Processing method and device of full-revolving-propulsor rudder angle sensor signals

A technology of azimuth thruster and rudder angle sensor, which is applied in the directions of ship propulsion, propulsion components, transportation and packaging, etc., can solve the problems of uneven distribution of the detection value of rudder angle, large error, affecting the navigation of ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

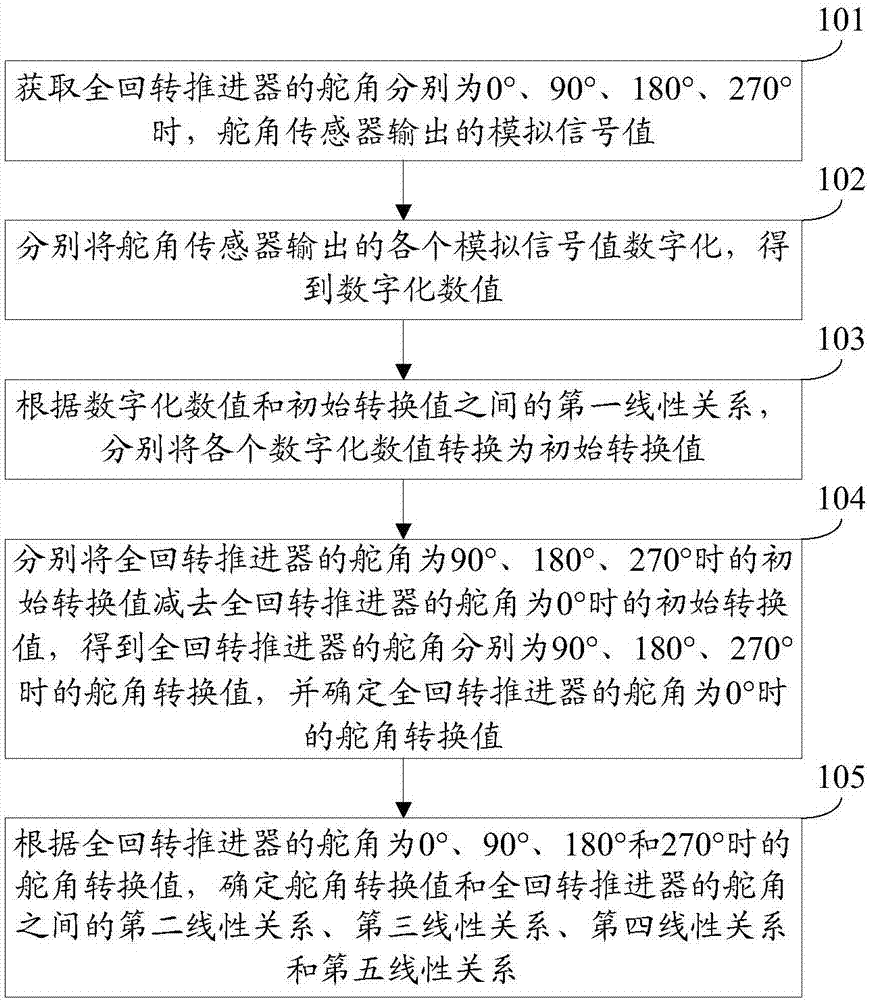

[0071] The embodiment of the present invention provides a processing method of the rudder angle sensor signal of an azimuth thruster, see figure 1 , The processing method includes:

[0072] Step 101: Obtain the analog signal value output by the rudder angle sensor when the rudder angles of the azimuth propeller are 0°, 90°, 180°, and 270° respectively.

[0073] In this embodiment, the rudder angle sensor is a sensor that detects the rudder angle of the azimuth propeller, which can be specifically implemented by an angle sensor. The rudder angle sensor will output a corresponding analog signal when detecting the rudder angle of the azimuth thruster. The analog signal is theoretically a current signal of 4-20mA or a voltage signal of 0-10V, but in actual implementation, due to the rudder angle sensor The detection range is limited. The minimum value of the analog signal output by the rudder angle sensor may be greater than 4mA or 0V, and the maximum value may be less than 20mA or 10V...

