Coal powder-prevention tubular discharging and extracting pump

A pulverized coal and tube-type technology, applied in the direction of variable capacity pump components, pumps, pump components, etc., can solve the problems of low flow rate into the pump, difficulty in opening the pump valve, wear, etc. Cycle, the effect of increasing the runner area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

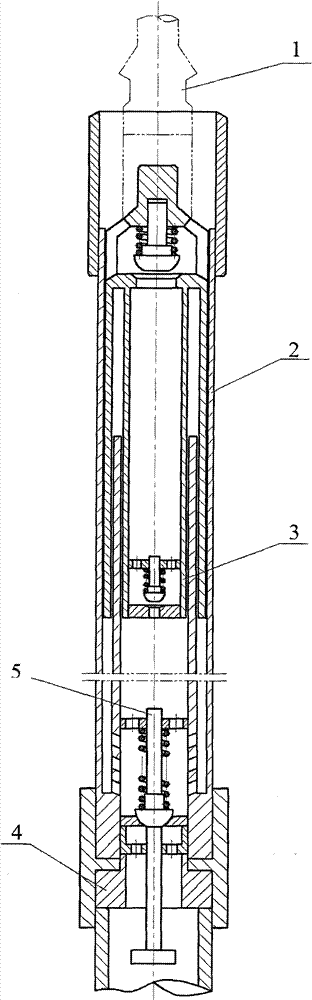

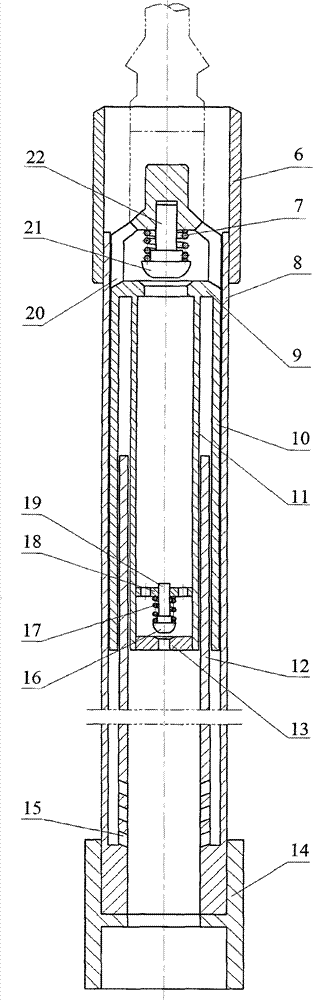

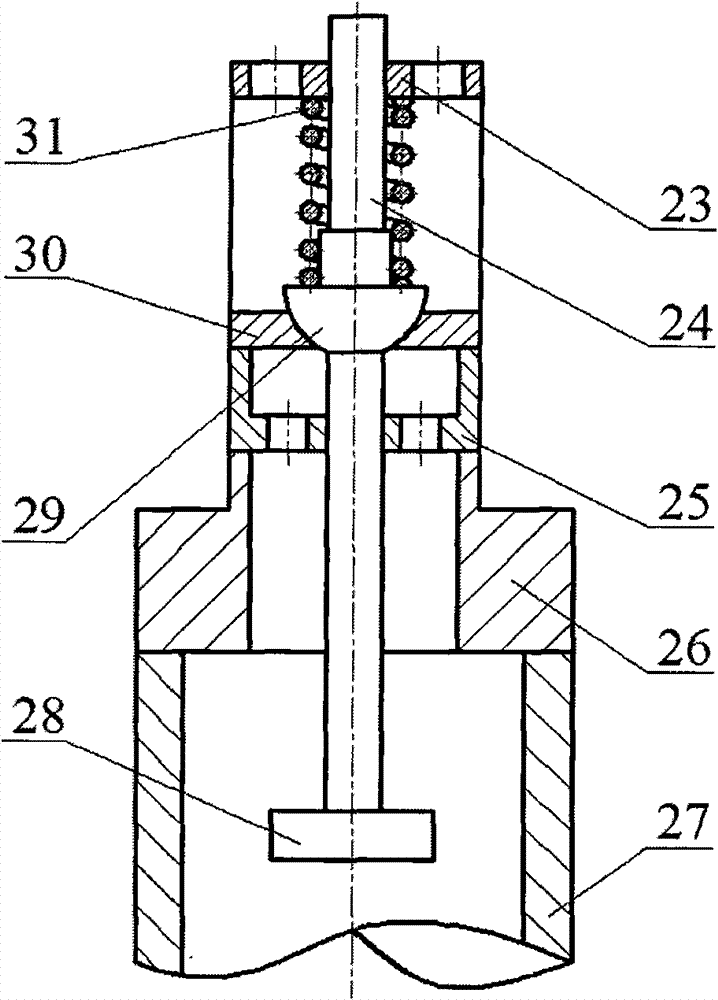

[0015] exist figure 1 Among them, the pulverized-coal-proof tubular drainage pump consists of drainage rod 1, plunger assembly 3, pump barrel assembly 2, liquid inlet valve assembly 5 and fixing device 4 from top to bottom, according to the actual production requirements of coalbed methane wells , the top of the upper pump barrel collar 6 can be installed with an extension nipple, and between the lower pump barrel collar 14 and the screen pipe 27, downhole appliances such as gas anchors and tailpipes can be added.

[0016] exist figure 1 Before pumping, carefully check the flexibility of the plunger assembly 3 in the pump barrel assembly 2, keep the plunger and pump barrel lubricated and clean, and check whether the threaded joints are firm, loose or damaged and rust. When running the pump, first lower the pump barrel assembly 2, fixing device 4 and liquid inlet valve assembly 5 together with the drainage pipe to the design depth in the well, and then lower the plunger assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com