A simulation test method for coal and gas outburst

A simulation test and gas outburst technology, applied in the field of endogenous gas simulation outburst test, which can solve the problems of staying in qualitative analysis, the understanding of the outburst mechanism is not clear and clear, and the occurrence mechanism of coal and gas outburst is complex.

Active Publication Date: 2019-10-01

HENAN POLYTECHNIC UNIV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The mechanism of coal and gas outburst is extremely complex, and the current understanding of the outburst mechanism is still at the stage of qualitative analysis and semi-quantitative description, and the understanding of the outburst mechanism is not yet clear and clear

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

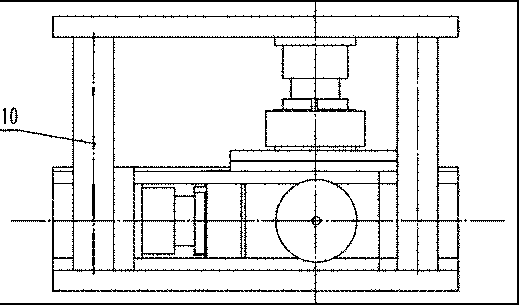

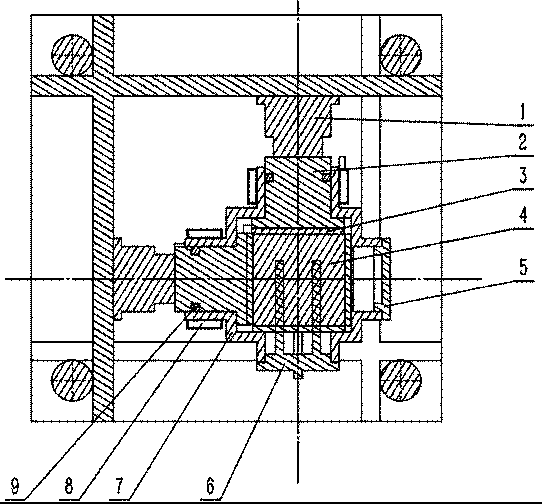

Belonging to the field of coal-mine gas disaster control, the invention puts forward an outburst simulation test method. Heating and pressurization are carried out on lignite and other low metamorphic non-outburst test coal samples in an outburst simulation test device to let the substances deform, break and metamorphose to generate gas so as to form outburst coal with outburst potential, and then coal and gas outburst simulation test study can be carried out. The specific test steps include: A. collecting lignite and other low metamorphic non-outburst coal samples on the spot, conducting laboratory vacuum drying and degassing for 48h, on the basis of maintaining a coal sample primary structure, preparing a coal sample according to the size of the test device; B. under an airtight condition, carrying out temperature (20-390DEG C), pressure (a confining pressure of 20-220MPa), time (1h-120d), moisture (moisture percentage) and other single parameter and multi-parameter coupled outburst potential inoculation evolution simulation test; and C. using a quick opening device to open an outburst cover suddenly, and simulating a dynamic emergence process of coal and gas outburst.

Description

technical field The invention relates to a test method for simulating prominent endogenous gas. Background technique With the increase of coal mining depth, the number of coal and gas outburst mines has increased significantly. Coal enterprises with outburst mines invest a lot of human, material and financial resources every year to prevent coal and gas outburst. In the blocks where anti-outburst measures have been taken, coal and gas outburst accidents still occur from time to time, and some mines are even forced to close due to serious coal and gas outburst disasters. The mechanism of coal and gas outburst is extremely complex, and the current understanding of the outburst mechanism is still at the stage of qualitative analysis and semi-quantitative description, and the understanding of the outburst mechanism is not yet clear and clear. Carrying out the research on the mechanism of coal and gas outburst has important theoretical significance for the effective prevention ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N21/84G01N33/22

Inventor 何俊刘明举牛振华郑则用樊东方肖知国冯雨雷文杰蔡成功陈岩

Owner HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com