Tire valve

A tire valve and valve seat technology, applied in the field of tire valves, can solve the problems of difficult dual airway arrangement, limited deflation speed, and limited deflation speed, so as to shorten execution time, fast deflate speed and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is further elaborated:

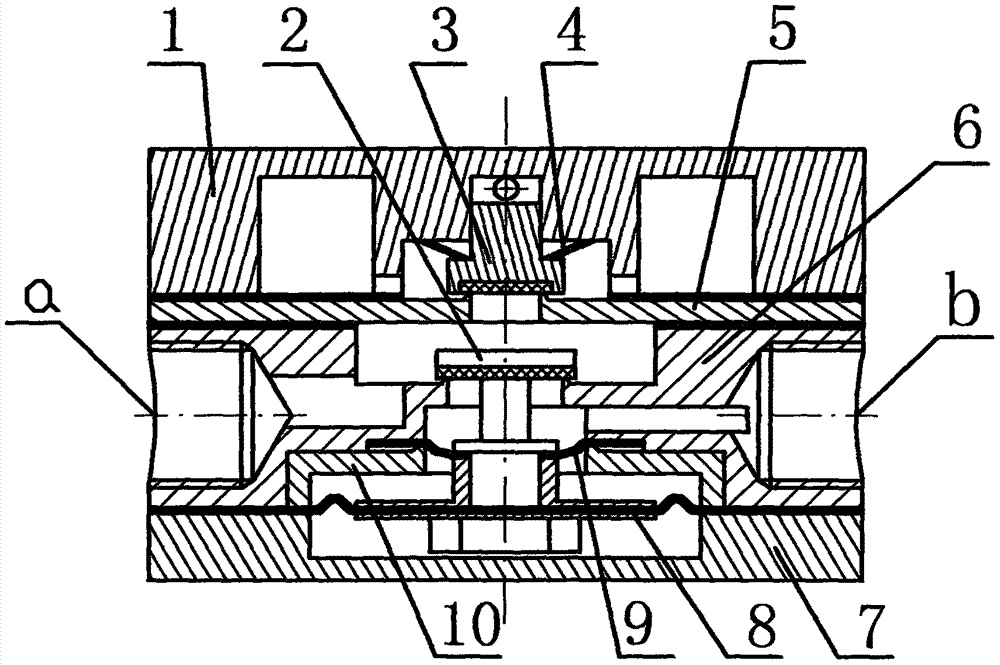

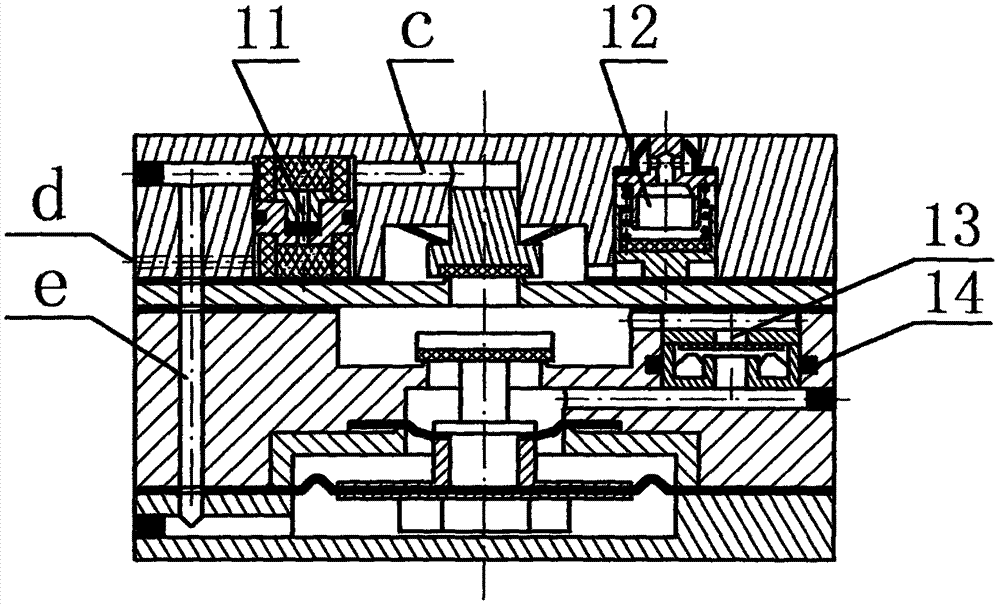

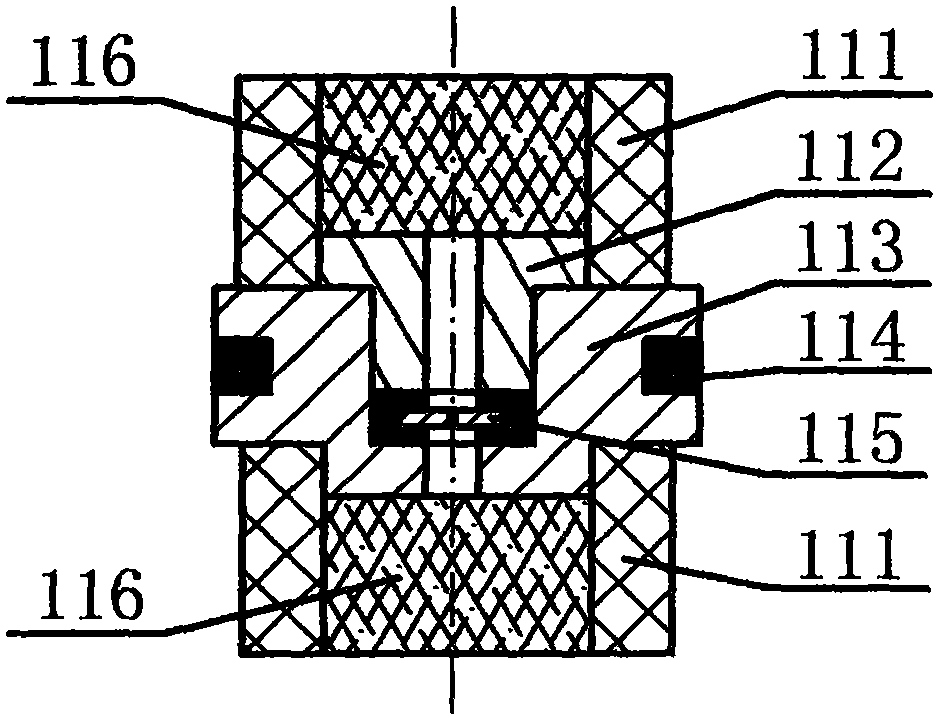

[0029]A tire valve, mainly comprising a valve body (1), a main valve disc (2), a one-way valve disc (3), a one-way valve return spring (4), a one-way valve seat (5), a main valve seat ( 6), valve bottom (7), second diaphragm (8), first diaphragm (9), spacer ring (10), delayed air release valve (11), low pressure exhaust valve (12) and inflation valve ( 13) and other components; the main valve seat (6) is divided into upper and lower chambers and is provided with a main valve port communicating with the upper chamber and the lower chamber, and the main valve seat (6) The lower chamber is further divided into upper and lower stepped holes arranged on the coaxial line, and the side wall of the main valve seat (6) is respectively provided with an air inlet (a) communicating with the upper chamber and An air outlet (b) communicating with the upper stepped hole of the lower chamber...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap