Method for rapid production of qualified flexible circuit board

A flexible circuit board, qualified technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of low production efficiency, waste of manpower and material resources, and it is difficult to completely detect unqualified finished products, so as to improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] attached Figure 1-6 The method for rapidly producing a qualified flexible circuit board according to the present invention includes the following steps, taking the design requirement of tolerance 0.2mm as an example:

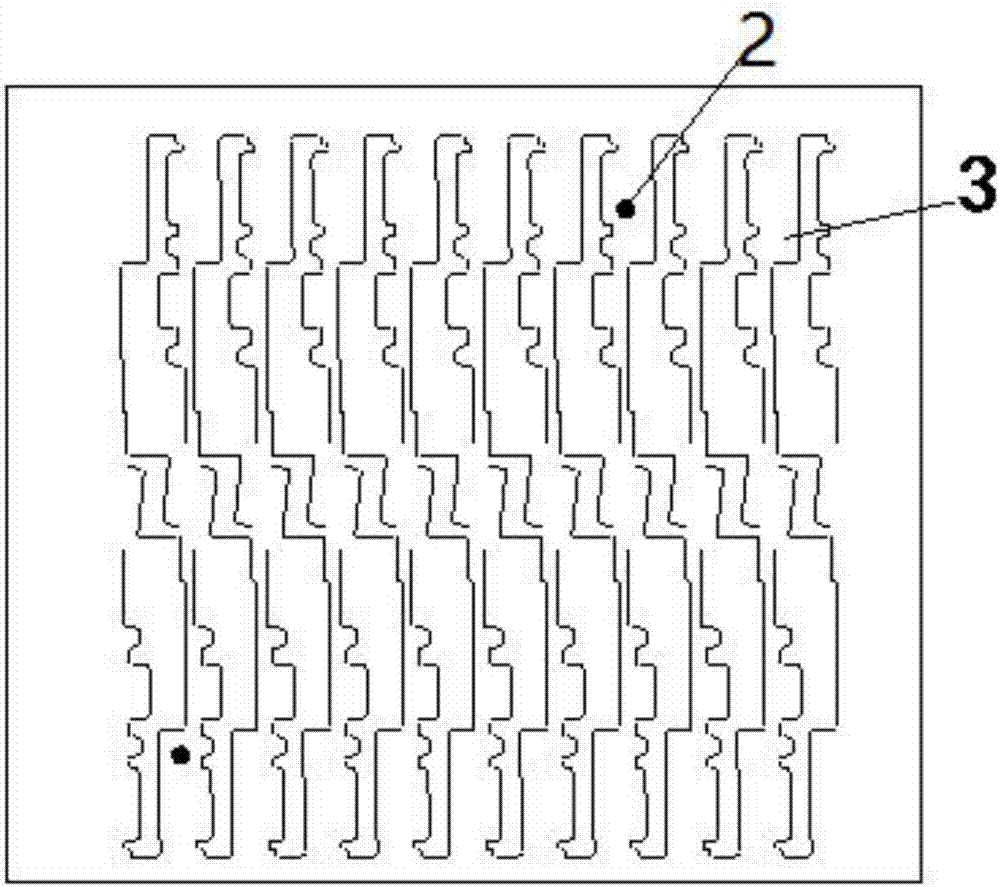

[0021] 1. Using the copper etching method, the circuits of a plurality of regularly arranged flexible circuit boards 4 and the process rings 2 distributed diagonally on the raw material plate 1 are copper-etched out on the original material plate 1; the process ring 2 includes concentric 1.4mm*1.8mm inner copper ring 6 and outer copper ring 8 with an inner diameter of 2.4mm;

[0022] 2. While punching the flexible circuit board 4, punch a round punch hole 5 in the inner ring of the 1.4mm*1.8mm inner copper ring 6, with an aperture of 1.0mm; Between the outer copper ring 8, punch a small hole 7 with a diameter ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap