Projection algorithm for generating curved surface non-interference five-axis processing locus

A technology of processing trajectory and projection algorithm, applied in the field of projection algorithm, can solve problems such as low calculation accuracy, low calculation efficiency, and actual tool contact error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

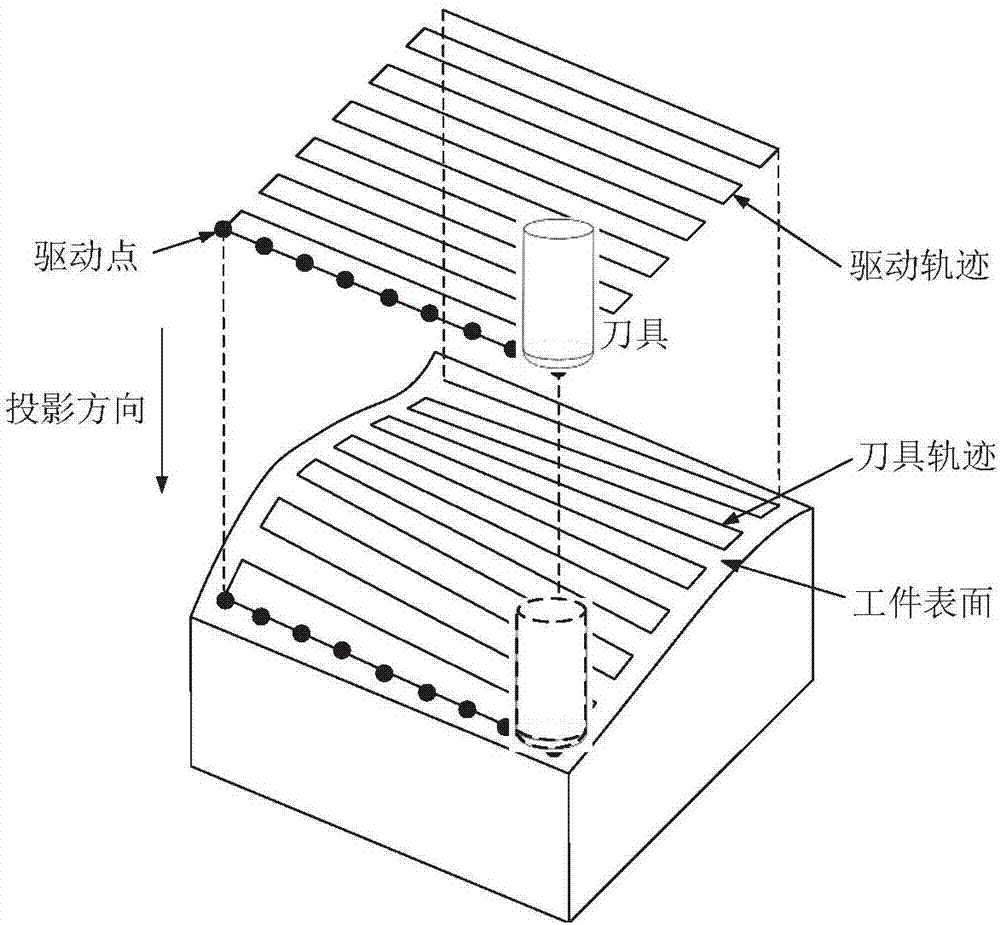

[0084] Examples of the present invention are Figure 7 shown, including the following steps:

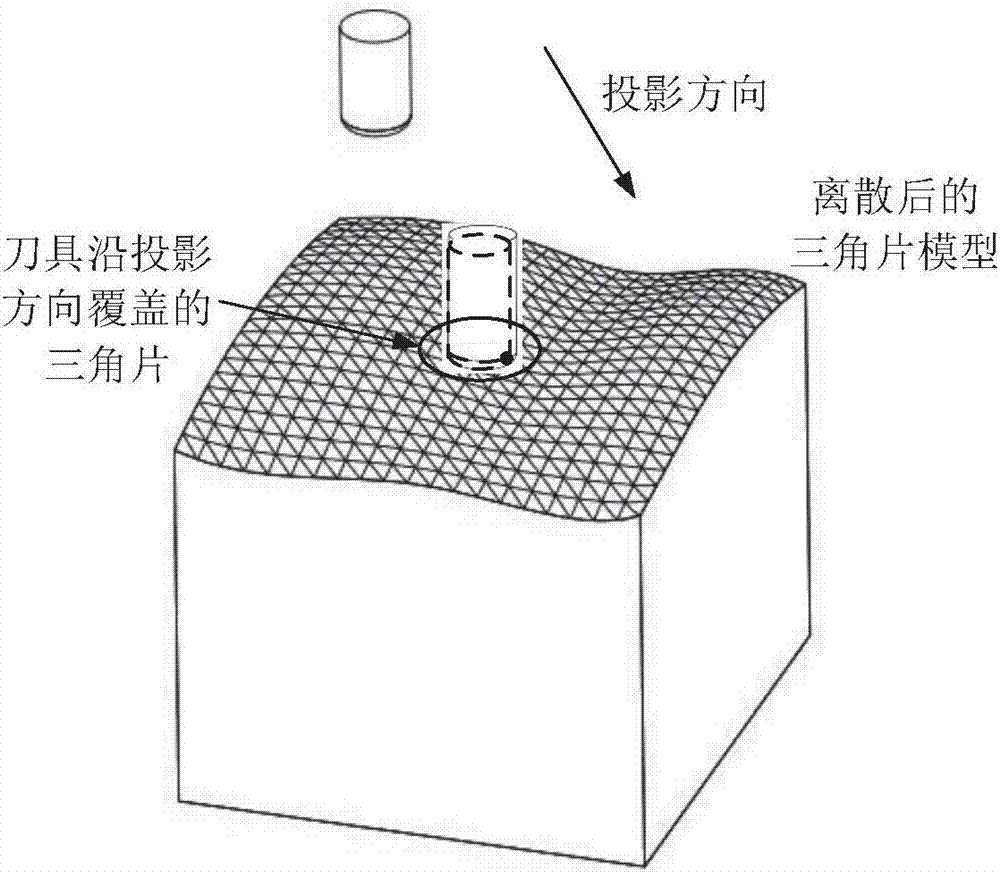

[0085] Step (1), set the number of iterations variable c 1 =1, set the maximum number of iterations M 1 is 30, the convergence precision ε 1 1.0 -6 , select the knife contact point projected by the tool on the triangular piece as the initial point P 0 ; The tool contact point projected by the tool on the triangular piece is the projection point corresponding to the shortest projection distance among the multiple triangular pieces covered by the tool along the projection direction;

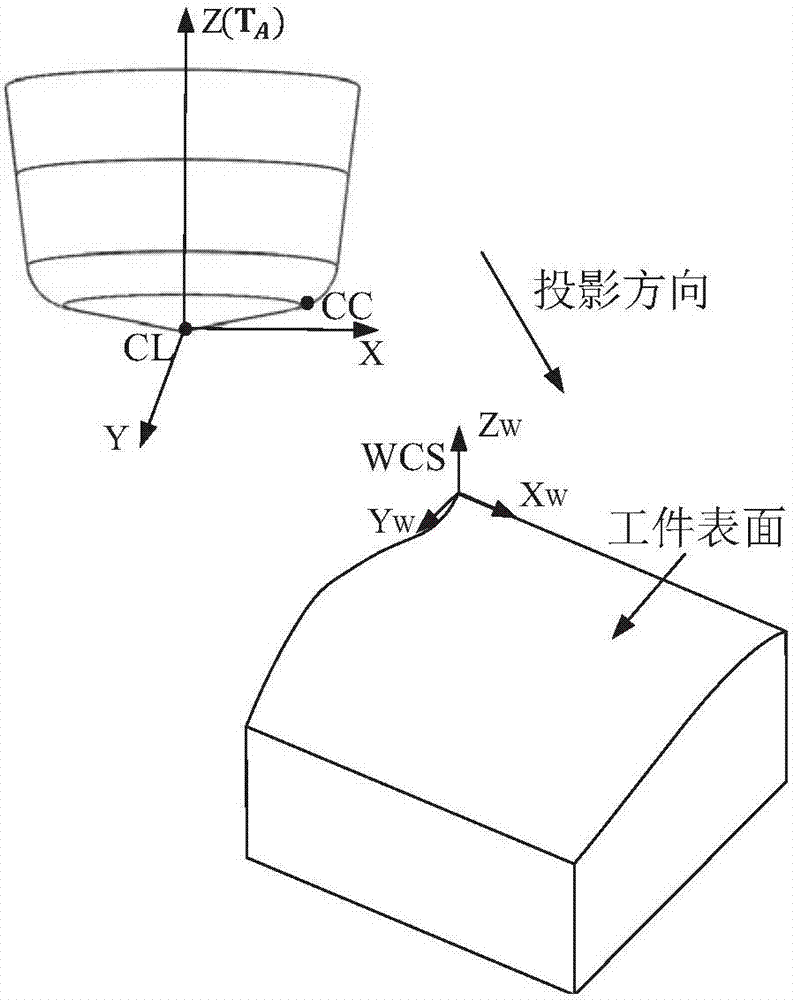

[0086] Step (2), calculate the initial point P in the workpiece coordinate system WCS 0 The shortest distance D to the workpiece surface 0 and on the workpiece surface D 0 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com