Fully-closed floating roof tank

A floating roof storage tank and fully enclosed technology, which is applied in the field of fully enclosed floating roof storage tanks, can solve the problems of large oil and gas leakage and poor sealing effect in storage tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

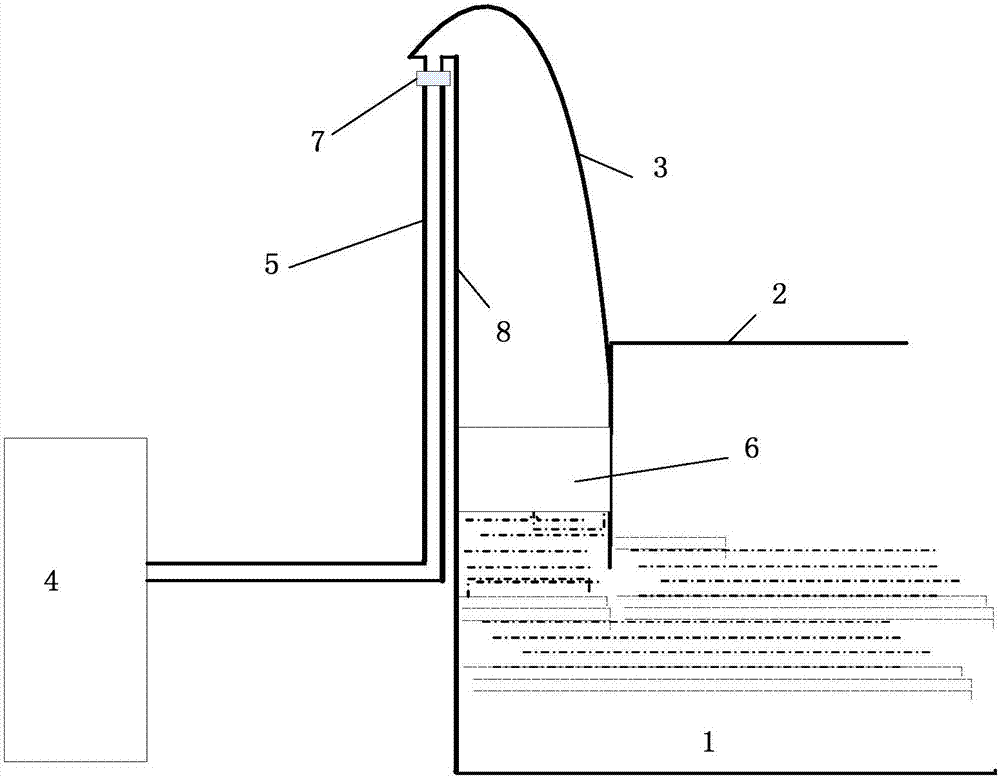

[0016] The invention relates to a fully enclosed floating roof storage tank, such as figure 1 As shown, the storage tank can realize the complete sealing of the oil and gas space of the storage tank, so that there is no oil and gas leakage on the top of the storage tank. The fully enclosed floating roof storage tank involved in the present invention comprises a floating roof storage tank body (1), a floating plate (2), a sealing film (3), a pressure regulating device (4), an oil gas conduit (5 ), the primary sealing device (6) and the flame arrester (7), the sealing film (3) is fixed between the tank roof and the floating plate (2), the sealing film (3) and the floating plate (2), the primary sealing device (6), crude oil, tank wall, oil-gas conduit (5) form a fully enclosed space, so that oil and gas can not leak out, can only carry out pressure adjustment along the oil-gas conduit (5) to the pressure regulating device (4). The primary sealing device (6) can reduce the oil-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com