Non-ironing non-point-location patch pocket template for kangaroo pouches

A kangaroo, point technology, applied in textile and paper making, cloth feeding mechanism, sewing equipment and other directions, can solve the problems of complicated process steps, increase working time, reduce work efficiency, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in combination with preferred embodiments and accompanying drawings.

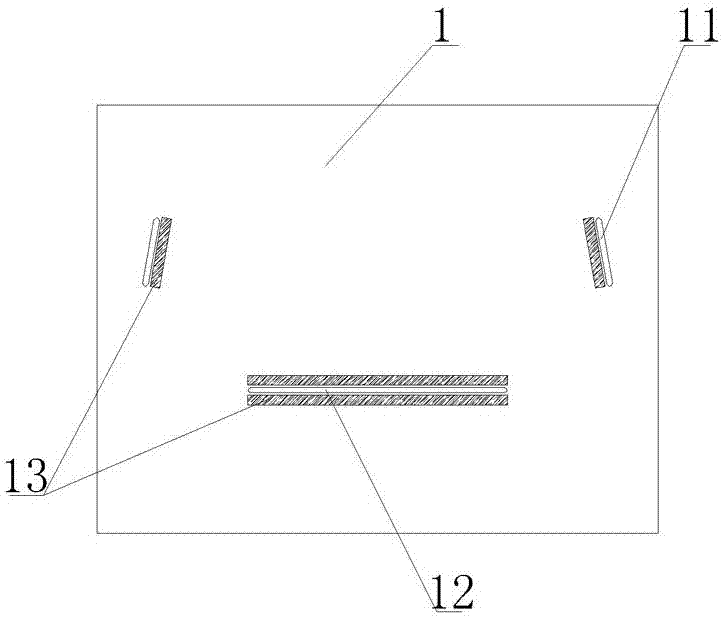

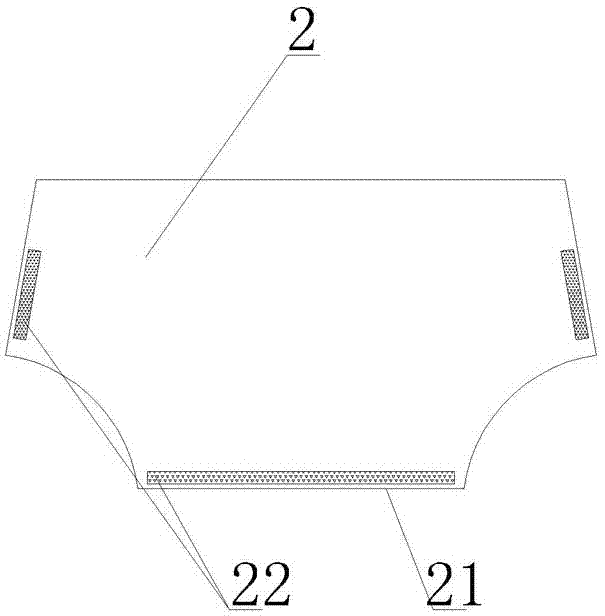

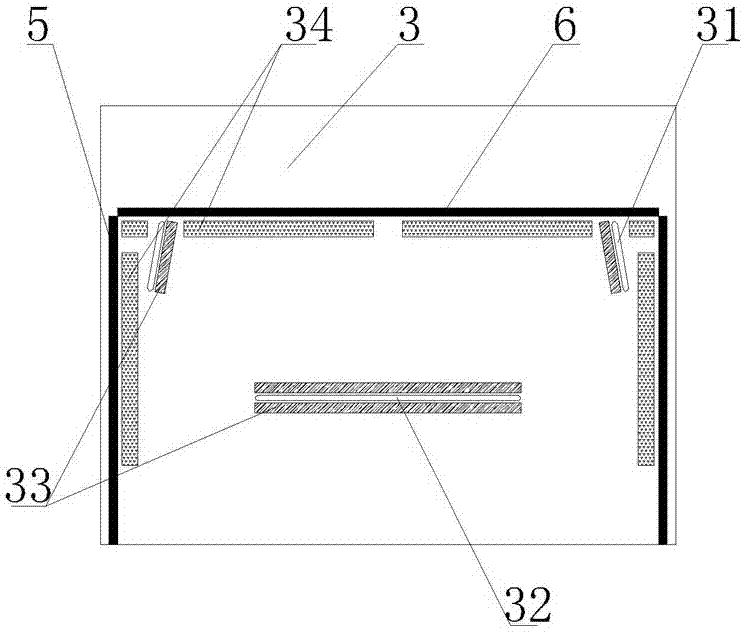

[0020] Such as Figure 1-7 As shown, the kangaroo bag non-ironing and point-free patch bag template according to the present invention includes a cover plate 1, a middle plate 2 and a bottom plate 3, and the cover plate 1, the middle plate 2 and the bottom plate 3 are all made of PVC transparent boards, and the cover plate One side of the plate 1, the middle plate 2 and the bottom plate 3 are pasted and connected with each other by adhesive tape to form a hinged edge 4. The sides are respectively provided with a first sewing groove 11 with a width of 4mm for sewing the side edges of the pocket cloth, and a width of 4mm is provided on the cover plate in the middle of the two first sewing grooves 11 for sewing the bottom of the pocket cloth. The second sewing groove 12 on the side, and along the first sewing groove 11 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com