Patents

Literature

30results about How to "Reduce the difficulty of opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

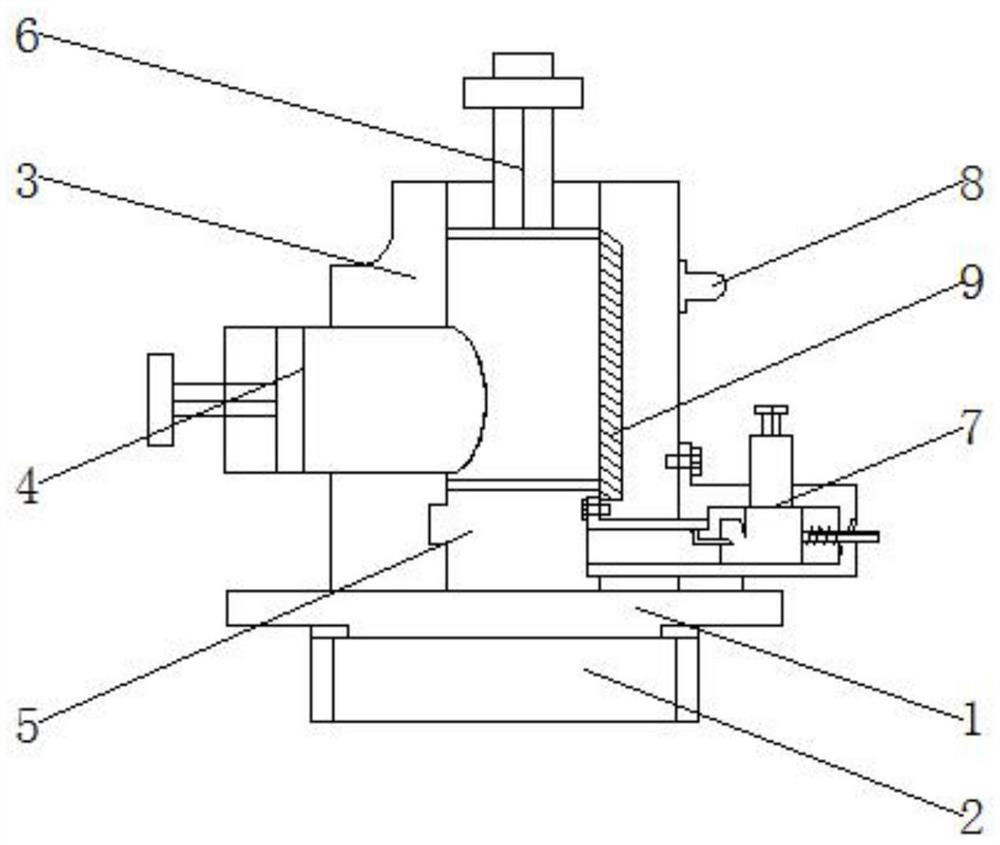

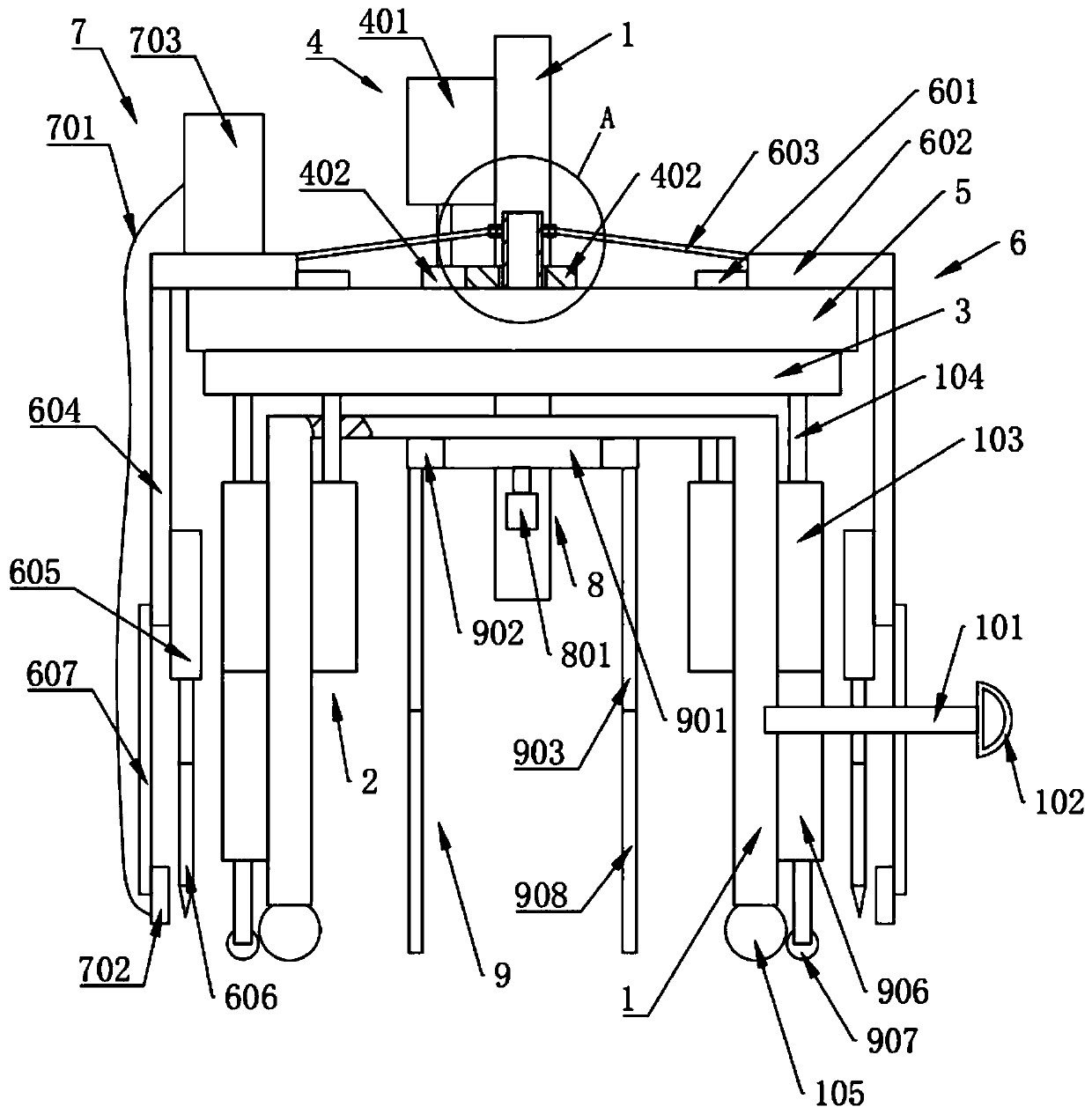

High-temperature high-pressure thermal fluid seepage simulation device

ActiveCN104897551AImprove sealingIncrease temperaturePreparing sample for investigationPermeability/surface area analysisEngineeringHigh pressure

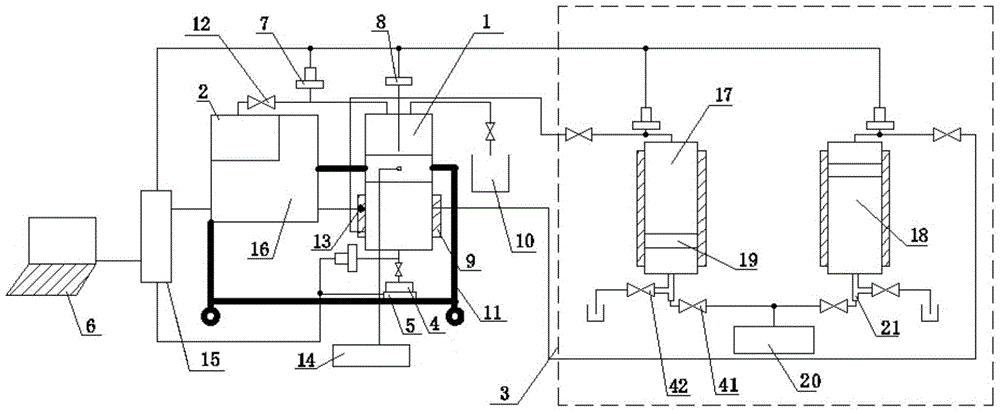

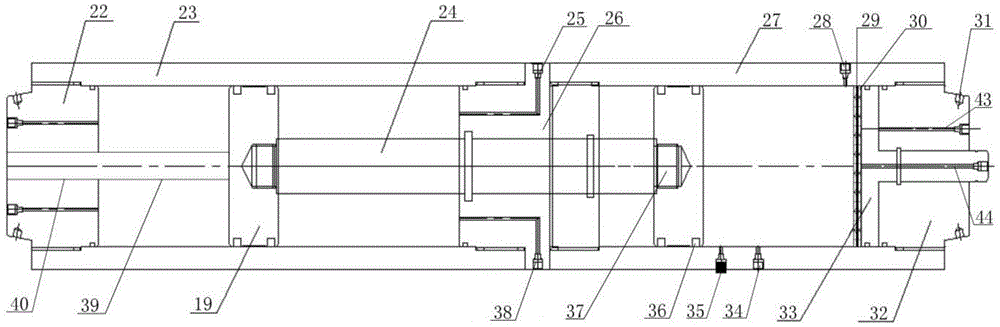

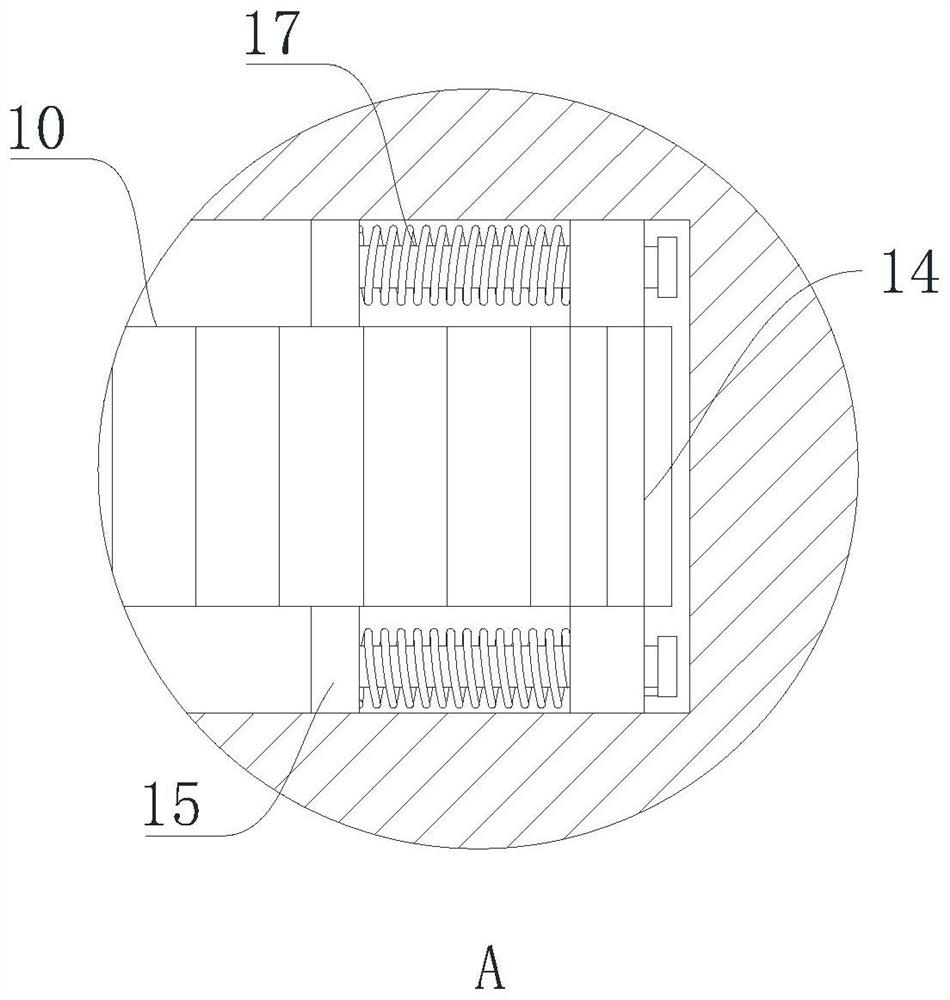

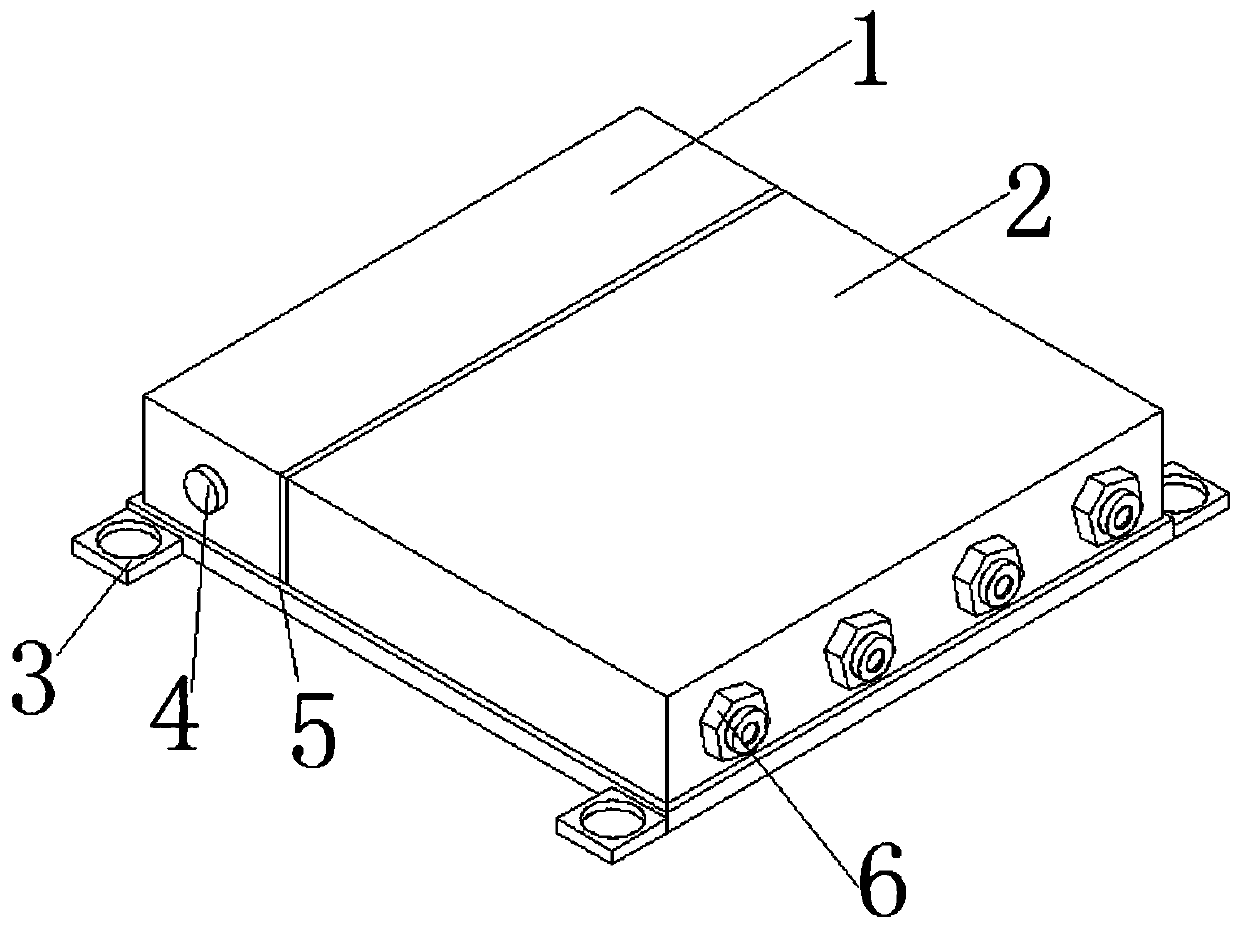

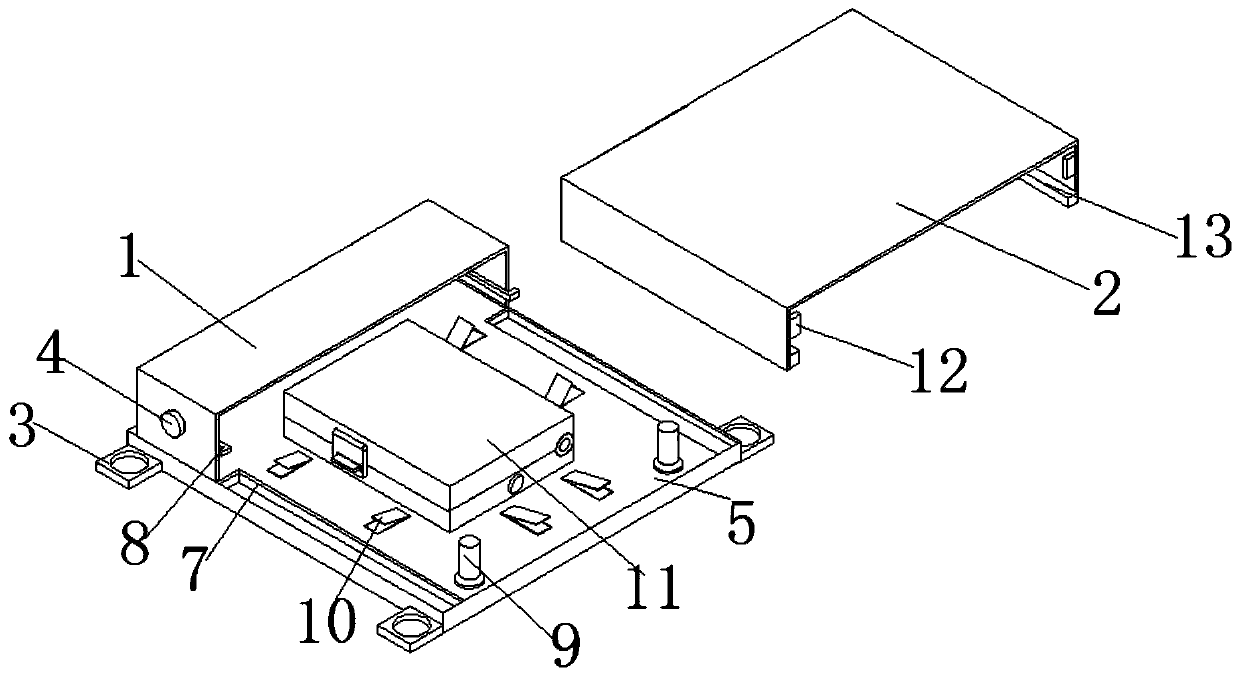

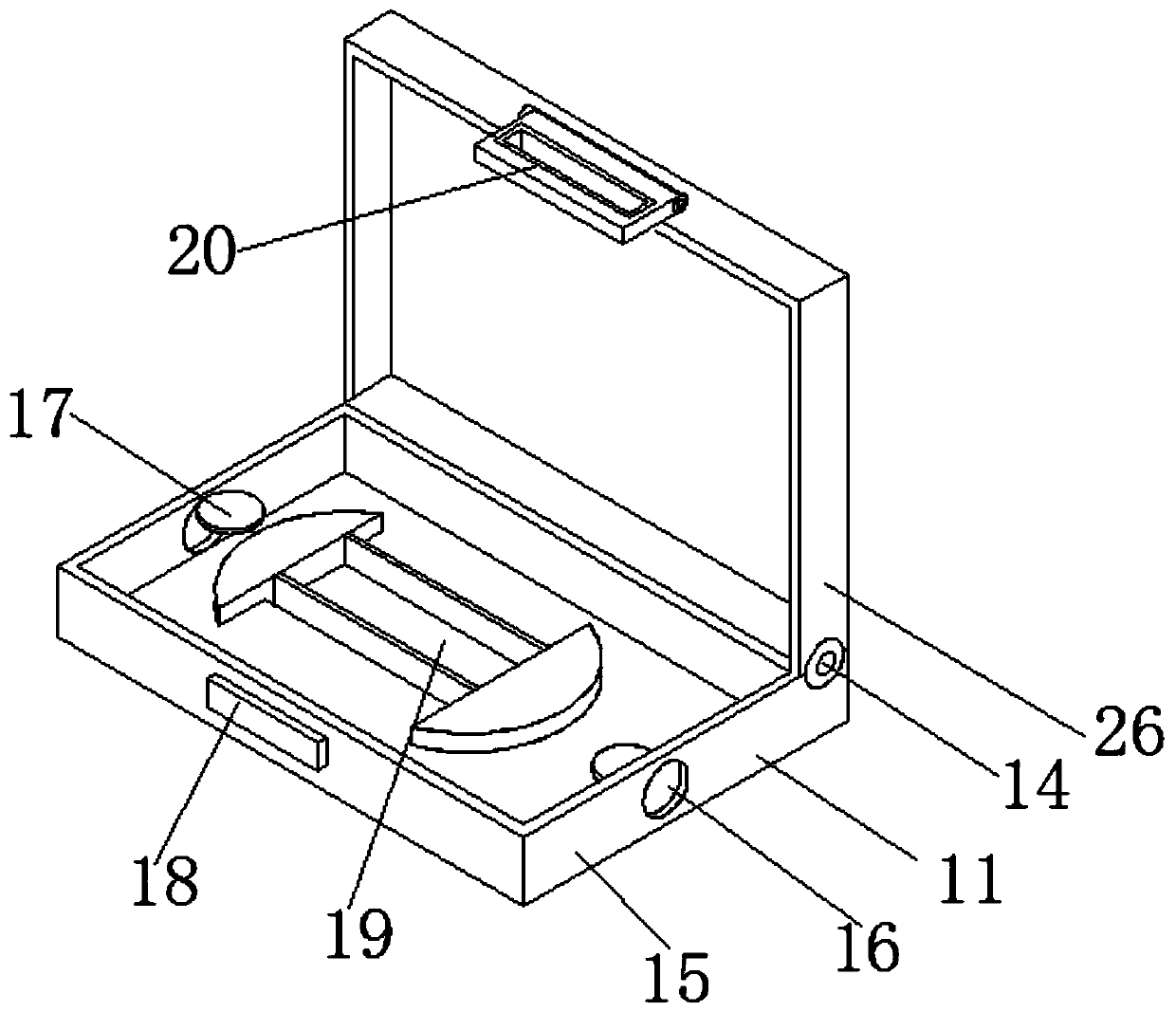

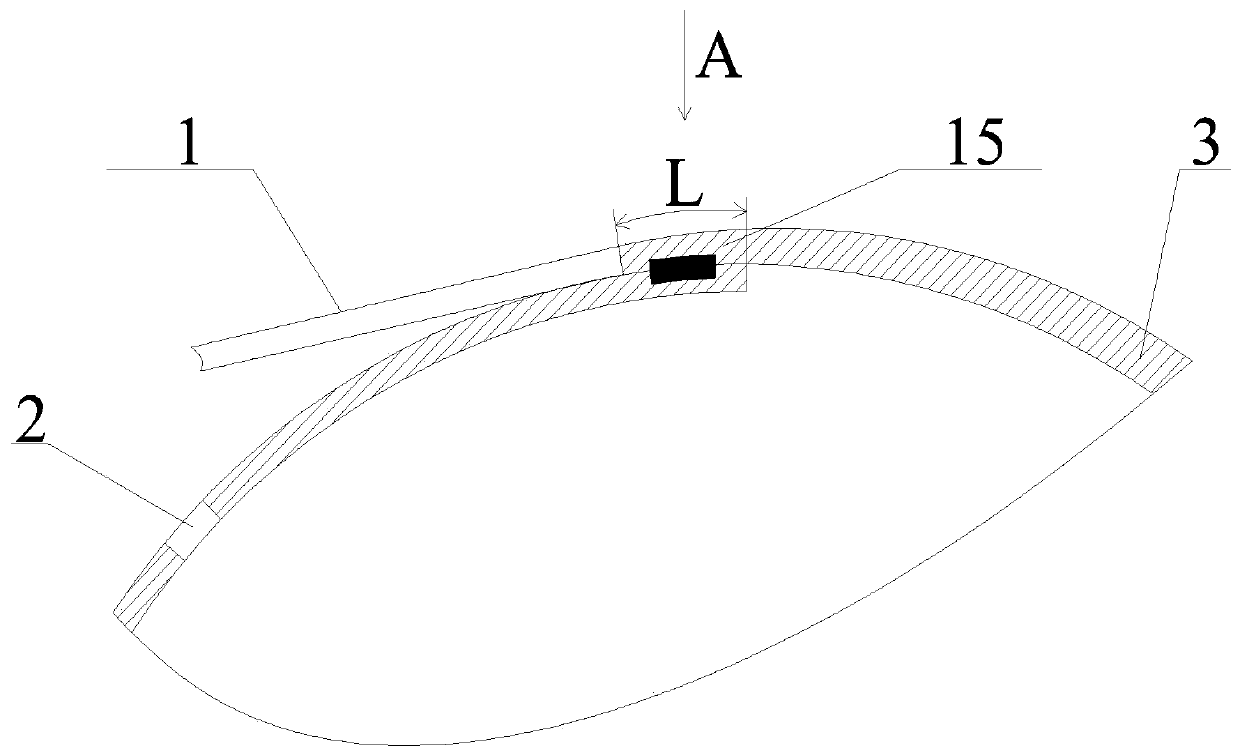

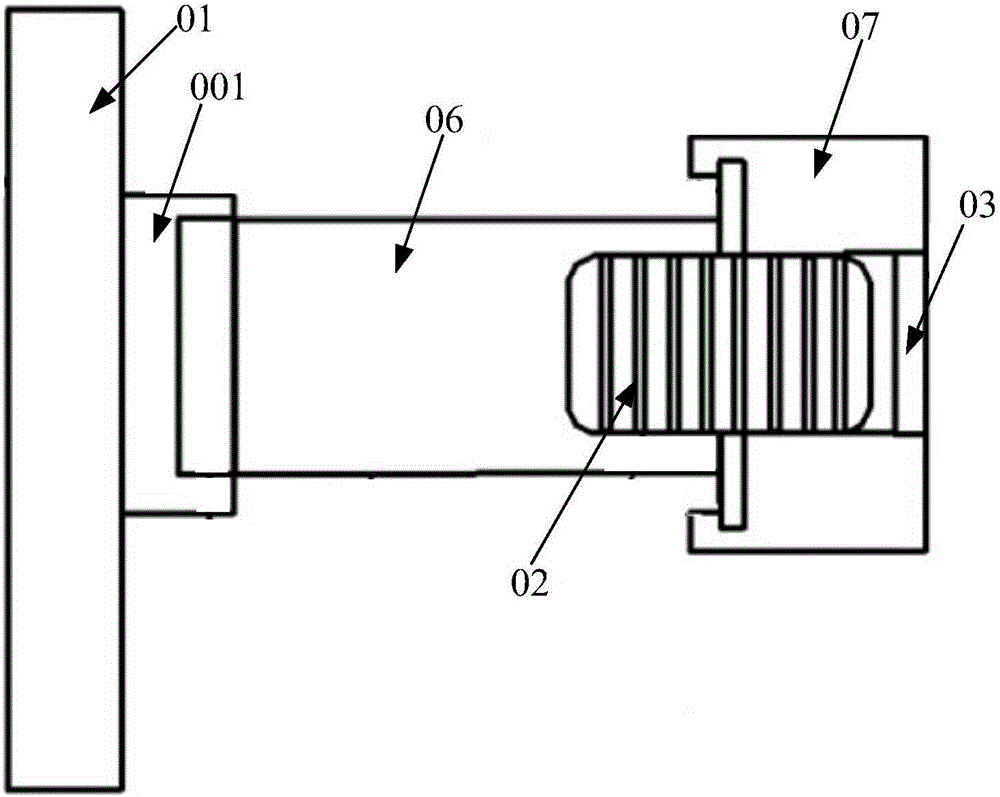

The invention provides a high-temperature high-pressure thermal fluid seepage simulation device. The high-temperature high-pressure thermal fluid seepage simulation device at least comprises a diagenesis reaction control simulation device, a high-temperature high-pressure pump and a thermal fluid circulation unit. The high-temperature high-pressure pump and the thermal fluid circulation unit are communicated with the diagenesis reaction control simulation device. The diagenesis reaction control simulation device comprises a front cavity, a rear cavity and a connection block connected with the front cavity and the rear cavity. A press rod penetrating the connection block is arranged in the connection block. Two ends of the press rod are connected with two pistons respectively. The ends of the front cavity and the rear cavity are sealed by a front press cap and a rear press cap respectively. The diagenesis reaction control simulation device is communicated with the thermal fluid circulation unit through liquid outlet holes and a liquid inlet hole which are formed in the front cavity, and is communicated with the high-temperature high-pressure pump through an oil inlet hole of the rear press cap. Intelligently-controlled thermostatic sleeves sleeve the diagenesis reaction control simulation device and a circulation container of the thermal fluid circulation unit respectively. The high-temperature high-pressure thermal fluid seepage simulation device can simulate high-temperature high-pressure thermal fluid seepage of the stratum physically, can analyze influence degrees of different influence factors on diagenesis time quantitatively and can be used for production of artificial cores.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

