Multi-station material preparing rotary table

A multi-station, turntable technology, used in plug-ins, cooking utensils, household appliances, etc., can solve problems such as imperfection and manual participation, and achieve the effect of short preparation time, stable placement, and shortened preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

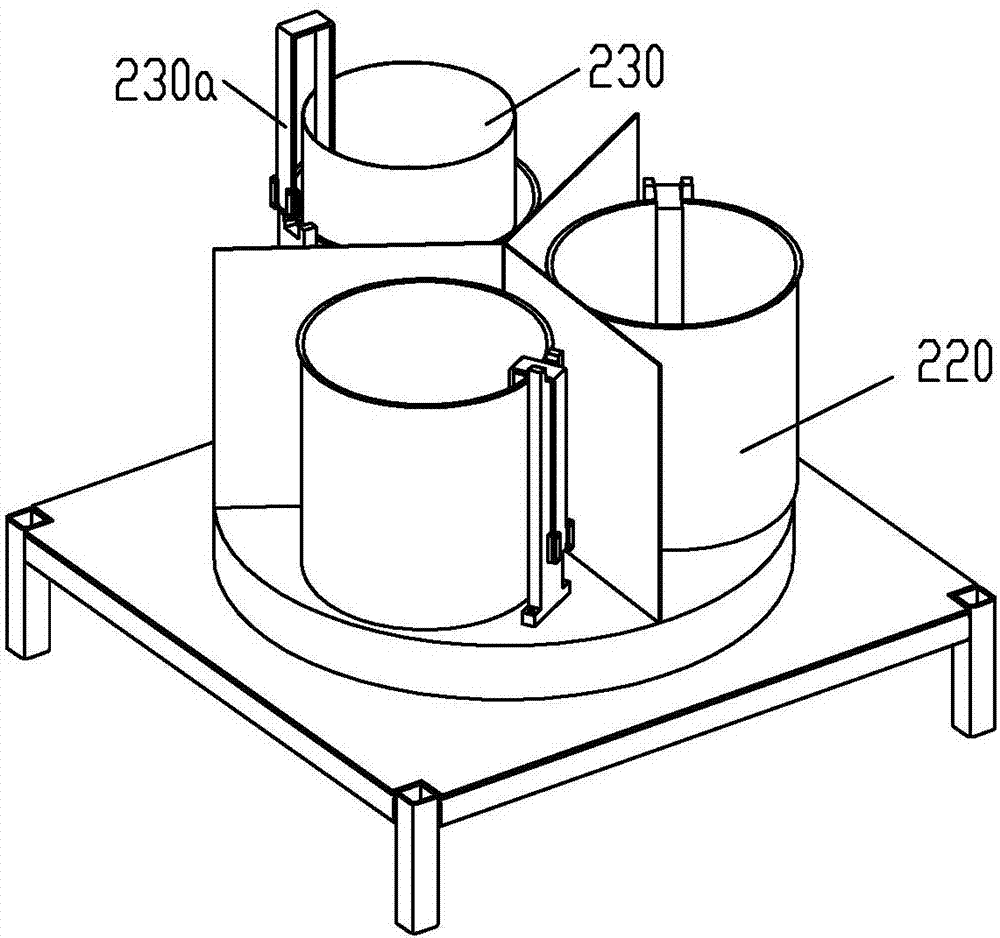

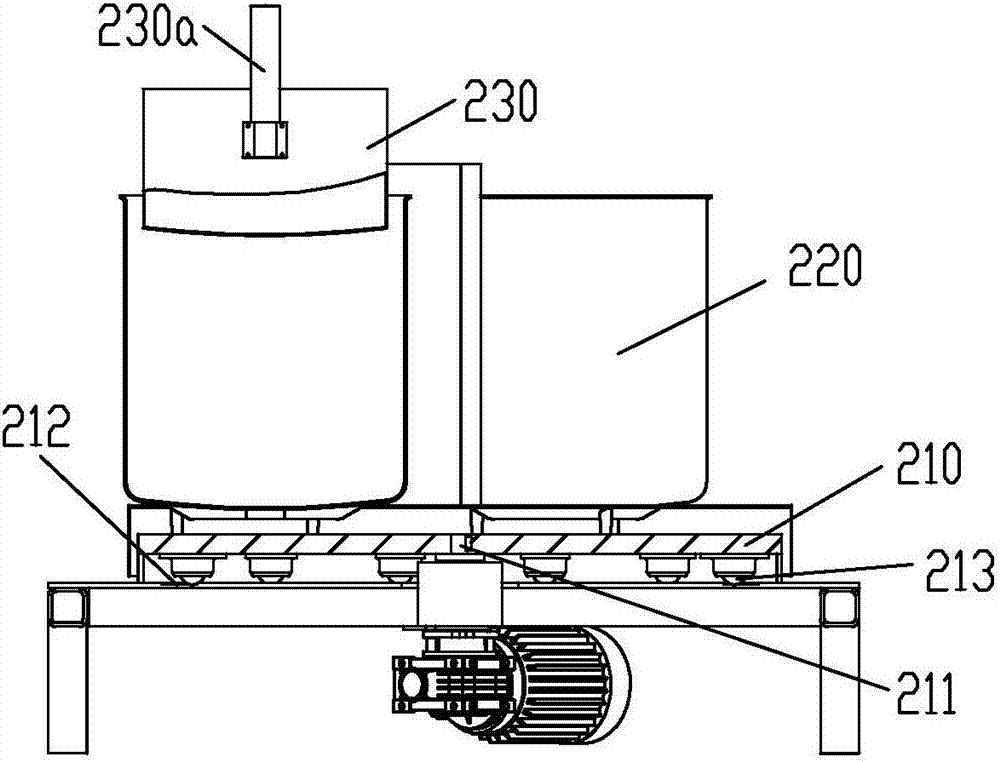

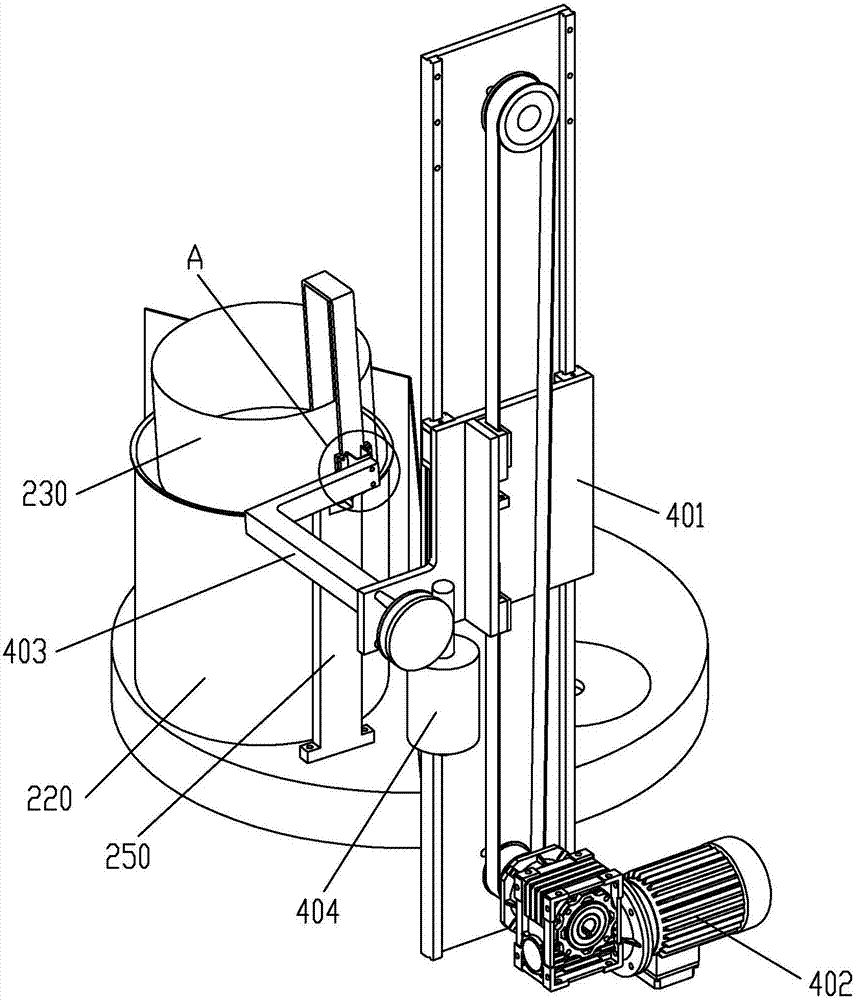

[0025] Example 1, see figure 1 , figure 2 with image 3 , a multi-station material preparation turntable, comprising a material preparation turntable, a plurality of preparation stations are formed on the material preparation turntable, each preparation station is provided with a material preparation cylinder 220, and a colander 230 and a colander 230 are placed in the preparation cylinder 220 according to a set position The colander handle 230a forms a plug-in connection with the spoon handle socket 250, the socket of the spoon handle socket 250 is vertically upward, and the spoon handle socket 250 is fixedly connected on the described material preparation turntable; The colander handle 230a is connected to the spoon handle socket 250 through a U-shaped bottom; the colander 230 is connected with a colander driving device through a magnetic force or elastic force coupling structure, and the colander driving device has the function of lifting the colander 230 from the mouth o...

Embodiment 2

[0027] Example 2, see Figure 7 , the spring clamp is composed of claws 407, and the two claws 407 are respectively fixedly connected to two claw arms 408, and the two claw arms 408 are hinged by hinge shafts 409, and there is a The loading spring 410 , the elastic force of the loading spring 410 drives the two claws 407 outward; the elastic clamp is connected with the connecting arm 403 through the transfer shaft 409 .

[0028] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0029] The colander driving device and the colander 230 in the foregoing embodiments are also connected through a magnetic coupling structure. The magnetic coupling includes two permanent magnets coupled to each other, the two permanent magnets are respectively arranged on the colander handle 230a and the connecting arm 403; when the connecting arm 403 moves to a set position, the connecting arm 403 forms a magnetic force with the colande...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com