Method and system for acquiring balance of chip materials

A material and patch technology, applied in logistics, electromagnetic radiation induction, instruments, etc., can solve problems such as reduced production efficiency, inability to refill materials, error-prone, etc., and achieve the goal of solving error-prone, improving production efficiency, and reducing manual intervention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

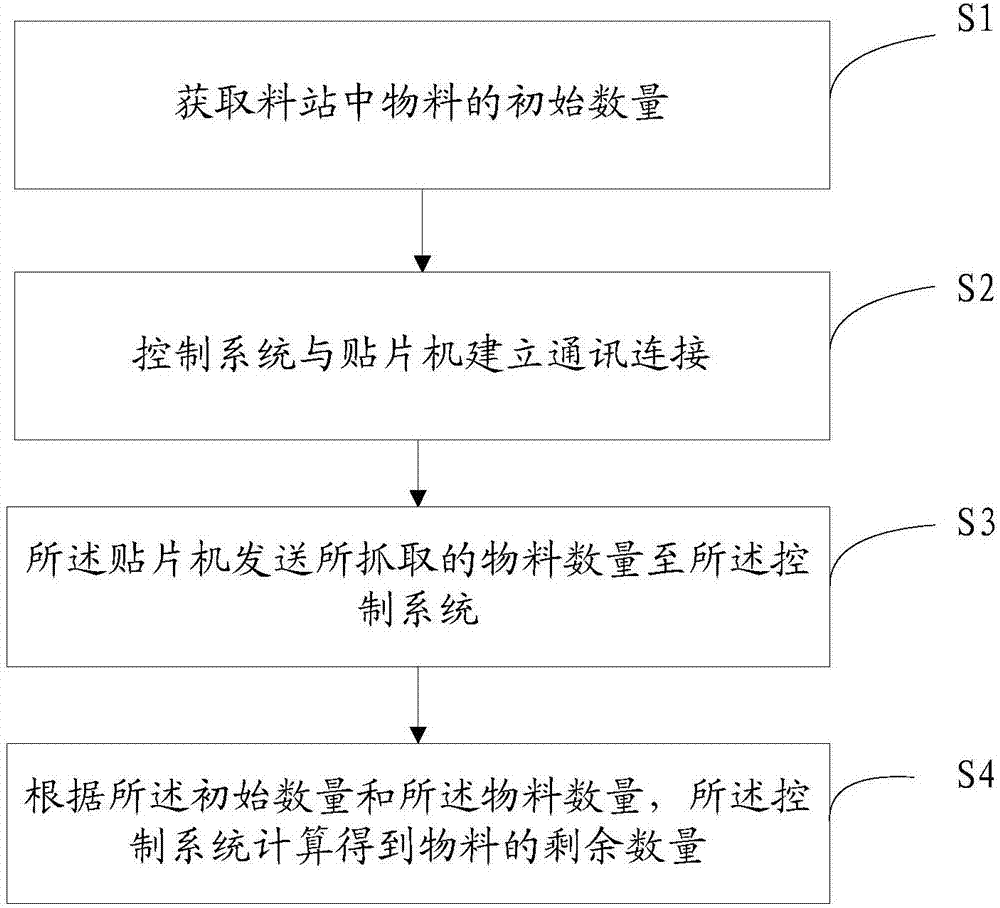

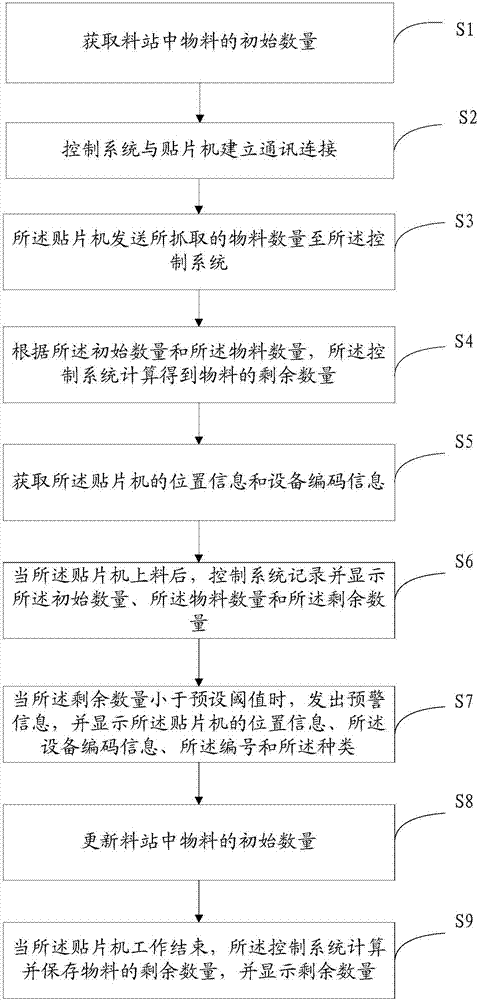

[0085] Please refer to figure 2 , Embodiment 1 of the present invention is:

[0086] A method for obtaining the balance of patch materials provided by the present invention includes the following steps:

[0087] S1: Obtain the initial quantity of materials in the material station;

[0088] Specifically: a plurality of material trays and a plurality of barcodes are preset, and the material trays correspond to the barcodes one by one;

[0089] The material tray is provided with a barcode corresponding to it, and the barcode includes the serial number of the material tray, the type of material and the initial quantity of the material;

[0090] The initial quantity of the material station before feeding is zero, and after feeding the material station through the first material tray, scan the barcode of the first material tray to obtain the serial number, the type and the initial quantity;

[0091] S2: The control system establishes a communication connection with the placement...

Embodiment 2

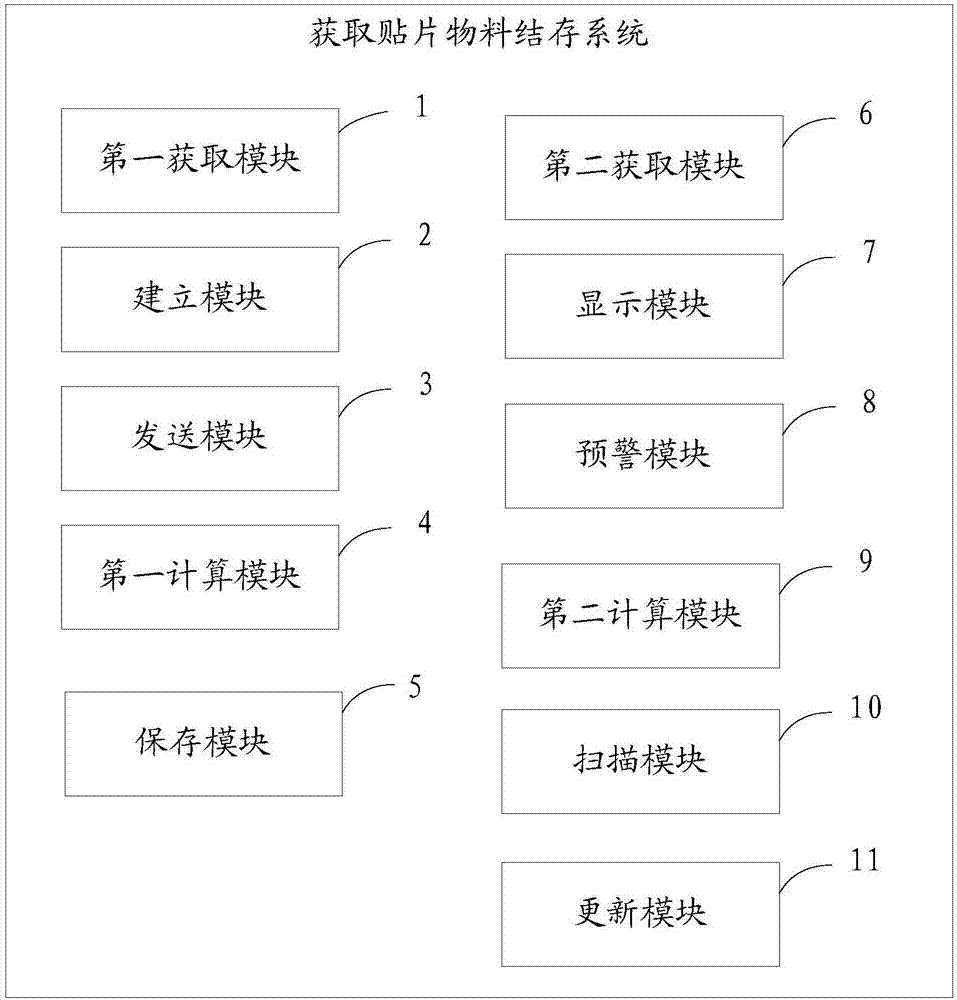

[0109] Please refer to Figure 3 to Figure 4 , the second embodiment of the present invention is:

[0110] The preset unit presets multiple material trays and multiple barcodes, the material trays correspond to the barcodes one by one, and sends the preset results to the setting unit; The corresponding barcode, the barcode includes the number of the material tray, the type of the material and the initial quantity of the material, and the setting result is sent to the scanning unit; after the scanning unit feeds the material to the material station through the first material tray, it scans the first The barcode of the material tray is obtained from the serial number, the type and the initial quantity, and the scanning result is sent to the first calculation module; the establishment module is used for the control system to establish a communication connection with the placement machine; the sending module is used for the The placement machine sends the captured material quanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com