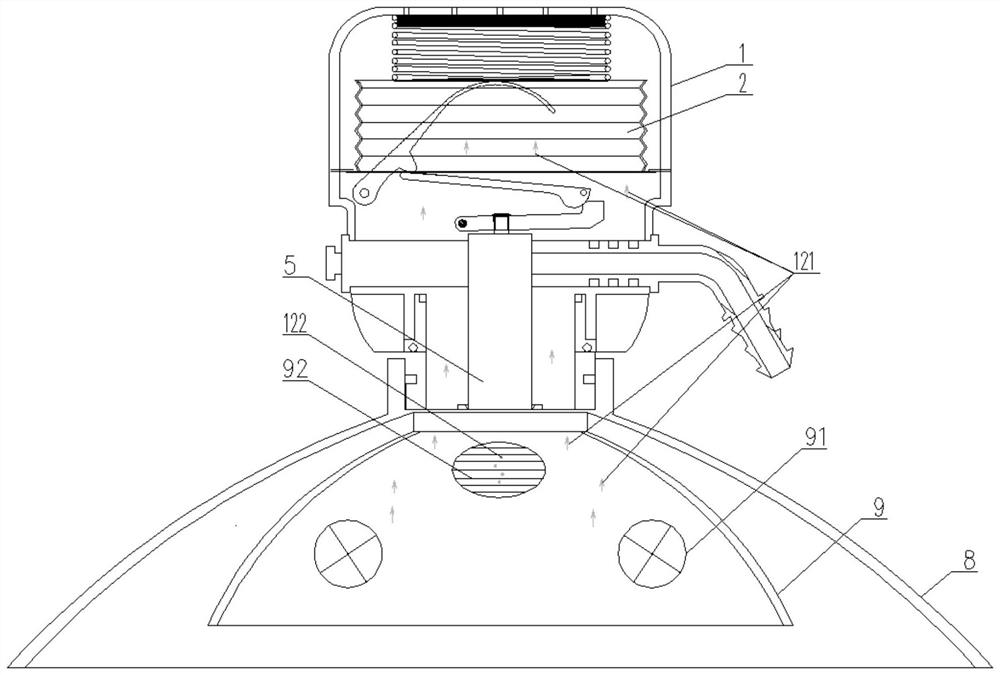

Tail door light-and-shadow assembly control method and device

PendingCN111691786AReduce the difficulty of openingImprove response timelinessPower-operated mechanismPower supplyAutomatic controlEngineering

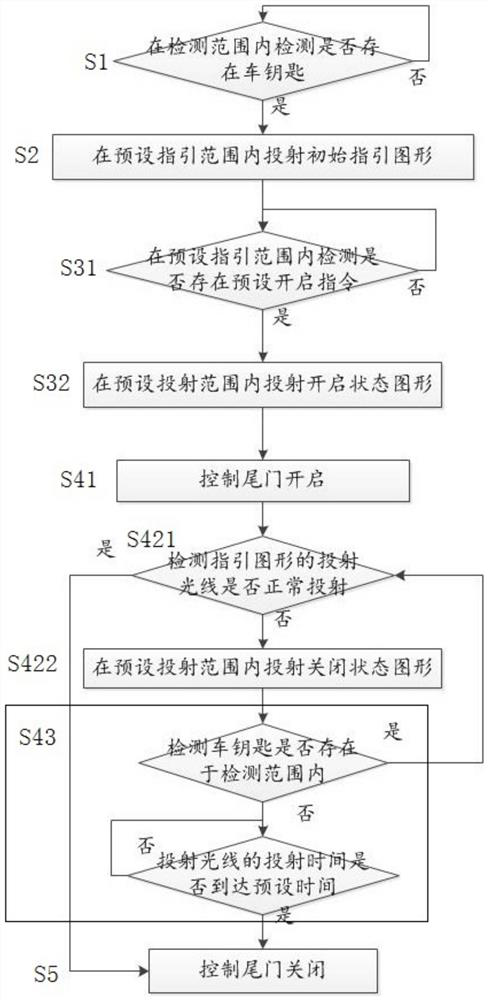

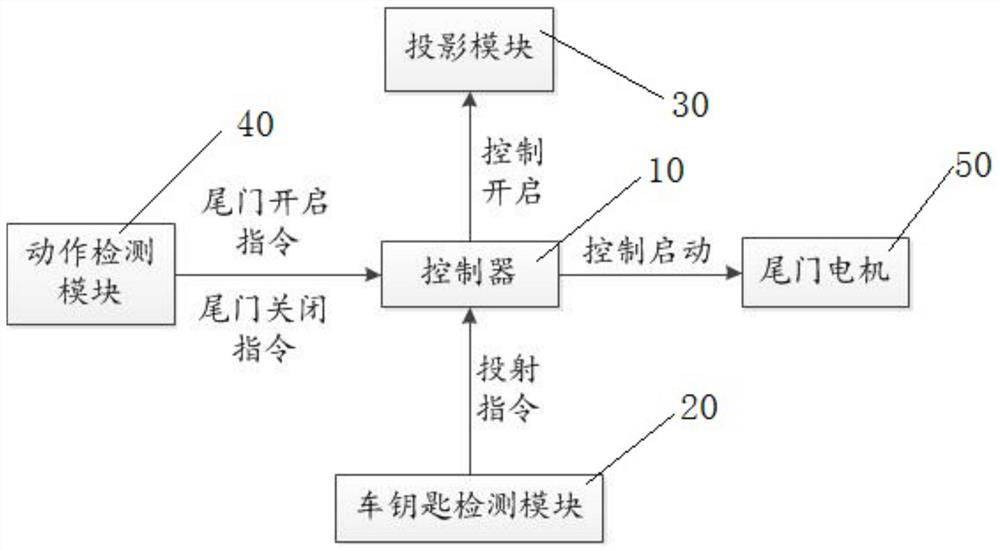

The invention relates to the technical field of automobile tail door automatic control, in particular to a tail door light-and-shadow assembly control method and device. The method comprises the following steps of S1, detecting whether an automobile key exists within a detection range, if yes, executing the next step, and if not, circularly executing the step; S2, projecting a guide graph in a preset guide range; S3, detecting whether a preset opening instruction exists in the preset guide range, if yes, executing the next step, and if not, not making a response; S4, controlling the tail doorto be opened, and continuously detecting whether a preset closing instruction exists in the preset guide range, if yes, executing the next step, and if not, not making a response; and S5, controllingthe tail door to be closed. According to the method, the problems that under an existing AR tail door automatic control technology, the detection range of a detection device does not conduct corresponding indication, the opening difficulty of an automobile tail door is increased, and the opening response timeliness of the automobile tail door is poor are solved.

Owner:富晟(广东)汽车电子有限公司

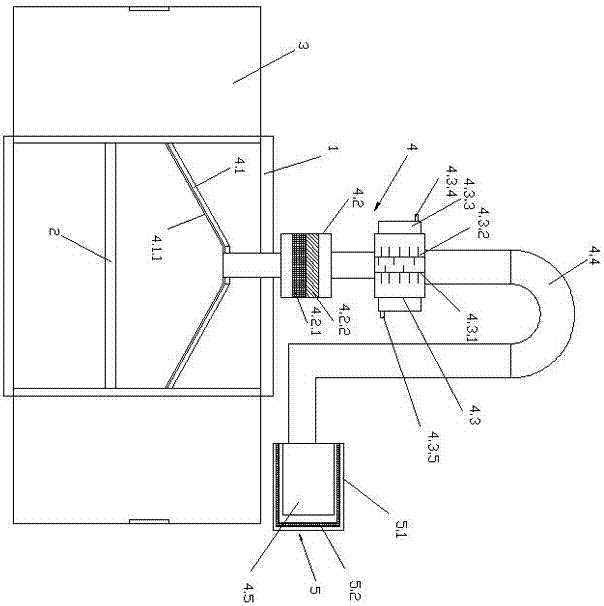

Floor type ventilation cabinet

PendingCN107185943AReduce the difficulty of openingExtended service lifeDispersed particle separationDirt cleaningEngineeringEnvironmental engineering

The invention discloses a floor type ventilation cabinet. The floor type ventilation cabinet comprises a cabinet body and a working table in the cabinet body; a front cabinet door of the cabinet body is an outward-pulling type double-door glass cabinet door; a waste gas collecting device is arranged at the top end of the cabinet body; the waste gas collecting device comprises a waste gas collecting cover, a filter bin and a heat exchange bin, wherein the filter bin is connected to the waste gas collecting cover, and the heat exchange bin is connected to the filter bin; the heat exchange bin is connected to an air suction pipeline; and the air suction pipeline is connected to an induced draft fan. The floor type ventilation cabinet is simple in structure, capable of effectively absorbing and filtering harmful gas and convenient to replace and maintain.

Owner:派尔实验装备有限公司

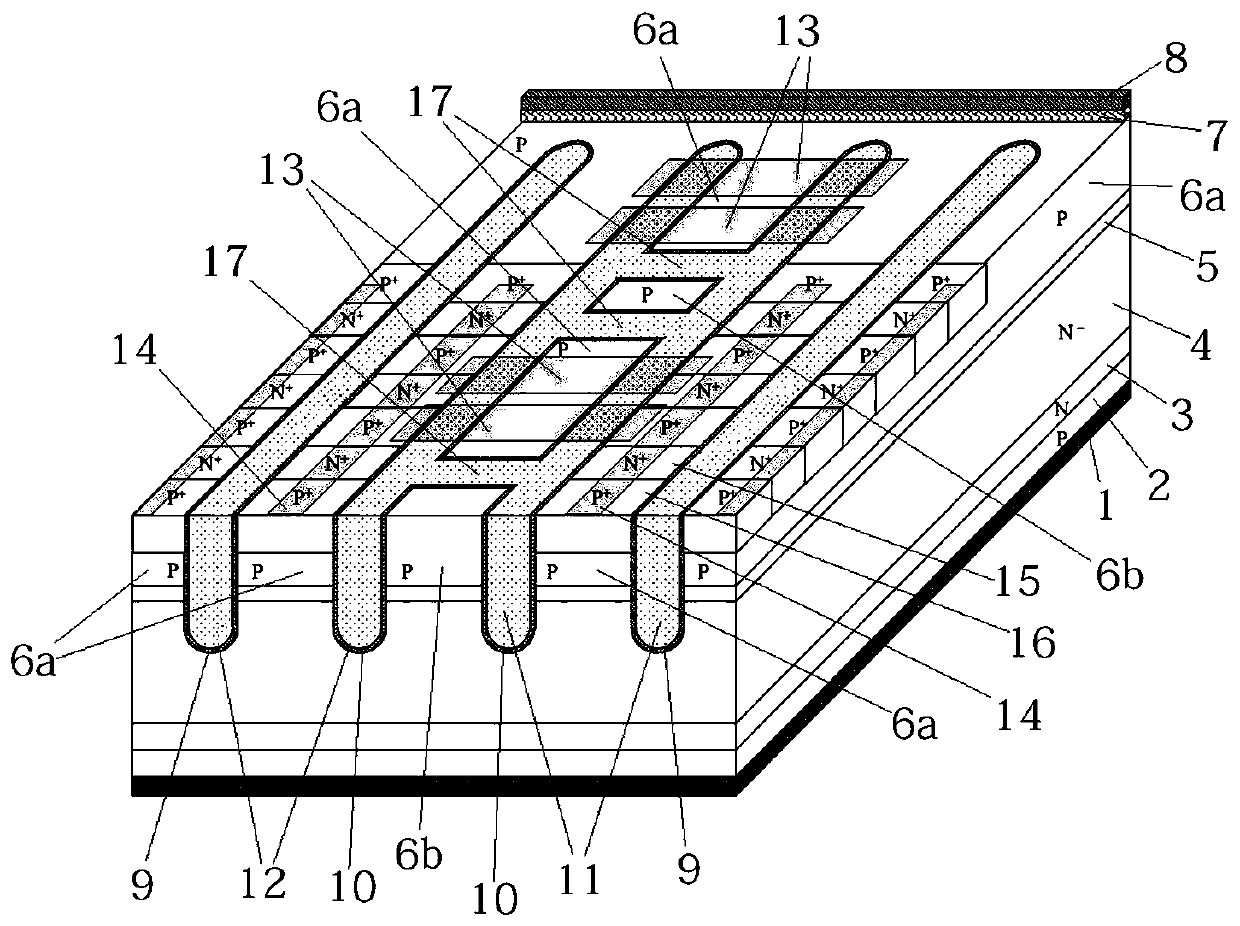

IGBT device structure

ActiveCN110416283AReduce on-state voltage dropIncrease current densitySemiconductor devicesPower semiconductor deviceCharge carrier

The invention discloses an IGBT device structure in the technical field of power semiconductor devices, aims to solve the technical problems that in the prior art, when an IGBT device adopting a virtual trench gate structure is turned off, the on-state voltage drop of a device cannot be reduced due to the fact that the concentration of carriers accumulated below a trench region is too low, and thedifficulty of opening a contact window from the middle of virtual trench polycrystalline silicon is increased as the width of a virtual trench is designed to be narrower and narrower. The top surfaceof the device is downwards provided with a plurality of active trenches and virtual trench regions which are distributed at intervals. Each virtual trench region comprises at least one bridge and a plurality of virtual trenches connected through the bridge, and a dielectric layer is provided with a contact window; and P-type well regions comprise a first P-type well region connected with the metal emitter through the contact window and a second P-type well region in a potential floating state.

Owner:NARI TECH CO LTD

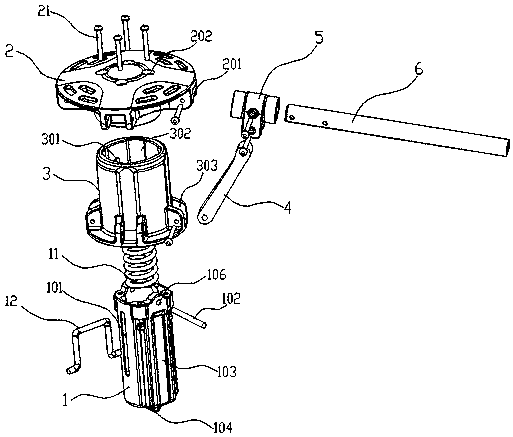

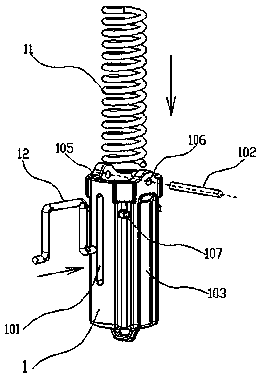

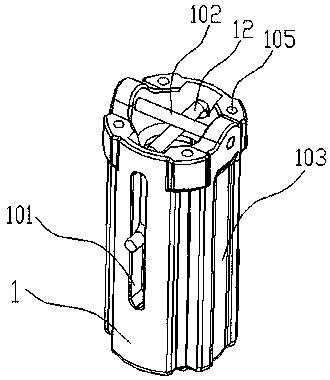

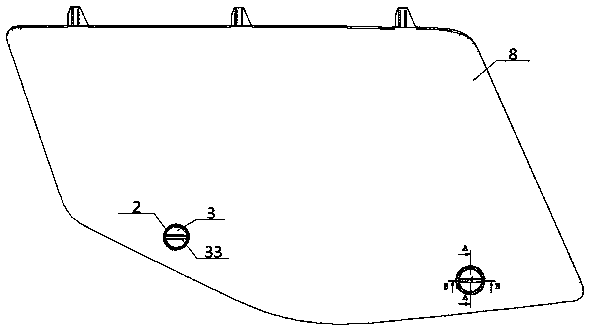

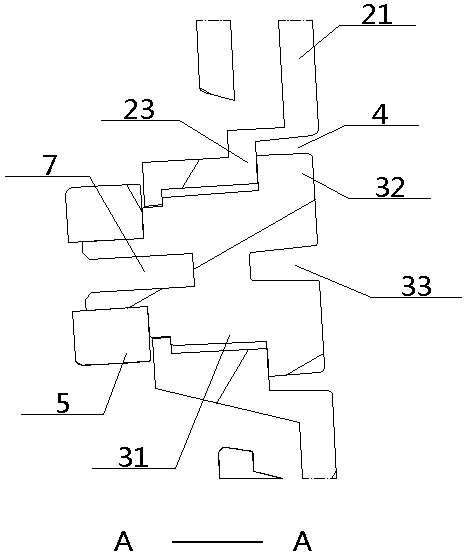

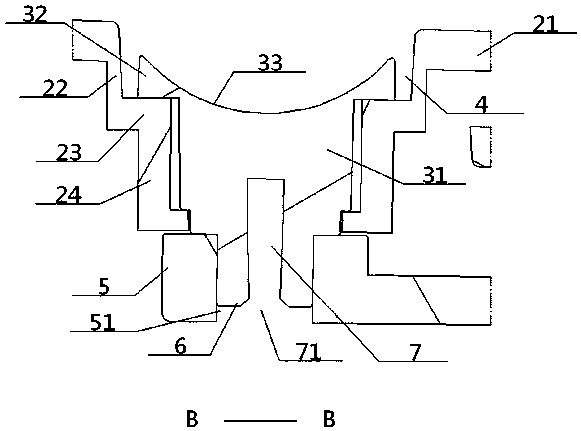

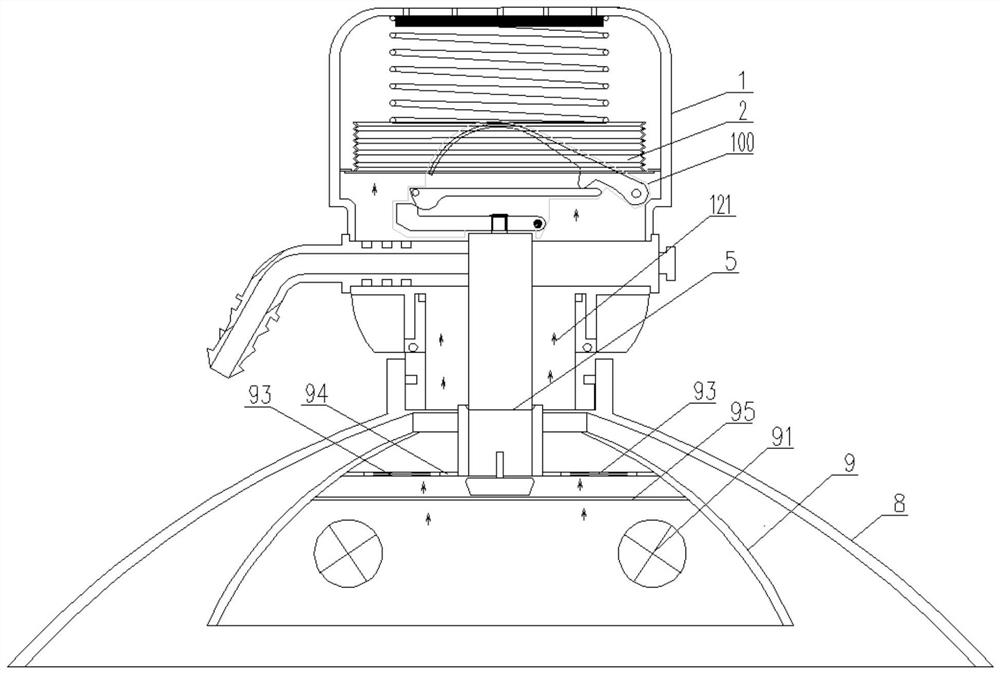

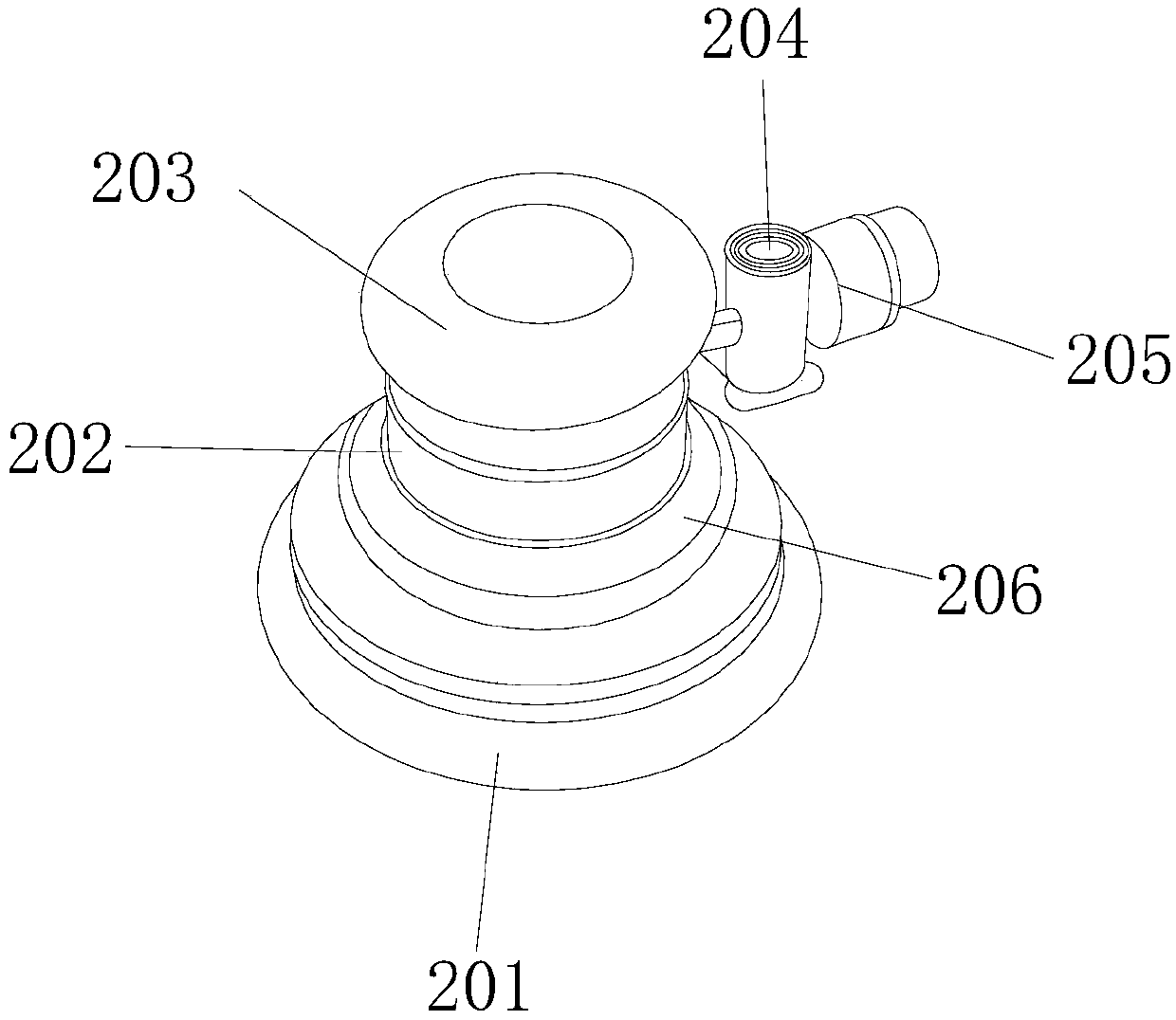

Power-assisted umbrella head for tent

PendingCN107916827ALow costReduce the difficulty of openingTents/canopiesDistractionAxial compression

The invention relates to a power-assisted umbrella head for a tent. The power-assisted umbrella head for the tent comprises an upper umbrella head and a lower umbrella head, wherein the lower umbrellahead can be moved axially relative to the upper umbrella head, a tent frame rod is pivotally connected to the upper umbrella head through a connecting piece, one end of a tent support rod is hinged to the connecting piece, and the other end of the tent support rod is hinged to the lower umbrella head to form a triangular support structure. The power-assisted umbrella head for the tent also comprises an independent booster assembly. The booster assembly comprises a sleeve, an elastic member and a clip member, wherein the elastic member is pre-tensioned by the clip member and enclosed in the sleeve, the sleeve is detachably and fixedly connected to the upper umbrella head, the lower umbrella head slidingly sleeves the sleeve, and the lower umbrella head is compressed axially by the elasticmember driven by the clip member. The umbrella head adopts an independent spring sleeve to independently carry the powerful booster assembly, has modularity features, can be independently assembled, integrally assembled and modularly disassembled and replaced, simplifies installation and replacement procedures, reduces difficulty, guarantees installation accuracy and can be used as a common core component; the booster assembly head assists the tent in a process of opening the tent.

Owner:福州昇立莱旅游制品有限公司

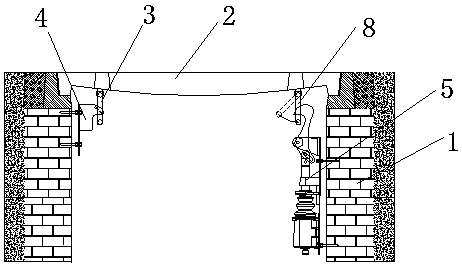

Well-wall-mounted manhole cover intelligent monitoring lock device

PendingCN108532638AAvoid holesAvoid damageArtificial islandsNon-mechanical controlsGyroscopeDynamic monitoring

The invention discloses a well-wall-mounted manhole cover intelligent monitoring lock device. The well-wall-mounted manhole cover intelligent monitoring lock device comprises a well wall, a manhole cover, a left elastic folding lock catch, a right elastic folding lock catch, a fixed manhole cover lock and an intelligent manhole cover lock. The left elastic folding lock catch and the right elasticfolding lock catch are installed at the bottom of the manhole cover, and the fixed manhole cover lock and the intelligent manhole cover lock which are separately matched with the left elastic foldinglock catch and the right elastic folding lock catch are separately mounted on the well wall. A well-wall-mounted manhole cover displacement dynamic monitoring probe is adopted to monitor the dip angledisplacement of the manhole cover in real time, and can be automatically folded; and the method of adopting magnetic induction to form a switching value is adopted to replace a commonly used gyroscope and inclinometer, and power consumption is greatly saved.

