High-temperature high-pressure thermal fluid seepage simulation device

A high temperature and high pressure, seepage simulation technology, applied in the field of diagenetic environment simulation and reservoir seepage physics simulation, can solve the problems of long compaction period, difficult to simulate real core, low efficiency, etc., and achieve good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

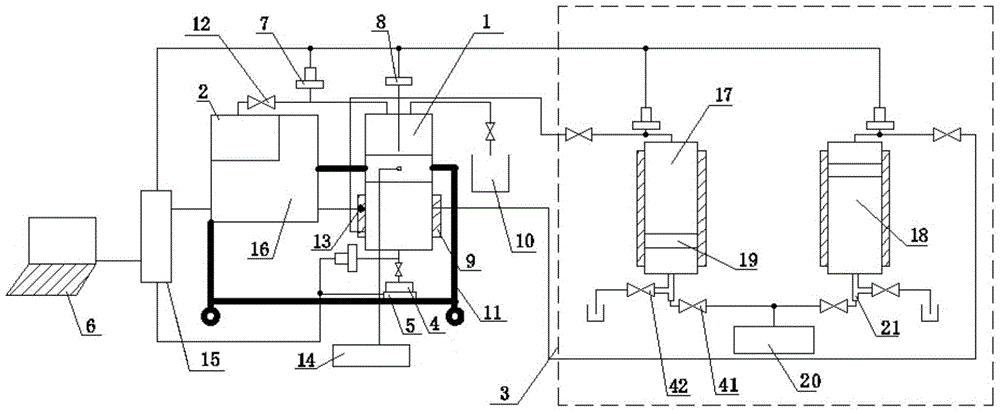

[0034] The high-temperature and high-pressure thermal fluid seepage simulation device provided by the present invention has a structure such as figure 1 and figure 2 As shown, it includes a diagenetic reaction control simulation device 1, a high-temperature and high-pressure pump 2 connected to the diagenetic reaction control simulation device, a thermal fluid circulation unit 3 and a power element 14. This embodiment adopts pneumatic reset, and the power element is an air compressor. The control simulation device is equipped with a computer 6, a data collector 15 electrically connected to the computer, and a power control switch 16 electrically connected to each electrical component;

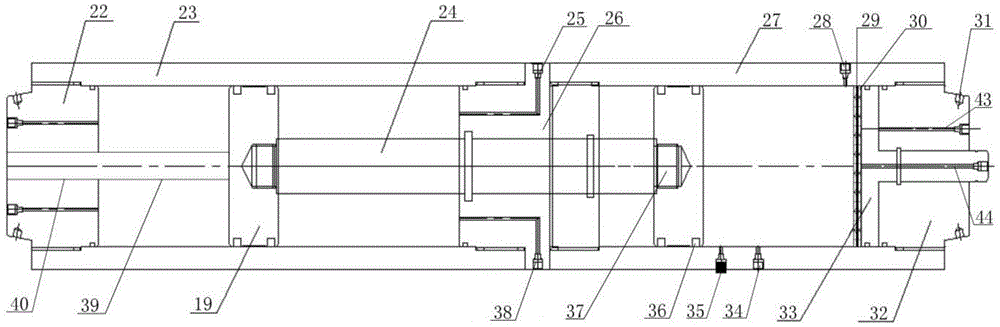

[0035] The diagenetic reaction control simulation device such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com