Vehicle-mounted continuous automatic Beckman beam mechanism

A vehicle-mounted, automatic technology, applied in roads, constructions, road repairs, etc., can solve the problems of large proportion of human factors, slow detection speed, high labor intensity, etc., to reduce labor intensity and workload, fast execution speed, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] The present invention takes the side where the front of the vehicle is located as the front, only to describe the structure of the present invention more clearly, rather than to limit the present invention.

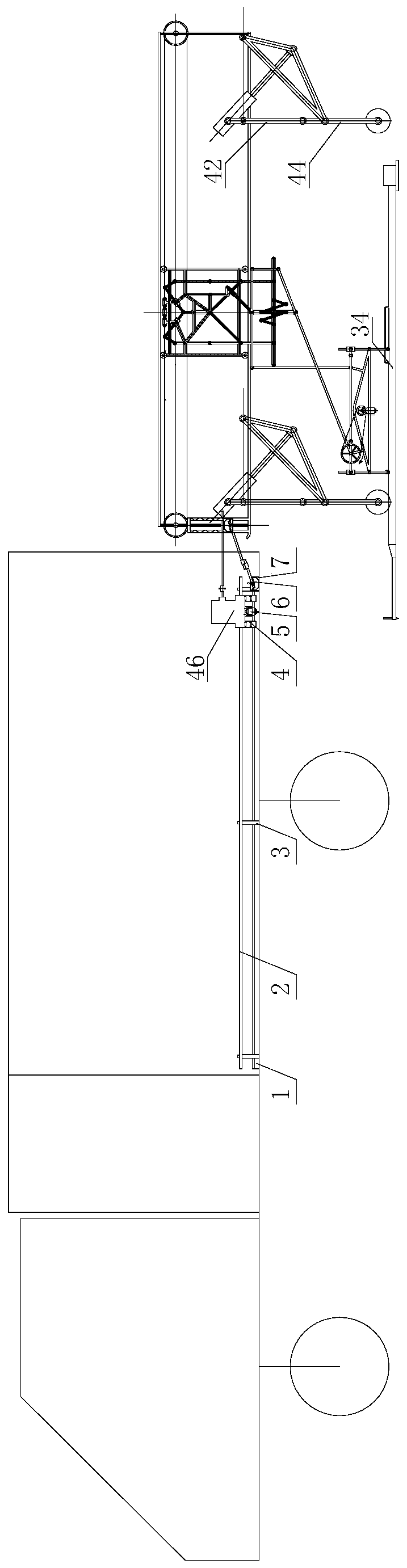

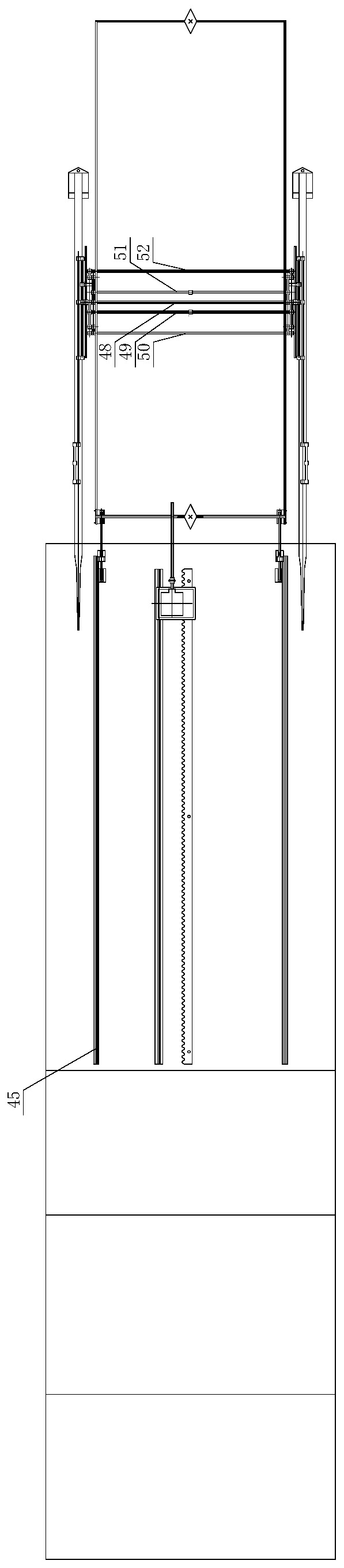

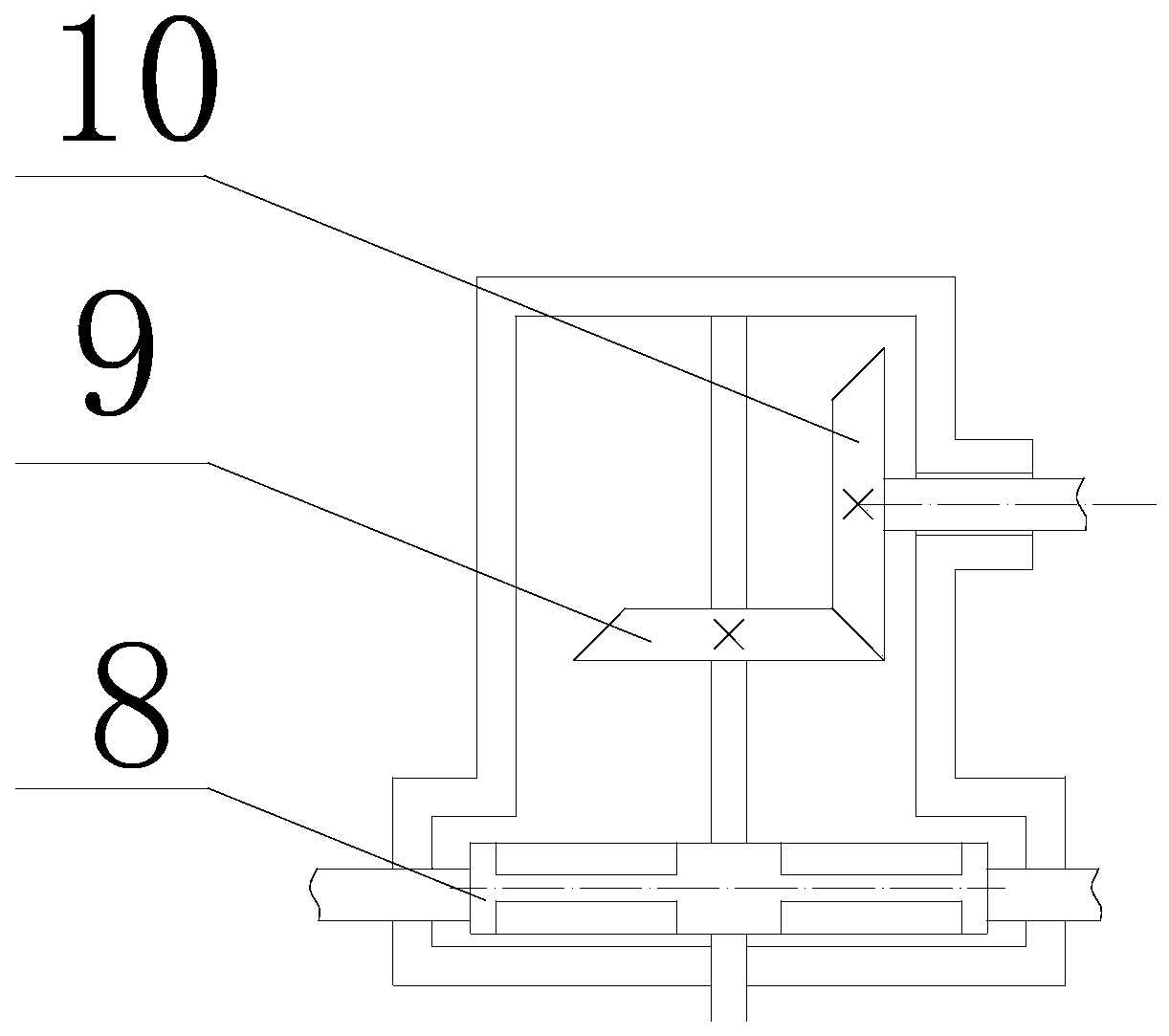

[0039] Such as figure 1 and figure 2As shown, the present invention includes a first translation device installed at the bottom of the compartment, connected to the mobile frame 16 on the first translation device, and the first translation device can push the mobile frame 16 to the outside of the compartment completely or reset the mobile frame 16. Two groups of second translation devices are installed on the mobile frame 16, and the second translation devices are respectively fixedly connected to the detection device base 17, and a vertical lifting device is installed on the detection device base 17, and the lower end of the vertical lifting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com