Owner:湖南天联城市数控有限公司

Vehicle door opening device

Owner:CHERY AUTOMOBILE CO LTD

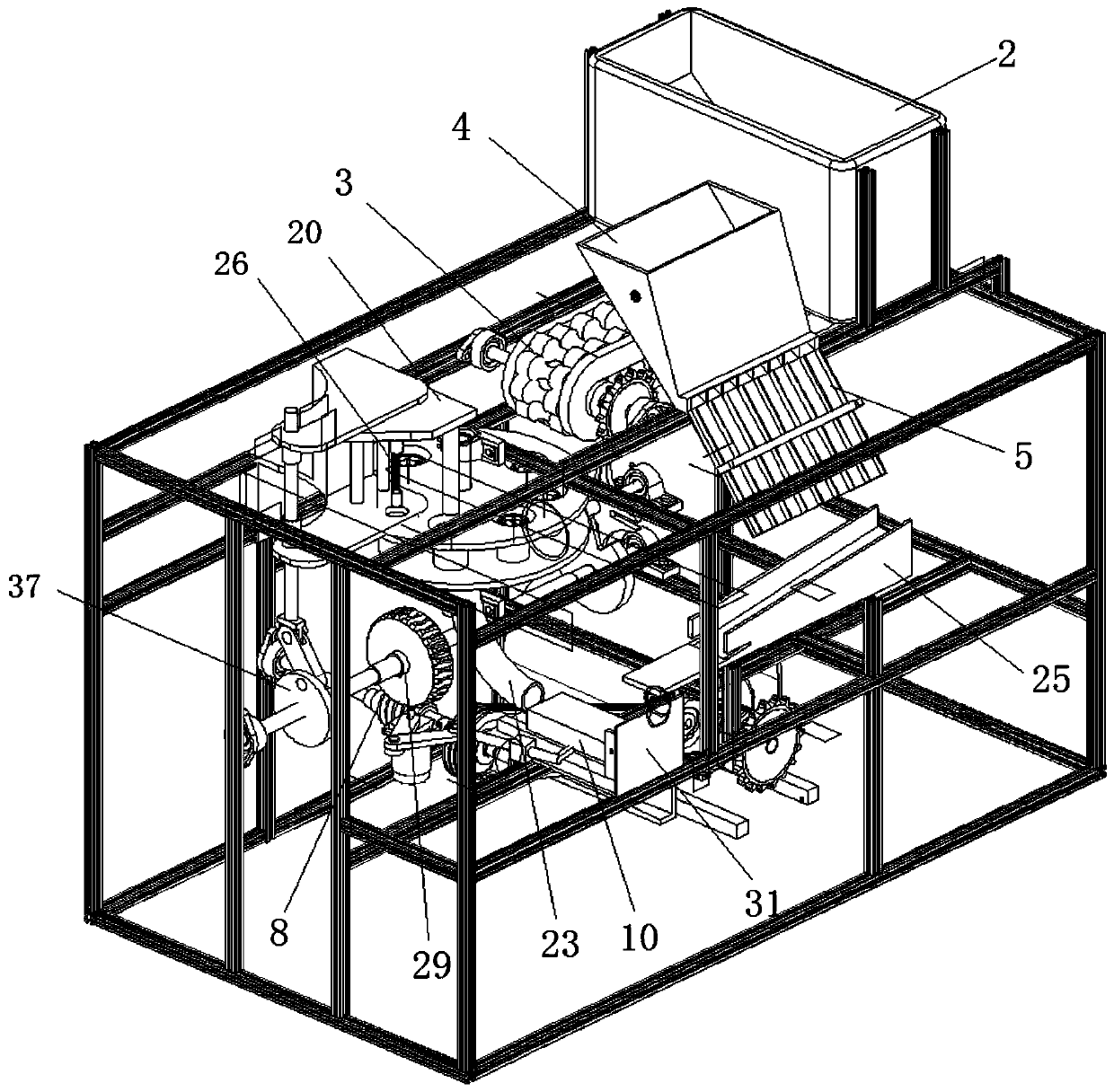

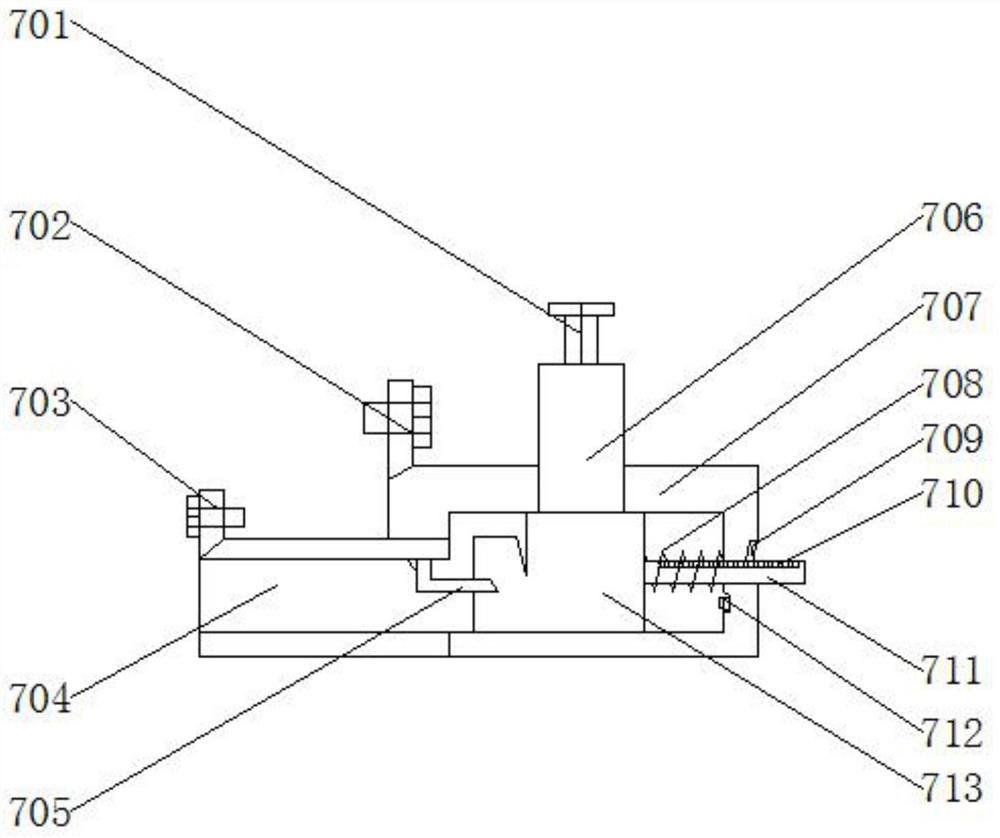

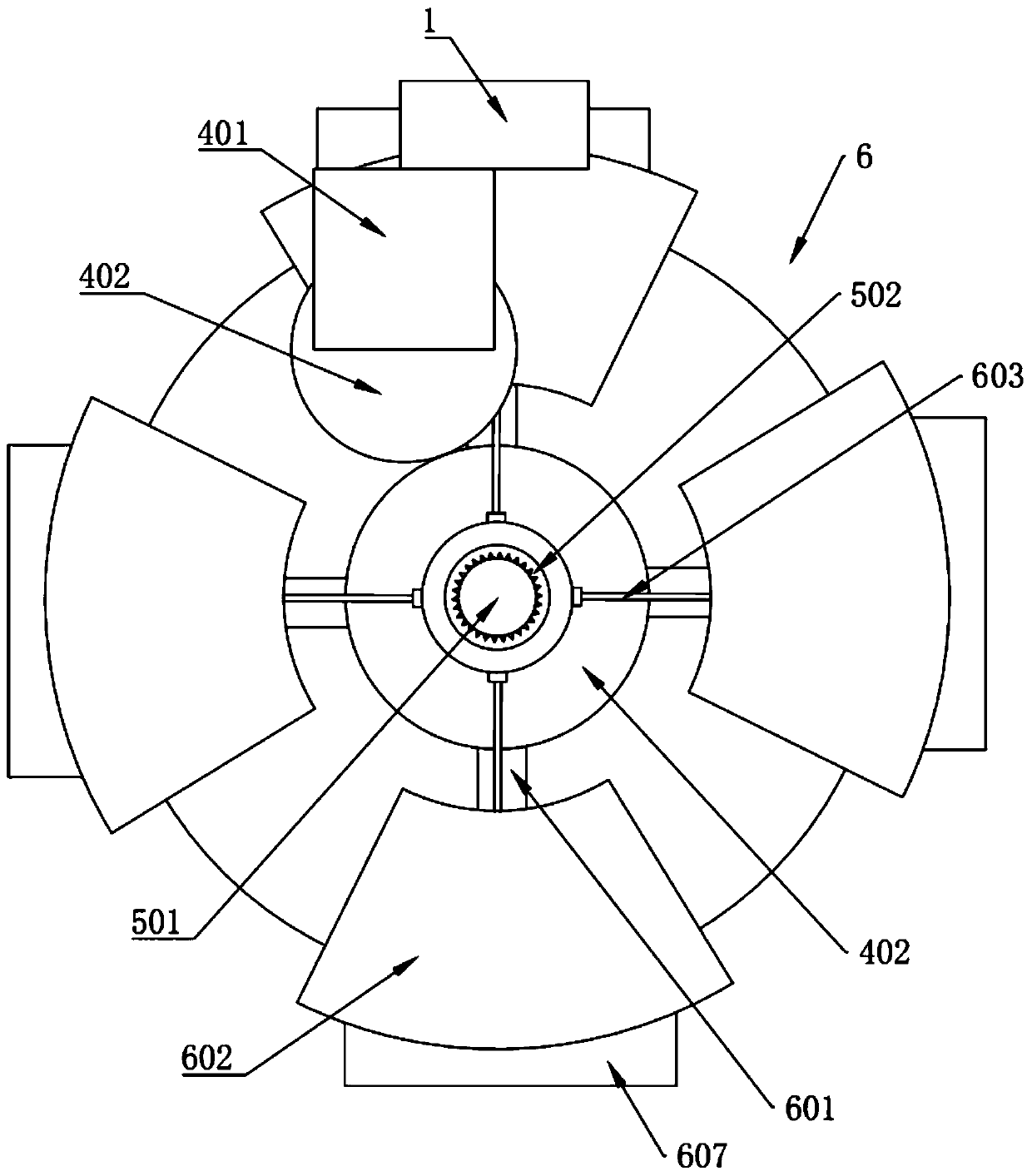

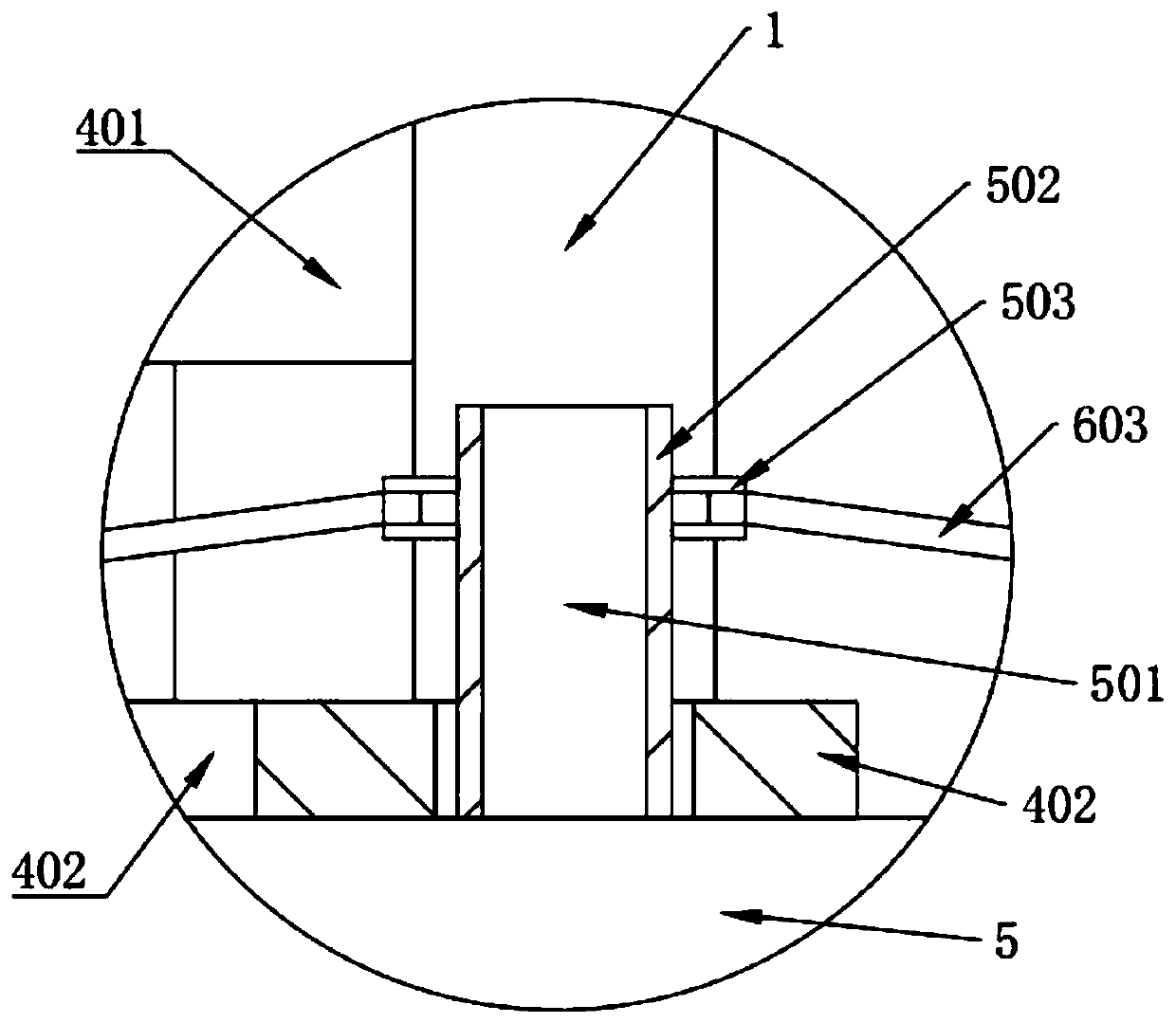

Manufacture machine and method for red jujube with walnut kernel

InactiveCN110584057ASimple structureImprove enucleation efficiencyFruit stoningFood shapingZiziphus jujubaManufacturing engineering

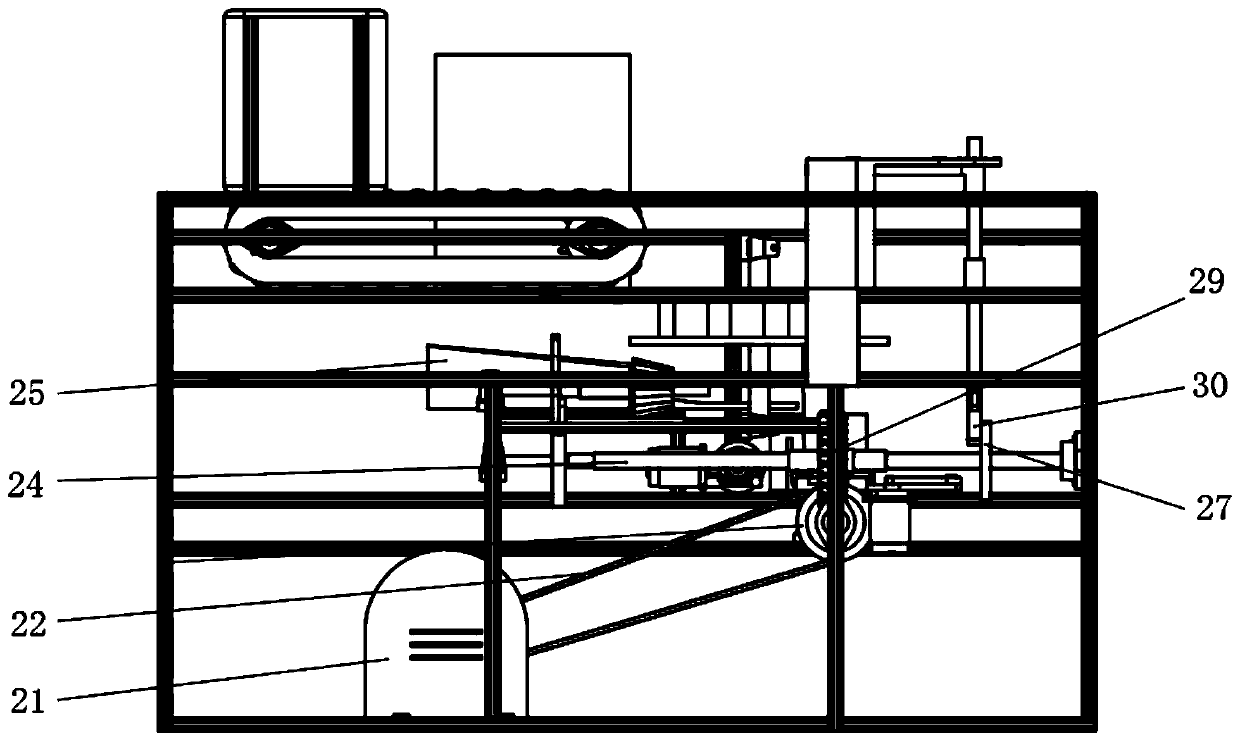

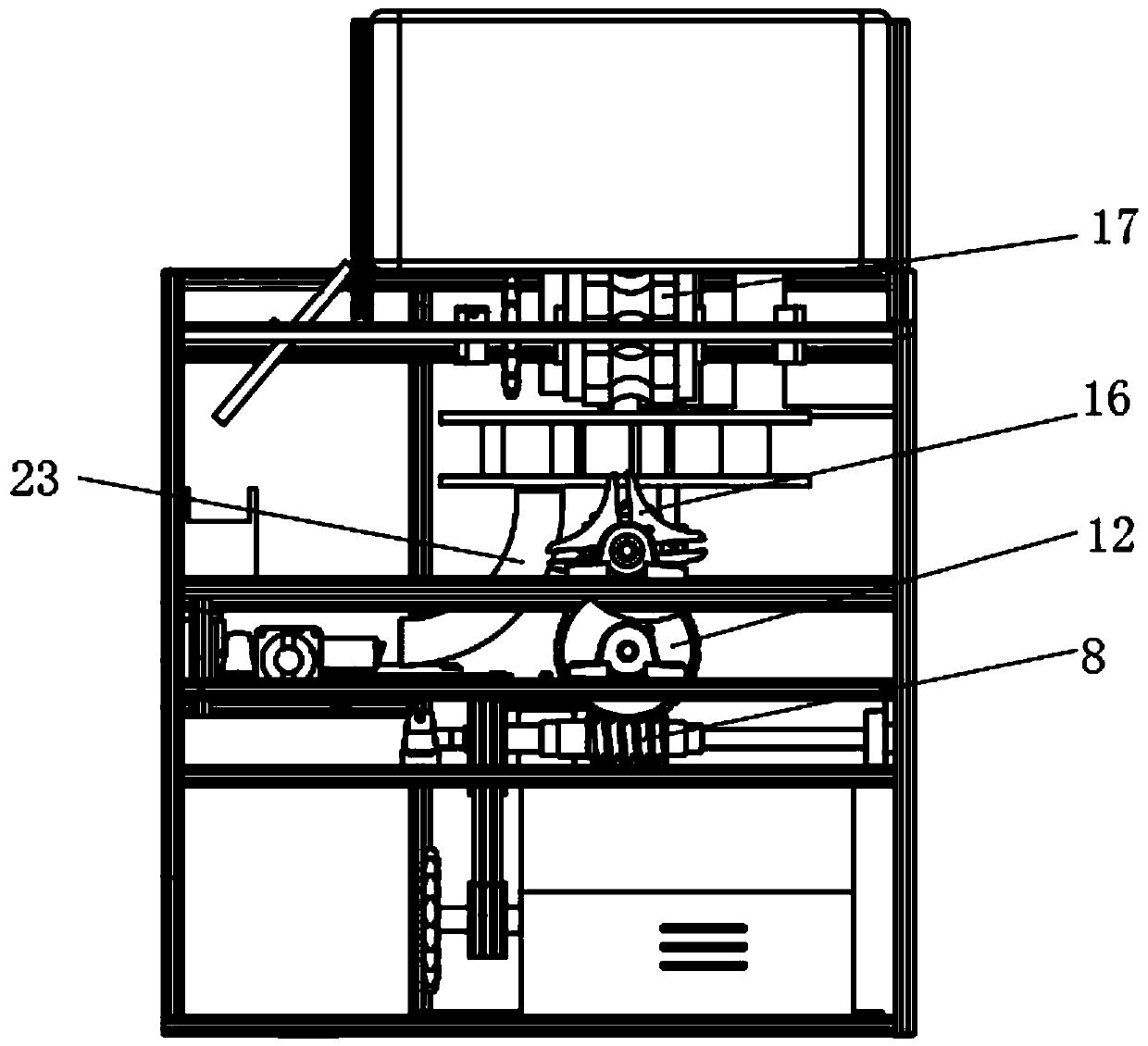

The invention discloses a manufacture machine and method for a red jujube with a walnut kernel, and solves the problems of low production efficiency and high cost of the red jujube with the walnut kernel in the prior art. One series of work, including the pit removal and the opening of the red jujube and the assembling of the red jujube and the walnut kernel, for manufacturing the red jujube withthe walnut kernel is finished, and efficiency is high. The technical scheme of the invention is that the manufacture machine comprises a red jujube adding device, a walnut kernel adding device, a redjujube pit removal device, a red jujube opening device and a finished product assembling device, wherein the red jujube adding device comprises a red jujube adding box and a spacing transmission beltinstalled below the red jujube adding box; the walnut kernel adding device comprises a walnut kernel adding box and an anti-stacking plate connected to the tail end of the walnut kernel adding box; the red jujube pit removal device comprises a pit removal round disk and a pit removal device installed above the pit removal round disk; the red jujube opening device comprises an opening groove structure, wherein one side of the opening groove structure is provided with a pushing mechanism, and an opening cutter is installed above the opening groove structure; and the finished product assembling device comprises a fixed clamping element and a movable clamping element, wherein the movable clamping element can carry out out reciprocating motion to be near or be far away from the fixed clamping element.

Owner:QINGDAO UNIV

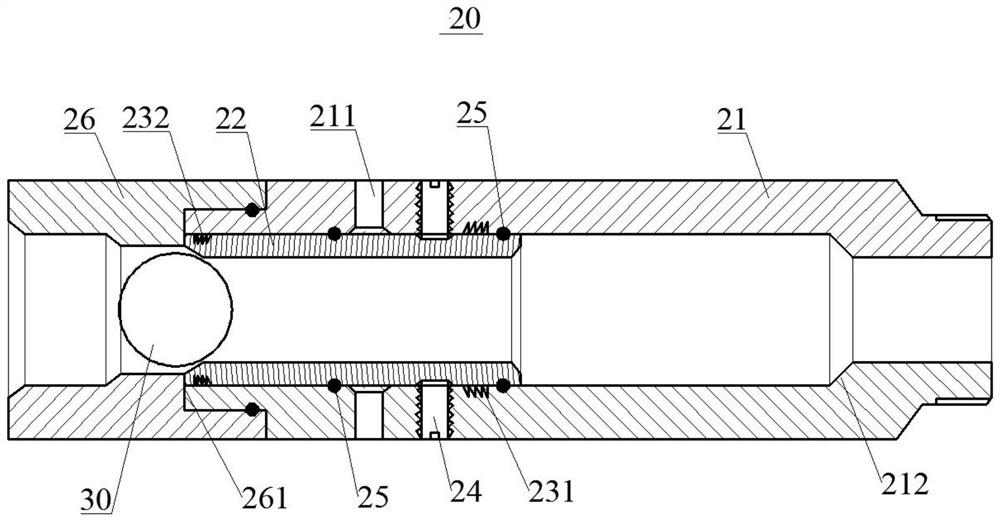

Differential pressure sliding sleeve and oil-gas well fracturing construction method

PendingCN113323627AReduce the difficulty of openingReduce construction riskFluid removalWell/borehole valve arrangementsWorking fluidEngineering

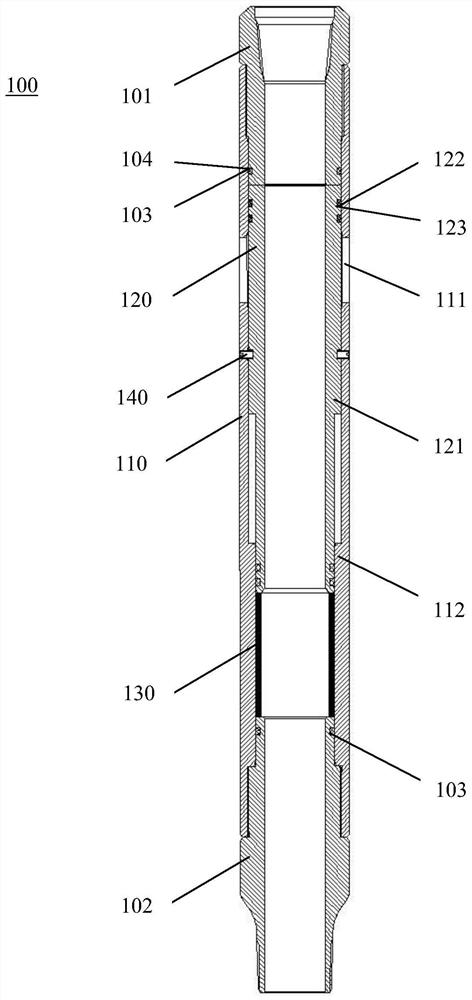

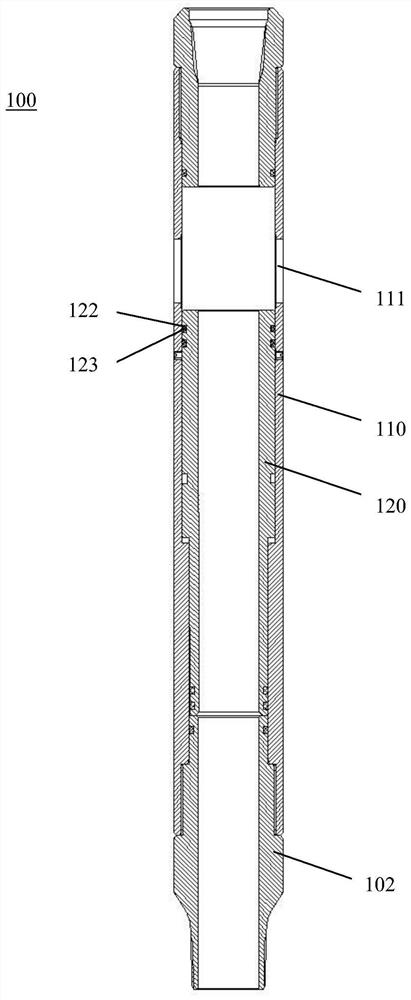

The invention provides a differential pressure sliding sleeve. The differential pressure sliding sleeve comprises an outer cylinder, an upper connector, a lower connector, an inner cylinder and a bearing ring, wherein a plurality of flow guide holes are formed in the side wall of the outer cylinder; the upper connector and the lower connector are arranged at the two ends of the outer cylinder and used for being connected with an underground pipe column respectively; the inner cylinder is arranged in the outer cylinder and used for sealing the flow guide holes; the bearing ring is arranged between the lower connector and the inner cylinder and can be dissolved under the action of working fluid; and the area of the upper end face of the inner cylinder is set to be larger than that of the lower end face of the inner cylinder so that the working fluid can form a pressure difference between the axial end faces of the inner cylinder to provide downward pressure for the inner cylinder, and then the inner cylinder can move downwards under the action of the pressure after the bearing ring is dissolved to open the flow guide holes. The invention further provides an oil-gas well fracturing construction method using the differential pressure sliding sleeve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Simple opening structure for fuse box cover and using method thereof

The invention discloses a simple opening structure for fuse box cover. The simple opening structure for fuse box cover comprises a lock groove and a lock pin positioned inside the lock groove, whereinthe lock pin comprises a pin roll and a pin head; the bottom surface of the pin head is vertically connected with the outer end of the pin roll; the inner end of the pin roll is positioned inside thelock groove; the diameter of the pin head is greater than that of the pin roll; an open hole is formed in the middle part of the pin head; the width of the open hole is greater than the thickness ofa coin; the cross section of the open hole is of a circular arc structure, and the radian of the circular arc is one quarter of a circle to three quarters of a circle. Through the design, the openingdifficult is relatively low, and the restriction of application is relatively low.

