Automatic ball grinding machine

A grinding machine and sphere technology, applied in the direction of grinding machine tools, grinding devices, grinding machine parts, etc., can solve the problems of low processing efficiency, complex structure, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

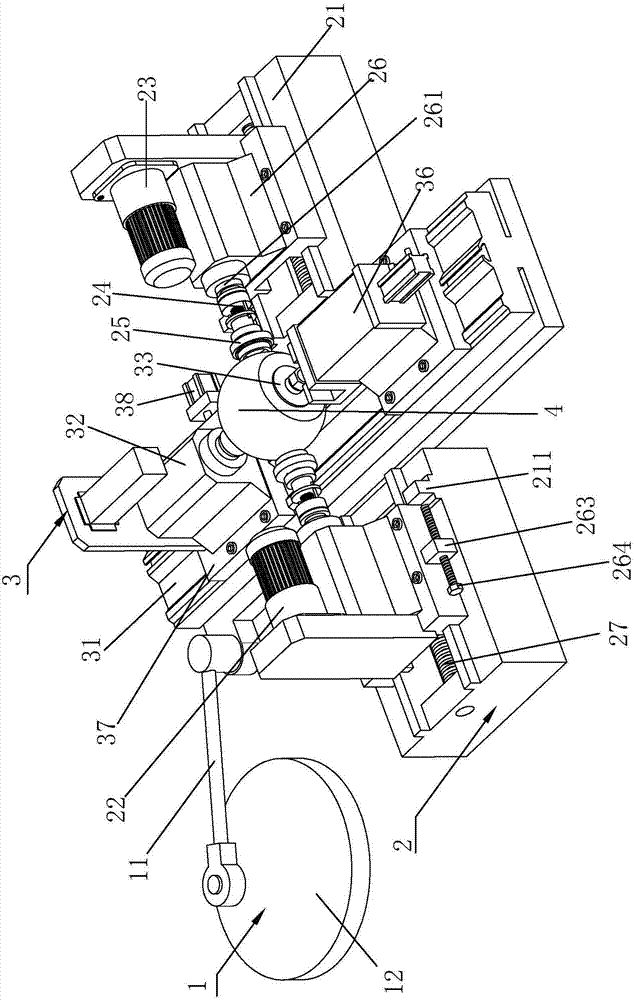

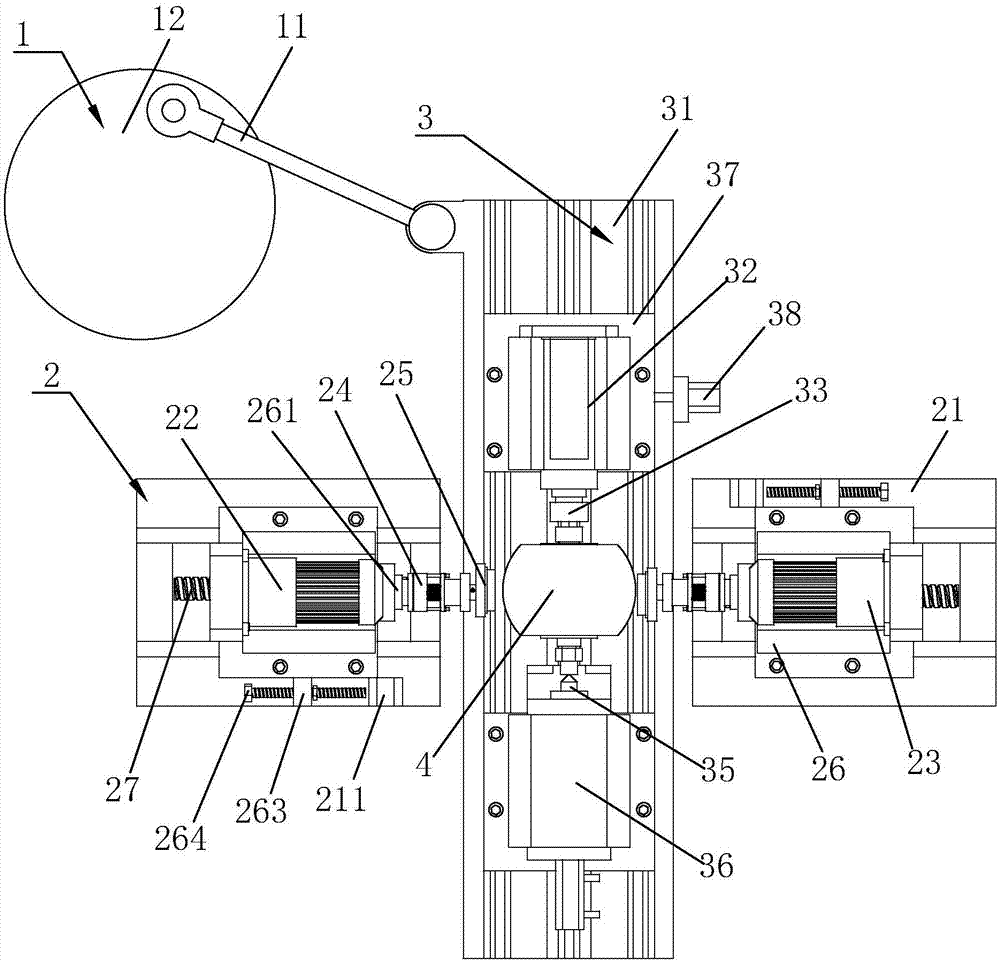

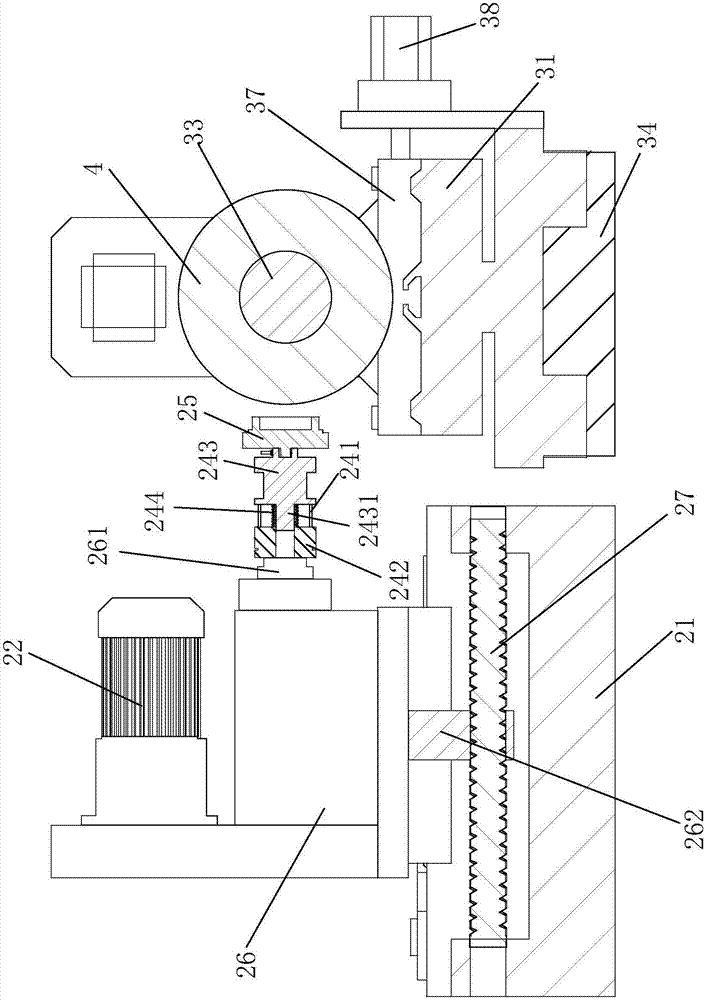

[0024] like Figure 1-Figure 3 The shown sphere automatic grinding machine includes a clamping mechanism 3 for fixing the sphere 4, a swing mechanism 1 for driving the clamping mechanism 3 to reciprocate in the horizontal direction, and a grinding head mechanism 2 for grinding the sphere 4. The grinding head mechanism 2 and the clamping mechanism 3 are in a staggered arrangement, and the swing mechanism 1 is connected to the clamping mechanism 3; the grinding head mechanism 2 includes a transverse track plate 21, and the transverse track plate 21 is provided with a first motor 22 and a second motor 23, and the first motor 22 and the second motor 23 are in a straight line and oppositely arranged, the first motor 22 and the second motor 23 are respectively provided with a tooling 24 and a grinding head 25, and the first motor 22 and the second motor 23 are respectively corresponding to the tooling 24 linkage connection, the clamp grinding head 25 is connected with the tooling 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com