Composite rim and manufacturing method thereof

A manufacturing method and composite technology, which are applied to vehicle parts, metal processing equipment, rims, etc., can solve the problems of high price, low production efficiency, and strength limitation of aluminum alloy rims, so as to improve aesthetics, improve production efficiency, The effect of ensuring overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

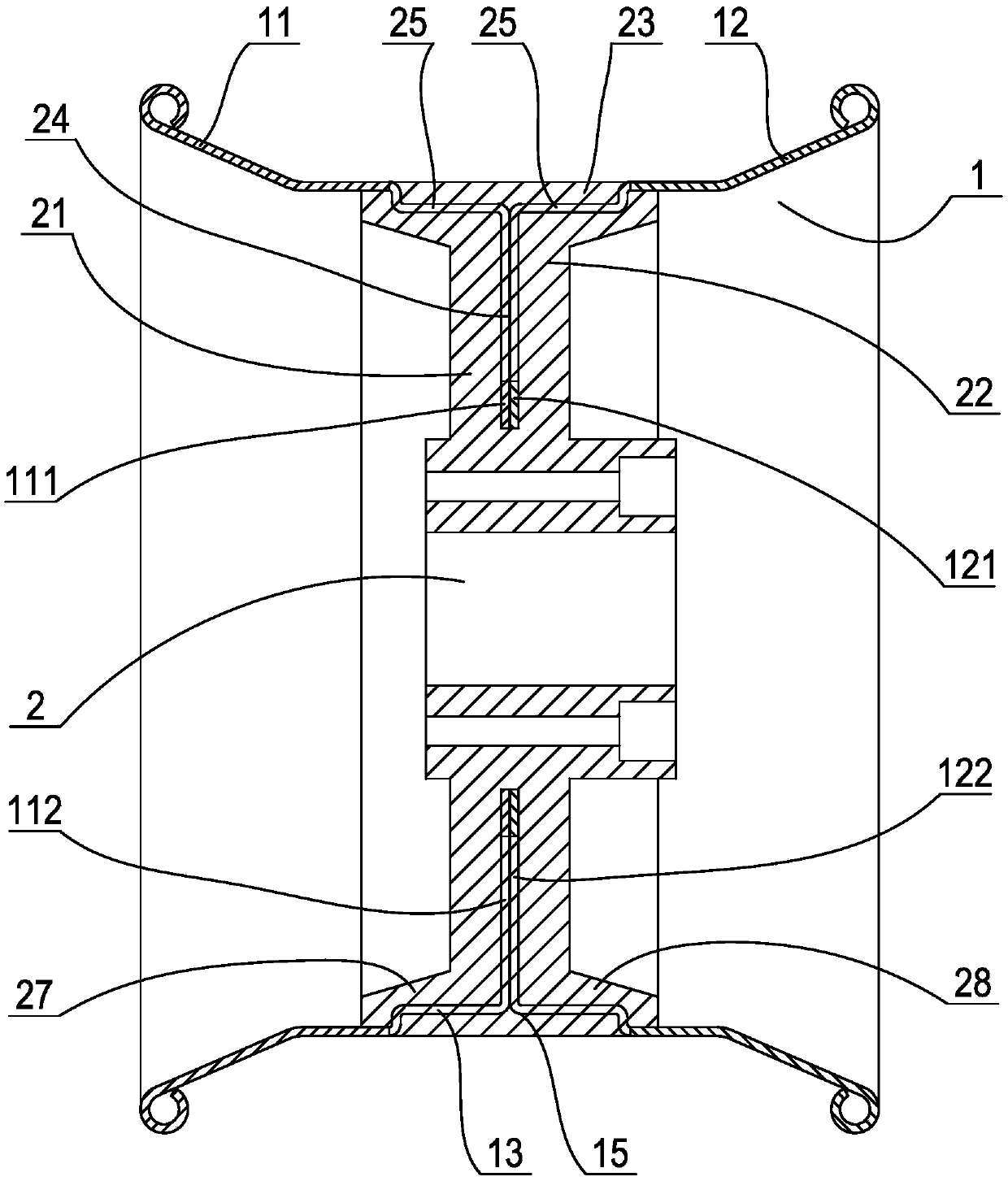

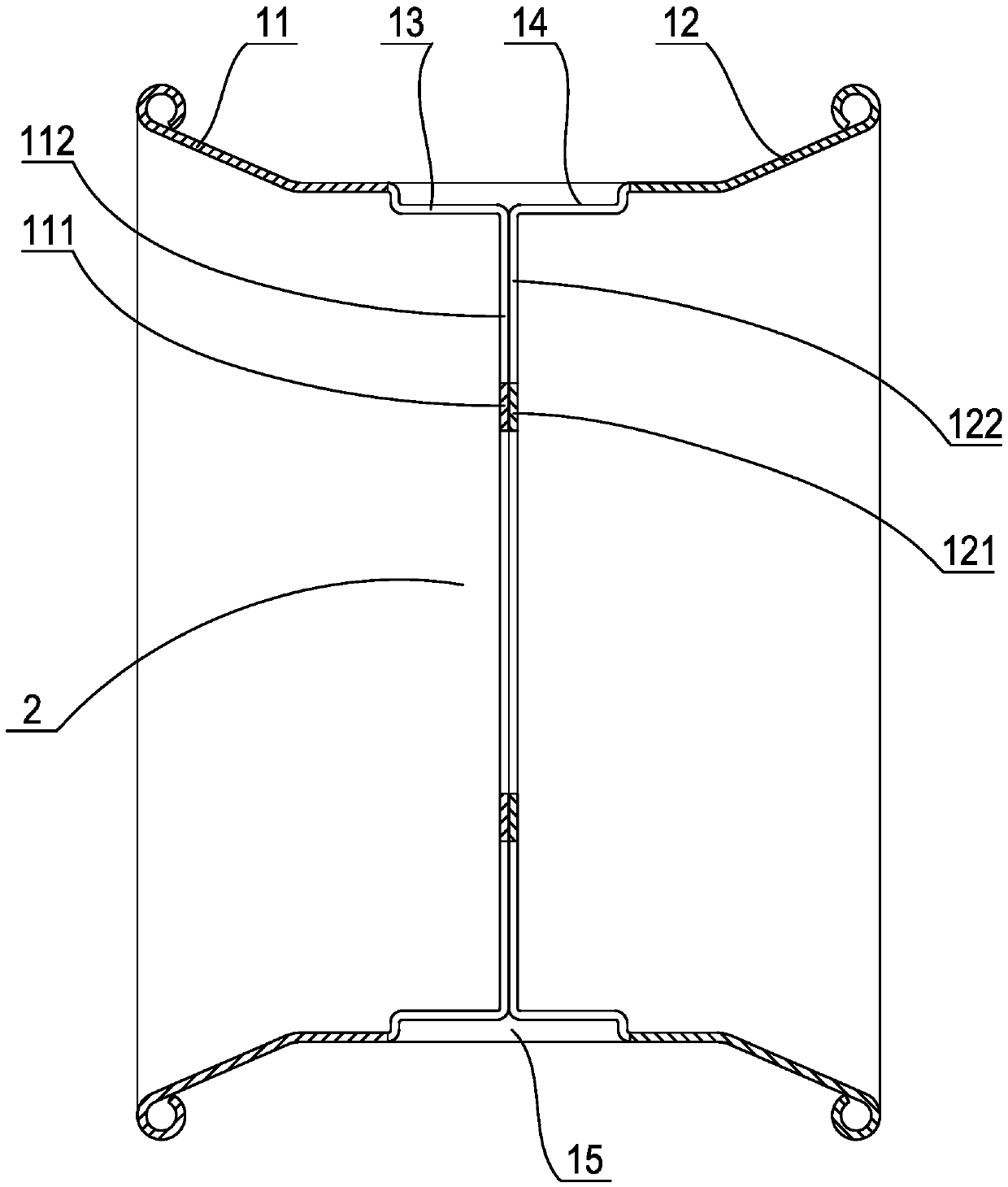

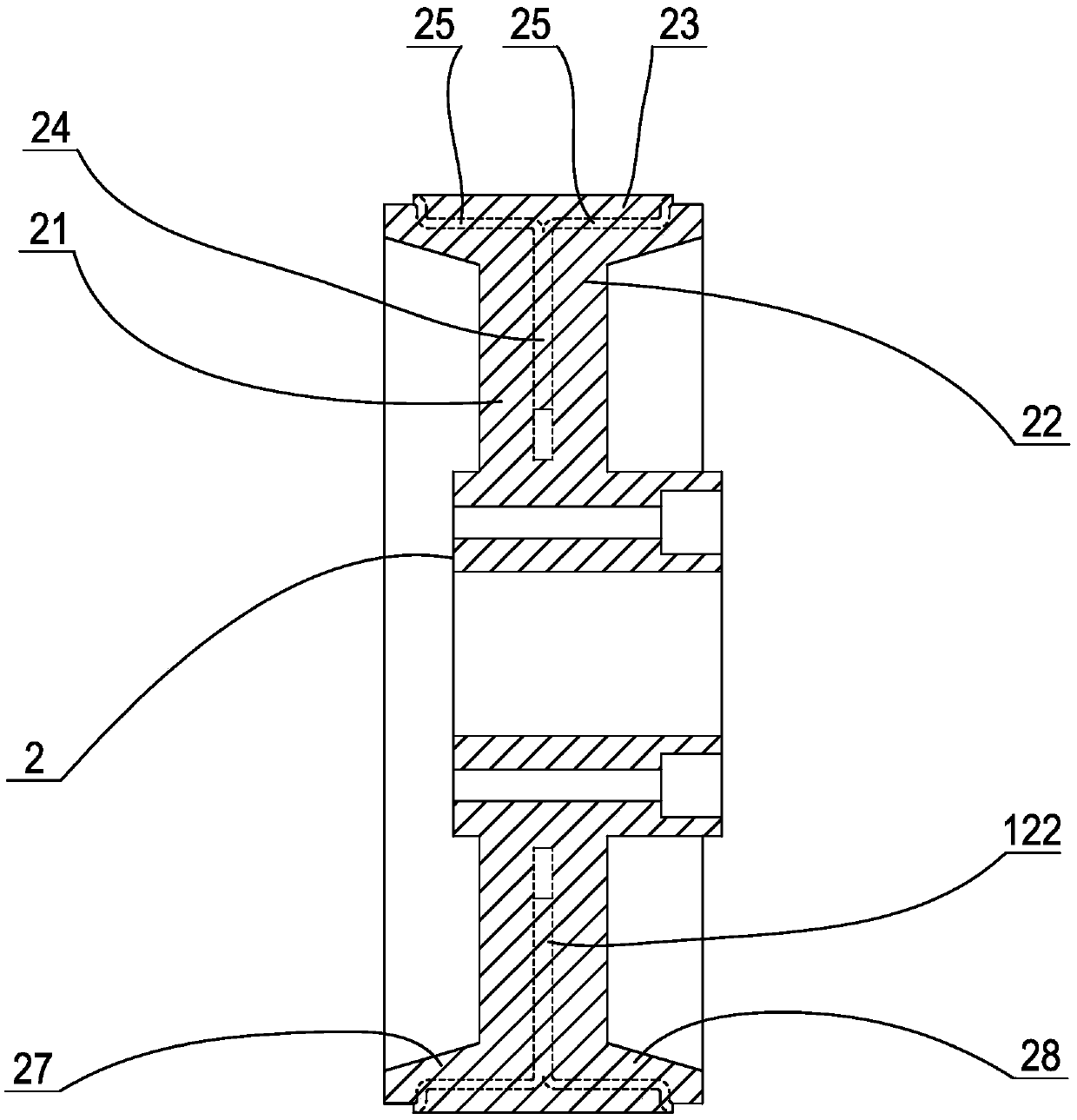

[0034] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a composite rim includes a steel ring body 1 and an aluminum alloy web 2, the ring body includes a left ring body 11 and a right ring body 12 coaxially arranged side by side, and the left and right ring bodies They are all made by stamping forming process. The left ring body forms a left connecting ring 111 that is bent and extended inwardly at the edge of the left ring body near one end of the right ring body, and the right ring body is integrally formed with the edge of the left ring body near one end. The right connecting ring 121 is bent and extended inward, and the left and right connecting rings are attached to each other, so that the axial section of the ring body is roughly I-shaped. In order to make the ring body and the panel reliably combined, we can respectively set a number of ring body connection via holes 13 evenly distributed in the circumferential direction on the left and right ring bodies, a...

Embodiment 2

[0038] Embodiment 2: A manufacturing method of a composite rim, which is suitable for manufacturing a composite rim having a steel ring body and an aluminum web as described in Embodiment 1, specifically comprising the following steps:

[0039] a. First punch out a number of ring body connection holes evenly distributed in the circumferential direction on the outer side of the first circular steel plate near the edge through the punching process, and punch out a number of left panel connections on the inner side of the steel plate near the center Via holes; similarly, on another circular steel plate near the edge, punch out a number of ring body connection via holes evenly distributed in the circumferential direction, and punch out a number of right panel connections on the inner side of the steel plate near the center Via. Then, the first steel plate is stretched into a bowl-shaped left ring body with a flat bottom by a stretch forming process, and the other steel plate is st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com