Owner:DONGFENG COMML VEHICLE CO LTD

Using method of air respirator

ActiveCN114073830AAvoid wastingMaximize utilizationFire rescueRespiratory apparatusGas cylinderFresh air

The invention provides a using method of an air respirator. The using method comprises the steps that a user wears the air respirator; in the expiration process, a gas firstly expired by the user every time is introduced into the gas storage chamber to be stored, and the gas later expired by the user every time is exhausted to the atmospheric environment; the first exhaled gas refers to the gas inhaled by the user last time and stored in the trachea and / or oral cavity of the user, and the later exhaled gas refers to the gas inhaled by the user last time and subjected to gas exchange through the lung of the user; and in the inspiration process, the gas exhaled by the user last time and stored in the gas storage chamber is inhaled into the lung for reuse. After the scheme is adopted, the effective use time of an existing common air supply bottle filled with fresh air can be prolonged, and the comfort in the use process is good.

Owner:重庆诗曼格科技有限公司

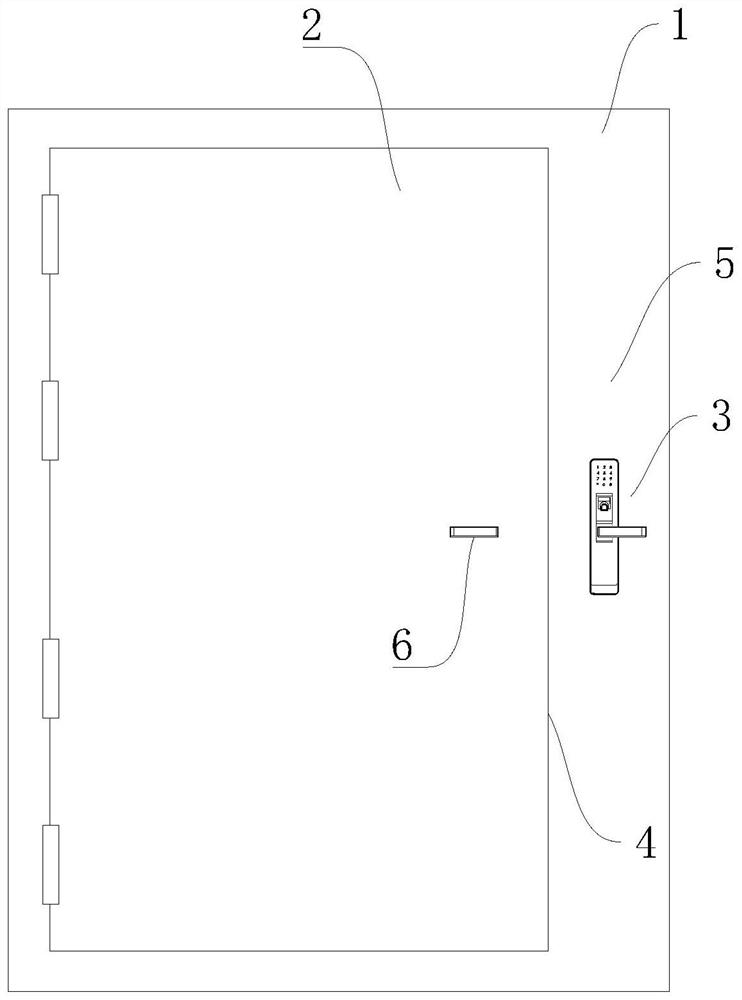

Door and lock with novel structure and mounting mode

PendingCN114837519AFlexible useEasy to useNon-mechanical controlsWindow/door framesElectrical batteryStructural engineering

The invention provides a door and lock of a novel structure and an installation mode, and relates to the technical field of doors and locks. Comprising a door frame and a door plate, an opening-closing end is formed at the end, away from the connecting position of the door plate and the door frame, of the door plate, when the door frame and the door plate are closed, a door lock mounting part is formed on the side, corresponding to the opening-closing end, of the door frame, and the door lock mounting part is wide enough to mount any door lock body; through the connecting structure and position of the door plate, the door frame and the door lock, the phenomenon that the electric quantity of a built-in battery is exhausted is avoided, the battery does not need to be replaced, the overall use is more flexible and durable, and the overall practicability is improved; and when the door lock main body needing power supply is installed, the cavity for wiring or wiring is formed in the corresponding position of the door frame, so that the opening difficulty of the cavity is greatly reduced, the installation intensity of installation personnel is reduced, and the whole equipment is more convenient and flexible to install and use in the actual use process.

Owner:武汉华夏理工学院

Fiber optic junction box with controllable incoming lines

ActiveCN109212699BNot intertwinedAchieve secondary fixationFibre mechanical structuresStructural engineeringJunction box

Owner:湖南率为控制科技有限公司

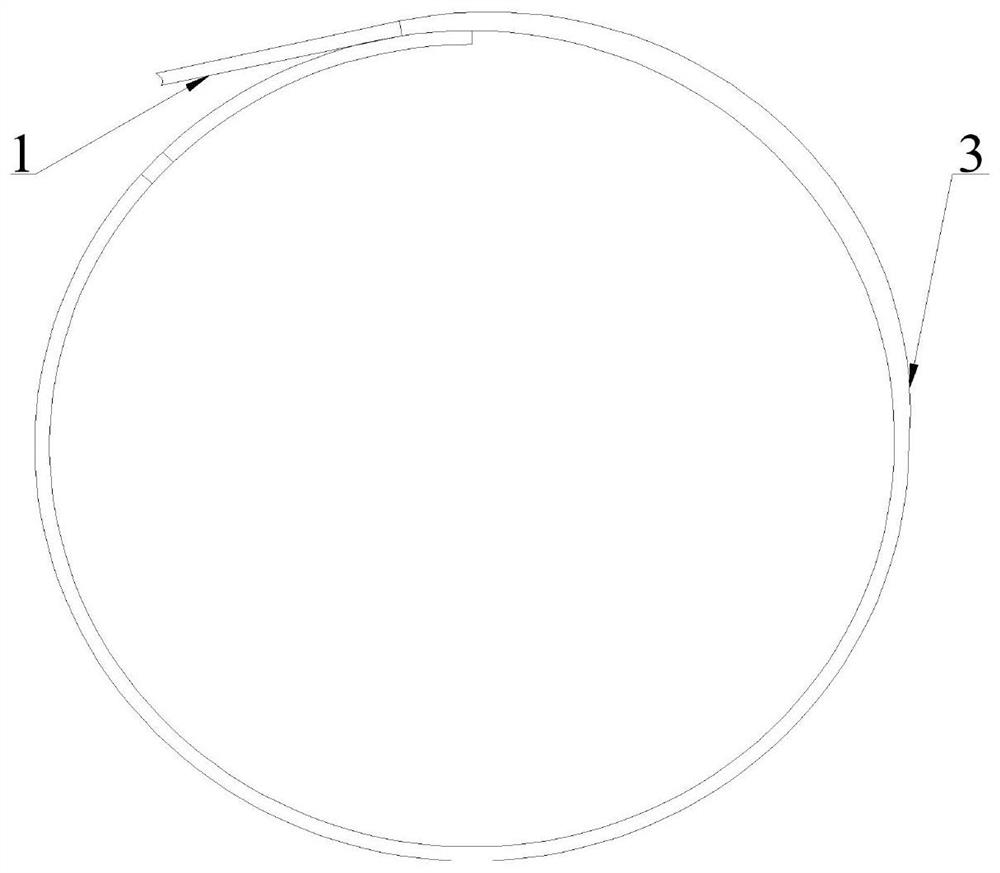

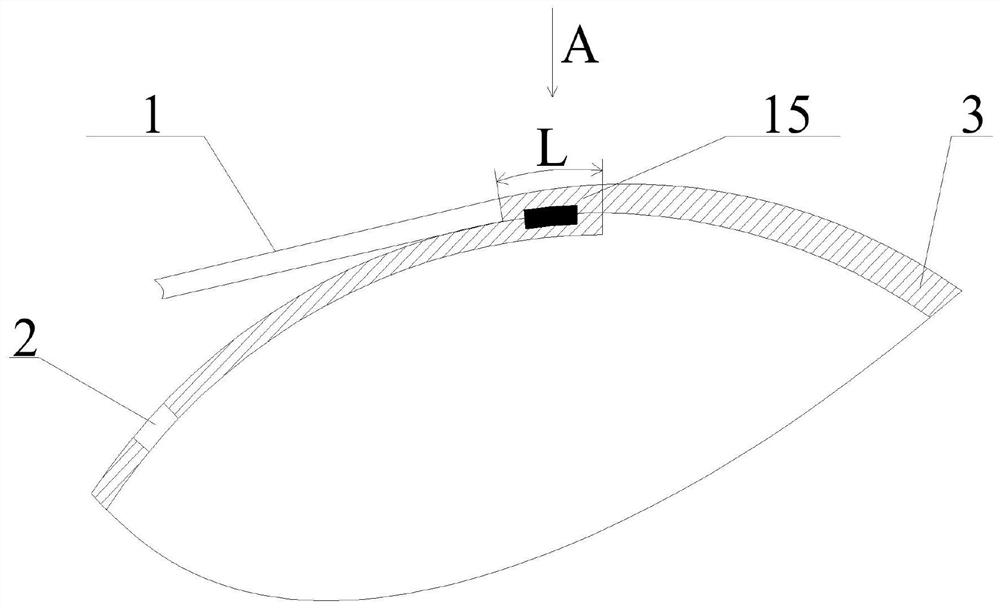

Valve body

PendingCN112081977AAvoid exposureIncrease productivityValve housingsStructural engineeringMechanical engineering

The invention relates to a valve body, and solves the problem that the welding position of a decorative panel on an annular sleeve is difficult to control accurately. The valve body comprises an annular pipeline, an inserting pipe, the decorative panel and an exhaust pipe, the inserting pipe, the decorative panel and the exhaust pipe are sequentially arranged on the annular pipeline in the exhaustdirection, an air inlet is formed in the inserting pipe, an exhaust port is formed in the exhaust pipe, the exhaust pipe comprises an inclined section, the inclined section extends upwards, the exhaust port is located above the inclined section, and the valve body is characterized in that the inserting pipe is arranged on the decorative panel in a manner different from the exhaust pipe.

Owner:HANGZHOU XIAOMI ENVIRONMENTAL SCI & TECH

Hollow layer forming method and multi-hollow layer thermal barrier tube

Owner:WEIFANG BELEAD AUTOMOBILE PARTS

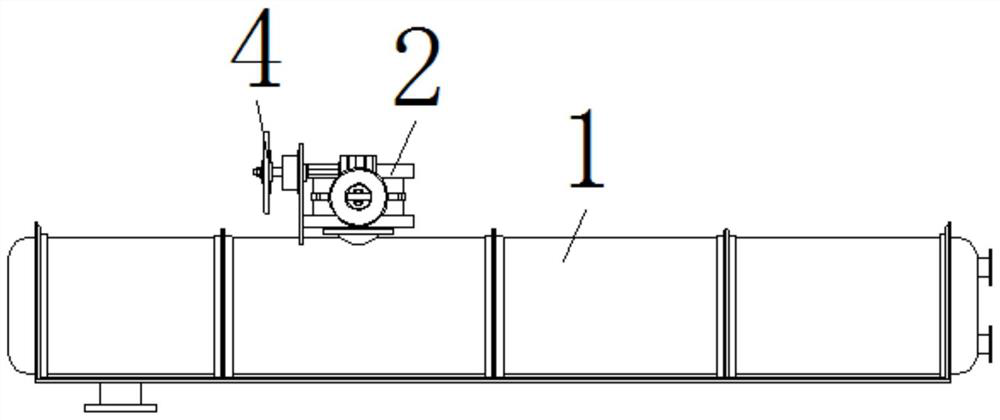

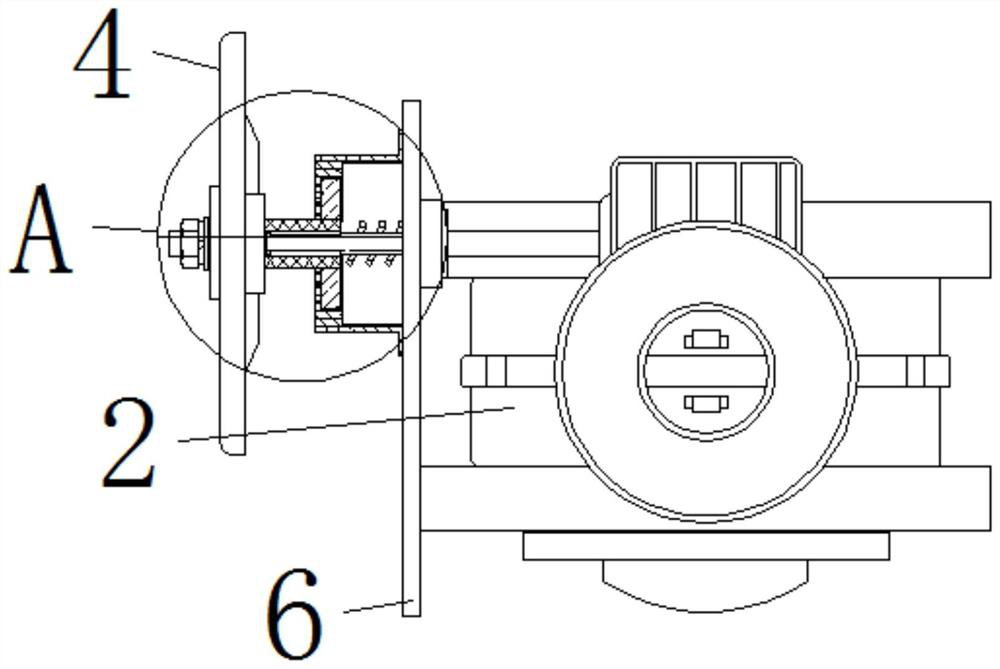

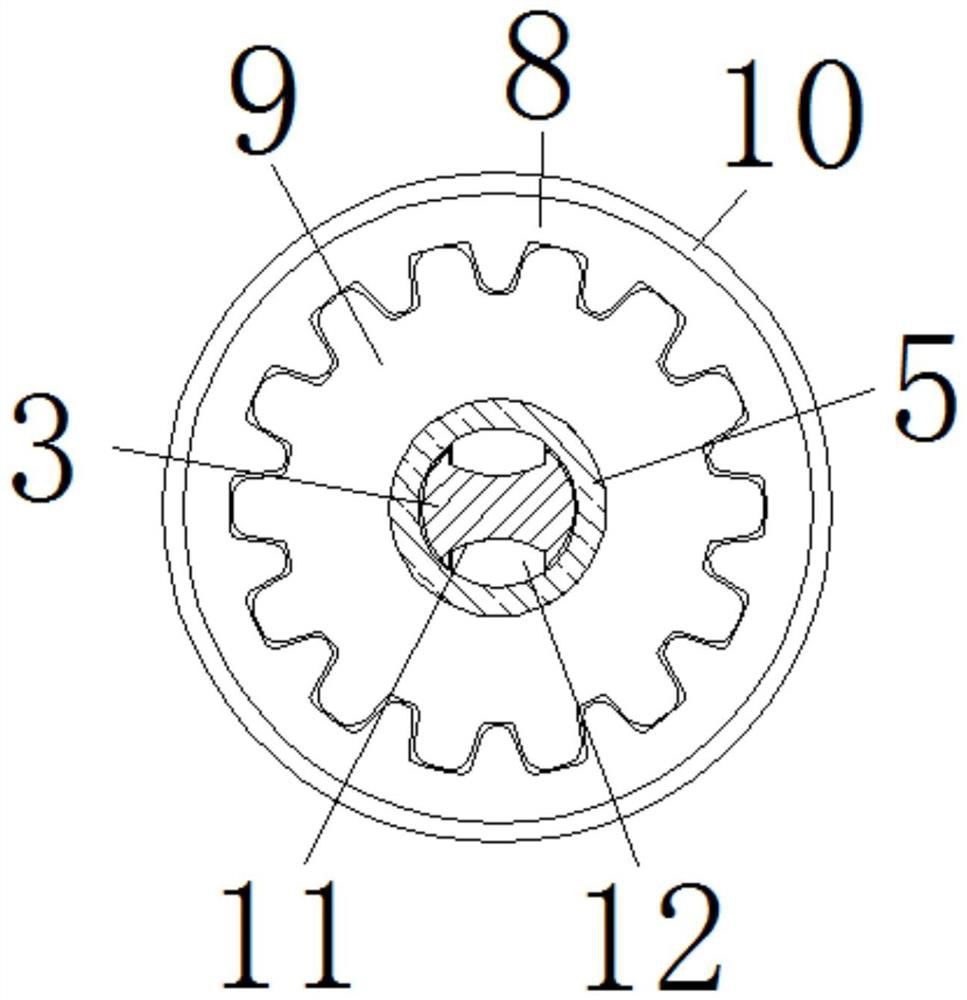

Horizontal pressure container with auxiliary locking structure

InactiveCN112324908AActs as an auxiliary lockPrevent rotationPressure vesselsVALVE PORTPressure vessel

The invention discloses a horizontal pressure container with an auxiliary locking structure. The horizontal pressure container comprises a pressure container body. A pressure relief valve communicatesto the top of the pressure container body, a transmission bar is fixedly connected to an output end of the pressure relief valve, a rotating wheel is arranged on the surface of the transmission bar in a sleeving manner, and a bushing is fixedly connected to the right side of the rotating wheel. A limiting wheel is limited by a gear ring, so that an effect of locking the rotating wheel in an auxiliary wheel can be exerted to prevent the rotating wheel from rotating due to vibration. By pushing the rotating wheel to move, the rotating wheel drives the limiting wheel to be out of contact with the gear ring through the bushing, so that it is convenient for a user to operate the pressure relief valve. By way of replacing an operating mode of starting the locking structure independently, the starting difficulty of the locking structure is reduced, and the problem that a pressure in the pressure container is easy to change irregularly to lead to accidents when a valve shifts due to vibrationas an existing pressure container is not provided with the auxiliary locking structure is solved.

Owner:陈春燕

Safety box avoiding infant accidental touching

PendingCN109368011ALow costPracticalNon-removalbe lids/coversChild proof meansEngineeringFull Term Infant

Owner:雷静

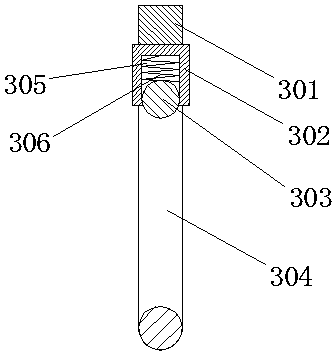

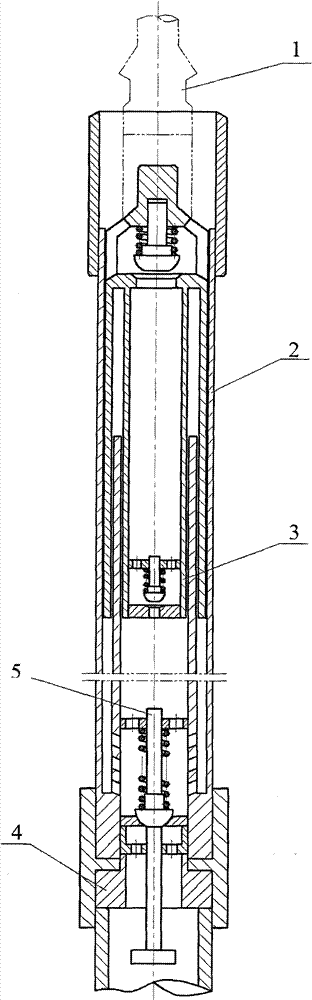

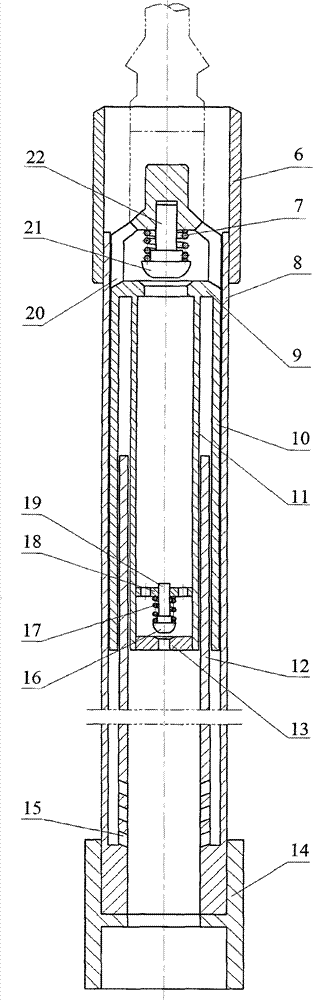

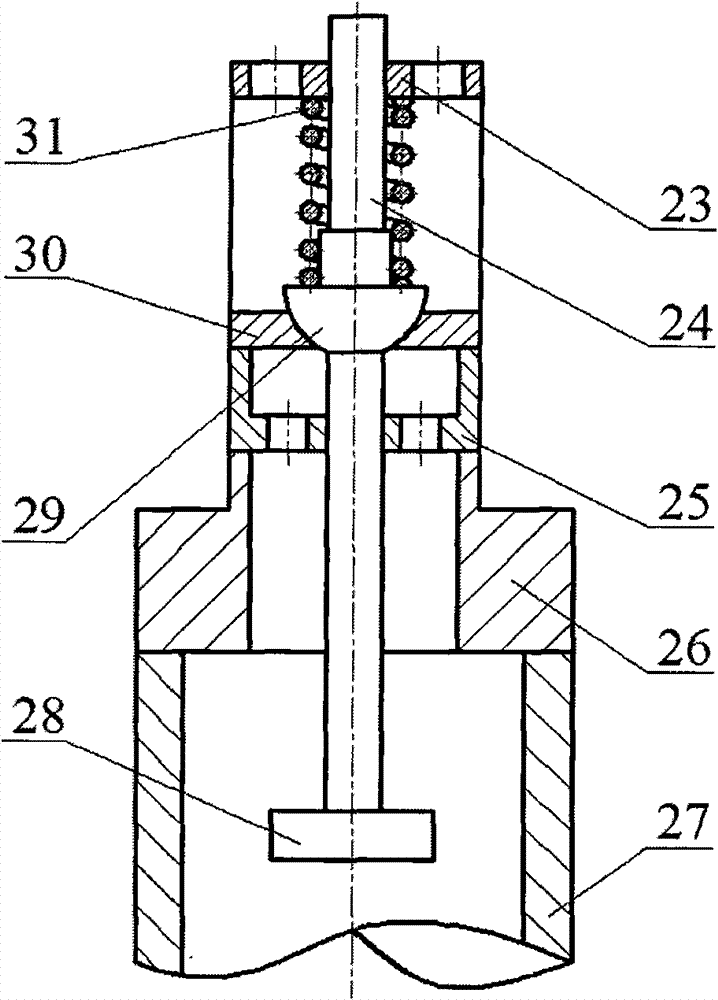

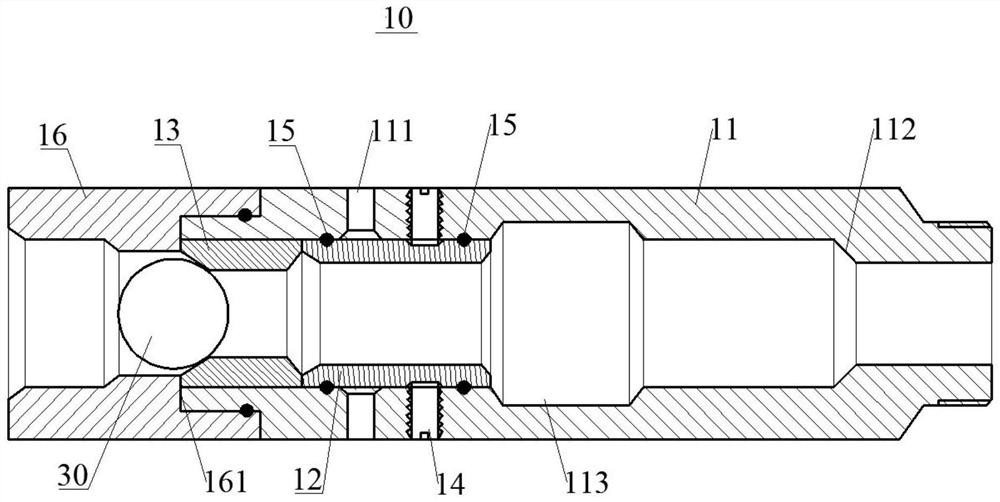

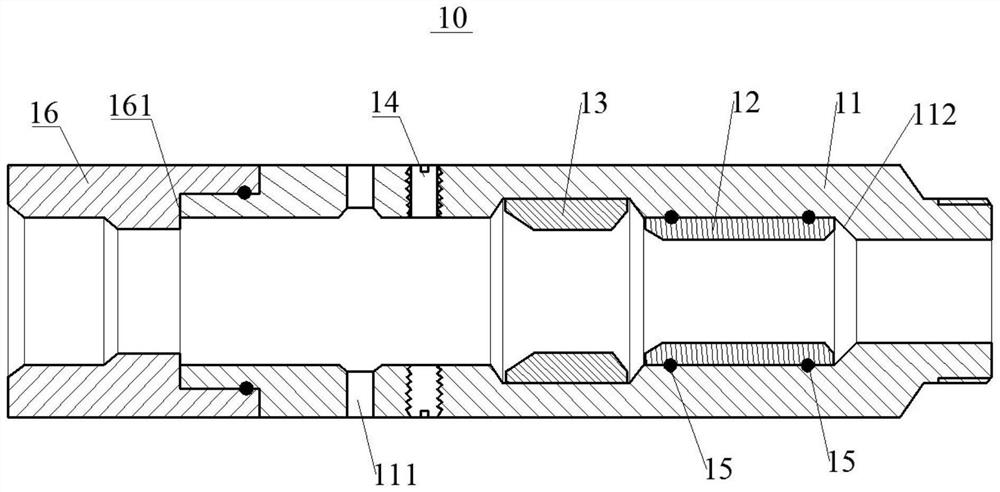

Coal powder-prevention tubular discharging and extracting pump

InactiveCN101956694BOpen smoothlyReduce the difficulty of openingPositive displacement pump componentsFlexible member pumpsReciprocating motionInlet valve

The invention provides a coal powder-prevention tubular discharging and extracting pump for pumping liquid in coal bed gas wells, which especially can prevent coal powder from burying pump, blocking the pump and extending the period of pump inspection. The coal powder-prevention tubular discharging and extracting pump comprises a pump cylinder assembly, a plunger assembly, a liquid inlet valve assembly and a fixing device. A hemispherical valve ball enlarges the flow area of a pump valve, improves the speed for well liquid to enter the pump, is beneficial to the discharging of well liquid outof the pump together with the coal powder to prevent the coal powder from blocking the pump; a resetting spring is matched with a positioning pin to reinforce the resetting capacity of the valve ballso that the tubular discharging and extracting pump reduces loss and realizes the purpose of smoothly opening the pump valve under low sinking degree; a coal powder-prevention slot can temporarily contain the coal powder to reduce the abrasion of the coal powder for plungers and pump cylinders; the bottom of the coal powder-prevention slot is provided with jetting holes so that the coal powder ina valve cover is washed by utilizing the well liquid stored in the slot, thereby the discharging and extracting pump realizes the function of self washing to prevent the blockage of the liquid inlet valve from blocking the pump; and a stirrer drives vanes to rotate along with the reciprocating motion of a plunger of the liquid inlet valve to constantly stir the well liquid and deposited coal powder in a sieve tube, thereby preventing coal powder particles from rapidly settling in the sieve tube to result in that the pump is buried by the coal powder.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

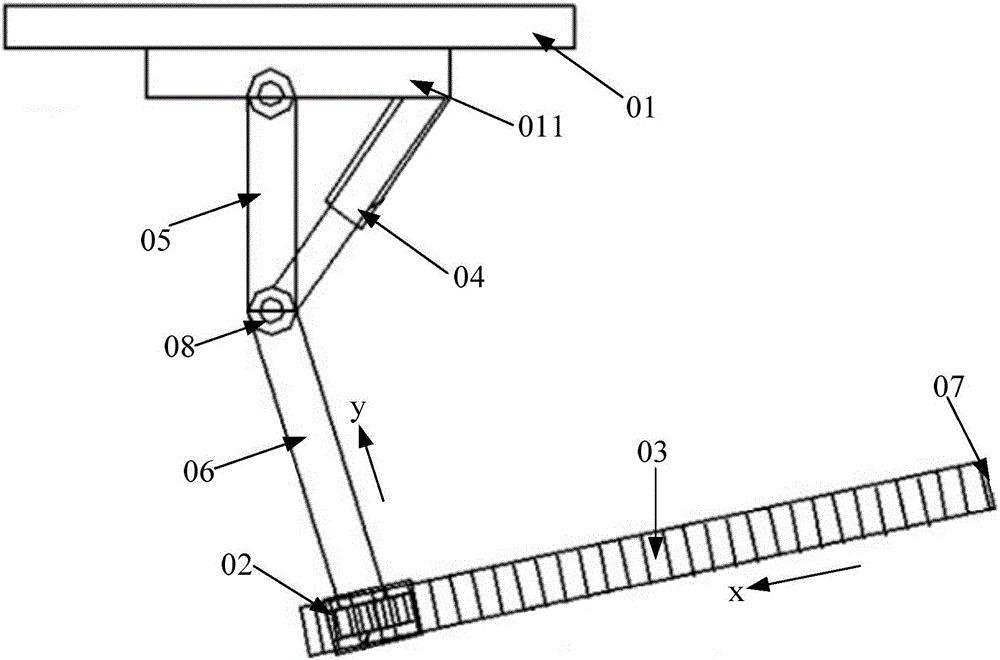

Lifting device for water conservancy gate

The invention discloses a lifting device for a water conservancy gate. The lifting device structurally comprises guide lifting rods, a speed controller, fixture blocks, screws, gate body driving shafts, a lifting laser distance measurement device, fixed bases, a motor and a regulator. The lifting laser distance measurement device is of a cylinder structure, the left end and the right end of the lifting laser distance measurement device are connected with the two fixture blocks in a penetrating manner, the laser distance measurement device, the guide lifting rods and the screws are in embeddedconnection inside the fixture blocks, and the laser distance measurement device, the guide lifting rods and the screws constitute T-shaped structures. The lifting device is provided with the speed controller, during lifting, a connecting plate is connected with the left fixture block, a controller is matched with a speed sensor to effectively control the lifting speed of the gate when the gate islifted, the situation that the gate is lifted too quickly and accordingly the gate is damaged is prevented, then a connecting block is matched with a slider to connect the speed sensor, the gate is easily controlled, the opening difficulty of the gate is reduced, and the requirements of people can also be met.

Owner:江苏金世康电器科技有限公司

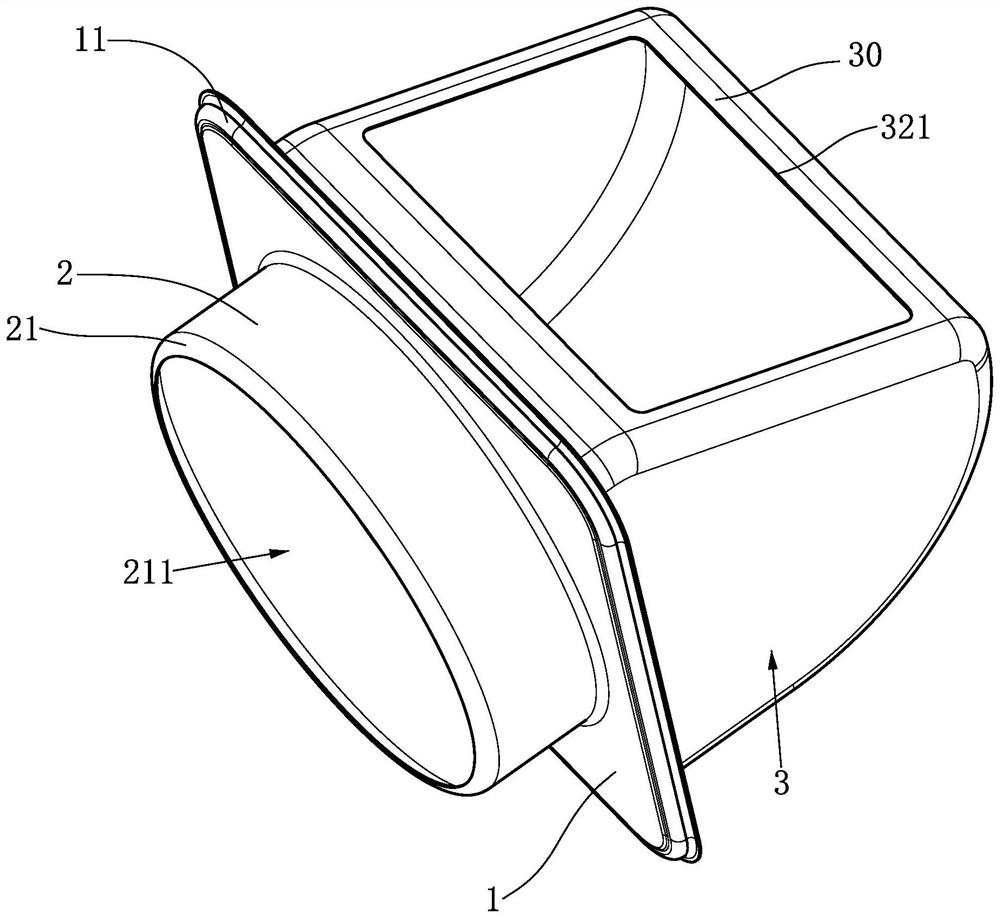

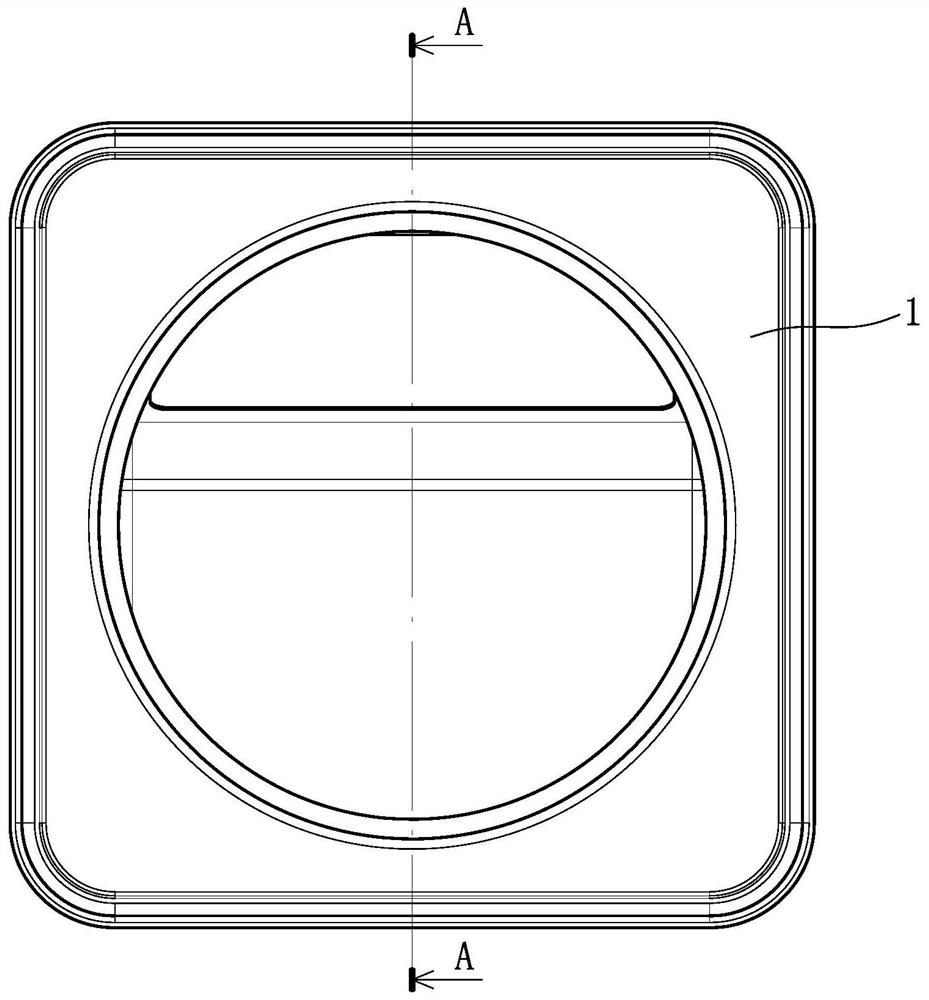

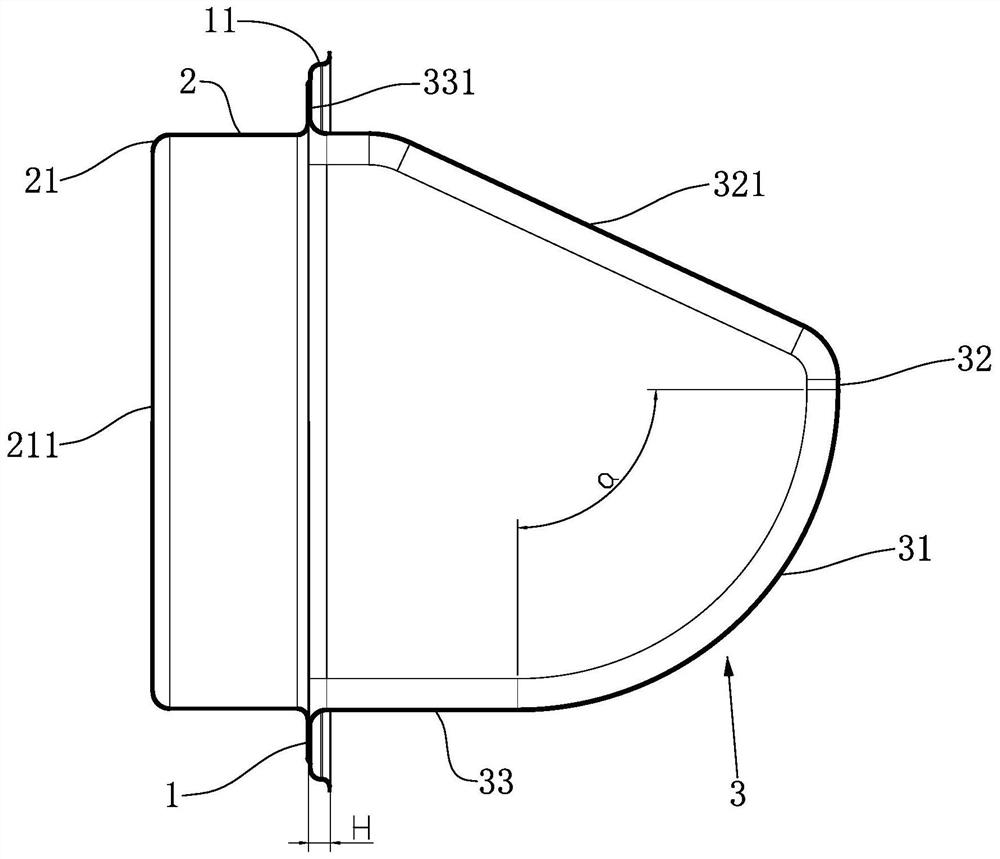

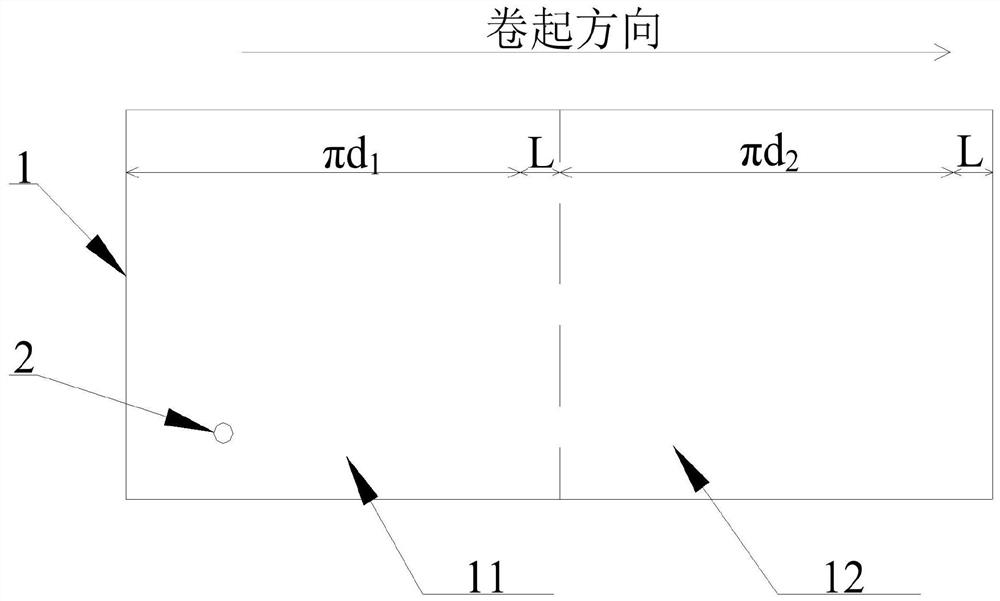

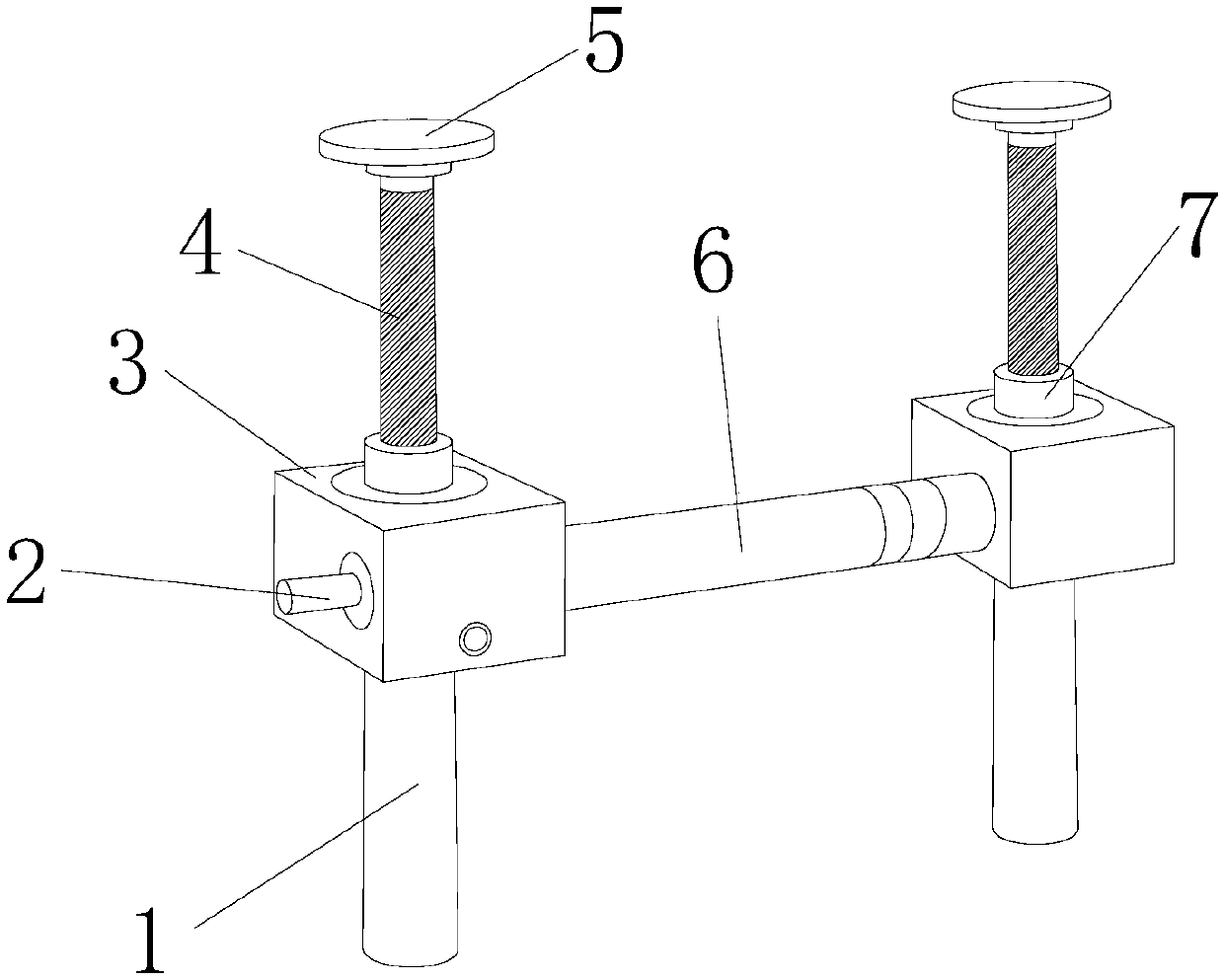

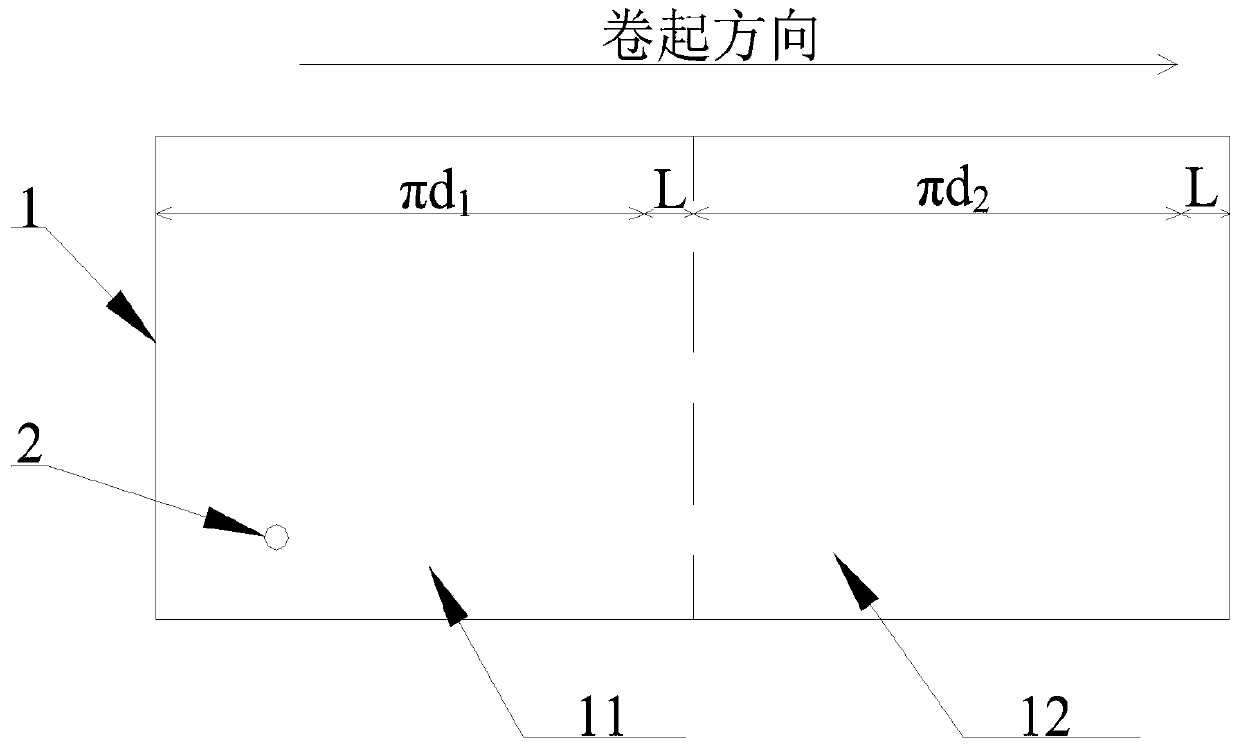

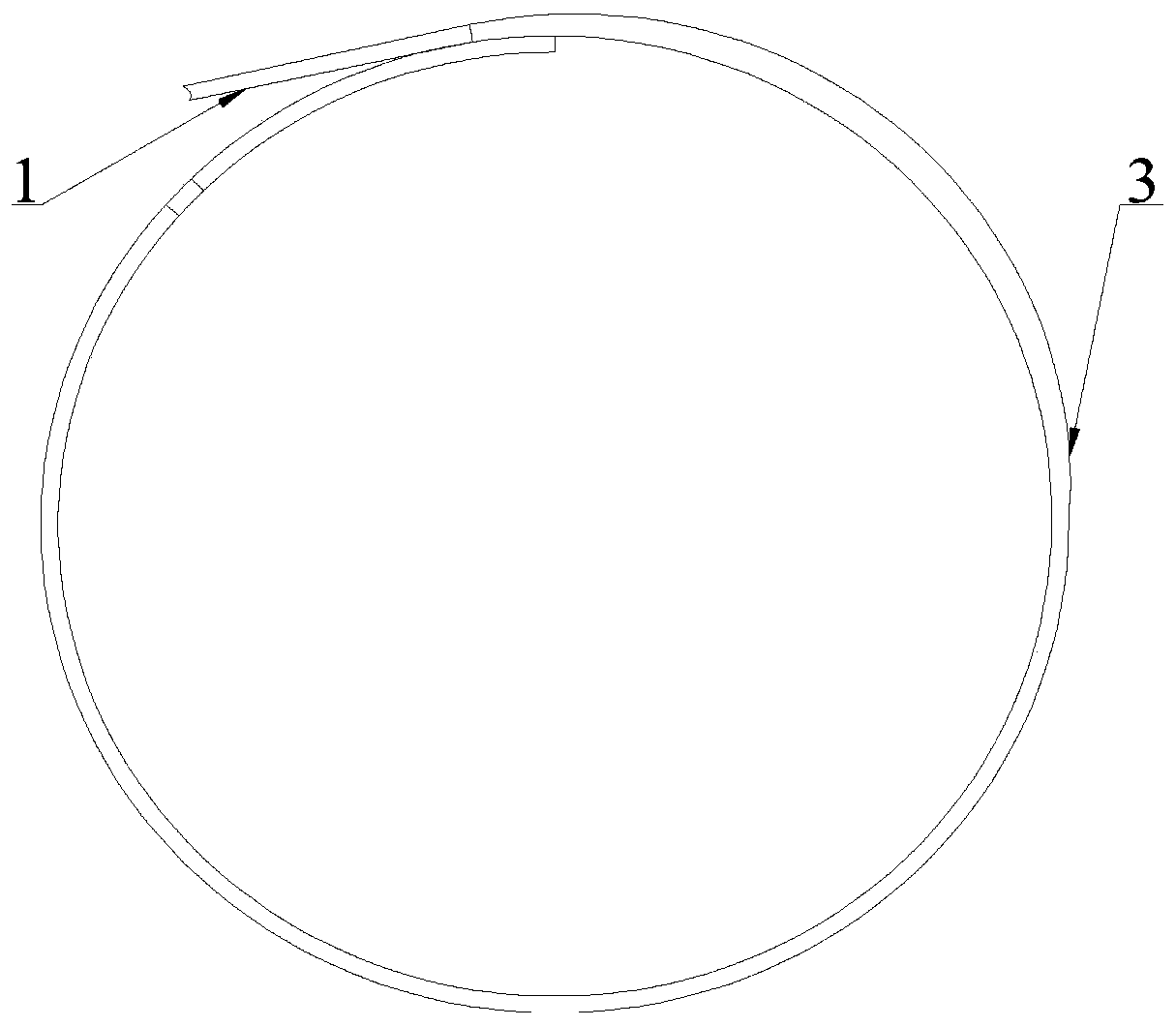

Hollow layer forming method and multi-hollow-layer thermal barrier pipe

ActiveCN110976547AReduce thicknessEliminate the preparation processEngineeringStructural engineering

The invention relates to the technical field of pipe hydraulic forming, and provides a hollow layer forming process. The process comprises the following steps: S1, performing blanking: preparing a plate with a preset size specification for rolling and plate rolling forming, and forming n through hole groups; S2, preparing a pipe blank: rolling the plate to sequentially form pipes from the first layer to the (n + 1)-th layer; S3, forming the hollow layer by adopting an internal high-pressure mode. In this way, multiple through holes are formed in the plate in advance, and then the plate is rolled into the pipe blank with the multi-layer pipe; a pre-bulging process in the prior art is replaced, so the development and manufacturing of a pre-bulging die are omitted, and the die development andprocess cost is saved. A hole patching procedure is omitted, so the forming difficulty of the water injection hole is greatly reduced; meanwhile, a plurality of groups of through holes can be formedin advance, and a plurality of water injection holes are formed after rolling, so the formation of a plurality of hollow layers is realized, and the blank of the prior art is filled. The invention provides a multi-hollow-layer thermal barrier pipe. The multi-hollow-layer thermal barrier pipe is provided with a plurality of hollow layers.

