Maintenance method without water supply shutdown for large channel

A channel, large-scale technology, applied in the field of non-stop water maintenance of large-scale channels, can solve problems such as inapplicability, and achieve the effect of simple structure, easy manufacture and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

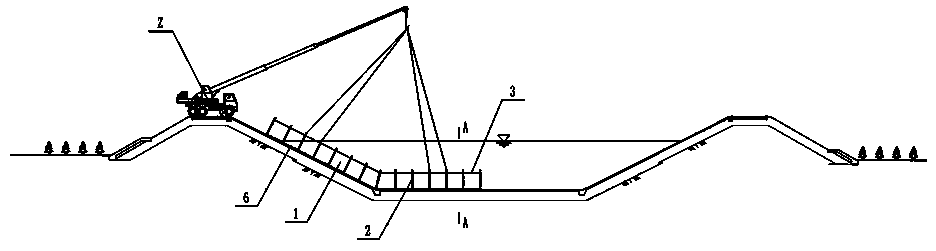

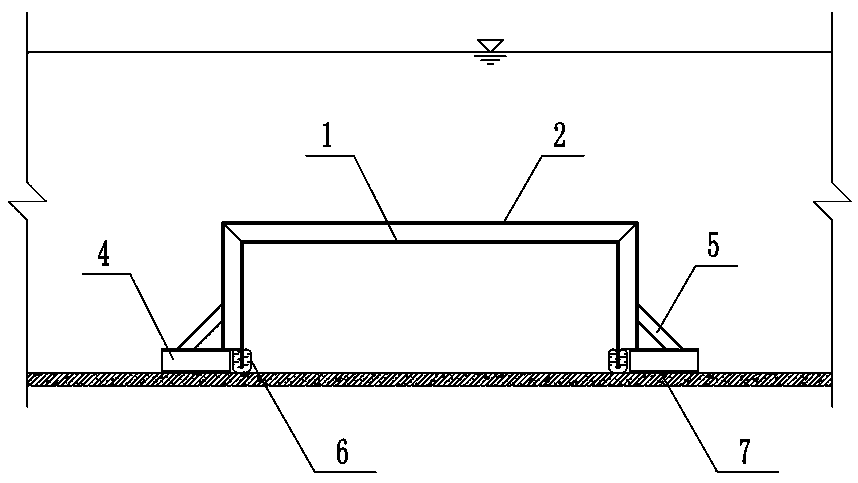

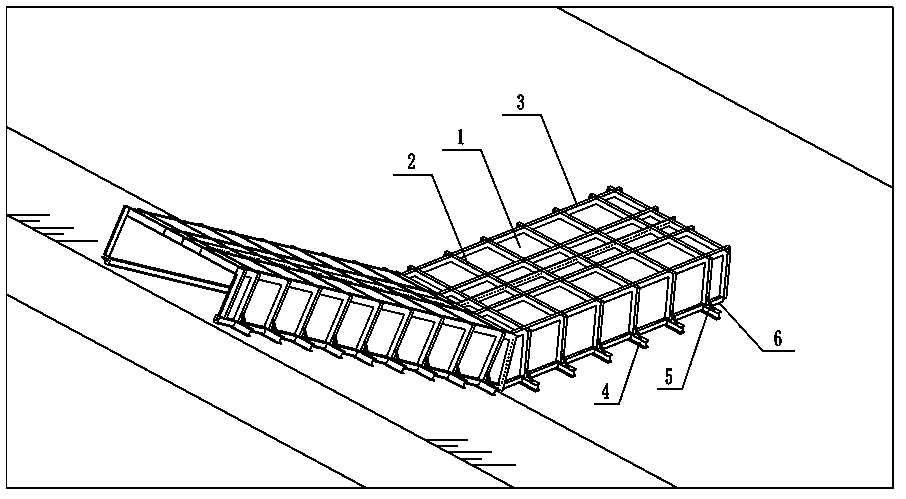

[0020] The non-stop water maintenance method for large-scale channels of the present invention needs to use such as Figure 1-3 The maintenance warehouse shown is composed of a steel frame and a water-retaining steel plate 1 welded on its inner side. The above-mentioned steel frame includes a plurality of door-shaped frames 2 arranged in sequence from the side slope of the channel to the bottom of the channel, and the door-shaped frames 2 are connected with a plurality of longitudinal steel beams 3 by welding. In order to strengthen the stability of the structure, diagonal braces 5 are welded between each door frame 2 and the extension bases 4 on both sides thereof. The above-mentioned water-retaining steel plate 1 is a steel plate with a thickness of 20 mm, and the rest of the steel components are all I-beams. In order to meet the construction space requirements for personnel to carry out inspection and maintenance in the inspection cabin, its height should be at least 2m; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com