Electrical connector applied to LED light strip

A technology of LED light strips and electrical connectors, which is applied in the direction of connection, parts and circuits of connection devices, etc., can solve problems such as workers' matching mistakes, and achieve the effect of improving the matching range and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

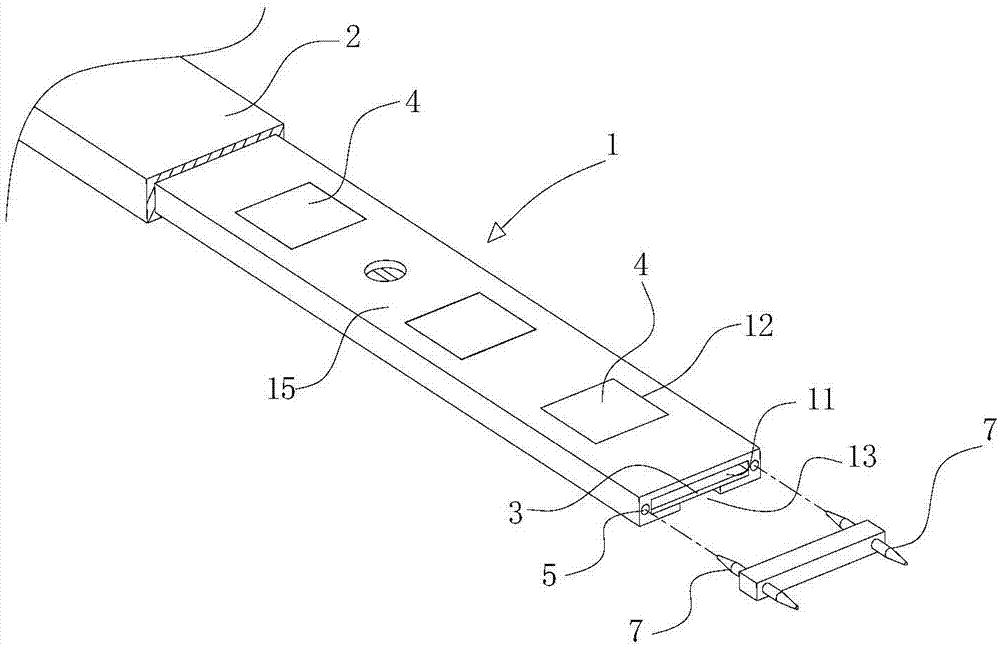

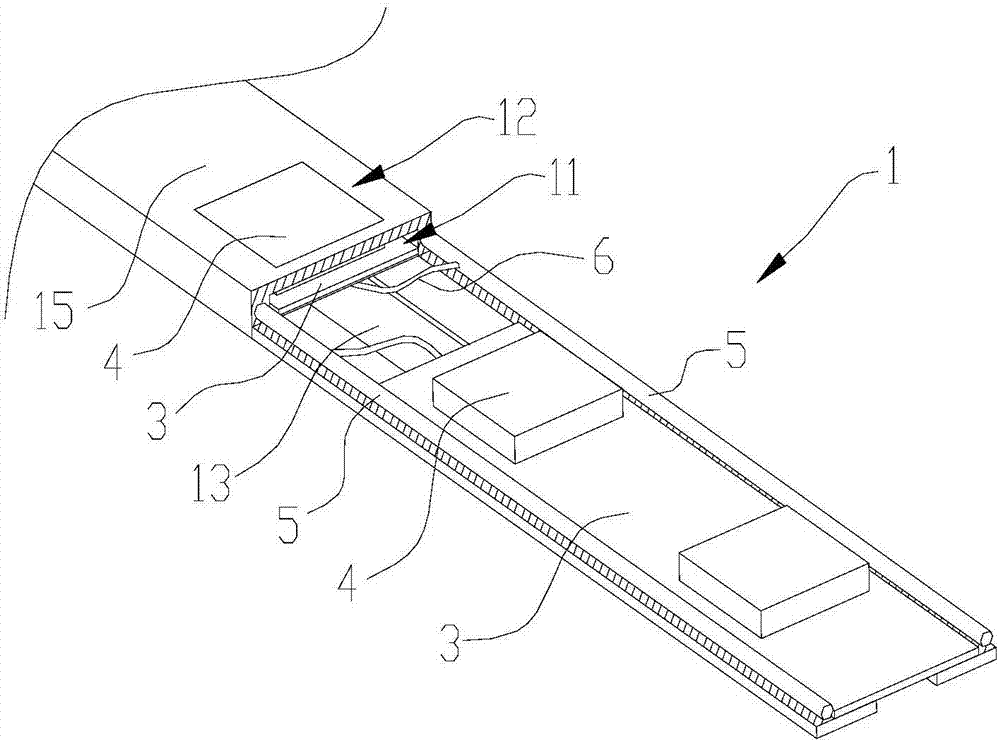

Embodiment 1

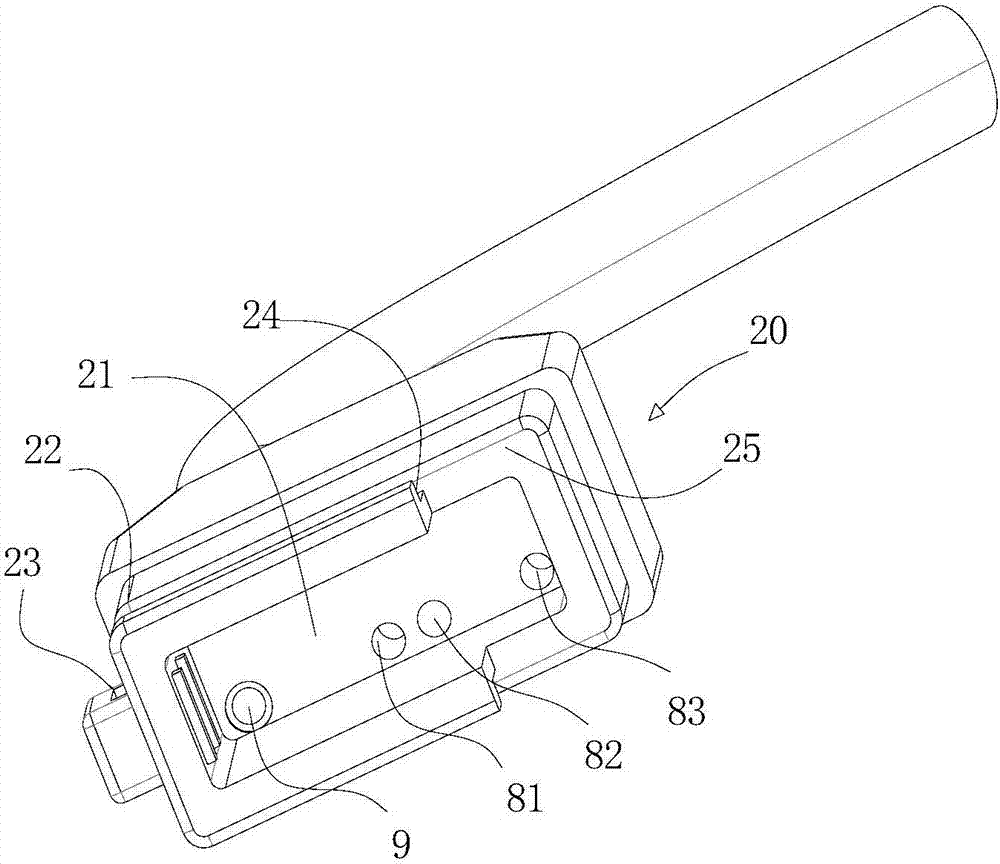

[0024] Such as Figure 3-Figure 5 As shown, the electrical connector 20 of the LED light strip provided by the present invention includes an output terminal for electrical connection with the LED light strip. The output terminal is composed of three interface terminal groups, and each interface terminal group is composed of a positive output interface terminal and a positive output interface terminal. It consists of negative output interface terminals. The spacing between the positive output interface terminals and the negative output interface terminals of each interface terminal group is different. All the interface terminals are jacks, and all interface terminal groups share a negative output interface terminal 9. The negative output interface terminal 9 respectively form interface terminal groups of different sizes with the three positive output interface terminals 81, 82, and 83 on the same straight line, and respectively connect with LED strip terminal blocks of different...

Embodiment 2

[0029] As another implementation, refer to Figure 7 , there is a plug-type negative output interface terminal 31 and three other jack-type positive output interface terminals 32, 33, 34 to form an output terminal group of 3 interface terminals, and each interface terminal is on the same straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com