A multi-directional paint spraying device for auto parts

An auto parts, multi-directional technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of uneven paint automation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

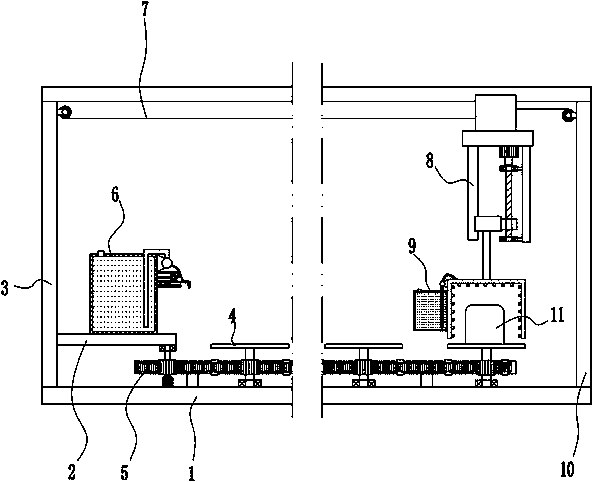

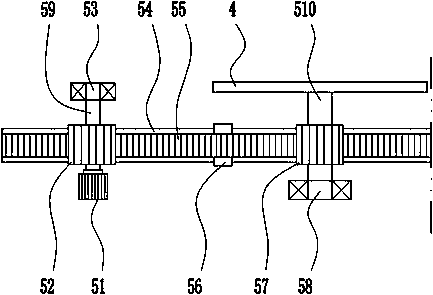

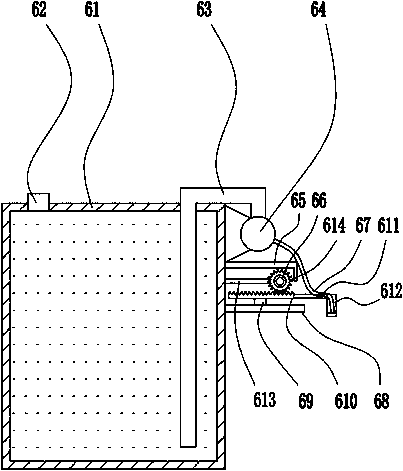

[0036] A multi-directional paint spraying device for auto parts, such as Figure 1-6 As shown, it includes a base plate 1, a support plate 2, a left bracket 3, a turntable 4, a rotating mechanism 5, a liquid feeding mechanism 6, a left and right moving mechanism 7, a lifting mechanism 8, a painting mechanism 9 and a right bracket 10, and the top surface of the bottom plate 1 is from From left to right, a left support 3, a rotating mechanism 5 and a right support 10 are arranged successively, a support plate 2 is provided at the lower part of the right side of the left support 3, a liquid feeding mechanism 6 is provided on the top surface of the support plate 2, and the right side of the bottom surface of the support plate 2 is connected with the rotation Mechanism 5 is connected, left and right support 3 tops and right support 10 tops are provided with left and right moving mechanism 7, and left and right moving mechanism 7 bottoms are provided with elevating mechanism 8, and e...

Embodiment 2

[0054] A multi-directional paint spraying device for auto parts, such as Figure 1-6 As shown, it includes a base plate 1, a support plate 2, a left bracket 3, a turntable 4, a rotating mechanism 5, a liquid feeding mechanism 6, a left and right moving mechanism 7, a lifting mechanism 8, a painting mechanism 9 and a right bracket 10, and the top surface of the bottom plate 1 is from From left to right, a left support 3, a rotating mechanism 5 and a right support 10 are arranged successively, a support plate 2 is provided at the lower part of the right side of the left support 3, a liquid feeding mechanism 6 is provided on the top surface of the support plate 2, and the right side of the bottom surface of the support plate 2 is connected with the rotation Mechanism 5 is connected, left and right support 3 tops and right support 10 tops are provided with left and right moving mechanism 7, and left and right moving mechanism 7 bottoms are provided with elevating mechanism 8, and e...

Embodiment 3

[0072] A multi-directional paint spraying device for auto parts, such as Figure 1-6 As shown, it includes a base plate 1, a support plate 2, a left bracket 3, a turntable 4, a rotating mechanism 5, a liquid feeding mechanism 6, a left and right moving mechanism 7, a lifting mechanism 8, a painting mechanism 9 and a right bracket 10, and the top surface of the bottom plate 1 is from From left to right, a left support 3, a rotating mechanism 5 and a right support 10 are arranged successively, a support plate 2 is provided at the lower part of the right side of the left support 3, a liquid feeding mechanism 6 is provided on the top surface of the support plate 2, and the right side of the bottom surface of the support plate 2 is connected with the rotation Mechanism 5 is connected, left and right support 3 tops and right support 10 tops are provided with left and right moving mechanism 7, and left and right moving mechanism 7 bottoms are provided with elevating mechanism 8, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com