Rotor assembly and permanent magnet motor

A technology for permanent magnet motors and rotors, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as torque ripple, insufficient motor output, and inability to form air gap flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

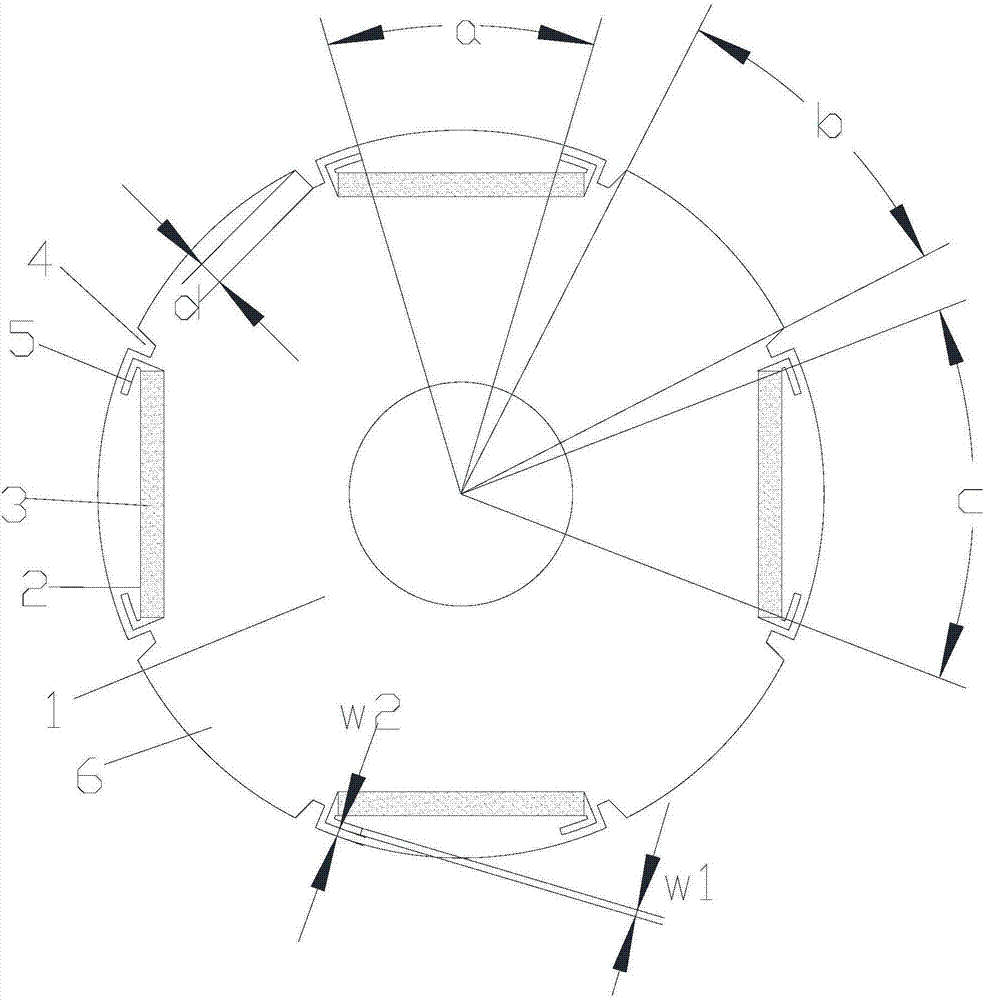

[0043] see in conjunction figure 1 As shown, according to the first embodiment of the present invention, the first air slot 4 extends inwardly from the outer edge of the rotor core 1, the second air slot 5 is located inside the outer peripheral edge of the rotor core 1, and is connected to the mounting slot 2 at the end The parts are connected, and a space is formed between the first air groove 4 and the second air groove 5 . In this embodiment, the installation groove 2 is in a straight shape, and correspondingly, the permanent magnet 3 is also in a straight shape as a whole. This structure can significantly reduce the amount of permanent magnets used, reduce the cost of the motor, and has a larger output and smaller torque ripple.

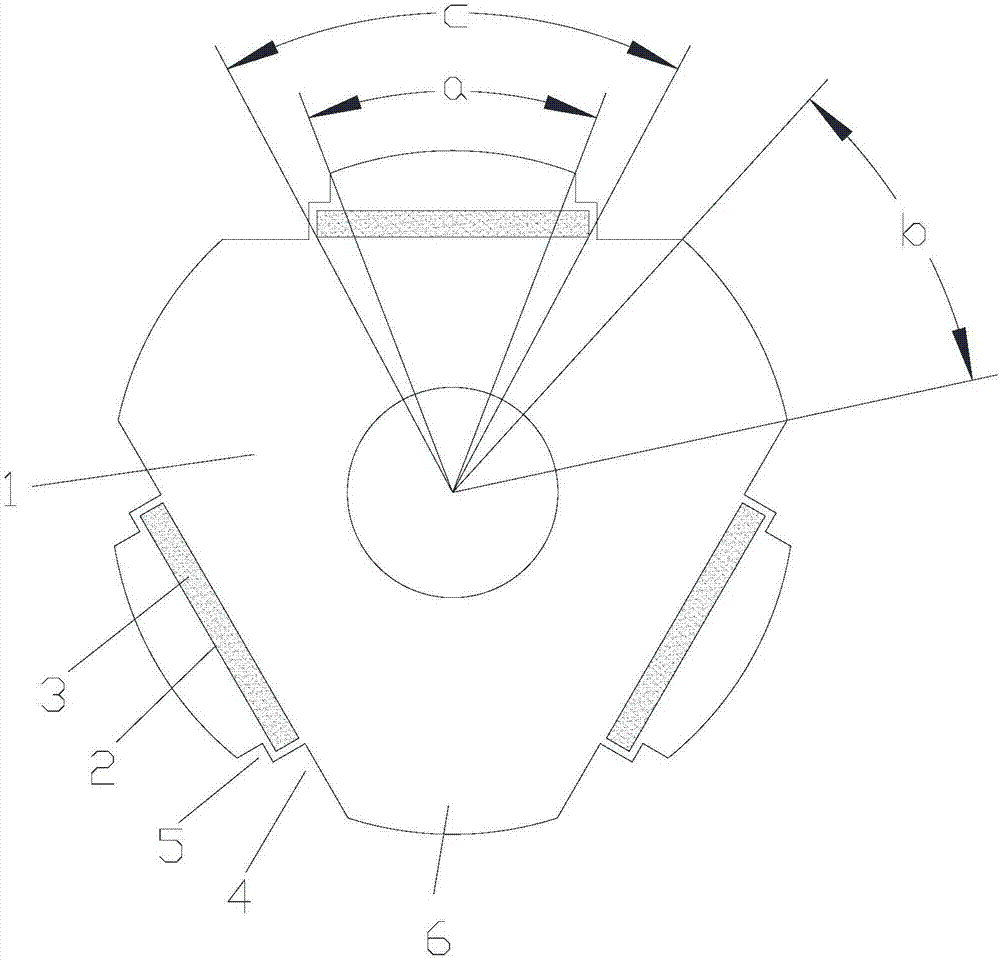

[0044] see in conjunction figure 2 As shown, according to the second embodiment of the present invention, the first air groove 4 extends from the outer edge of the rotor core 1 to the inside, the second air groove 5 extends from the outer edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com