Mounting method for prestress tensioning end slip-form formworks

An installation method and prestressing technology, applied in the direction of formwork/formwork/work frame, large-capacity bulk material storage, building type, etc., can solve the problem of affecting the prestressing effect, insufficient compactness and low strength of concrete at the tension end, etc. problems, to achieve the effect of safe and reliable engineering quality, ensure the tightness of the seams, and the structure of the template is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

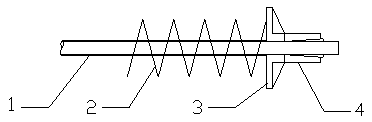

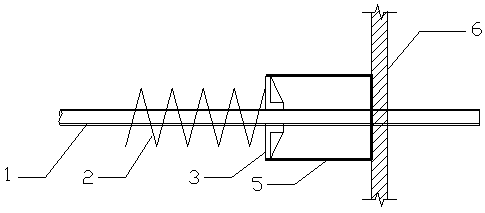

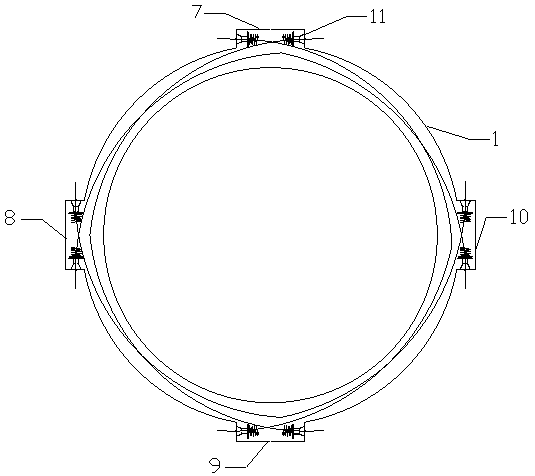

[0039] The construction process of the installation method of the prestressed tension end sliding formwork formwork of the present invention:

[0040] Modification of buttress column formwork → installation of stop angle steel → installation of prestressed tendons, spiral reinforcement, cavity formwork and installation of wooden baffles → pouring concrete, lifting of sliding form → removal of wooden baffles, turnover use.

[0041] The installation method of the prestressed tension end slipform formwork of the present invention is used in the slipform technology of large-diameter reinforced concrete silos. Four buttress columns are arranged on the concrete silo wall, and the buttress columns are evenly arranged along the concrete cylinder wall 13. The buttress column is used as the tension end 11 of the prestressed tendon, and the prestressed tendon 1 is provided with several bundles of steel strands, and each bundle of steel strands is provided with three steel strands. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com