Compressor de-spring test device and test method thereof

A test equipment and compressor technology, applied in mechanical equipment, pump testing, machine/engine, etc., can solve problems such as compressor vibration aggravation, inability to verify the influence of centripetal acceleration, compressor de-spring, etc., to reduce the failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

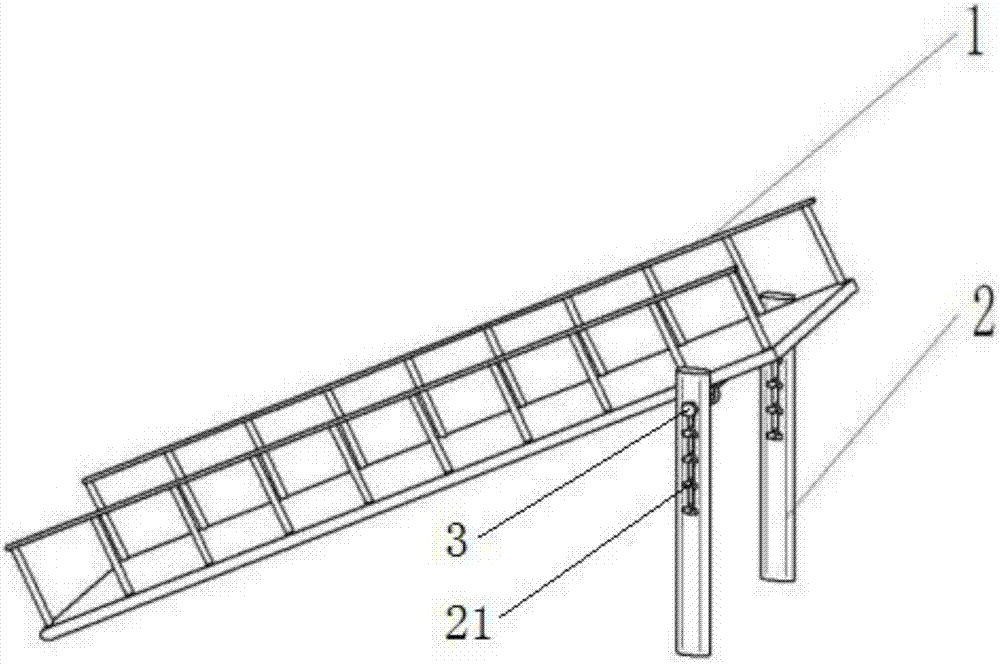

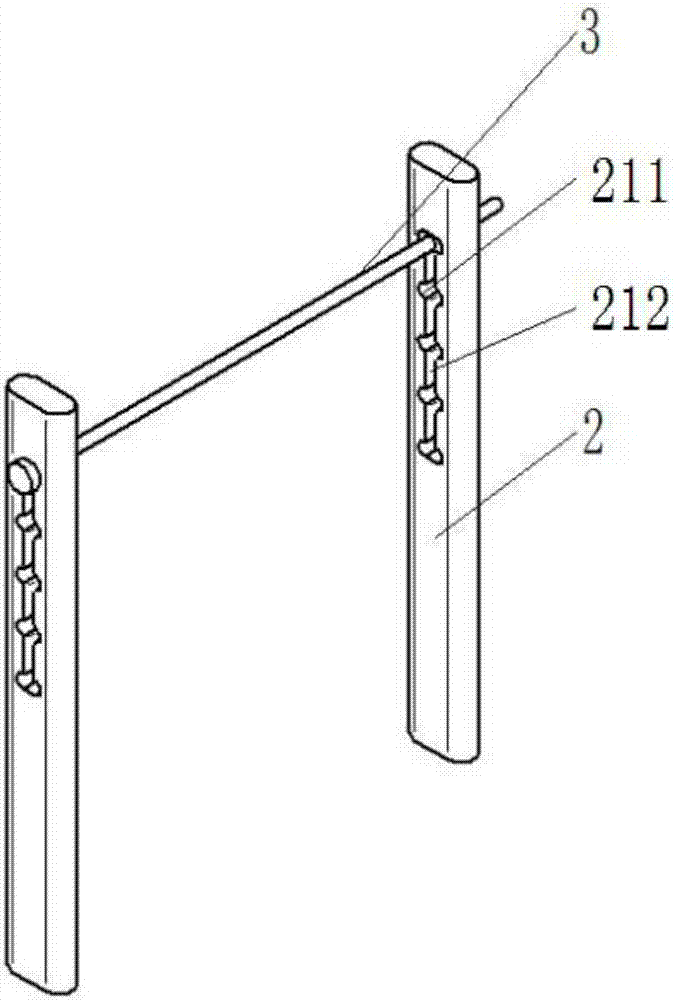

[0024] figure 1 Show the specific embodiment of the present invention: a kind of compressor off-spring test equipment, comprise slide device 1, fixed pile 2 and positioning rod 3; Fixed column is provided with two, and fixed column is provided with through groove 21 on vertical direction, The positioning rod 3 passes through the through grooves 21 of the two fixed columns, and the height of the positioning rod 3 relative to the ground is arbitrarily adjusted and fixed. When the positioning rod 3 and the fixed column remain in a fixed state, the positioning rod 3 is parallel to the horizontal plane; the slide device 1 The bottom of the bottom is provided with a hook 12, and the slide device 1 is fixed on the positioning rod 3 by the hook 12, so that the slide device 1 is inclined relative to the horizontal plane.

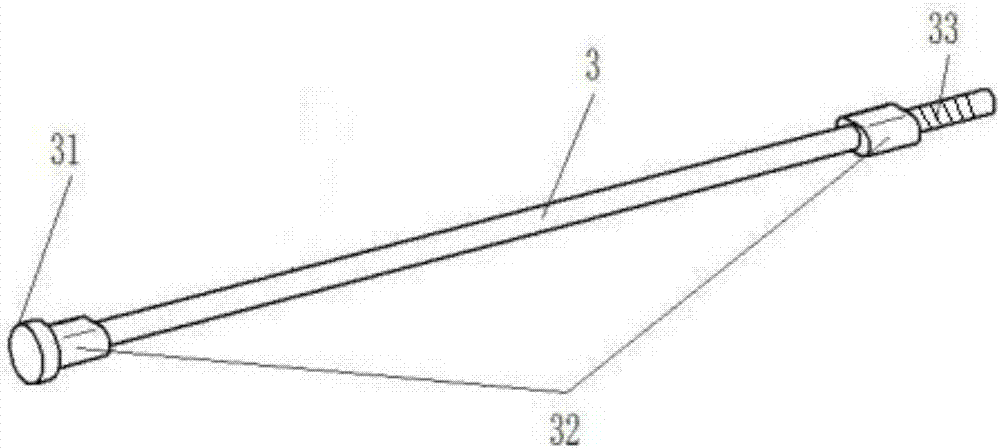

[0025] The two ends of positioning bar 3 are provided with fixing block 32, and described through groove 21 is formed by a plurality of fixing holes 211 and Unicom h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com