A device for evaluating local corrosion of aluminum alloys

A technology for local corrosion and evaluation devices, which is used in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

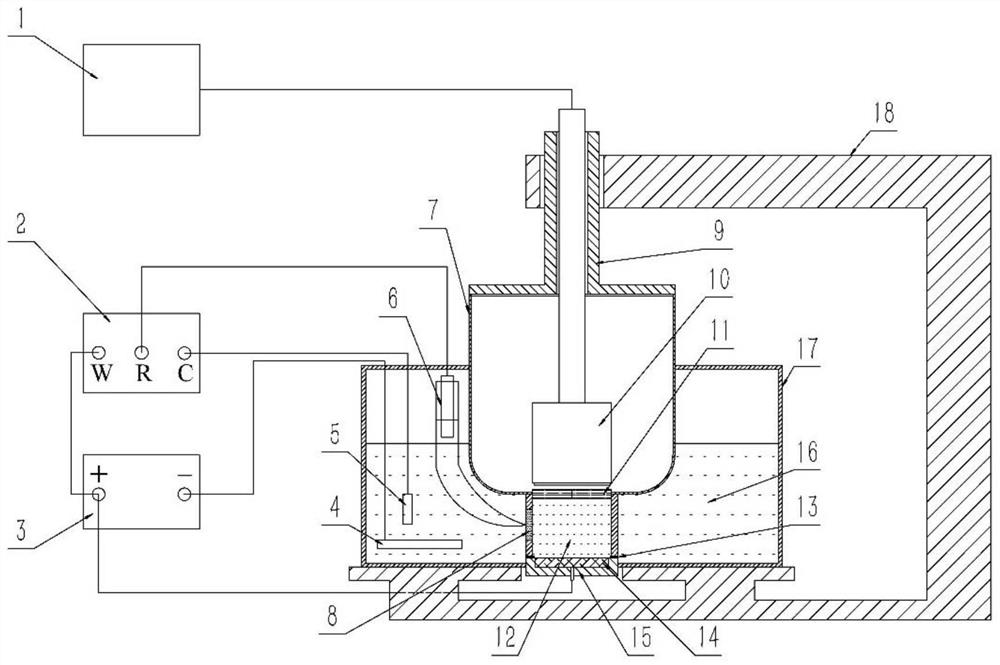

[0022] The invention provides a device for evaluating local corrosion of aluminum alloy, which includes a simulated environment unit and a real-time corrosion observation unit. The simulated environment unit includes a blocked anode, a macro cathode, an auxiliary electrode, a reference electrode device, and a simulated solution pool. The observation unit includes a real-time observation microscope and the main body of the corrosion real-time observation system.

[0023] Wherein, the real-time observation microscope selects an eyepiece with a larger depth of field with a resolution of 1 micron, the upper end of the microscope fixing device is fixed on the main support of the observation system, and the eyepiece is suspended above the observation window through the observation channel for real-time observation. The lower end of the microscope holder fixing device is fixed on the top of the observation channel, and a certain force is given to the observation channel, which is applied...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com