice layer rotates, under the action of gravity The icicle moves in the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com