Floor type ventilation cabinet

A fume hood, floor-standing technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, and separation of dispersed particles, can solve the problems of corrosion and damage to fume hood components, affecting the ventilation performance and service life of the fume hood, and achieves improved ventilation equipment, The effect of reducing the difficulty of opening and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

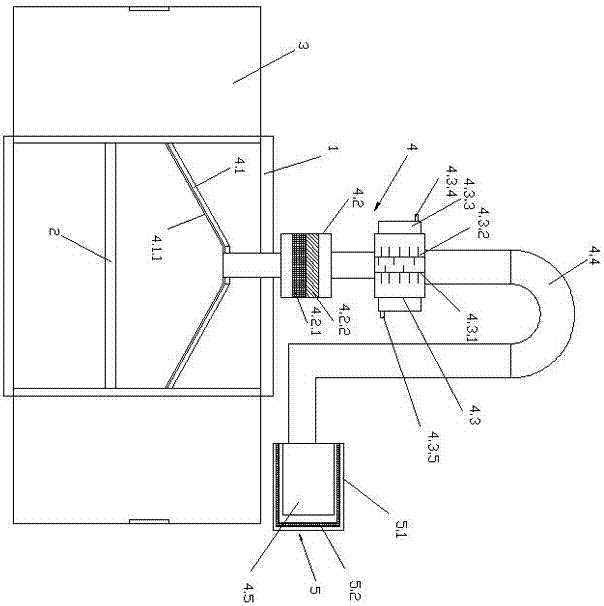

[0011] Embodiment 1: a floor-standing fume hood, comprising a cabinet body 1, a worktop 2 in the cabinet body 1, the cabinet door 3 in front of the cabinet body 1 is a pull-out double-door glass cabinet door, and the top of the cabinet body 1 is provided with waste gas collection Device 4, the waste gas collection device 4 includes a waste gas collection cover 4.1, a filter chamber 4.2 connected to the waste gas collection cover 4.1, a heat exchange chamber 4.3 connected to the filter chamber 4.2, the heat exchange chamber 4.3 is connected to the air extraction pipeline 4.4, and the air extraction pipeline 4.4 is connected to Induced fan 4.5. The filter chamber 4.2 includes a chamber body, a filter packing layer 4.2.1 in the chamber body, and an activated carbon layer 4.2.2. The heat exchange chamber 4.3 includes a chamber body, a central cylinder 4.3.1 is arranged in the chamber body, heat dissipation fins 4.3.2 are arranged on the inner and outer walls of the central cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com