Owner:WEIFANG BELEAD AUTOMOBILE PARTS

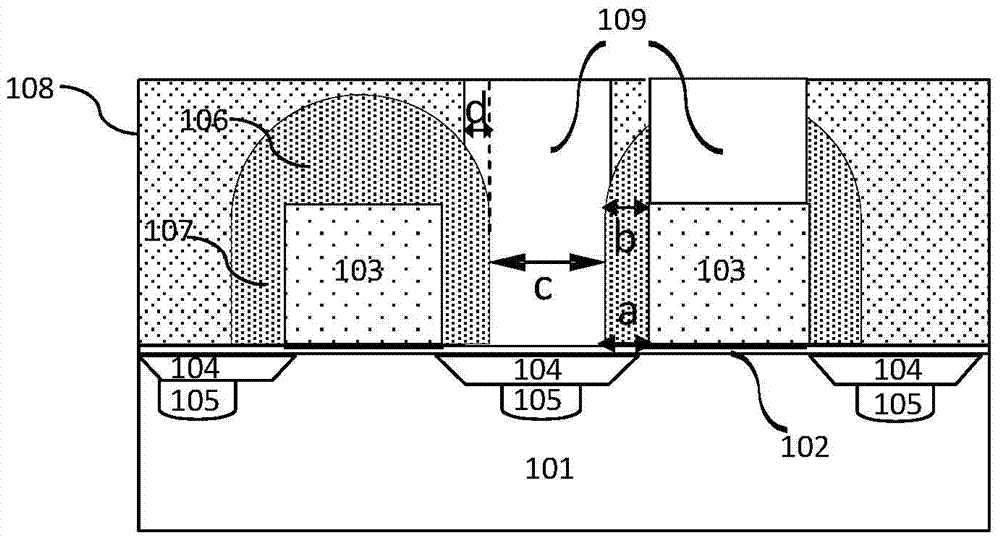

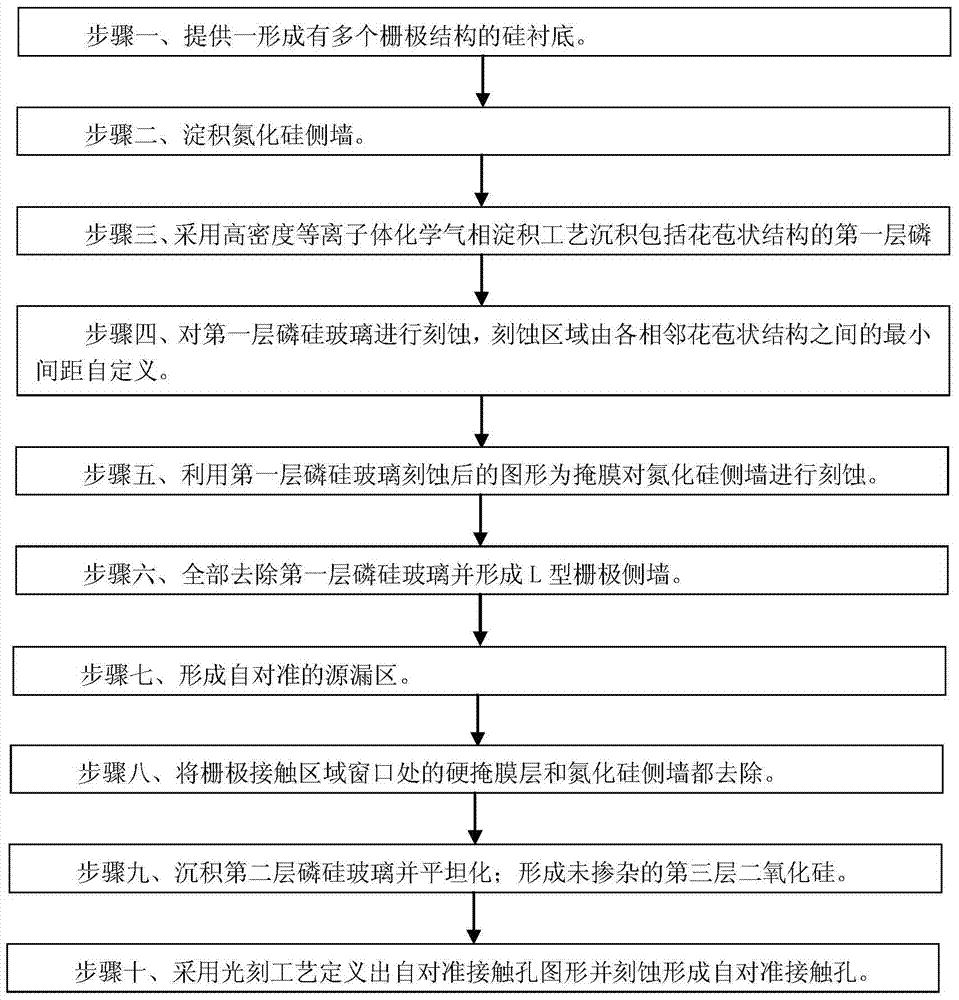

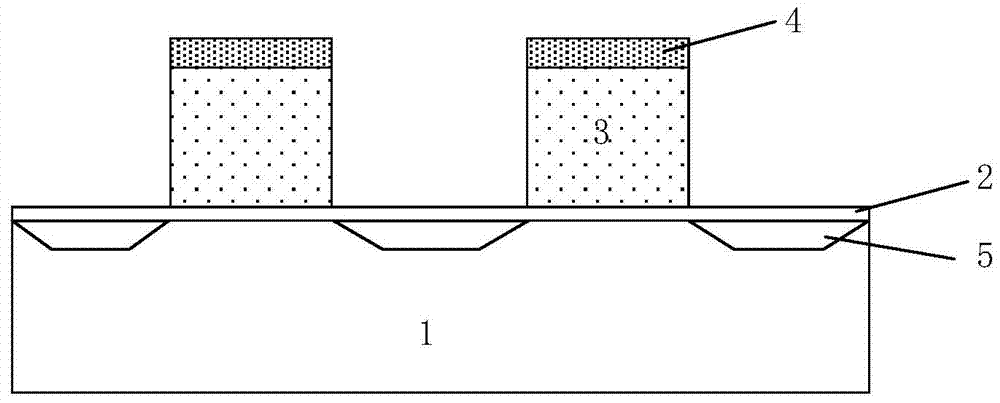

Self-Aligned Contact Hole Etching Method

ActiveCN104576510BAvoid lossLower the altitudeSemiconductor/solid-state device manufacturingCell buddingSilicon dioxide

The invention discloses a self-aligned contact hole etching method, which includes the steps of: providing a silicon substrate formed with multiple gate structures; depositing silicon nitride sidewalls; using HDPCVD technology to deposit a first layer including a bud-like structure. layer of phosphosilicate glass; the first layer of phosphosilicate glass is etched, and the etching area is customized by the minimum spacing between adjacent bud-like structures; the etched pattern of the first layer of phosphosilicate glass is used as a mask Etch the silicon nitride sidewalls; remove all the first layer of phosphosilicate glass and form L-shaped gate sidewalls; form a self-aligned source and drain region; nitride the hard mask layer at the gate contact area window The silicon sidewalls are all removed; a second layer of phosphosilicate glass is deposited and planarized; a third layer of undoped silicon dioxide is formed; a photolithography process is used to define a self-aligned contact hole pattern and etching to form a self-aligned contact hole. The invention can reduce the height of the gate structure, increase the gate spacing, reduce the difficulty of PSG filling between the gate structures, enhance the etching ability of the self-aligned contact hole, and improve the etching quality of the self-aligned contact hole.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

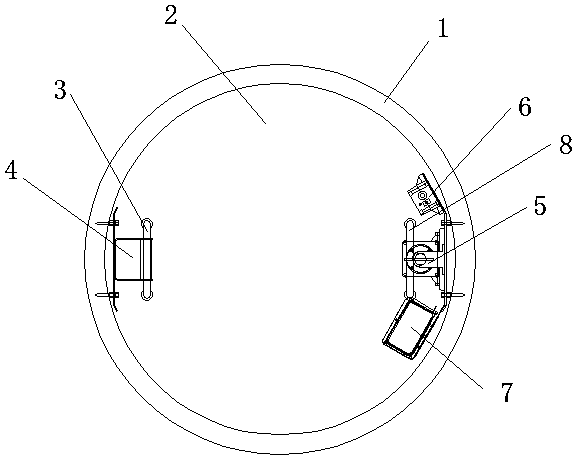

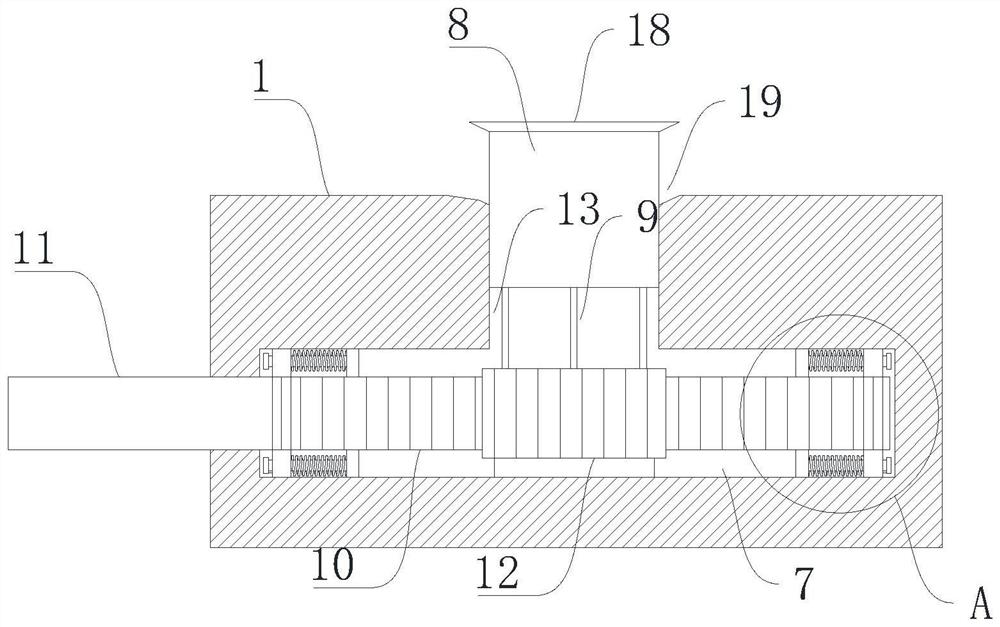

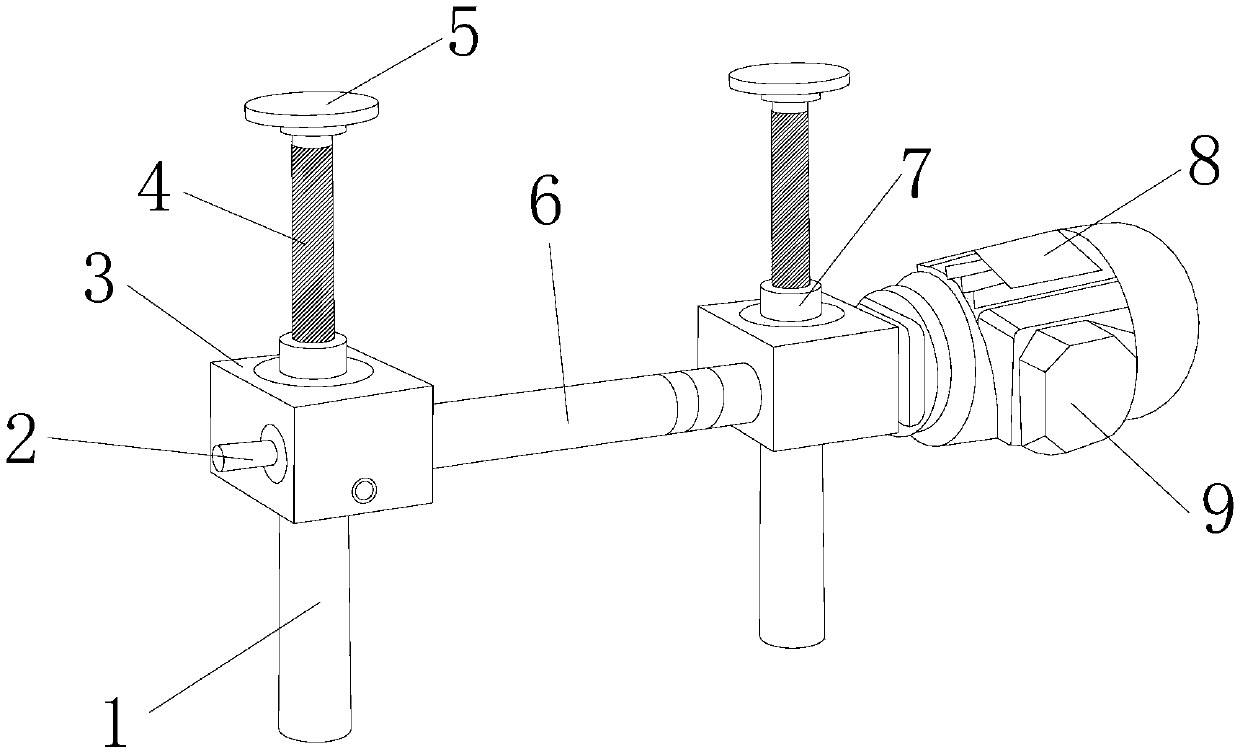

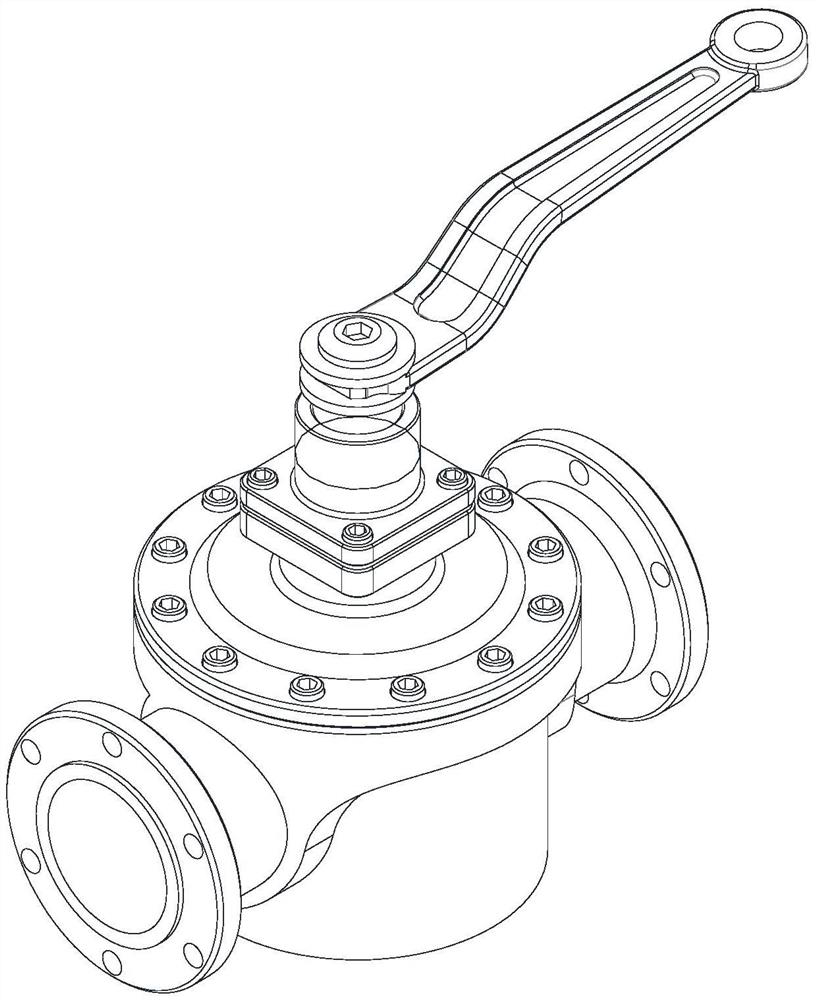

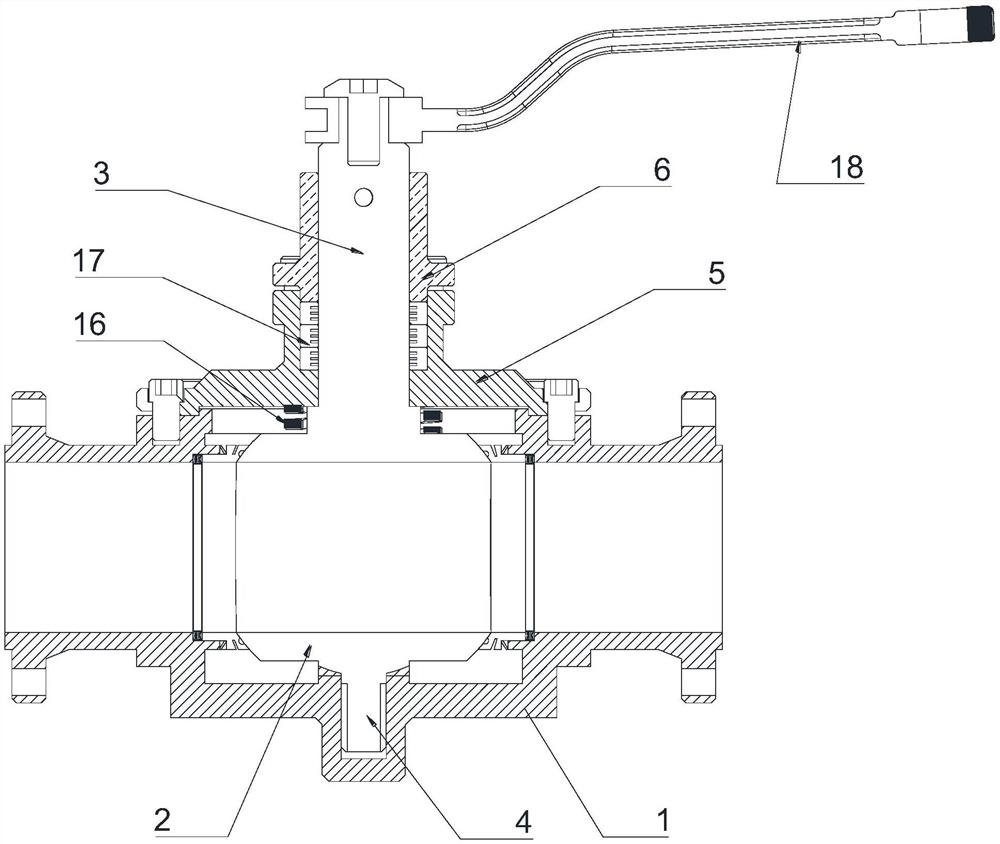

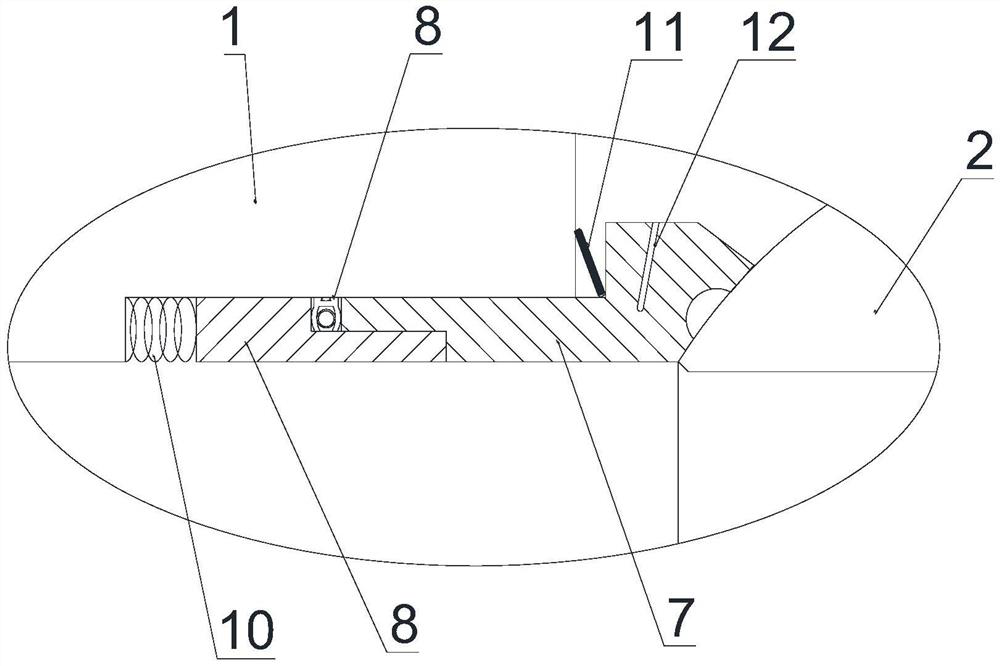

A Gravity Assisted Opening Ball Valve

ActiveCN111503310BReduce the difficulty of openingEasy to openPlug valvesCleaning using toolsEngineeringControl valves

The object of the present invention is to provide a gravity-assisted opening ball valve, which can be assisted to open by means of the gravity of the ball valve core itself, and the movable valve seat structure is redesigned in conjunction with the ball valve core, so as to realize the convenient opening of the ball valve core and ensure sufficient sealing performance, including The valve body and the sphere, the valve body is provided with an inflow channel, an outflow channel and a valve cavity, and the ball is provided with an overflow channel and is rotatably arranged in the valve cavity to control the flow of the valve body inflow channel and outflow channel. The valve body is provided with a valve seat at the junction of the valve body inflow channel and outflow channel and the valve cavity. The valve seat cooperates with the ball to realize the sealing of the ball valve in the closed state. The upper part of the valve body is provided with a valve cover. The cover seals the sphere in the valve cavity, the upper end of the sphere is connected to the upper valve stem, and the lower end of the sphere is connected to the lower valve stem. Thread out and attach to the handle.

