Homogenizer

A homogenizer, the other side of the technology, applied in the direction of mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve the situation where the fineness requirements are high, the requirements cannot be met, and the shearing effect of the homogenizer is not ideal And other problems, to achieve good effect, strong mechanical shear force, to ensure the effect of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

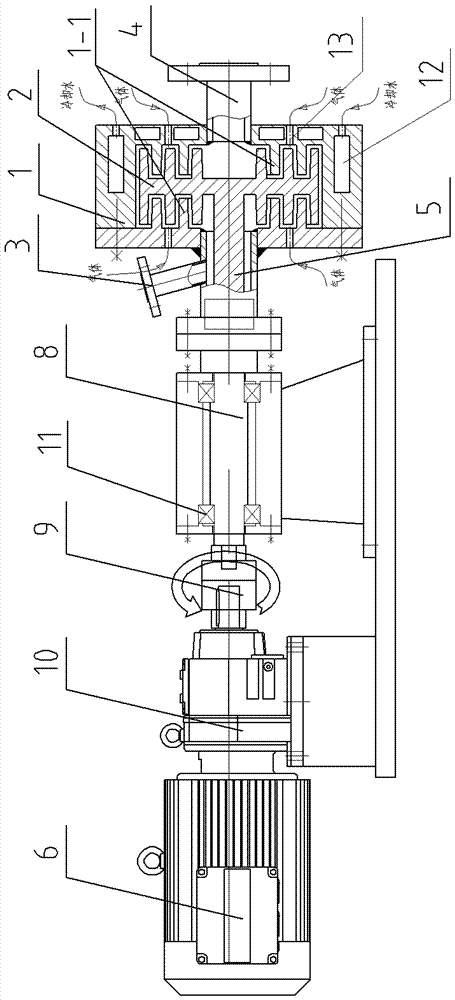

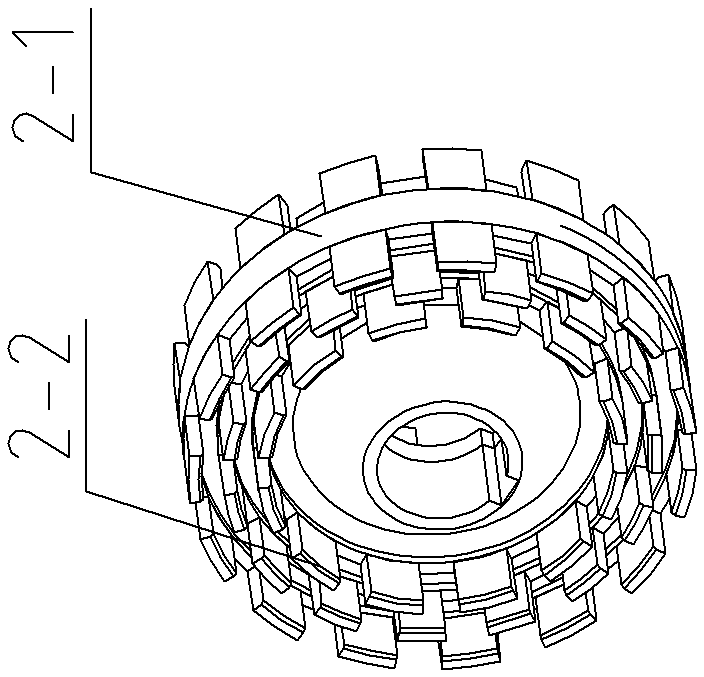

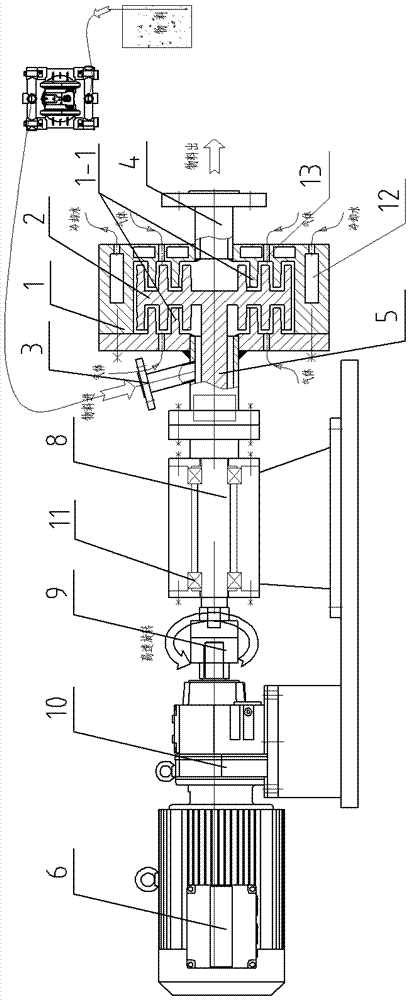

[0015] See figure 1 , figure 2 , image 3 As shown, a homogenizer includes a matched stator 1 and a rotor 2, one side of the stator 1 is provided with a material inlet 3, the other side of the stator 1 is provided with a material outlet 4, and the material inlet 3 is connected to a diaphragm pump 7, The rotor 2 is connected to the motor 6 through the rotating shaft 5. The rotor 2 includes a turntable 2-1 fixedly set on the rotating shaft 5. The front and back sides of the turntable 2-1 are provided with three circles of ring teeth and symmetrically arranged. The ring teeth structure is composed of tooth plates arranged at intervals. 2-2, the inner wall of the stator 1 is provided with an annular plate 1-1 located between two adjacent ring-tooth structures, and the tooth plates 2-2 of two adjacent ring-tooth structures are arranged in a staggered manner. After the ring tooth structure is installed on both sides of the turntable 2-1, the final fineness of the material can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com