Manufacture machine and method for red jujube with walnut kernel

An integrated machine technology for jujube and walnut, which is applied in the field of jujube and walnut making all-in-one machine, which can solve the problems of high cost and defective processing, and achieve the effect of simple structure, saving space and reducing the difficulty of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

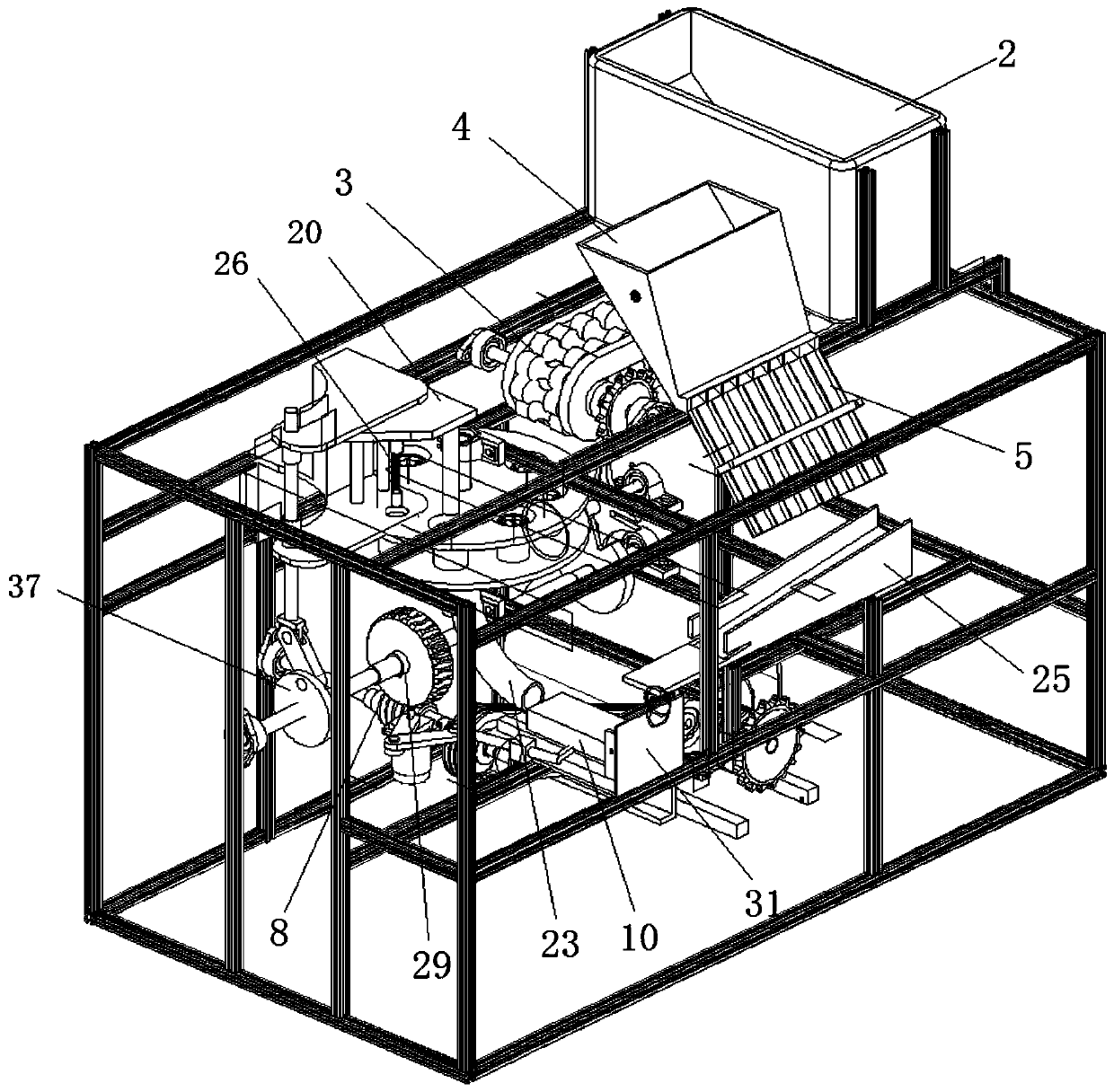

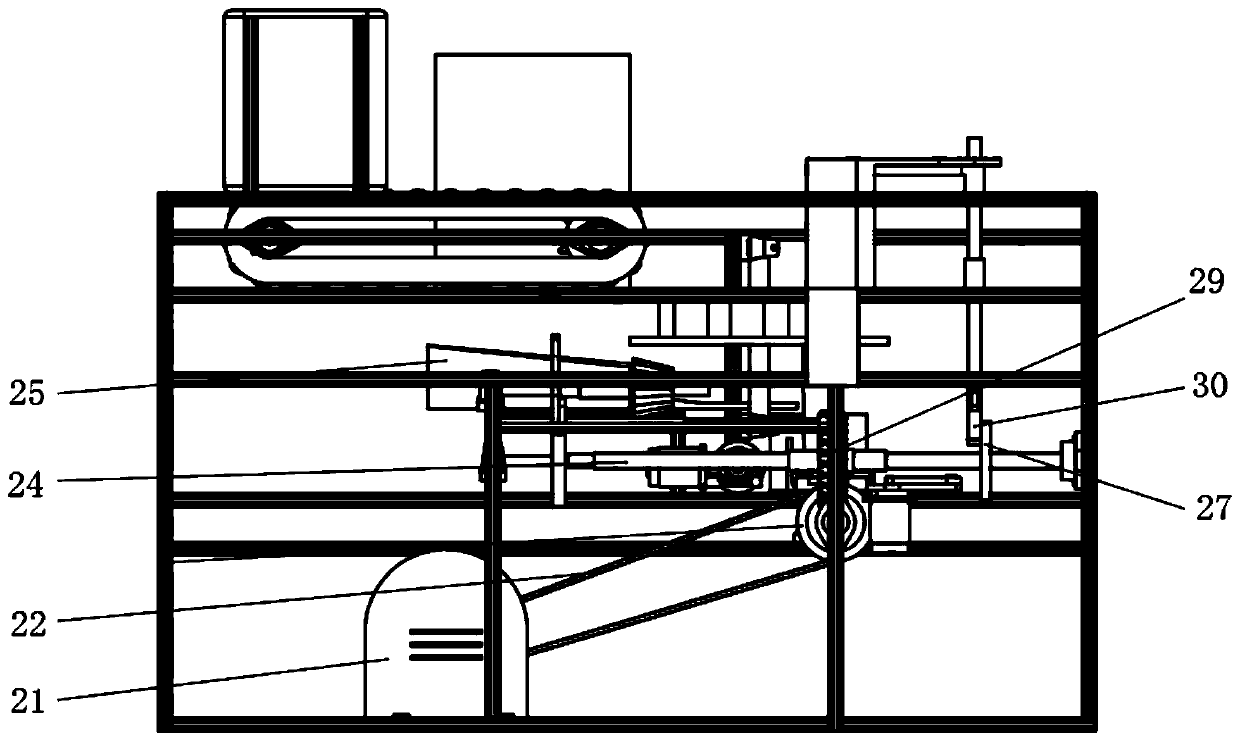

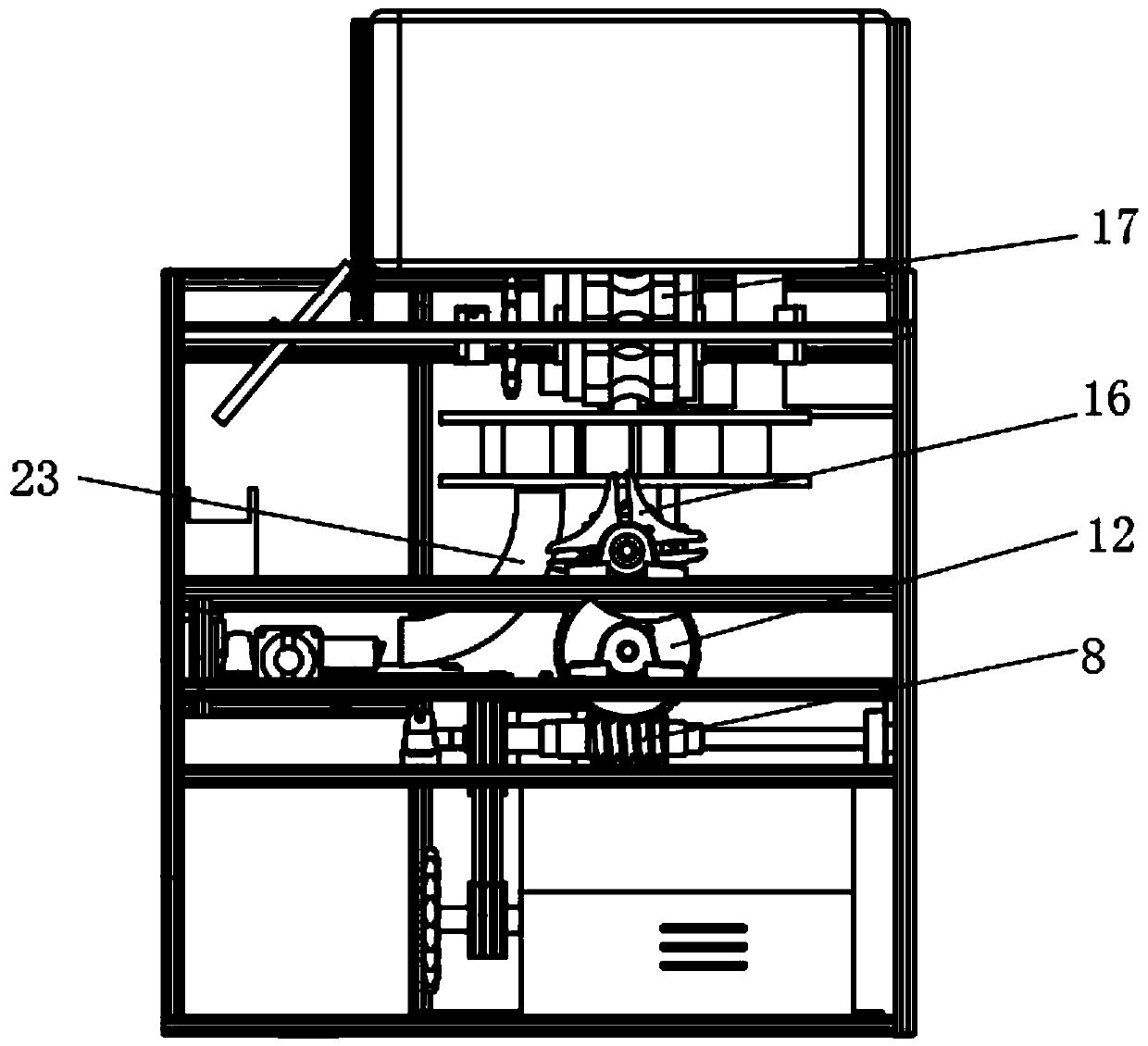

[0043] Attached below Figure 1-Figure 3 The present invention is described in detail, specifically, the structure is as follows:

[0044] This embodiment provides an all-in-one machine for making dates and walnuts, which is composed of a control system, a transmission system, and an execution system. The execution system includes a jujube feeding device installed on the frame body 1, a walnut feeding device, and a jujube pitting device. , jujube opening device, finished product assembly device, wherein, frame body 1 is the frame structure that is made of aluminum profile. The transmission system includes a motor-driven pulley transmission mechanism 22, a sprocket transmission mechanism, and a worm gear mechanism. The control system takes the single-chip microcomputer as the core, and then drives the orderly operation of each mechanism by controlling the rotation state of each motor.

[0045] Such as Figure 5Shown, red date feeding device comprises red date feeding box 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com