Owner:TIANJIN CARLS VALVE CO LTD

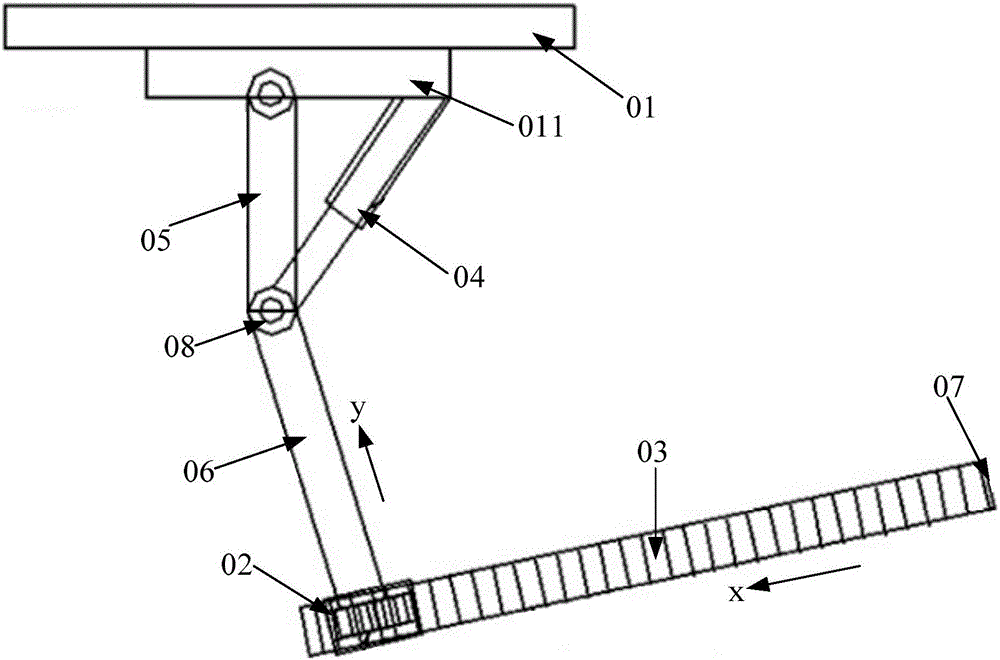

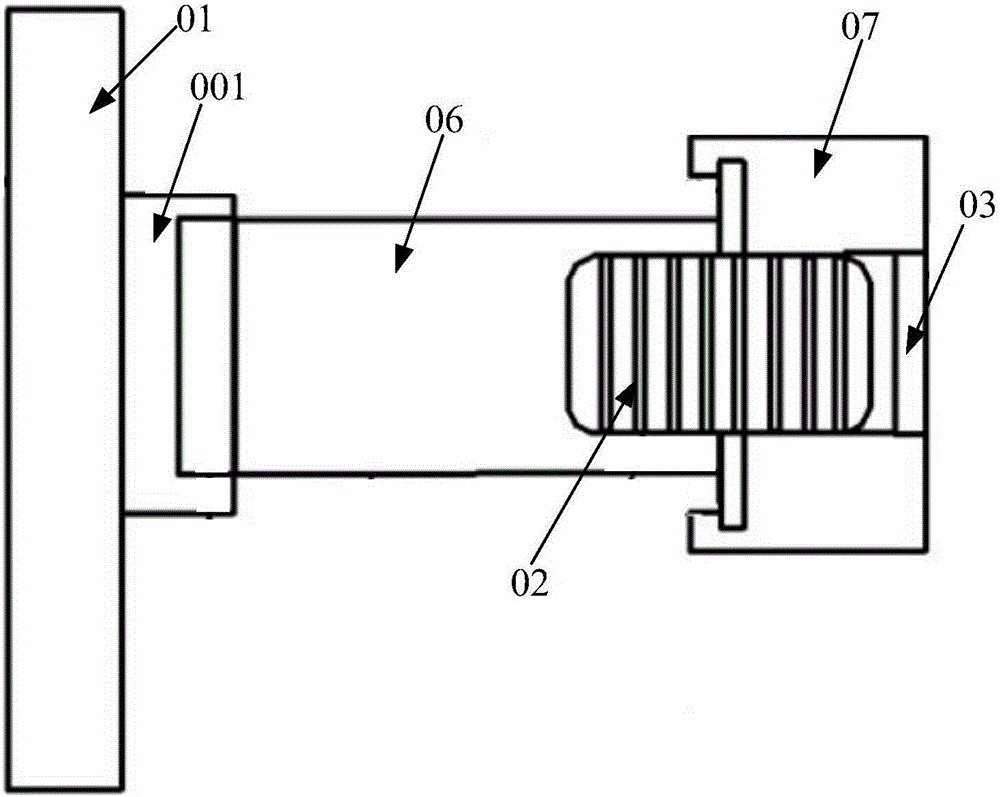

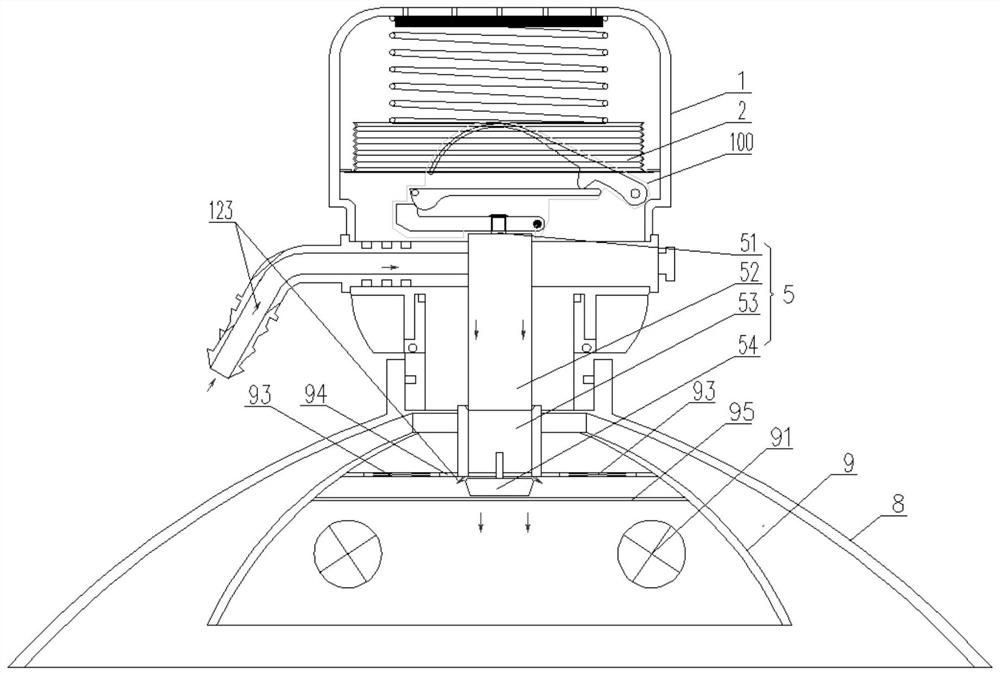

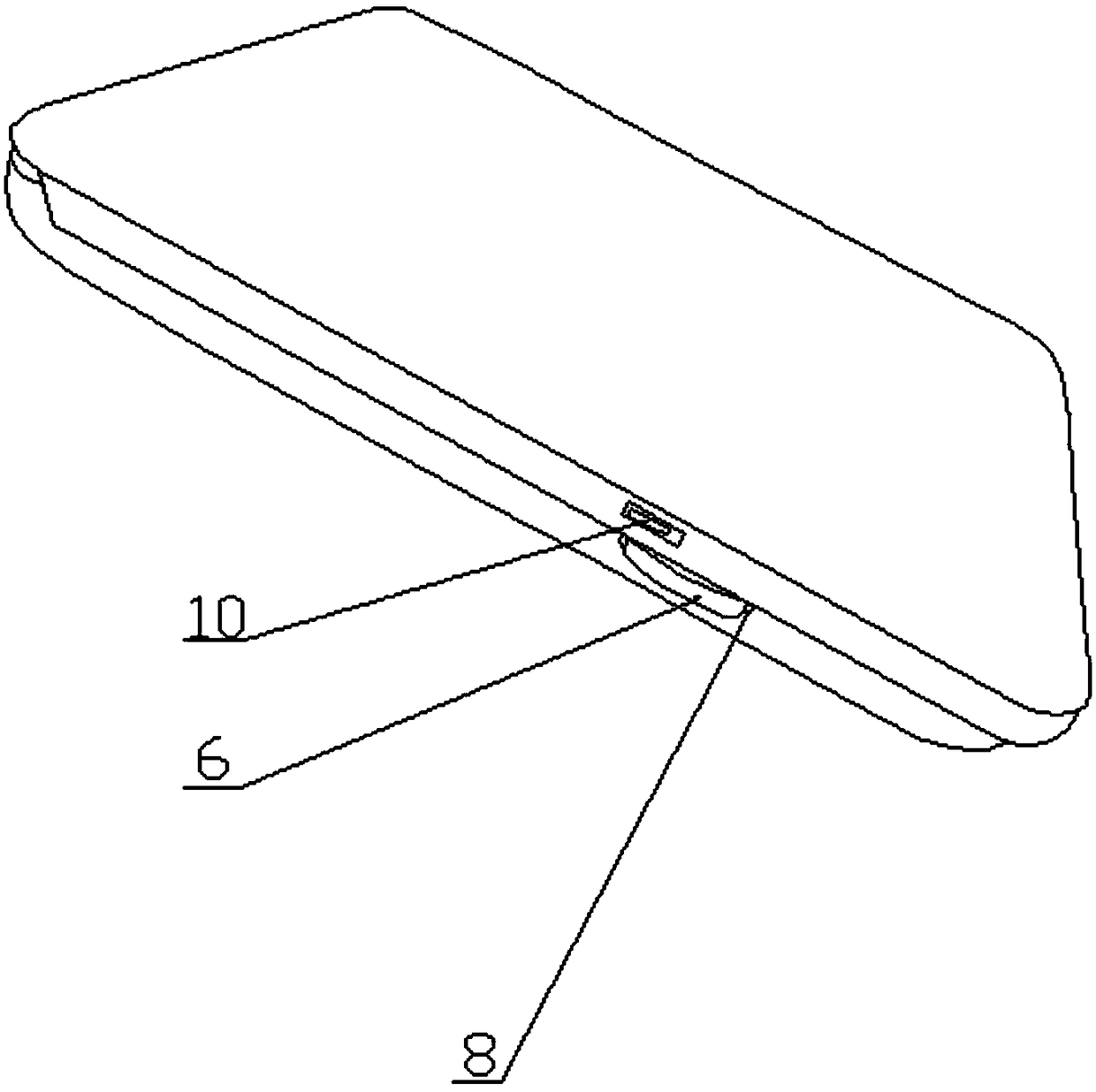

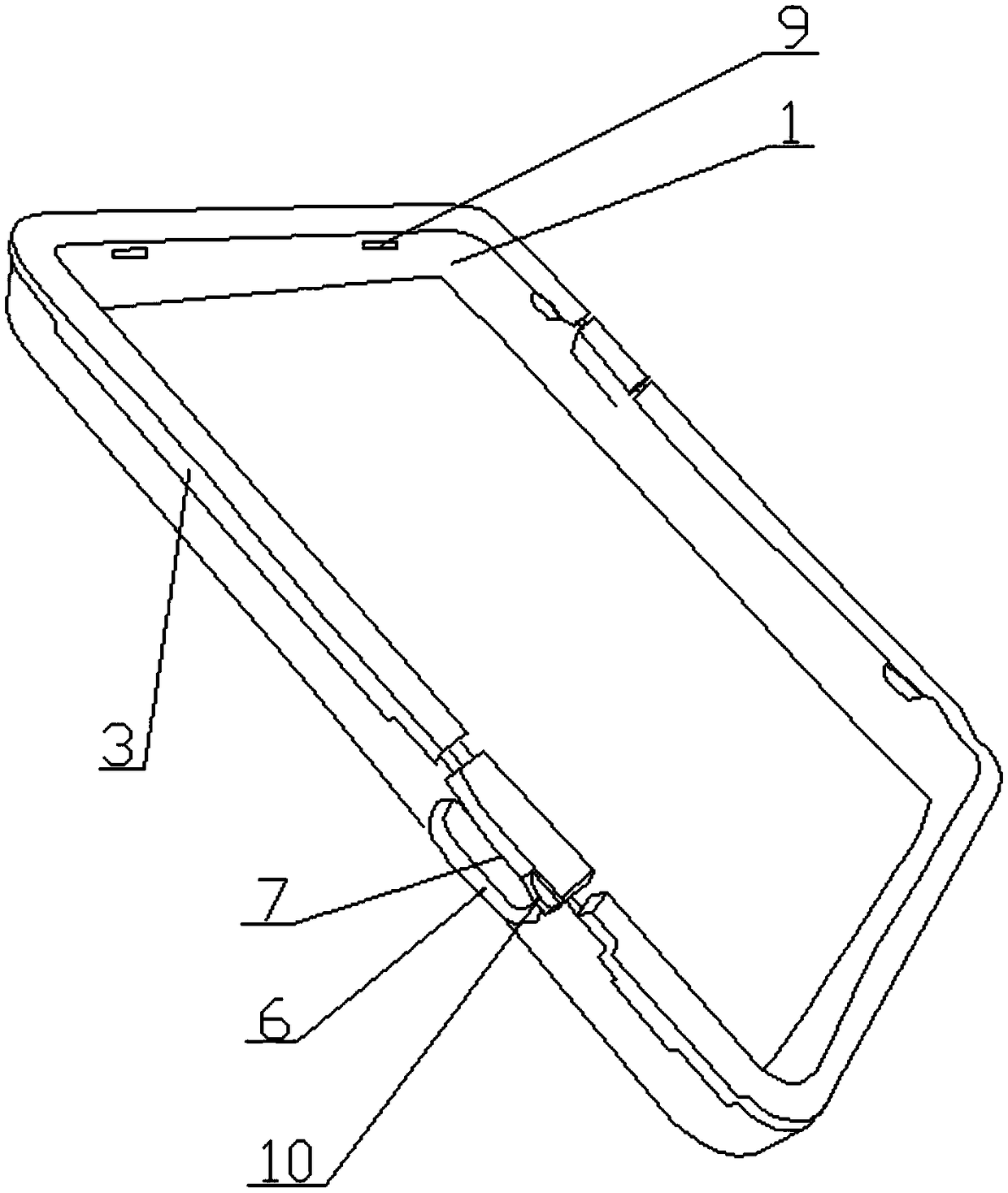

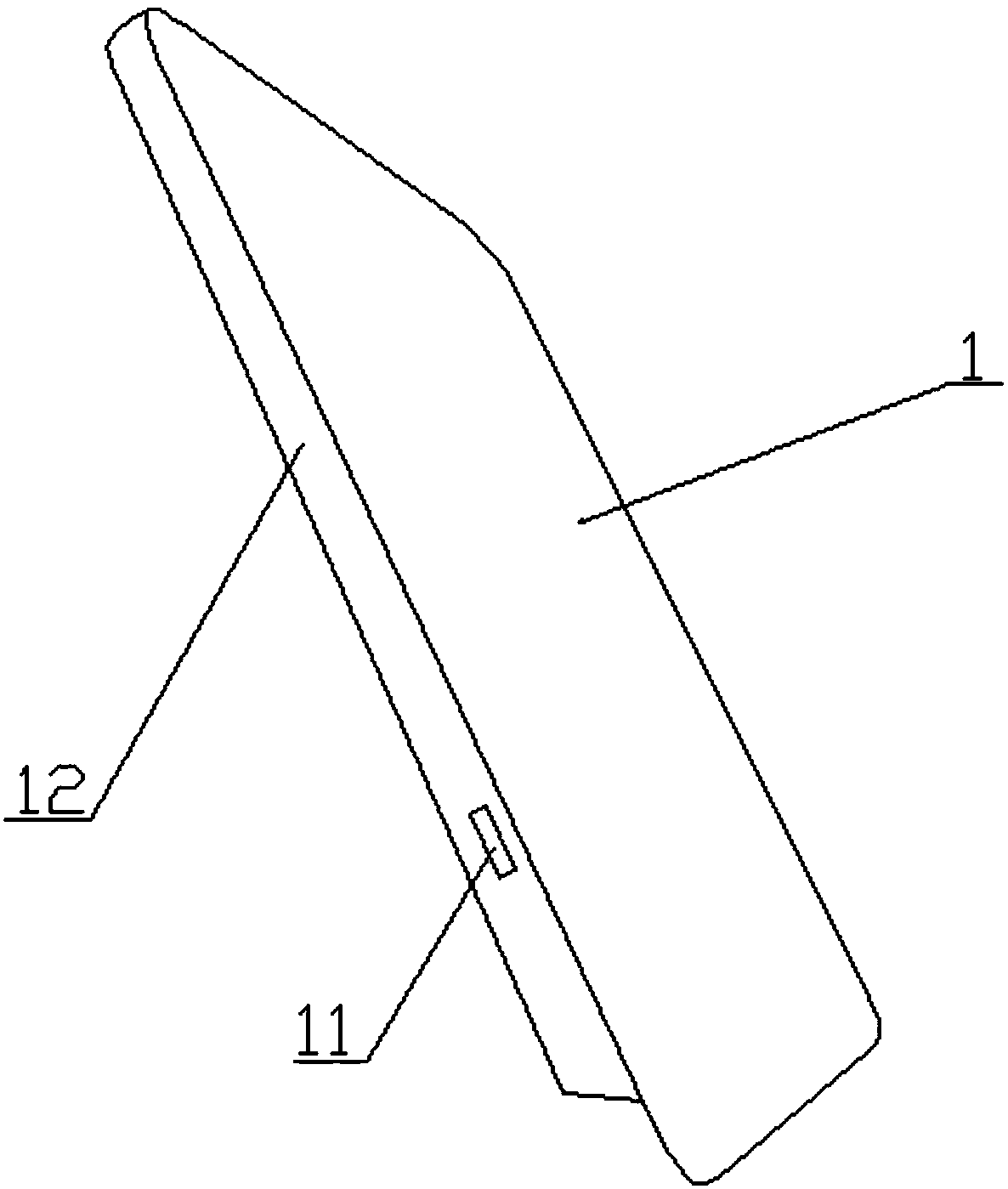

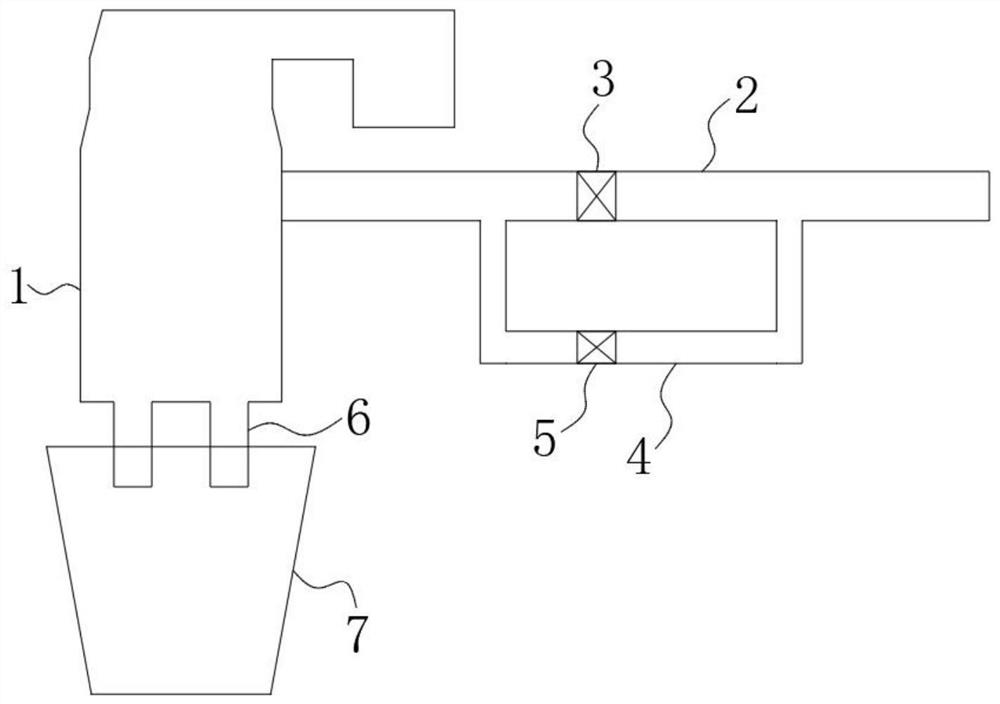

door opener

The invention discloses a vehicle door opening device, which belongs to the field of automobiles. Including: the first rod, the second rod, the third rod, the body fixing seat, the gear and the door track, the first rod, the second rod and the third rod are movably connected, and any rod can be wound around three The connection point of each rod rotates; the body mount is provided with a mounting groove, the first rod and the second rod are both movably connected with the body mount, and the first rod can go around the connection point between the first rod and the body mount Rotate, the second rod can slide in the installation groove; the third rod is fixedly connected with the door track, the gear and the door are set on the door track, the gear is used to drive the door to slide on the door track, so that the door slides to open or close . The invention solves the problems of low security and high difficulty in the existing way of opening the car door, and achieves the effects of improving the safety of opening the car door and reducing the difficulty of opening. The invention is used for opening the car door.

Owner:CHERY AUTOMOBILE CO LTD

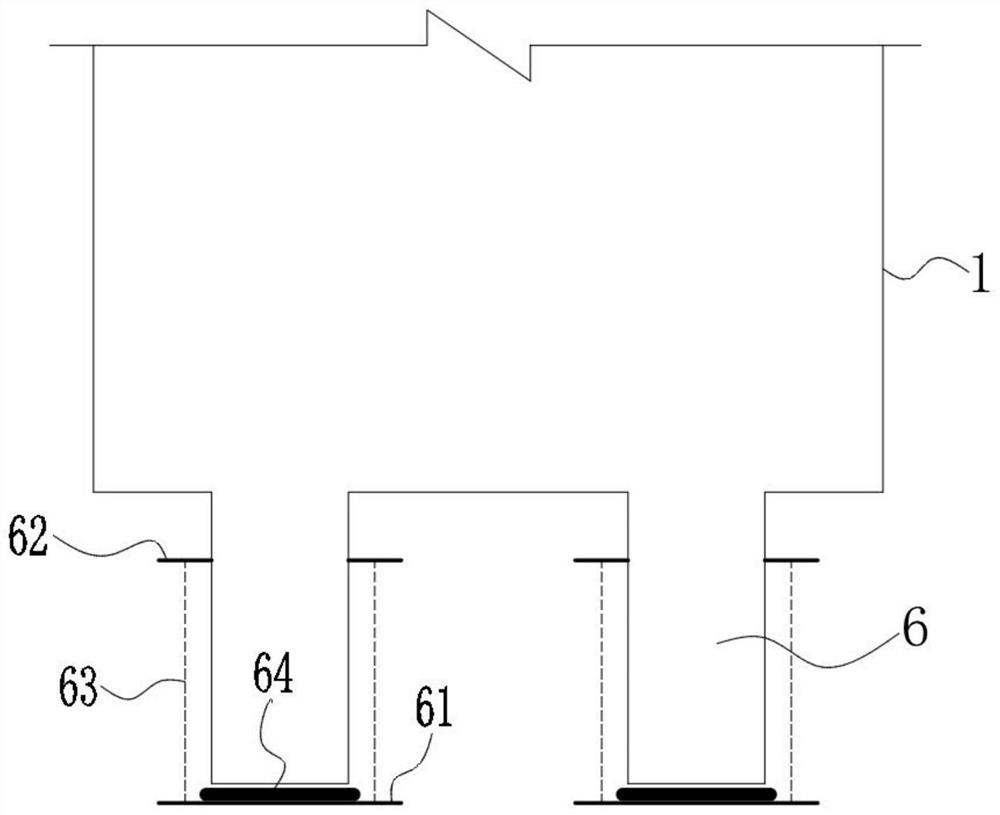

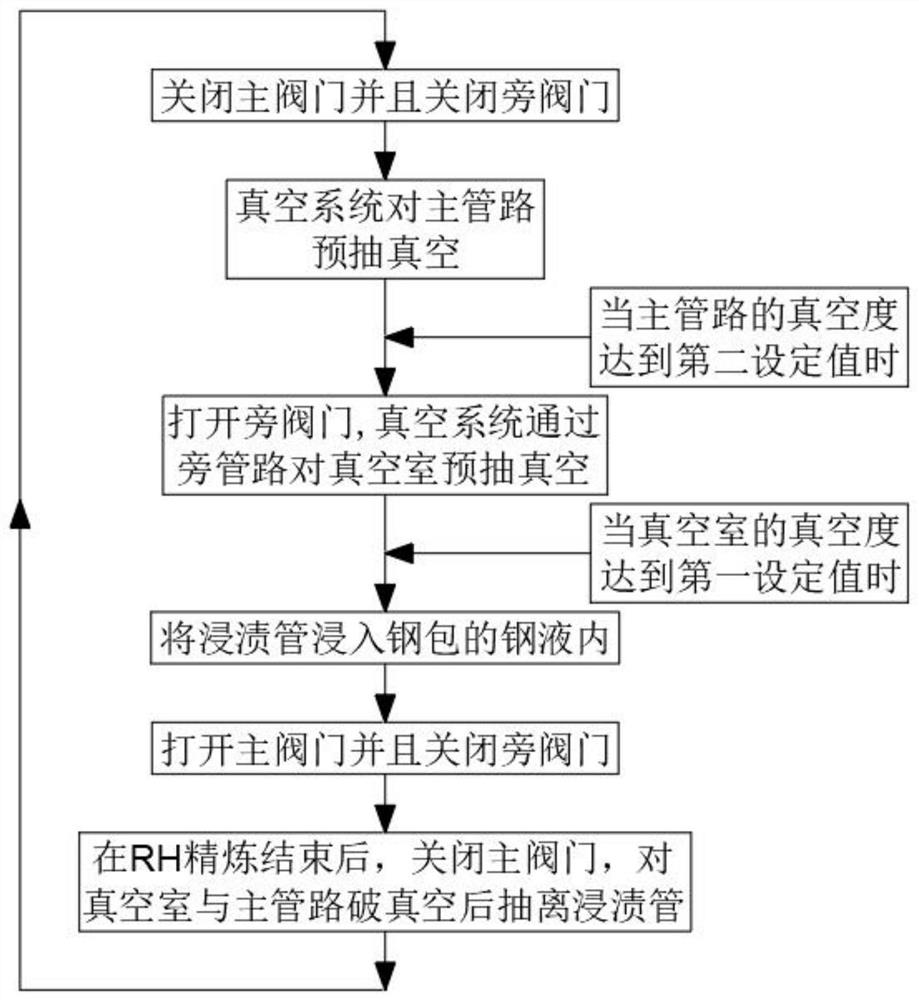

RH pre-vacuumizing device and method

ActiveCN112609044AReduce the difficulty of openingImprove RH efficiencyProcess engineeringPumping vacuum

The invention discloses an RH pre-vacuumizing device and method, relates to the technical field of external refining, and solves the technical problems that a vacuum chamber in the prior art cannot have the vacuum degree before RH and a main valve is difficult to open. The device comprises a vacuum chamber, a main pipeline and a bypass pipeline, the vacuum chamber is connected with a dip pipe, the main pipeline is communicated between a vacuum system and the vacuum chamber, a main valve is arranged in the main pipeline, two ends of the bypass pipeline are respectively communicated with the main pipeline on two sides of the main valve, a bypass valve is arranged in the bypass pipeline, and the dip pipe is connected with a plugging device. By additionally arranging the bypass pipeline and the bypass valve on the main pipeline and sealing the dip pipe through the plugging device, the vacuum chamber can be pre-vacuumized through the bypass pipeline, and therefore the vacuum chamber has the vacuum degree before RH. Meanwhile, in the RH process, due to the fact that the two sides of the main valve have the vacuum degree, the opening difficulty of the main valve is lowered, and the RH efficiency is improved.

Owner:BEIJING SHOUGANG CO LTD

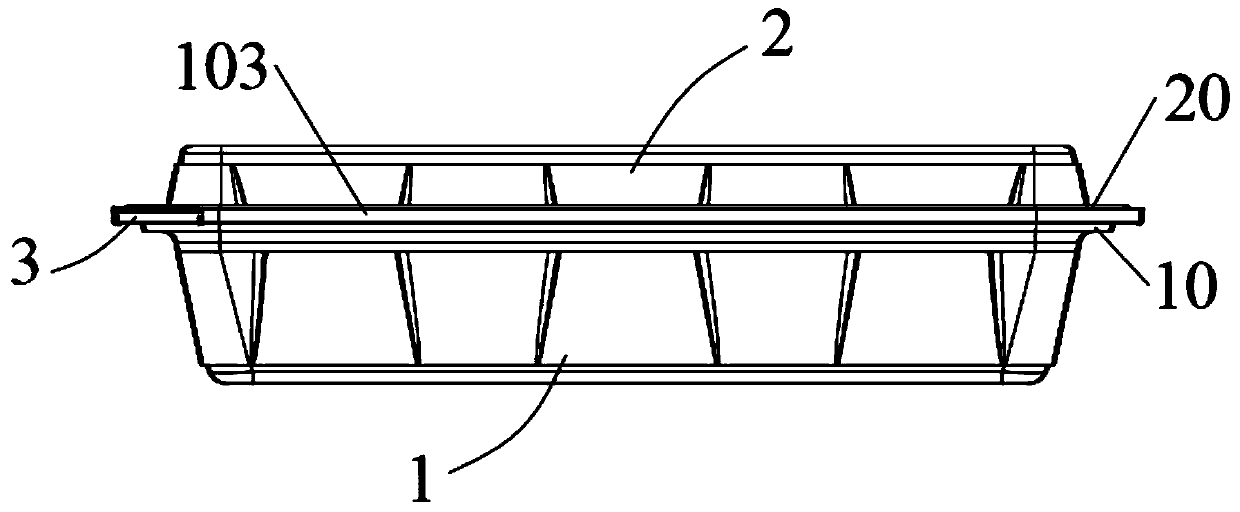

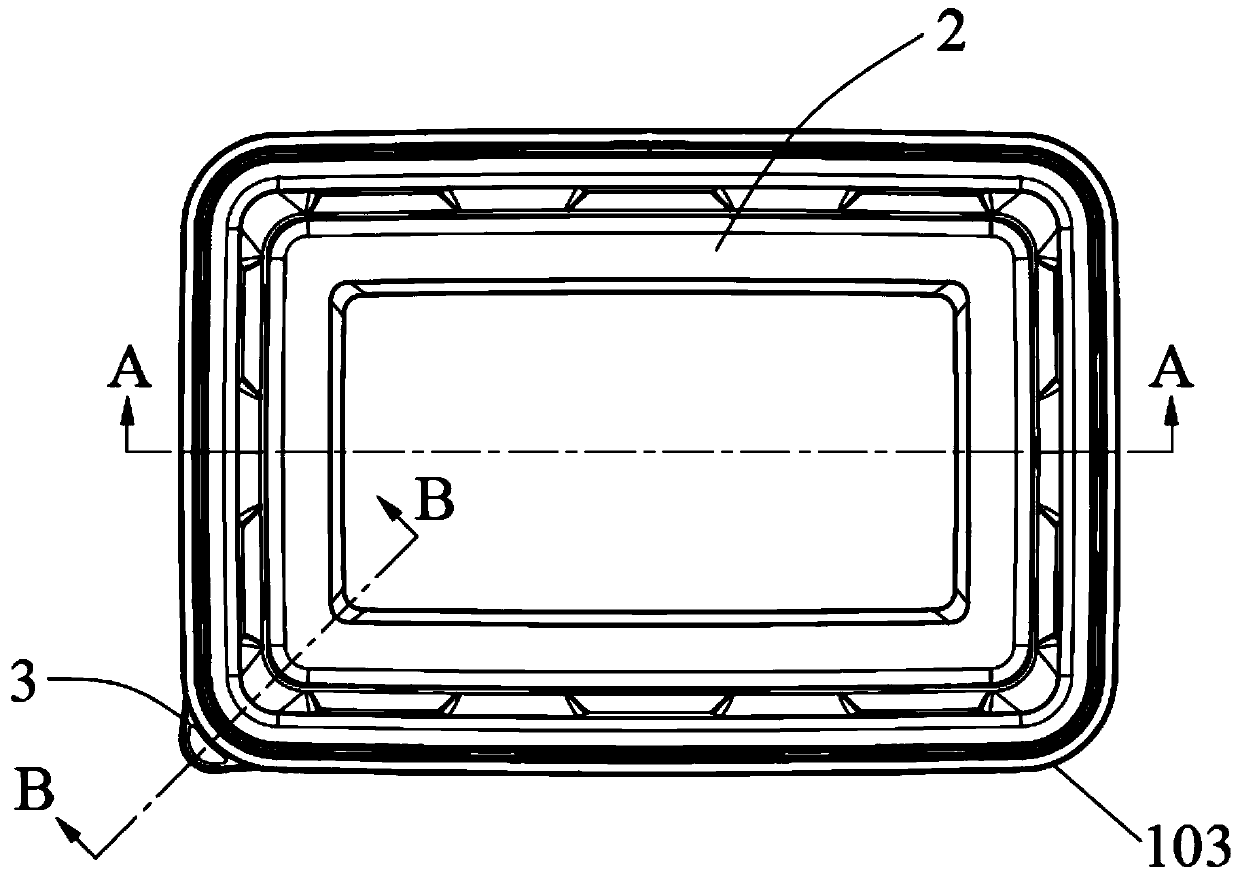

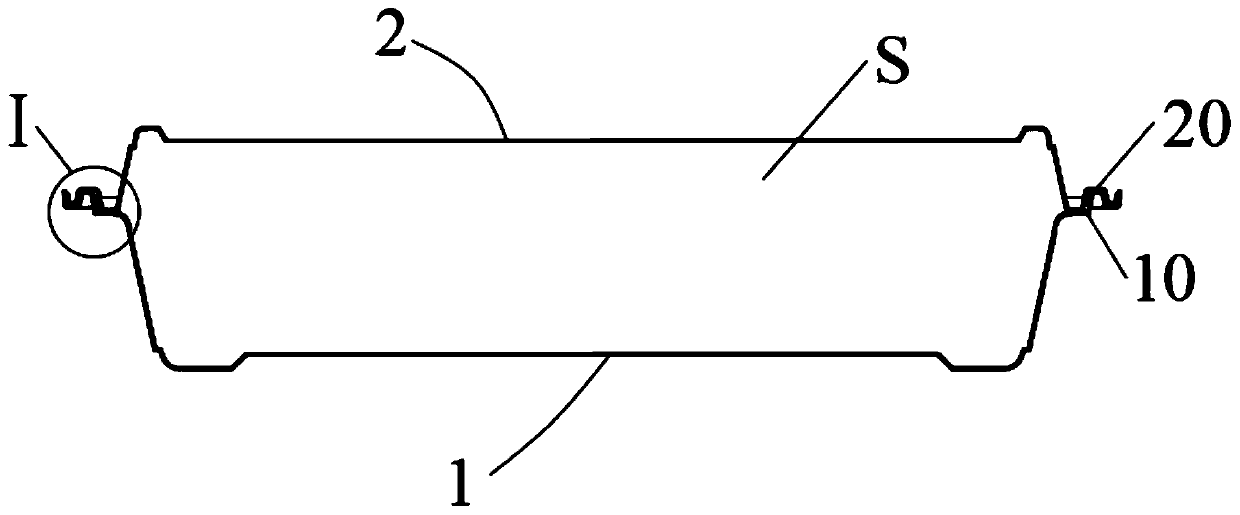

Food container

PendingCN109969584AReduce the difficulty of openingGuaranteed tightnessOther accessoriesSealingEngineeringFoam food container

The invention relates to a food container. The food container comprises a box body, a cover body and a lock catch, the cover body is buckled above the box body, the peripheral edge part of the box body is clamped and connected with the peripheral edge part of the cover body, a storage cavity is formed between the box body and the cover body, the outer edge of the box body wraps the outer edge of the cover body, a section of gap is formed in the outer edge of the box body, the gap is exposed out of the outer edge of the cover body, the lock catch consists of a sealing strip and a pull ring part, the sealing strip is arranged in the gap, the sealing strip is connected with a cross section formed by the box body at the gap through a plurality of connecting bridges, and the pull ring part is arranged on the outer side of the sealing strip and is connected with the sealing strip. The food container is easy to open and can also ensure the sealing performance.

