Rock similar to pore rock mass and uses for experiments, and production method thereof

A testing and porosity technology, which is applied in the field of geotechnical engineering, can solve the problems of large similarity ratio, low strength of similar rock samples, and small elastic modulus of similar materials, and achieves high compressive strength, wide application range and simple operation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

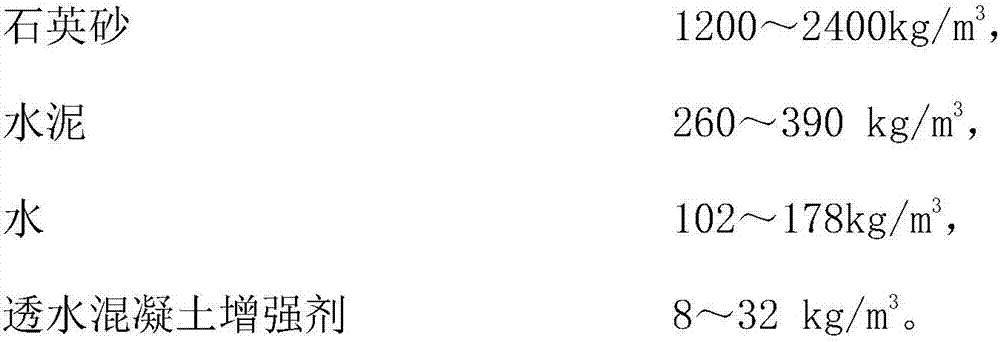

[0018] The invention discloses a method for preparing similar rocks with porous rock masses for testing, comprising the following steps: weighing raw materials according to the formula; mixing the quartz sand, cement and permeable concrete reinforcing agent uniformly; gradually adding water and stirring evenly; putting the mixture into a mold Compaction molding; demoulding maintenance.

[0019] In the method of the invention, the raw materials are all measured by weight, and the allowable deviation of the measurement is: ±1% of cement, ±1% of quartz sand, ±1% of water and permeable concrete reinforcing agent. The preparation process of the mixture is as follows: first pour the quartz sand, cement and permeable concrete reinforcing agent with the formula content into the mixing pot and mix evenly, then gradually add water and stir until uniform. Or, according to the recipe, mix quartz sand, cement and permeable concrete reinforcement and mix in a concrete or mortar mixer, gradu...

Embodiment 1

[0022] Example 1, the raw materials used are: quartz sand with a particle size of 1.0-1.4 mm; clean water; P.O. 42.5 ordinary Portland cement; permeable concrete reinforcing agent.

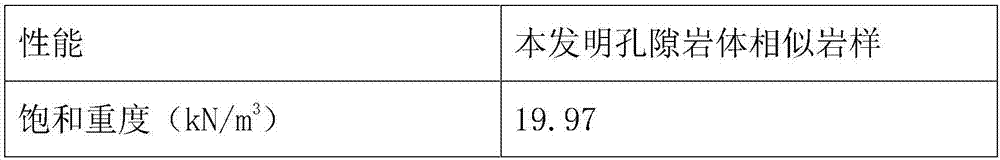

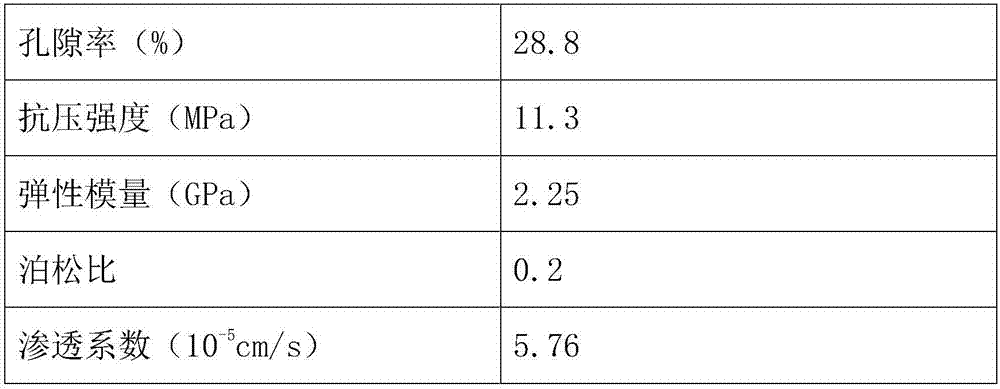

[0023] Weigh 1200kg / m 3 Quartz sand, 260kg / m 3 Cement, 112kg / m 3 Water and 20kg / m 3 Permeable concrete enhancer, after mixing quartz sand, cement and permeable concrete enhancer in a concrete mixer, gradually add water and stir evenly, put the mixture into the mold in layers, the amount of each layer is roughly the same, wait for each After the layer mixture is loaded into the mold, it is compacted with a compactor according to the same compaction degree each time, and the surface is smoothed, and then the mixture is pressed with high pressure to make it densely formed in the mold. After the constant temperature and humidity standard curing and grinding are completed, the similar rock samples of the porous rock mass are obtained. The physical properties of the obtained samples are shown in Tabl...

Embodiment 2

[0026] In Example 2, the raw materials used are: quartz sand with a particle size of 0.1mm≤particle size<2mm; clean water; P.O.52.5 ordinary Portland cement; permeable concrete reinforcing agent.

[0027] Weigh 1520kg / m 3 Quartz sand, 310kg / m 3 Cement, 132kg / m 3 Water and 20kg / m 3 Permeable concrete enhancer, pour quartz sand, cement and permeable concrete enhancer into a mixing pot and mix well, then gradually add water and stir until uniform, then put the mixture into a mold and place it on a press at a constant pressure of 5MPa After the pressure is pressed to a compact state and the surface is formed, the surface is smoothed. After the mold is removed and the high temperature curing is completed, the similar rock prepared is placed on a grinder and ground to ensure that the upper and lower end faces are ground flat and parallel to the upper and lower end faces. The physical properties of the obtained samples are listed in Table 2.

[0028] performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com