Equipment capable of improving production efficiency of wooden framed cases

A production efficiency, wooden box technology, applied in metal processing equipment, grinding/polishing equipment, grinding racks, etc., can solve the problems affecting the polishing quality and polishing efficiency, and achieve the effect of improving the polishing efficiency and increasing the polishing angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

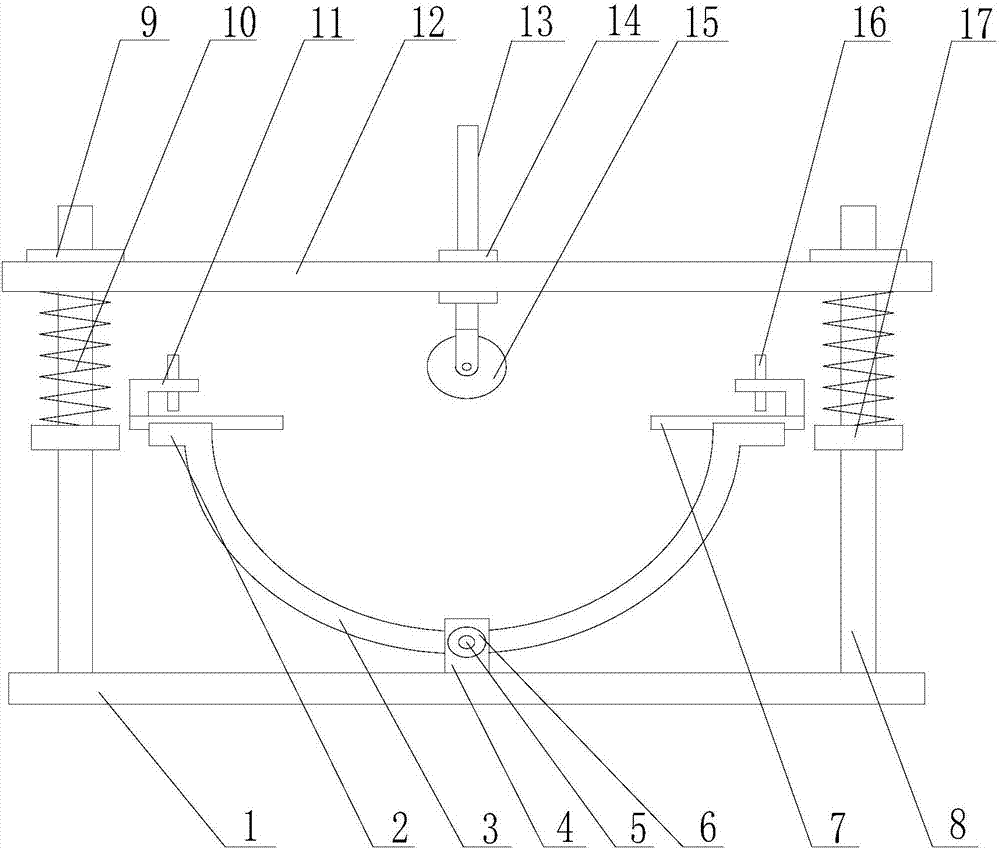

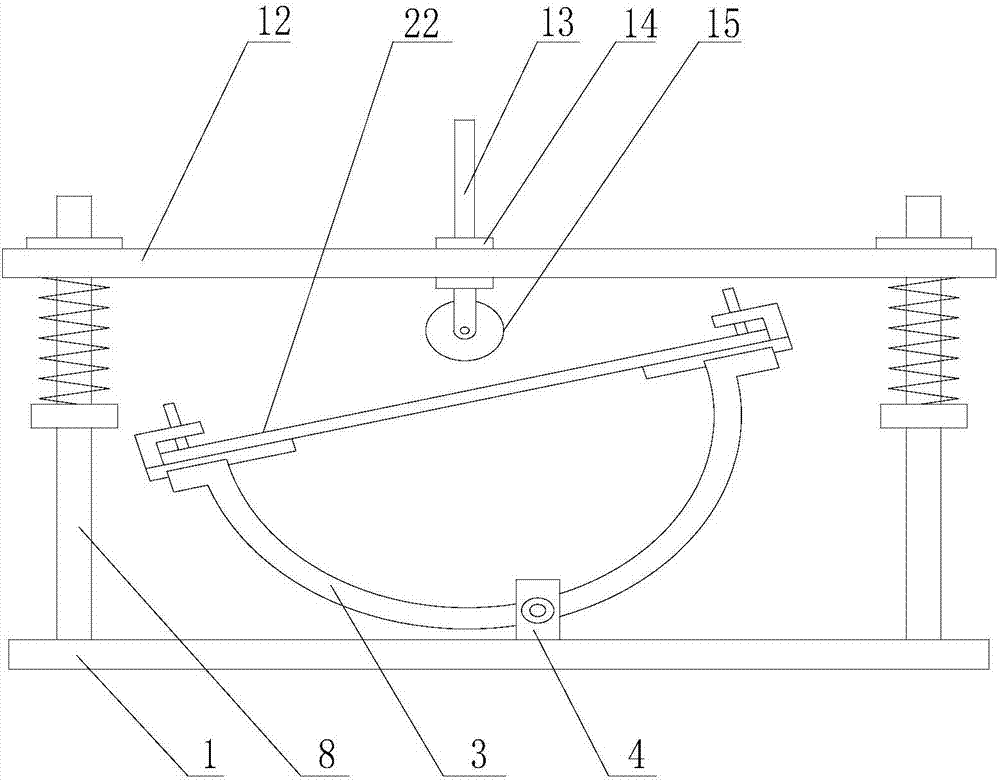

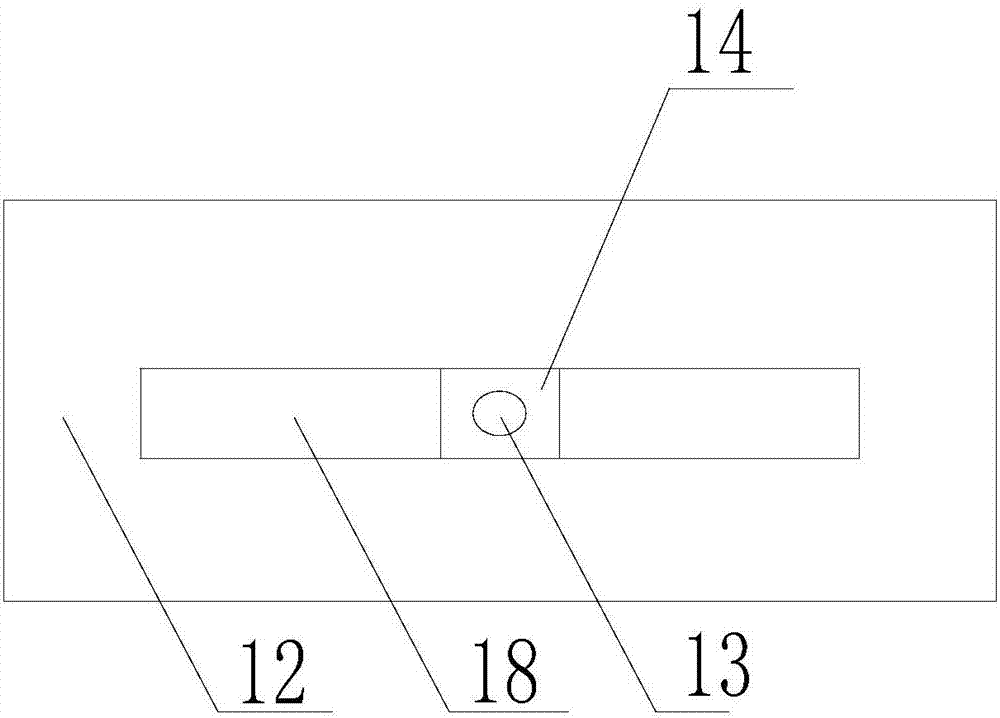

[0025] Such as Figure 1 to Figure 5 As shown, the present invention can improve the production efficiency of the frame wooden box, including a base 1, the top of the base 1 is provided with a connecting block 4, the connecting block 4 is located at the central position of the base 1, and the top of the connecting block 4 is provided with a concave Groove 21, be provided with the arc frame 3 that opening faces upwards in the groove 21, also be provided with movable shaft 5 on the described connection block 4, and movable shaft 5 passes through the movable shaft 5 in the groove 21, movable shaft 5 can Rotate in the connection block 4, when the movable shaft 5 rotates, the arc frame 3 will rotate together, the movable shaft 5 is also provided with a fixed element 6, the fixed element 6 is connected with the movable shaft 5 through threads, and the fixed element 6 is a nut , when the fixed element 6 is loosened, the movable shaft 5 can rotate in the connecting block 6, when the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com