Alternately oblique and straight pile group-pile cap-superstructure similarity model manufacturing formwork

A technology of alternating oblique and straight, structural formwork, applied in the direction of basic structure engineering, basic structure test, construction, etc., to achieve the effect of ensuring production quality, strong practicability, and simple formwork structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

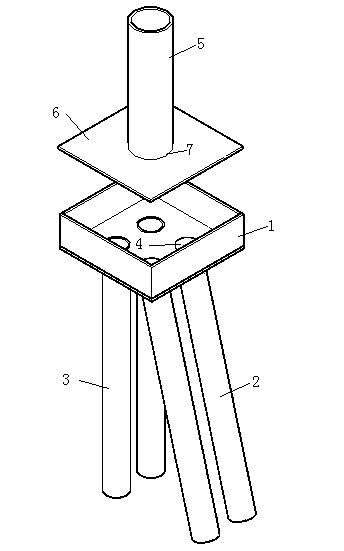

[0011] Such as figure 1 Shown, the present invention's oblique and straight alternating pile group-cap-upper structure similar model making formwork, it is made up of oblique and straight alternate pile group formwork, cap formwork 1 and superstructure formwork; Described oblique and straight alternate pile group formwork consists of It consists of an inclined PVC round pipe 2 with a closed bottom and a vertical PVC round pipe 3; the platform template 1 is made of plexiglass, which is a hollow cubic box without a top cover and a reserved hole 4 on the bottom plate, and the platform template 1 It is bonded with the oblique and straight alternating pile group formwork at the reserved hole 4 through glass glue; the upper structure formwork is composed of a PVC round pipe 5 and a platform cover plate 6, and the platform cover plate 6 is made of plexiglass A hole 7 is rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com