Owner:台山市中尚餐厨用品有限公司

Reaction kettle pressure relief auxiliary device for p-chlorobenzyl chloride production

PendingCN113559788ANo wasteReduce the difficulty of openingPressure vessel componentsHalogenated hydrocarbon preparationProcess engineeringChloride

The invention discloses a reaction kettle pressure relief auxiliary device for p-chlorobenzyl chloride production, and relates to the technical field of chemical production. The reaction kettle pressure relief auxiliary device for p-chlorobenzyl chloride production comprises a mounting frame, a penetrating pipe is arranged at the bottom of the mounting frame, a device shell is arranged at the top of the mounting frame, a main electric control valve is arranged in an inner cavity of the device shell, and the control end of the main electric control valve penetrates through the left side of the device shell and is arranged outside the shell. According to the reaction kettle pressure relief auxiliary device for p-chlorobenzyl chloride production, two air outlet structures are additionally arranged on the reaction kettle, air pressure inside and outside the reaction kettle is balanced before the reaction kettle is opened, the opening difficulty of an operator is reduced, meanwhile, a circuit system of the whole device is simple and exists independently, the manufacturing cost is relatively low, and the existing reaction kettle can be improved, so that the waste of the existing reaction kettle is avoided, and the improvement cost is saved to a great extent.

Owner:安徽海顺化工有限公司

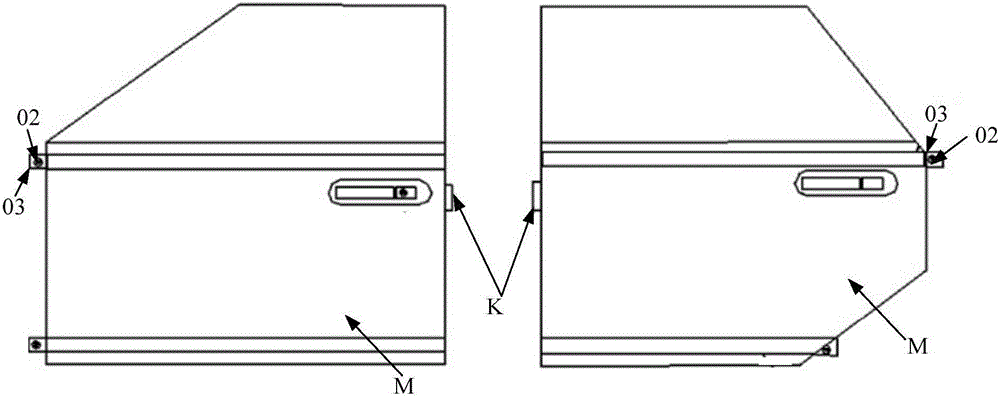

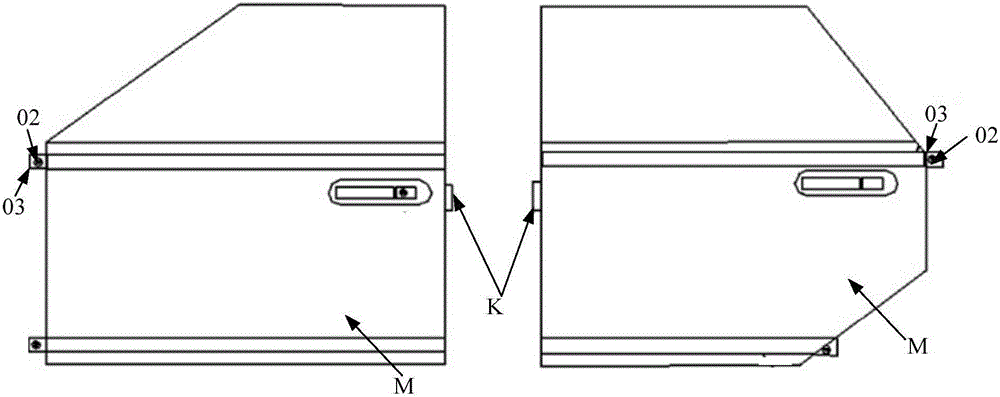

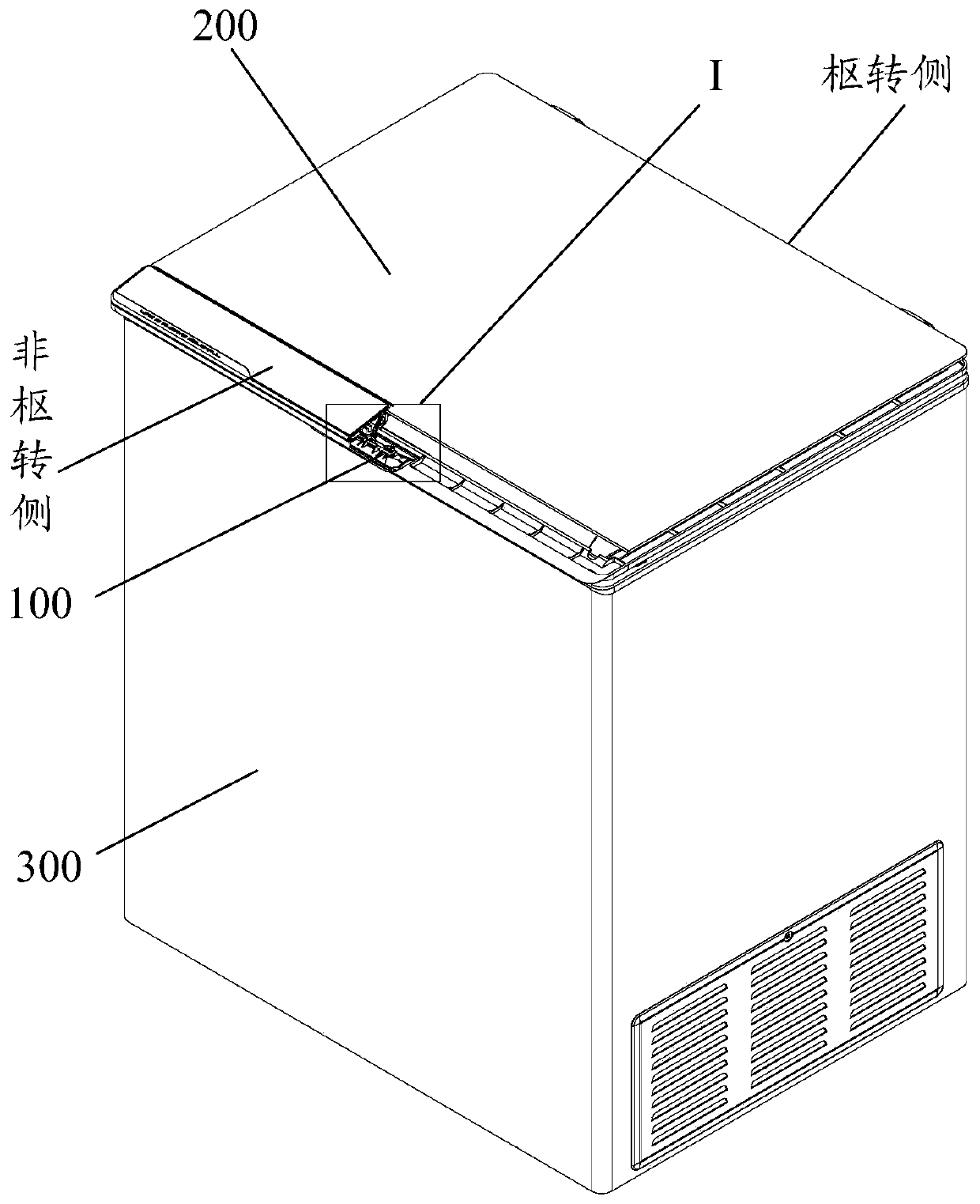

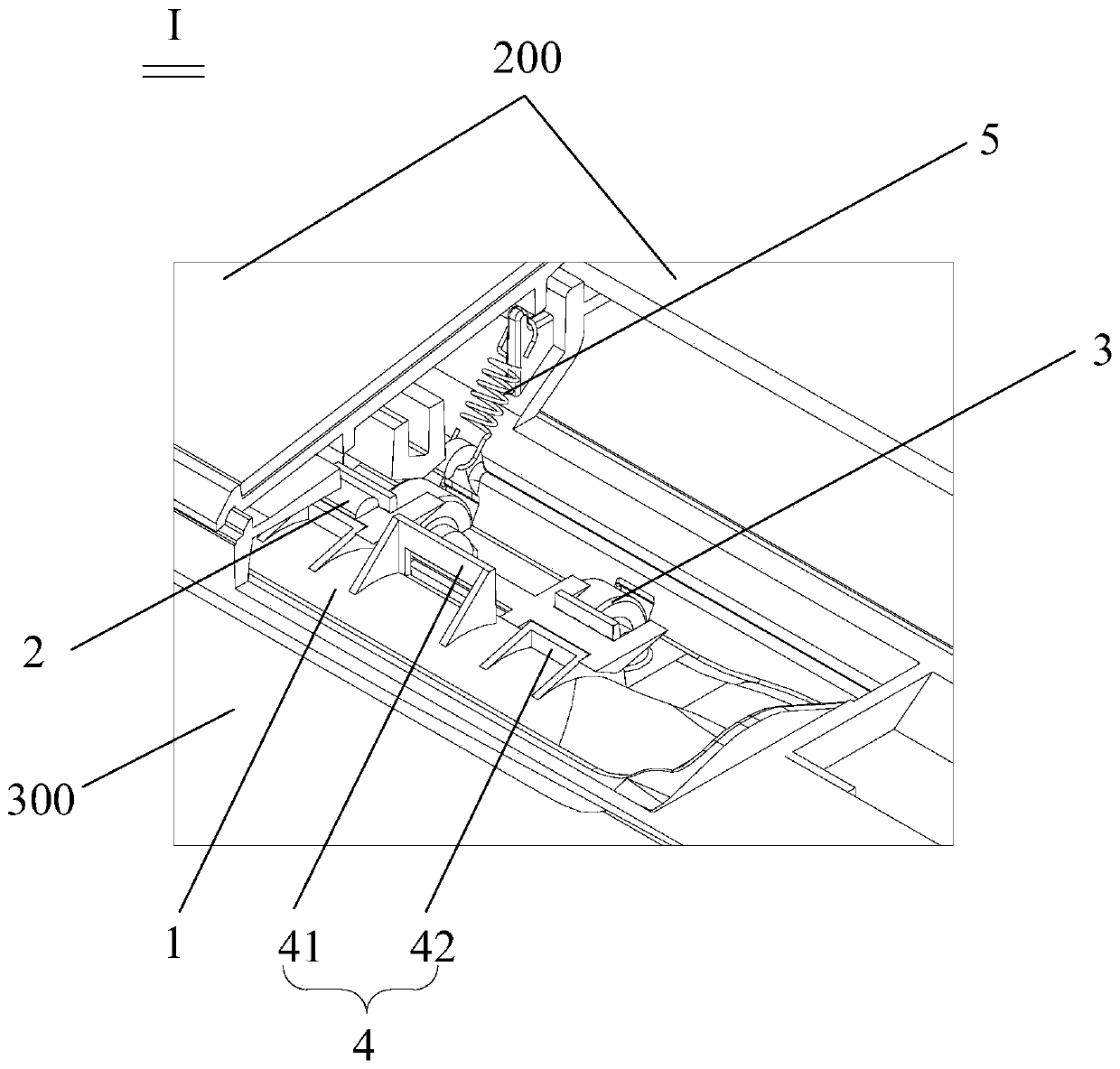

Cold storage device

InactiveCN109827372AReduce the difficulty of openingPlay a labor-saving effectDomestic cooling apparatusLighting and heating apparatusElectrical and Electronics engineeringCold storage

The invention discloses a cold storage device, relates to the technical field of cold storage devices, and aims at reducing the opening difficulty of a door body of the cold storage device. The cold storage device comprises a cold storage chamber and a door body assembly, wherein the door body assembly comprises a door body which is used for opening or closing the storage chamber and a power handle which is installed on the door body; the power handle comprises a handle body, and the handle body is rotatably installed on a non-pivot side of the door body through a handle rotary shaft; a driving part and a supporting part are arranged on the parts, located on the two opposite sides of the handle rotary shaft, of the handle body; the supporting part is close to the pivot side of the door body, and the driving part is away from the pivot side of the door body; the supporting part can be driven to move along the frame of the storage chamber by the rotation of the driving part to further drive the non-pivot side of the door body to move in the direction away from the cold storage chamber. The cold storage device is used for low-temperature storage of items.

Owner:HISENSE RONSHEN GUANGDONG FREEZER

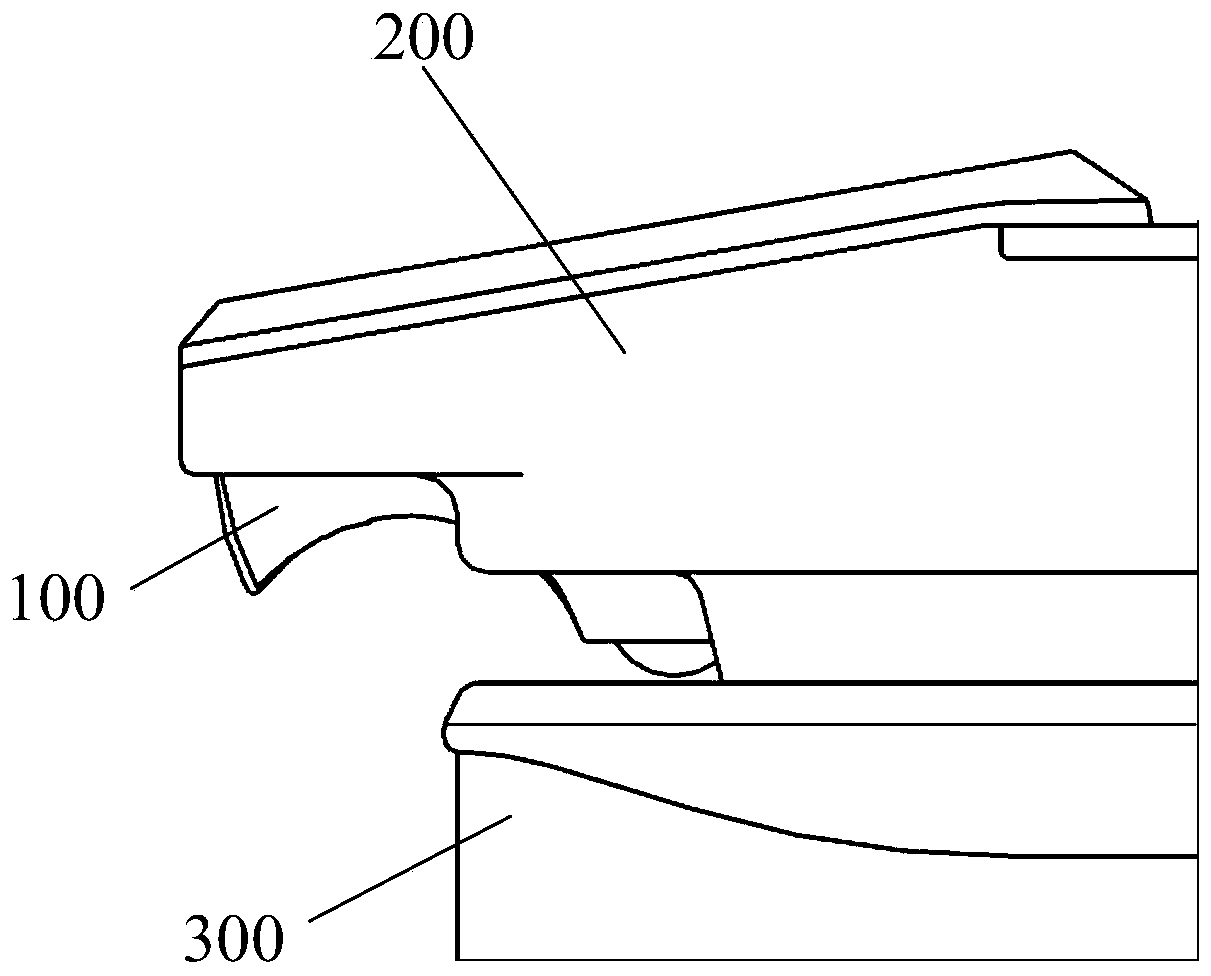

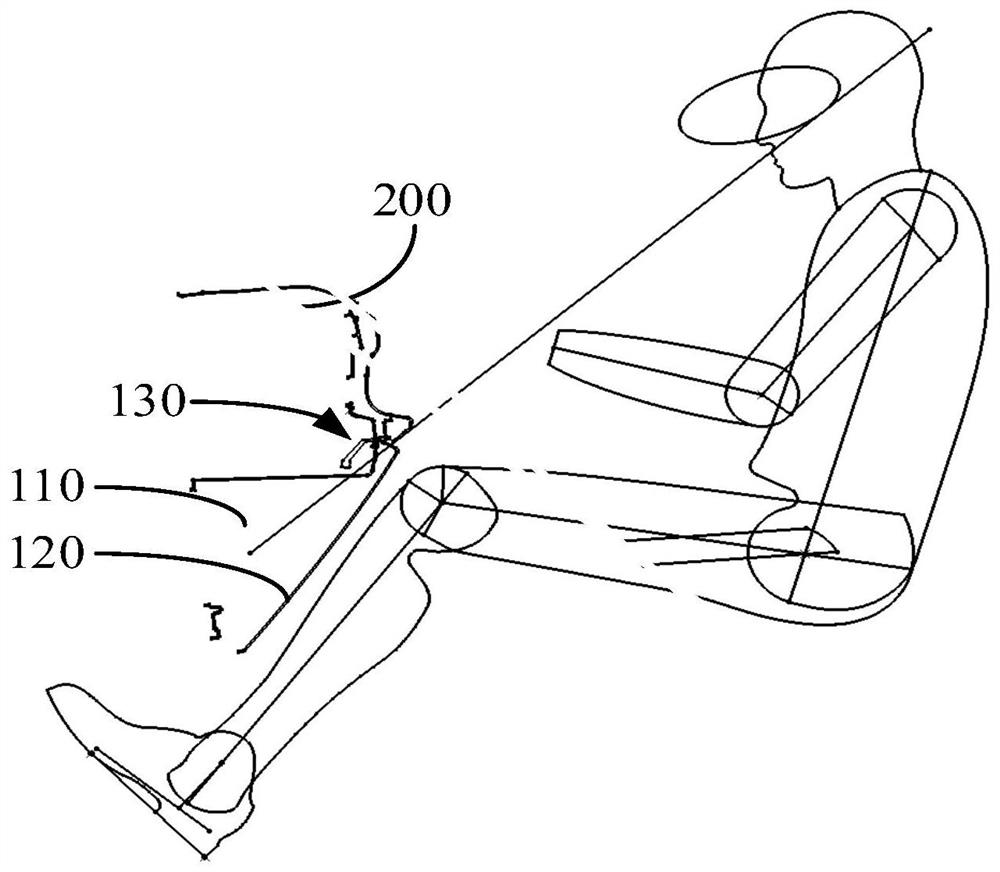

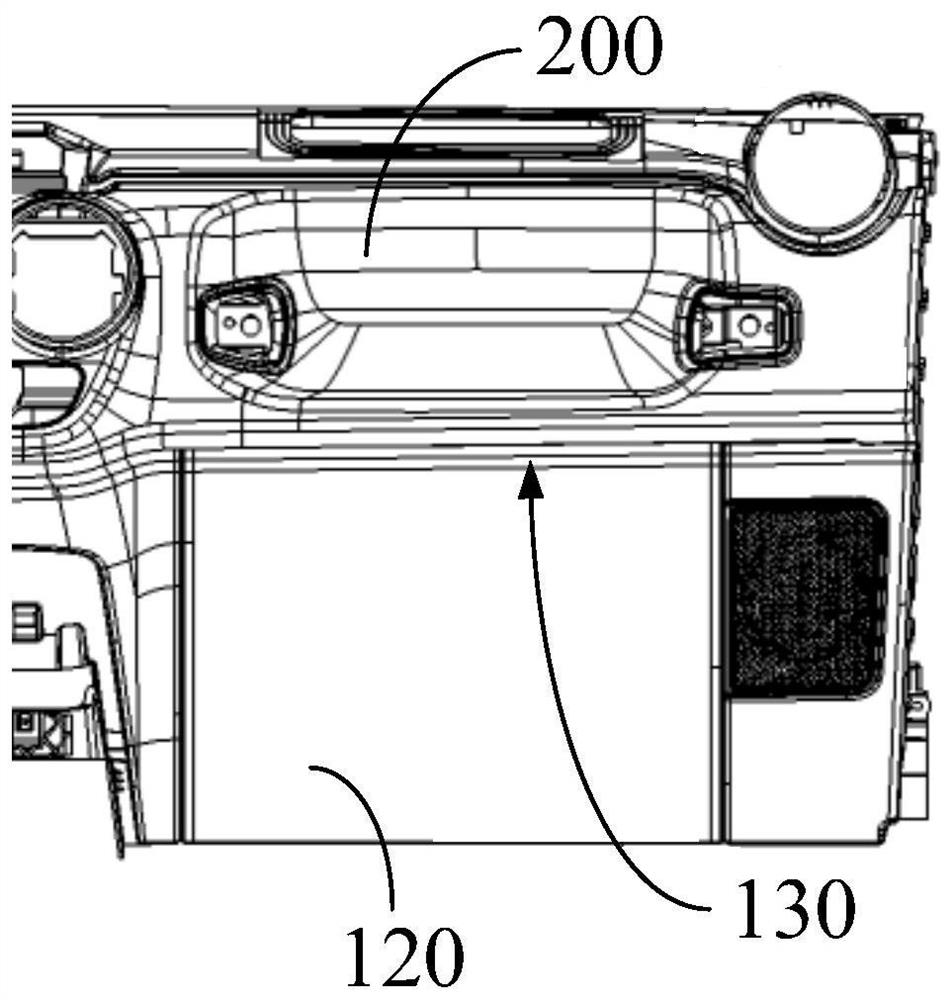

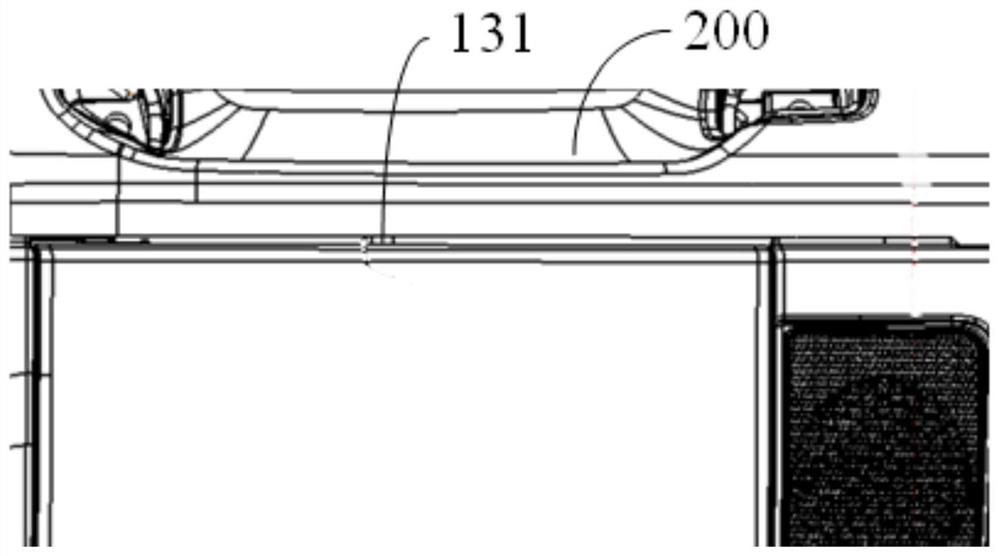

Glove box and vehicle

PendingCN112158140AReduce manufacturing costReduce the difficulty of openingPassenger spaceIndustrial engineeringGlovebox

The invention provides a glove box and a vehicle. The glove box is applied to the vehicle, and comprises a box body which is installed below an instrument board in an auxiliary cab of the vehicle, andis disposed at an interval with a pedal of the vehicle, and a box door which is hinged to the bottom edge of the box body and used for defining a closed containing space together with the box body, the box door and the instrument board are arranged at an interval to form a gap; the glove box further comprises a locking mechanism which comprises a poking piece, the poking piece is arranged in thegap, and when the poking piece is located at the first position, the box door and the box body are closed; and when the poking piece is located at the second position, the box door and the box body are closed and opened. According to the glove box and the vehicle provided by the embodiment of the invention, the opening difficulty of the glove box in the vehicle can be reduced, and meanwhile, the production cost of the vehicle can be saved.

Owner:BAIC GRP ORV CO LTD

Sliding sleeve assembly and construction pipe column

ActiveCN113653463AEasy assembly and productionReduce the difficulty of openingFluid removalWell/borehole valve arrangementsStructural engineeringOil production

The invention relates to the technical field of oil production engineering, and discloses a sliding sleeve assembly and a construction pipe column. The sliding sleeve assembly comprises a ball intercepting sliding sleeve and at least one ball passing sliding sleeve, wherein the at least one ball passing sliding sleeve is coaxially connected to the front of the ball intercepting sliding sleeve, the ball passing sliding sleeve is configured to be capable of pushing a first sealing inner sleeve to move to the rear section of a first outer sleeve through pressure building of a fracturing ball so as to open a first flow guide opening and release the fracturing ball into the ball passing sliding sleeve or the ball intercepting sliding sleeve behind the first flow guide opening, and the ball intercepting sliding sleeve is configured to be capable of pushing a second sealing inner sleeve to move to the rear section of a second outer sleeve through pressure building of the fracturing ball so as to open a second flow guide opening and block a rear end opening of the second outer sleeve. According to the sliding sleeve assembly, the ball passing sliding sleeve and the ball intercepting sliding sleeve can be completely opened through one-time ball throwing, the level difference does not exist between the sliding sleeves, the number of construction sections of the construction pipe column can be increased on the premise that the extreme difference of the fracturing ball is not changed, and therefore the productivity advantage of an oil-gas well is fully exerted.

Owner:CHINA PETROLEUM & CHEM CORP

Auxiliary device for opening manhole cover

InactiveCN109437071BEasy to openLoose and easySafety devices for lifting equipmentsDirt cleaningPower gridStructural engineering

The invention discloses an auxiliary device for opening a working well lid. The auxiliary device comprises a rack, wherein a mounting table driven by a first power plant is vertically mounted on the rack in a sliding manner; a rotary disc driven by a second power plant rotates on the mounting table; a dust loosening mechanism is mounted above the rotary disc in a sliding manner, is distributed onthe circumference of the rotary disc and extends downwards; a dust cleaning mechanism is arranged on the dust loosening mechanism; and a well lid shaking mechanism driven by a third power plant is arranged below the mounting table. Compared with traditional manual opening, the auxiliary device greatly lowers the labor strength of working staff and the well lid opening difficulty, costs less time,is high in well lid opening efficiency, ensures fast repairing and maintenance and normal electric power supply of a power grid system, does not cause any damage to the well lid body, ensures the service life of the well lid, and is convenient in operation, excellent in using effect and high in practicality.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com