Heating plate flatness automatic detection device

An automatic detection device and automatic detection technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of poor plane flatness, low detection efficiency, unsuitable for batch detection, etc., and achieve the effect of fast detection efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

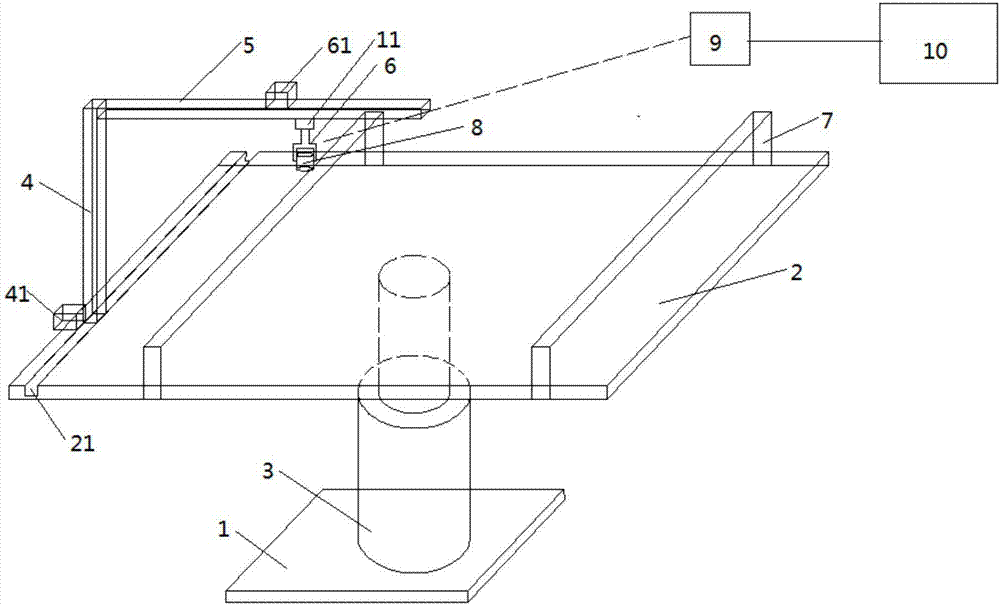

[0051] figure 1 A schematic structural view of a heating plate flatness automatic detection device according to the present invention is shown.

[0052] Such as figure 1 As shown, an automatic detection device for flatness of a heating plate in this embodiment includes: a detection module and an automatic detection platform.

[0053] Among them, the automatic detection platform includes:

[0054] base1;

[0055] Working platform 2, the working platform 2 is square, one side of which is provided with a first slideway 21, and the working platform is connected to the base 1 through a hydraulic cylinder 3;

[0056] The working vertical arm 4 is vertically arranged in the first slideway 21 and driven by the first motor 41;

[0057] Work cross bar 5, work cross bar 5 is vertically arranged and fixedly connected with work vertical arm 4, and work cross bar 5 is provided with a second slideway (not shown) on the plane facing work platform 2;

[0058] The gripper 6, the gripper 6 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap