Electric oven

An electric oven and inner cavity technology, which is applied in the field of electric ovens, can solve the problems of inability to cool and dissipate electric ovens, burn out electrical components, and high temperature, and achieve the effects of improving stability and safety, preventing damage, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

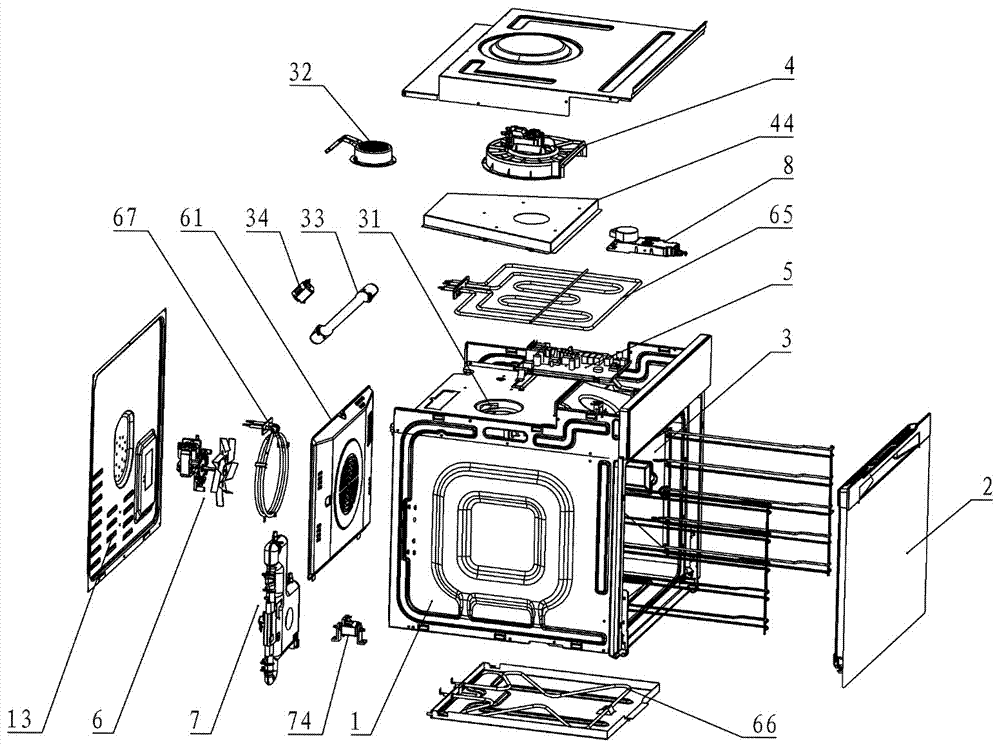

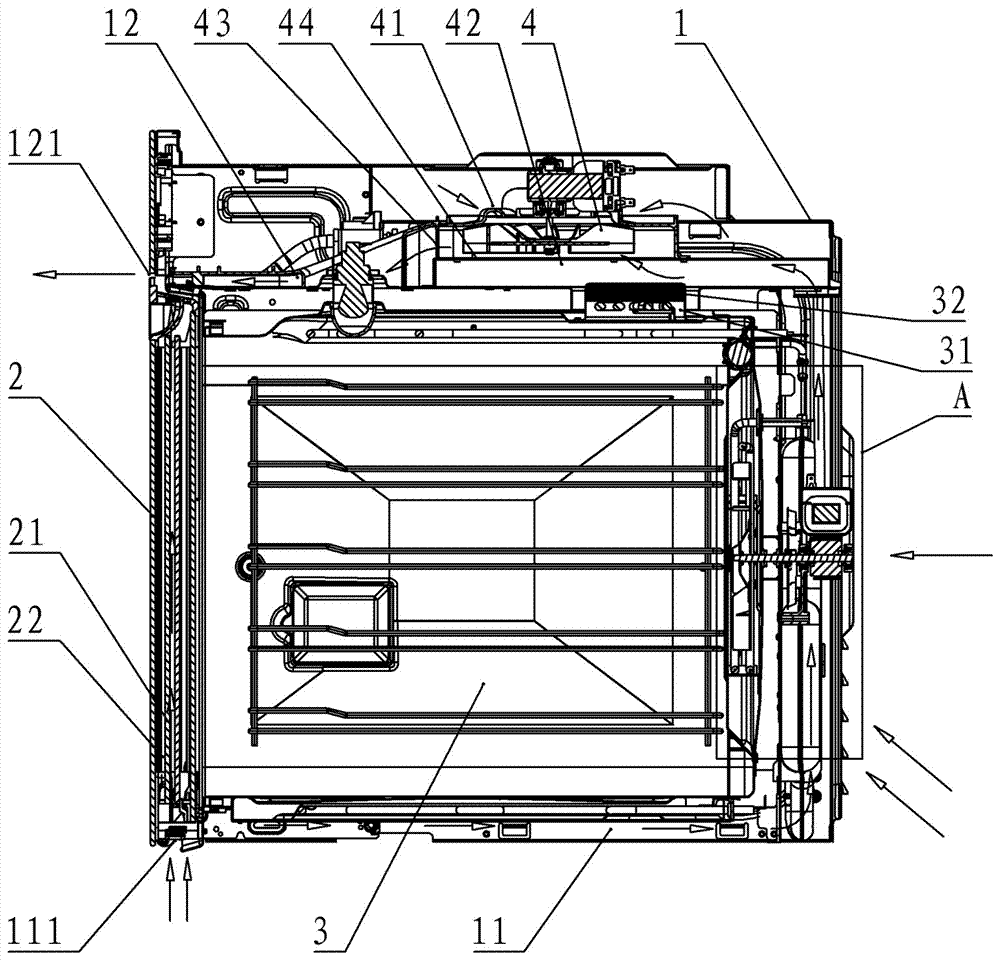

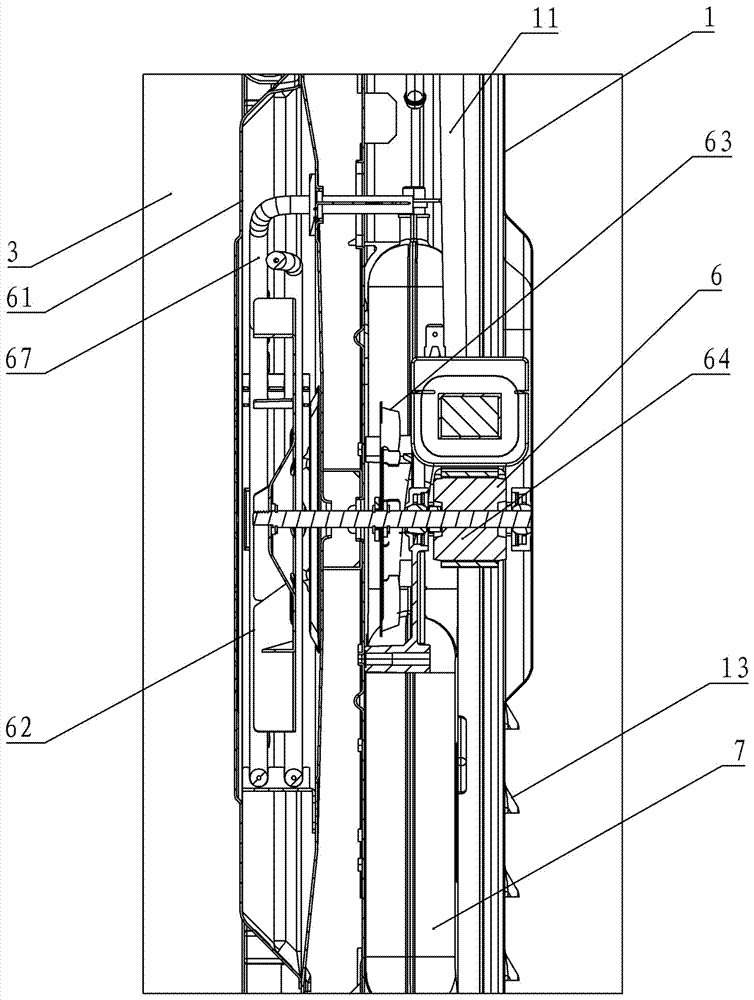

[0027] Such as figure 1 and figure 2 As shown, the present invention provides an electric oven. The electric oven is at least composed of an outer shell 1, a door body 2 and an inner cavity 3 installed in the outer shell 1. The inner cavity 3 of the outer shell 1 is surrounded by a further Air passage 11, exhaust passage 12 and cooling fan 4, described exhaust passage 12 is connected with air inlet passage 11 through cooling fan 4; The inside of described casing 1 is also provided with main control electronic board 5, temperature equalization mechanism and The steam generators 7 are also located in the air intake passage 11. Therefore, the outside natural wind can enter the cooling fan 4 along the air inlet passage 11 sequentially through the total air inlet 111, and is discharged to the outside of the electric oven through the outlet of the exhaust passage 12, and in the process, the shell 1 and the main control electronic board 5 , uniform mechanism, and steam generator 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com