Spiral spring of a brush holder

A technology of coil spring and brush holder, applied in the field of coil spring, can solve the problems of switching mass loss, brush wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

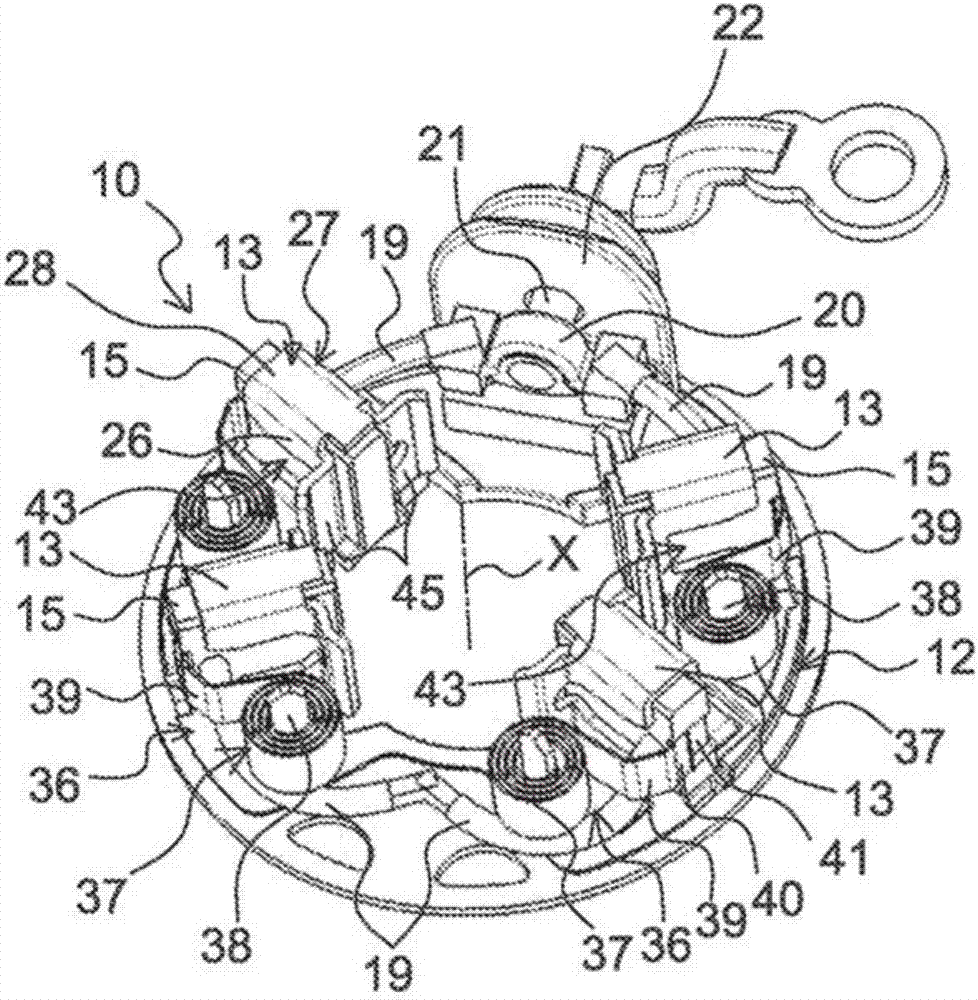

[0030] figure 2 A brush holder 10 according to the invention is shown, which is designed for use with a starter of a motor vehicle. This brush holder 10 comprises a support plate 12 having a substantially annular shape around an axis X, on which is fixed a series of brush holders 13 , each brush holder serving as a receptacle for a brush 15 . The axis X of the support plate 12 corresponds to the axis of the brush holder 10 .

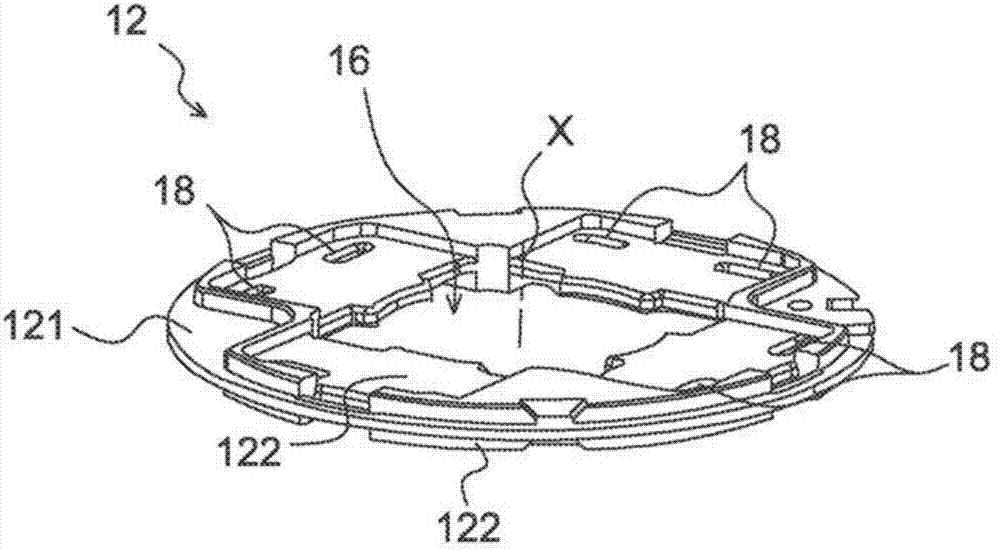

[0031] exist image 3 The support plate 12 , which can be clearly seen in , is part of a single piece comprising a metal plate 121 and a layer 122 overmoulded on both sides of the metal plate 121 . Layer 122 is made of plastic material, which ensures good electrical insulation. The overmolding layer 122 covers all areas of the plate 12 that are at risk, ie all areas where short circuits may occur. The overmold layer 122 is heat sensitive and deformable from a predetermined temperature so as to be able to cause a short circuit when overheating occurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com