Gap measuring ruler and use method thereof

A technology for measuring rulers and gaps, which is applied in the direction of mechanical gap measurement, etc., which can solve problems such as performance discounts, unsatisfactory measurement positions, and insufficient measurement space, etc., to achieve simple and convenient measurement operations, improve work efficiency and quality, and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

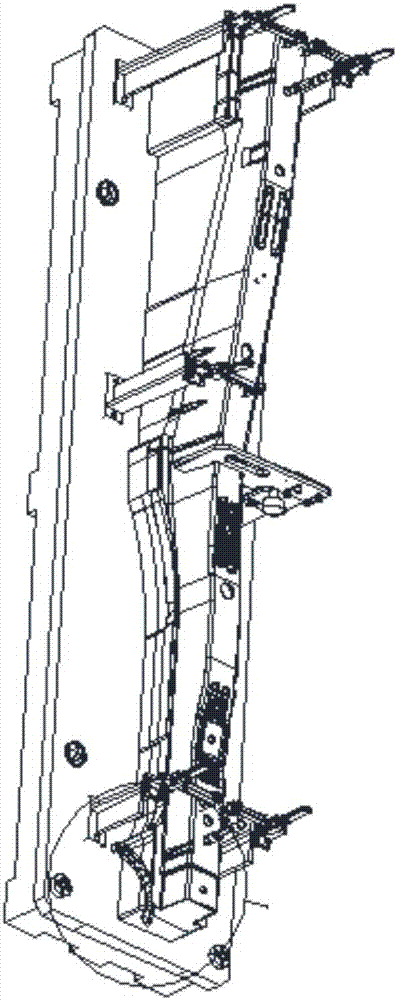

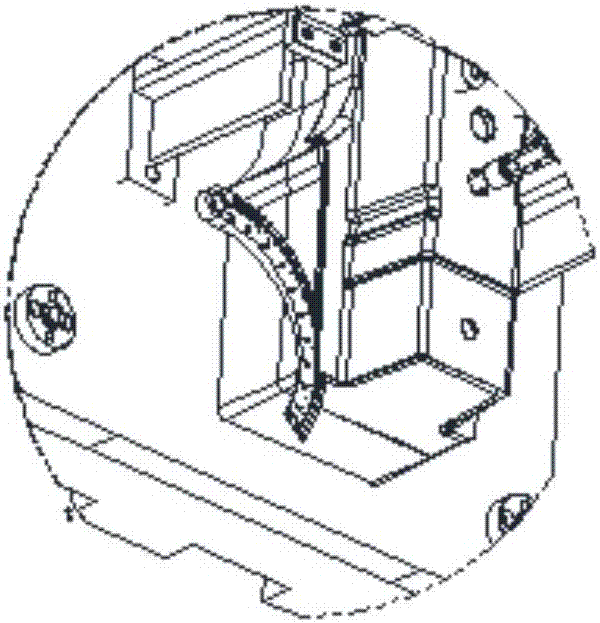

[0017] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

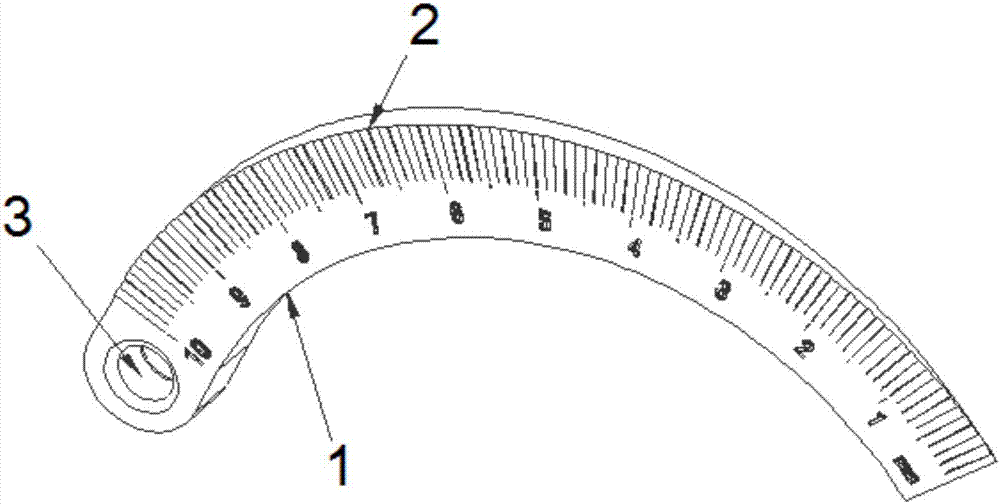

[0018] Such as figure 1 As shown, this kind of gap measuring ruler includes an arc-shaped measuring ruler body 1, and the thickness of the measuring ruler body 1 increases sequentially from one end to the other end. The scale represented by each scale line 2 on the scale body 1 is to measure the cross-sectional thickness value of the scale body 1 at the position of the scale line 2 . The gap measuring ruler has an arc-shaped structure, which can well adapt to changes in space, and can detect some positions with special measurement positions and insufficient measurement space in a targeted manner, which can more effectively improve the work efficiency and quality of detection.

[0019] This kind of gap measuring ruler is viewed as an arc from a top view, that is, an arc-shaped measuring rul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com