Spiral scanning measurement track planning method for cylindrical curved surface

A trajectory planning and spiral technology, which is applied in the field of spiral scanning measurement trajectory planning, can solve the problem that the effect of improving measurement efficiency is not obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

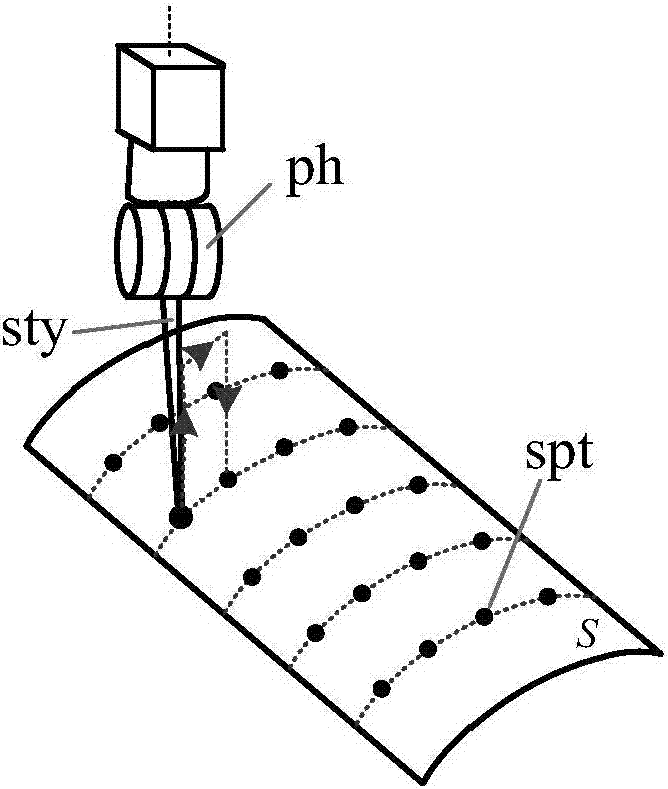

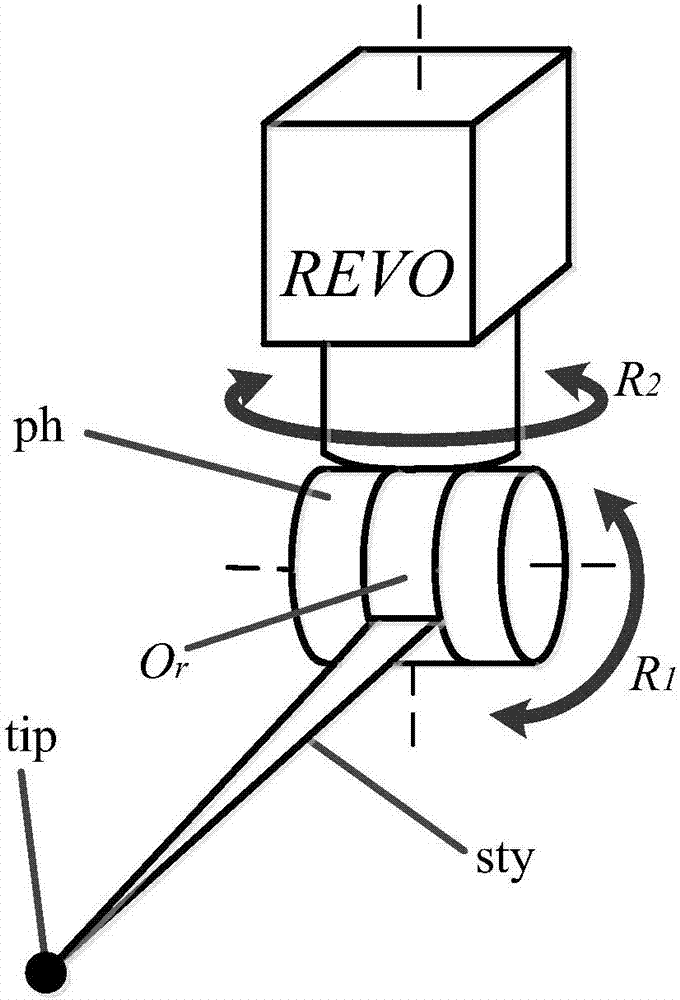

[0125] Such as Figure 9 As shown, the present invention includes (1) forming an offset curved surface S r Step; (2) offset surface S r Triangulation step; (3) triangulation offset surface S t Parameterization step; (4) planning guide line and interval line step; (5) calculating spiral guide line G (t) and spiral interval line E (t) step; (6) calculating guide trajectory C (t) step; (7 ) Step of generating swing trajectory reference scan curve; (8) Step of generating swing scan trajectory P(t).

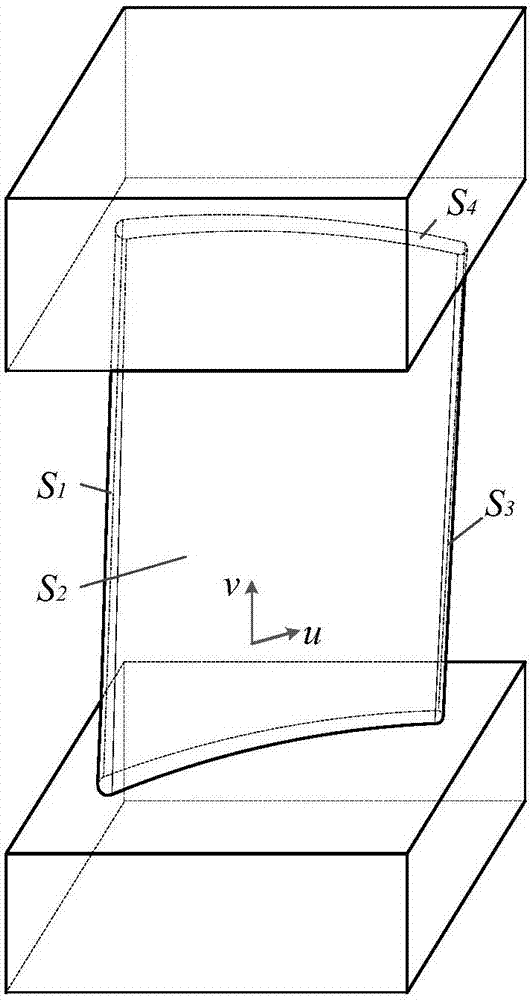

[0126] As an embodiment, the composite curved surface formed by the leading edge, blade basin, trailing edge, and blade back in the aviation blade is selected as the cylindrical curved surface to be measured, and the CAD three-dimensional model of the aviation blade is as follows Figure 10 shown. Due to the large curvature at the leading edge and trailing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com