Embodiment 2

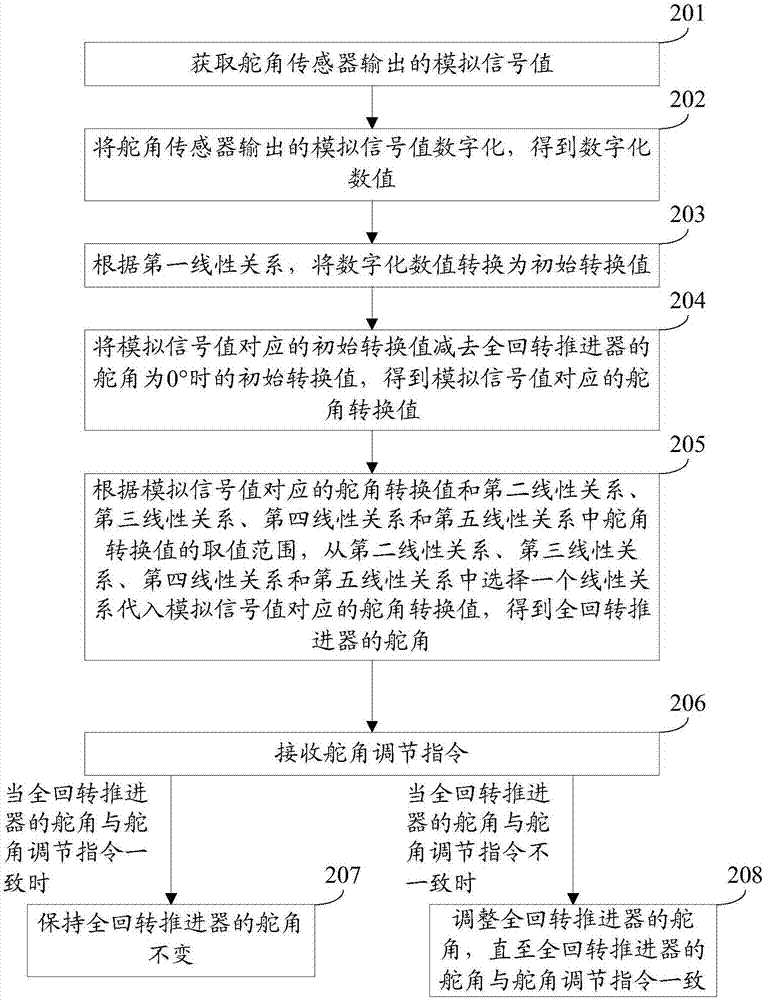

[0112] The embodiment of the present invention provides a processing method of the rudder angle sensor signal of an azimuth thruster, see figure 2 , The processing method includes:

[0113] Step 201: Obtain the analog signal value output by the rudder angle sensor.

[0114] Specifically, this step 201 is similar to step 101, and will not be described in detail here.

[0115] Step 202: digitize the analog signal value output by the rudder angle sensor to obtain a digitized value.

[0116] Specifically, step 202 is similar to step 102, and will not be described in detail here.

[0117] Step 203: According to the first linear relationship between the digitized value and the initial conversion value, the digitized value is converted into the initial conversion value.

[0118] Specifically, this step 203 is similar to step 103, and will not be described in detail here.

[0119] Step 204: Subtract the initial conversion value when the rudder angle of the azimuth propeller is 0° from the initia...

Embodiment 3

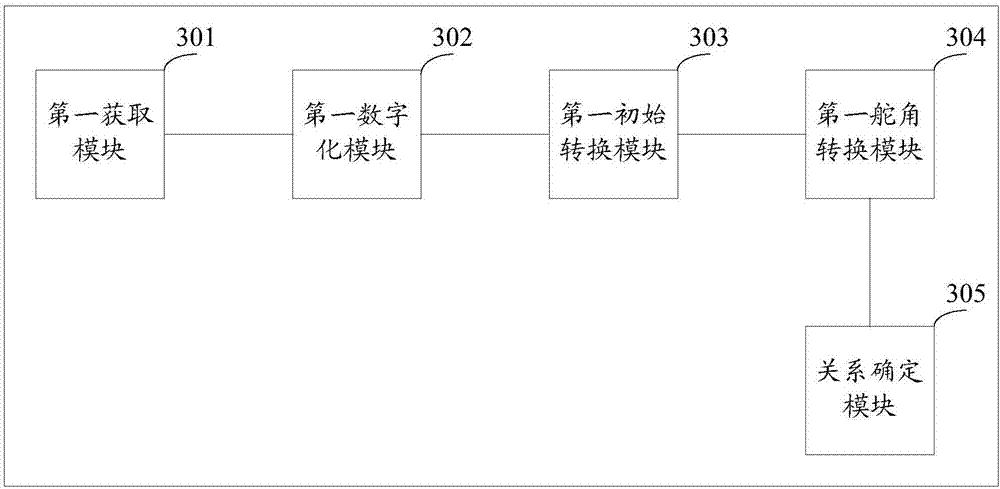

[0170] The embodiment of the present invention provides a signal processing device for the rudder angle sensor of an azimuth thruster, which is suitable for implementing the processing method provided in the first embodiment, see image 3 , The processing device includes:

[0171] The first acquiring module 301 is used to acquire the analog signal value output by the rudder angle sensor when the rudder angle of the azimuth propeller is 0°, 90°, 180°, and 270° respectively;

[0172] The first digitizing module 302 is configured to digitize each analog signal value output by the rudder angle sensor to obtain a digitized value;

[0173] The first initial conversion module 303 is configured to convert each digitized value into an initial conversion value according to the first linear relationship between the digitized value and the initial conversion value. The range of the digitized value in the first linear relationship is the rudder angle sensor As a result of the digitization of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com