Wire harness connector

A wire harness and connector technology, applied in the direction of connection, connection insulation, conductive connection, etc., can solve the problems of loose connection, poor contact, affecting the normal use of equipment, etc., to ensure stability, improve stability, and improve anti-interference strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

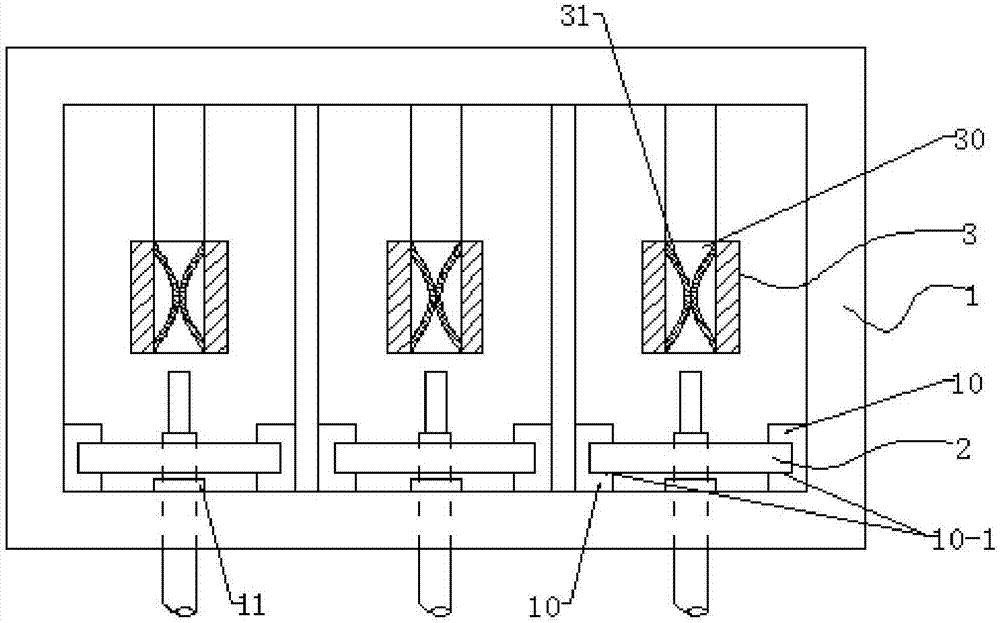

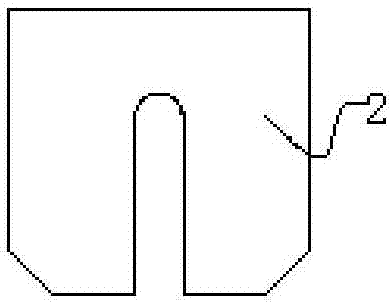

[0021] In this wire harness connector, the wire harness with one end of the outer insulation skin stripped is inserted from the outside of the connector body 1, and then passed through the protrusion 11, so that the wire of the wire harness is inserted into the wiring 3, and then the card 2 is inserted from the slot on the fixed block 10 10-1, where the wire harness is snapped into the "U" groove 10-1 on the card 2, and is clamped by the "U" groove 10-1, and then the space formed between the connector body 1 and the card 2 Connecting glue is dripped in the cavity to improve the stability of the connection between the wire harness and the wire harness connector; the inner wall of the connector body 1 is provided with a bump 11 to improve the tensile strength of the connector body 1 .

Embodiment 2

[0023] The connector 3 is provided with a cylindrical cavity 30, and a plurality of metal contact pieces 31 are arranged in the cylindrical cavity 30. The metal contact pieces 31 are in the shape of curved strips, and are evenly arranged along the circumference of the cylindrical cavity 30. Four, to ensure the stability of the electrical connection between the wiring harness and the connector, and improve the anti-interference strength against vibration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com