Cement mixer

A mixer and cement technology, applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve problems such as slurry plugging, cost reduction, uneven discharge, etc., to reduce consumption, save usage costs, The effect of improving work efficiency and work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

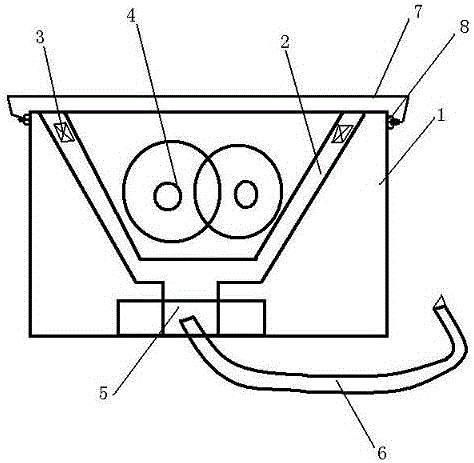

[0011] Example: such as figure 1 As shown, a cement mixer in this example includes a tank body (1), which is characterized in that the tank body (1) is provided with a water inlet channel (2), a control switch (3), a rotating gear (4 ), cement mixing channel (5), the inner two sides of the tank body (1) are respectively processed with water inlet channels (2), and the water inlet channel (2) is equipped with a control switch (3), and the A cement mixing channel (5) is connected to the water inlet channel (2), and a pair of meshing rotating gears (4) are installed on the water inlet channel (2), and the two ends of the pair of meshing rotating gears (4) The tooth surfaces are respectively provided with water inlet channels (2), and the water inlet channels (2) are fixedly connected with high-pressure nozzles (6), and the other end thereof is connected with the tank body (1), and the tank body (1) The upper end is connected with a top cover (7), and its top cover (7) is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com